Patents

Literature

36results about How to "Guaranteed aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roasted famous high-quality green tea and production process thereof

InactiveCN102669313AGuaranteed qualityPromote hydrolysisPre-extraction tea treatmentTemperature controlGreen tea

The invention relates to roasted famous high-quality green tea and a production process thereof, belongs to the technical field of tea processing, and provides a production process of roasted famous high-quality green tea to effectively improve quality of the green tea. The production process includes steps of fresh tea leaf fixation, shaping and drying. Fresh tea leaves are further cured before fixation by placing the fresh tea leaves in a precision temperature control device at the set temperature of 35DEG C to 36 DEG C for 2-4 hours of curing.

Owner:中国测试技术研究院生物研究所

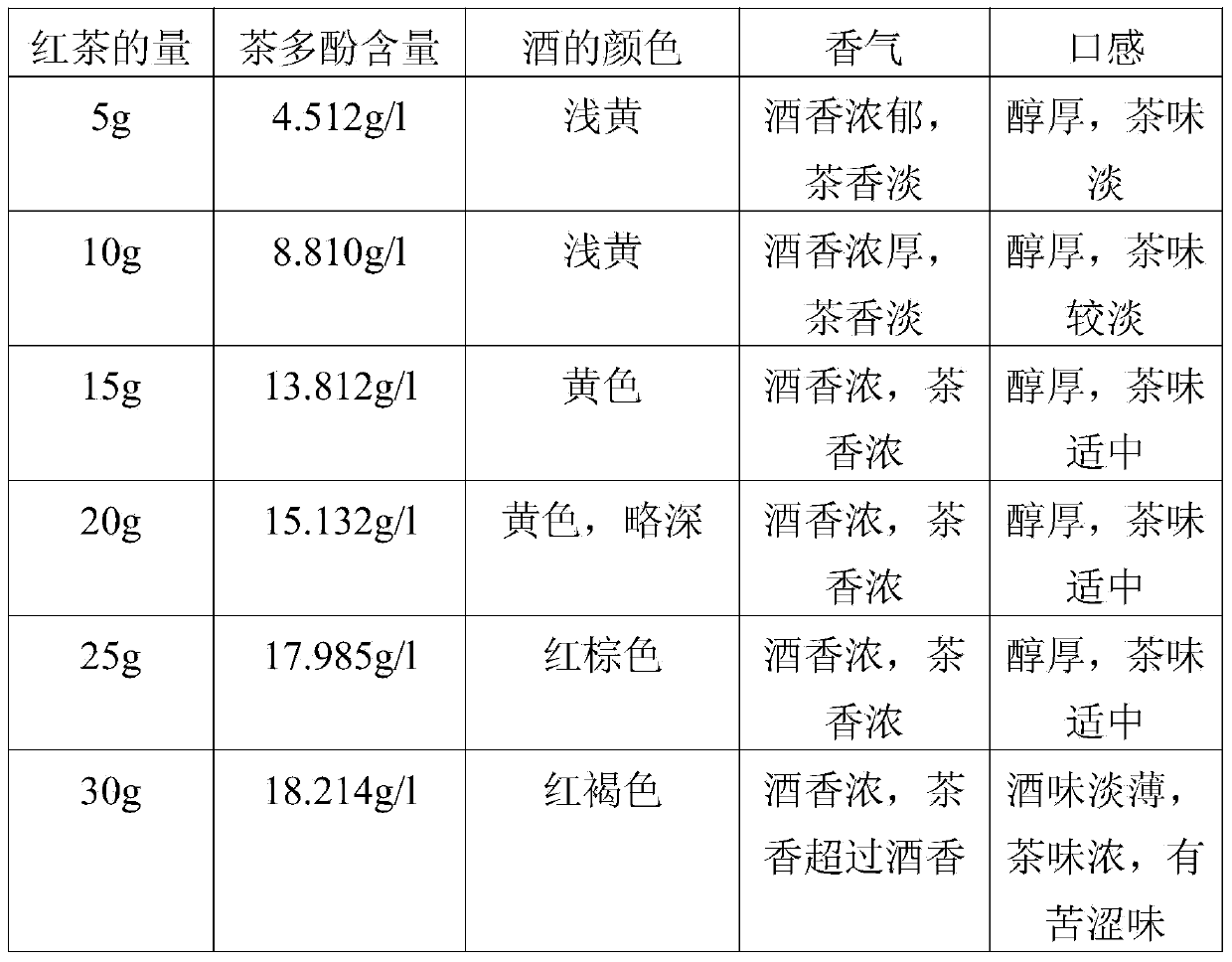

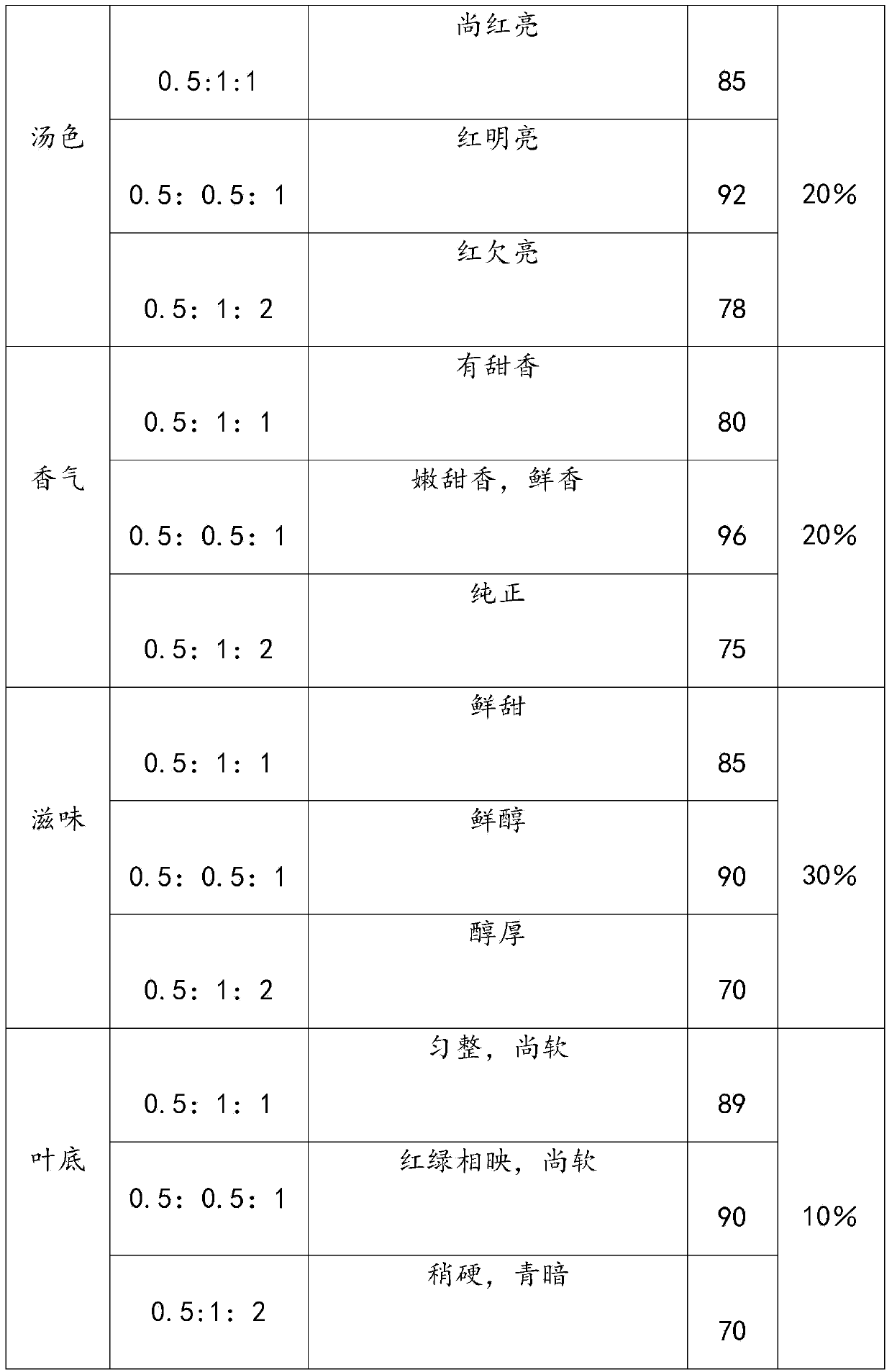

Black tea wine and preparation method thereof

ActiveCN103627613AIncrease contentIncrease productionAlcoholic beverage preparationAlcohol contentBlack tea

The invention relates to the field of foods, and particularly relates to black tea wine and a preparation method thereof. Particularly, the preparation method comprises the steps: processing sorghum, black tea and fragrant grains, and auxiliary materials such as rice hull and rice bran meal, then soaking, primarily steaming, stewing, re-steaming, discharging from a rice steamer, spreading for cooling, discharging yeast, cultivating, adding the black tea, preparing distiller grains, mixing, feeding a pool for fermenting, distilling, storing, and blending so as to obtain the black tea wine. The black tea wine is cool and transparent in vinosity, pure in faint scent, grace in tea perfume, mellow and clean, long in remaining taste, higher in polyphenol content and low in alcohol content, and has the remarkable black tea fragrance and taste, and a wine body is soft and harmonious.

