Polyolefin elastomer material with negative ion functions, method for preparing polyolefin elastomer material and application thereof

A polyolefin elastomer and negative ion technology, applied in the field of polyolefin elastomer materials with negative ion function and its preparation, can solve the problems of insufficient stability, easy hardening and yellowing, and avoid environmental pollution and waste of social resources , Improve compatibility, enhance toughness and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

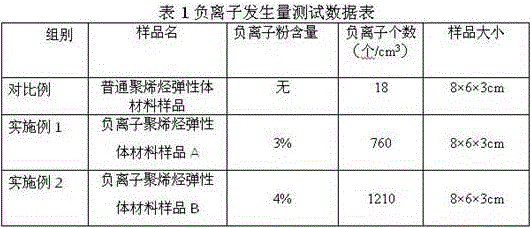

[0034] Example 1 A polyolefin elastomer material with anion function, which consists of the following components by weight: 80g polyolefin elastomer, 8g paraffin oil, 8g titanate coupling agent, four [β-(3,5-三 G-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester 1g, anion functional powder 3g.

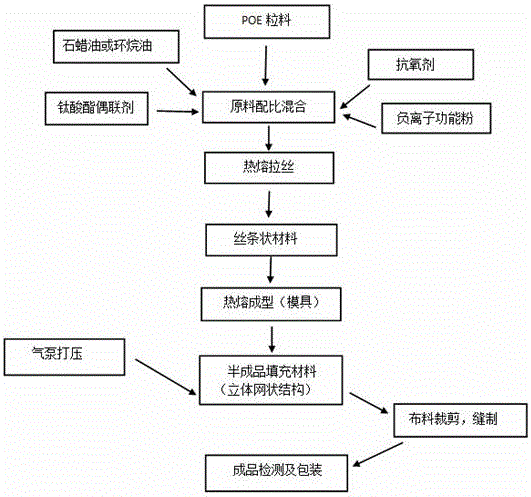

[0035] The above-mentioned polyolefin elastomer, paraffin oil, titanate coupling agent, tetra[β-(3,5-tertiarybutyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester and anion functional powder are uniformly mixed to obtain The mixture material is hot melted and drawn into a strand-shaped material, and then the material is combined with a molding machine to heat and press. During the molding process, an air pump is used to inflate and press, so that the material is compressed and expanded in the molding die, the structure is loose, and the surrounding combination , A sample A of 8×6×3 cm is obtained.

Embodiment 2

[0036] Example 2 A polyolefin elastomer material with anion function, which is composed of the following components by weight: 74g polyolefin elastomer, 10g naphthenic oil, 10g chromium complex coupling agent, 2,6-tertiary butyl -4-methylphenol 2g, anion functional powder 4g.

[0037] The above-mentioned polyolefin elastomer, naphthenic oil, chromium complex coupling agent, 2,6-tertiary butyl-4-methylphenol, and anion functional powder are uniformly mixed, and the resulting mixture is processed into filaments by hot melt drawing The material is then hot-pressed with the molding machine. During the molding process, the air pump is used to inflate and press the material, so that the material is compressed and expanded in the molding die, the structure is loose, and the surrounding combination is obtained to obtain a sample of 8×6×3cm B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com