Composite dope and preparation method thereof

A paint and formula technology, applied in the field of combined paint and its production, can solve the problems of low fire resistance, long drying time, poor moisture resistance, etc., and achieve high fire resistance, pure and lasting color, high moisture resistance and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

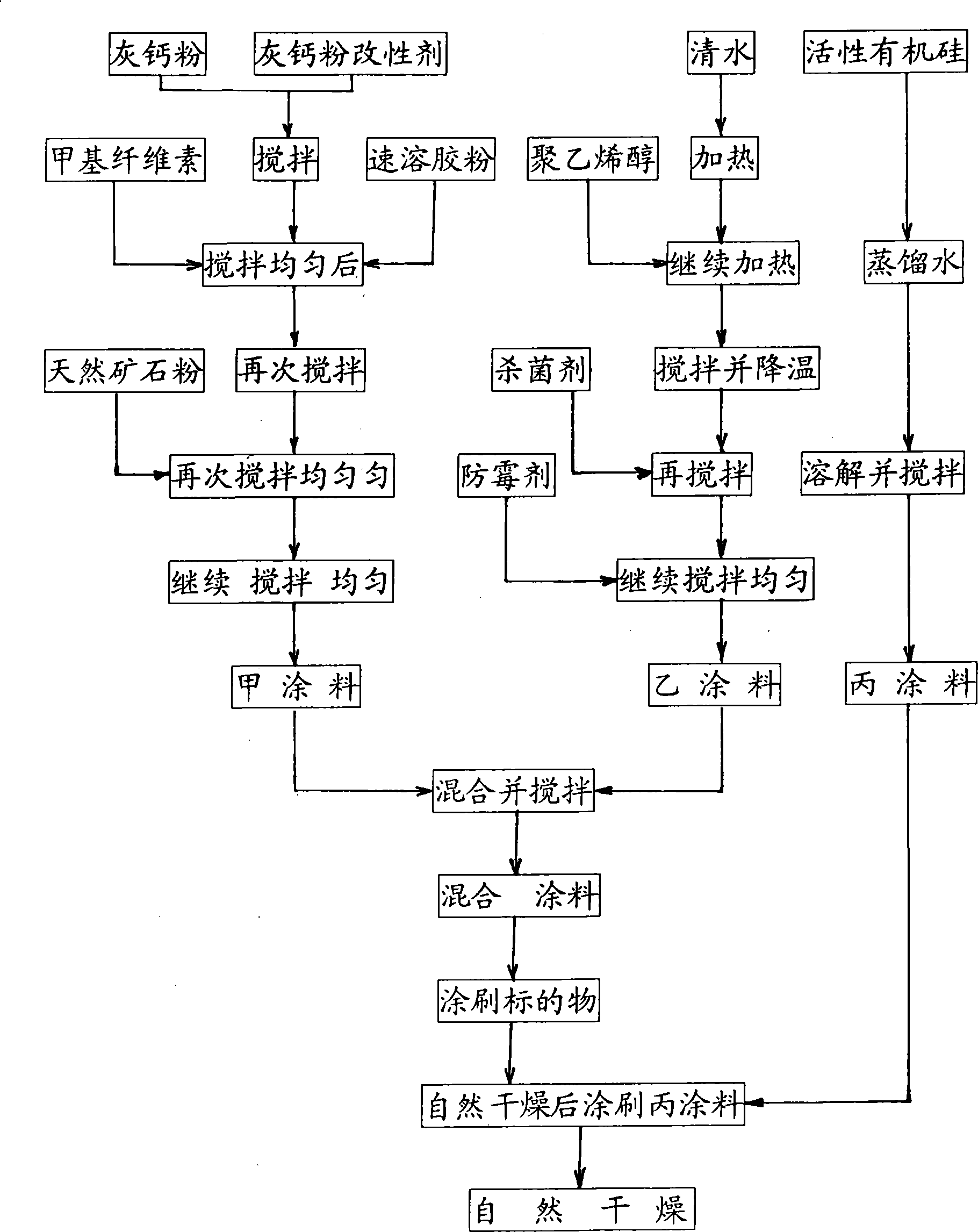

Method used

Image

Examples

specific Embodiment approach 2

[0062] Carry out by specific implementation mode one, just:

[0063] The first formula and the first formula raw materials are: natural ore powder 85.94% is 85.94 grams, ash calcium powder modifier 0.06% is 0.06 grams, ash calcium powder 10% is 10 grams, methyl cellulose 2% is 2 grams , instant gelatin powder 2% is 2 grams;

[0064] The second formula and the raw materials of the second formula are: 2 grams of polyvinyl alcohol 2%, 0.1 grams of bactericide 0.1%, 0.3 grams of antifungal agent 0.3%, 97.6 grams of clear water 97.6%;

[0065] The formula C and the raw materials of formula C are: 10 grams of active silicone 10%, 90 grams of distilled water 90%.

specific Embodiment approach 3

[0066] Carry out by specific implementation mode one, just:

[0067] The first formula and the first formula raw materials are: natural ore powder 78.905% is 78.905 grams, ash calcium powder modifier 0.095% is 0.095 grams, ash calcium powder 15% is 15 grams, methyl cellulose 3% is 3 grams , instant gelatin powder 3% is 3 grams;

[0068] The second formula and the second formula raw materials are: polyvinyl alcohol 3% is 3 grams, bactericide 0.15% is 0.15 grams, antifungal agent 0.9% is 0.9 grams, clear water 95.95% is 95.95 grams;

[0069] The formula C and the raw materials of the formula C are: 15 grams of active silicone 15%, and 85 grams of distilled water 85%.

specific Embodiment approach 4

[0070] Carry out by specific implementation mode one, just:

[0071] The first formula and first formula raw materials are: natural ore powder 81.7% is 81.7 grams, ash calcium powder modifier 0.8% is 0.8 grams, ash calcium powder 12.5% is 12.5 grams, methyl cellulose 2.5% is 2.5 grams 2.5 grams of instant gelatin powder 2.5%;

[0072] The second formula and the raw materials of the second formula are: 2.5 grams of polyvinyl alcohol 2.5%, 0.13 grams of bactericide 0.13%, 0.6 grams of antifungal agent 0.6%, 96.77 grams of clear water 96.77%;

[0073] The formula C and the raw materials of formula C are: 13 grams of active silicone 13%, 87 grams of distilled water 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com