Tea leaf processing technology and processing equipment thereof

A technology of processing equipment and production technology, which is applied in the field of tea processing and production technology and its processing equipment, can solve the problems such as tooth tip, yellow leaf edge burnt, etc., achieve the effects of neat tea shape, improved tea quality, and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples are only examples for clarifying the present invention, rather than limiting the embodiment of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

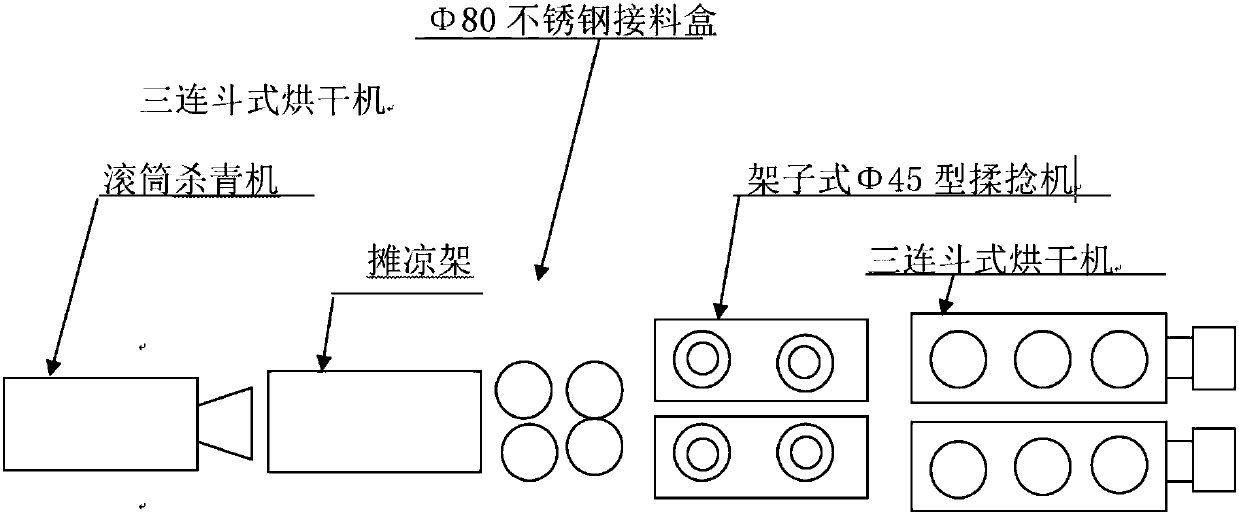

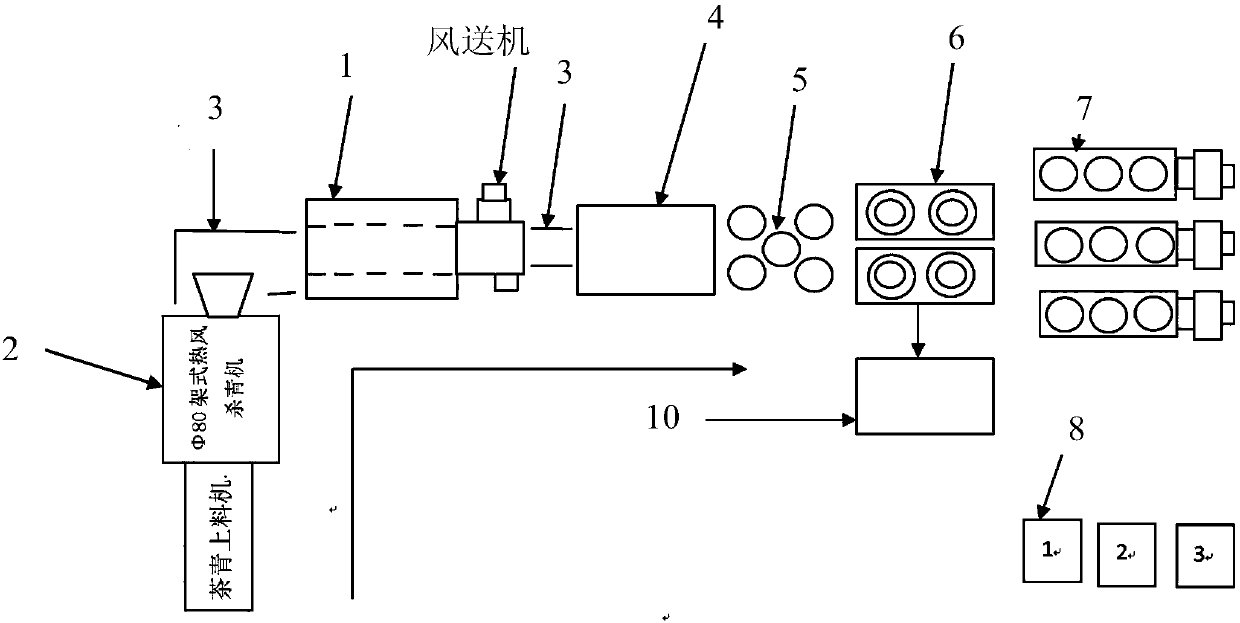

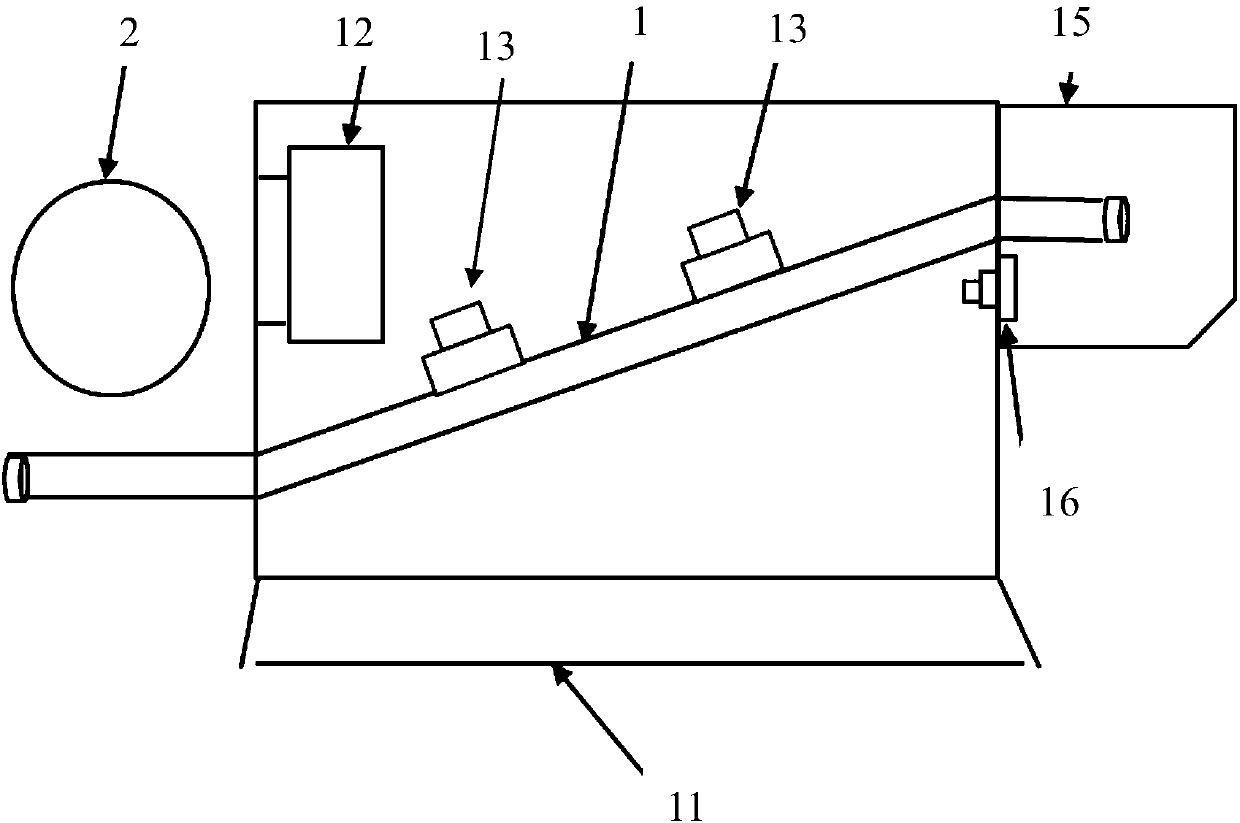

[0049] Such as Figure 1-4 Shown, a kind of tea processing manufacture craft, this method comprises:

[0050] Step 1, cooling the green tea leaves at 120°C to 180°C to 1°C to 5°C within 10 to 15 seconds through air cooler room 1;

[0051] Step 2, the tea leaves after step 1 cooling down are rehydrated;

[0052] Step 3, kneading the tea leaves after the moisture regain in step 2, and the temperature of the tea leaves after kneading rises to normal temperature;

[0053] Step 4, putting the tea leaves at room temperature after kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com