Owner:GUIZHOU MEITAN DIANXI TEA WINE

Preparation method of freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes

The invention provides a preparation method of freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes. The preparation method comprises the following steps of cleaning fruits and vegetables, performing pulping, mixing and blending pulp with yoghourt, performing homogenizing, adding cereals, nuts and fruit granules, performing stirring, performing membrane filling, performing quick-freezing, performing demolding, performing vacuum freeze drying, and performing packaging so as to obtain the freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes. The freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes are produced by a vacuum freeze drying technique, so that original thermal sensitivity components and antioxidation components of products canbe sufficiently guaranteed, the color and the fragrance of fruits and vegetables and the activity of probiotics can also be guaranteed, and transportation and long term storage are facilitated; and besides, the cereals, the nuts and the fruits cooperate, so that the nutrition is more balanced.

Owner:清谷田园食品有限公司

Yunnan black tea essential oil and preparation method thereof

ActiveCN103087828ANo solvent residueNo environmental pollutionEssential-oils/perfumesSolventSupercritical fluid extraction

The invention relates to a Yunnan black tea essential oil and a preparation method thereof. The essential oil is prepared by a supercutical fluid extraction-molecular distillation combination technique. The preparation method comprises the following steps: carrying out supercritical extraction on Yunnan black tea, and carrying out molecular distillation to obtain the Yunnan black tea extract. Compared with the traditional extraction method, the invention adopts the newest supercutical fluid extraction-molecular distillation combination technique, has the advantage of high extraction efficiency, does not introduce any harmful organic reagent, and obtains the Yunnan black tea essential oil with no solvent residue and with good scent and quality under the conditions of low temperature and low pressure. The method is simple to operate, has the advantages of high extraction rate and no pollution, and provides an efficient green environment-friendly extraction separation method for preparing Yunnan black tea essential oil.

Owner:云南天宏香精有限公司

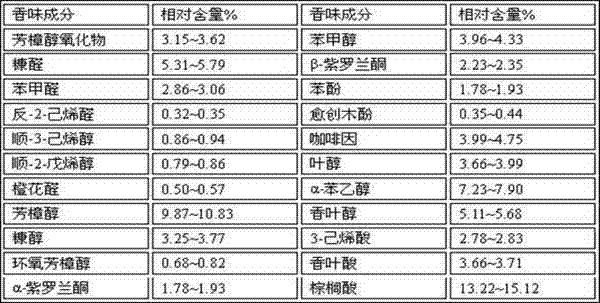

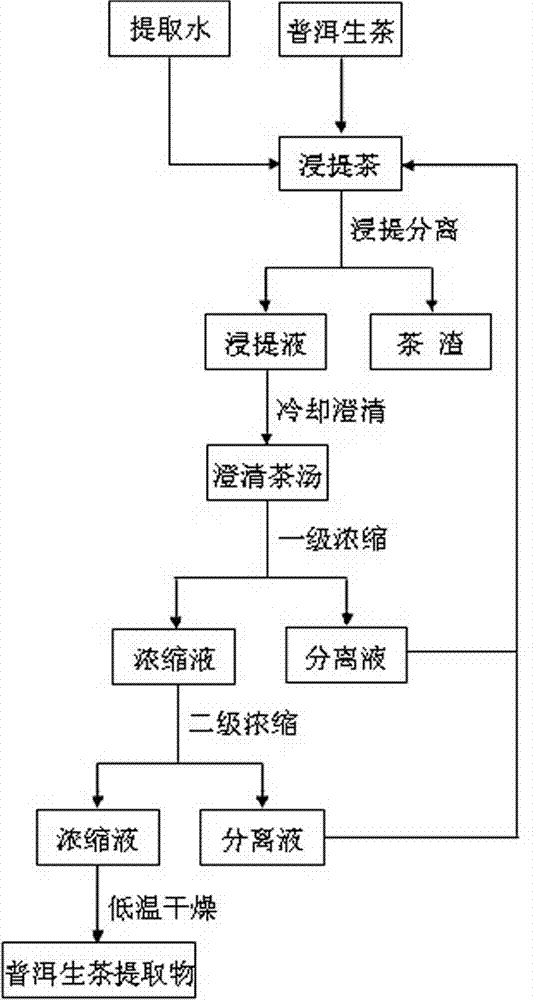

Pu'er raw tea extract for effectively retaining quality of original tea and preparation method and application of same

ActiveCN102919424AReduce oxidation and dissipationGuaranteed extraction efficiencyTea extractionFood preparationChemistryCaffeine

The invention discloses a pu'er raw tea extract for effectively retaining quality of original tea and a preparation method and an application of same. The pu'er raw tea extract comprises tea polyphenol, caffeine, tea polysaccharide, amino acids, and an aroma component. The mass percents of the components are respectively as follows: 25-69% of tea polyphenol, 8-20% of caffeine, 10-30% of tea polysaccharide, 5-23% of amino acids, and 0.01-0.1% of aroma component. The sum of mass percents of the component is not greater than 100%. The preparation method comprises the steps of: tea digestion, cooling and clarification, primary concentration, second concentration and low temperature drying. The pu'er tea extract is applied to instant tea beverages, tobacco or foods. Oxidation and loss of main thermosensitive substances such as aroma and taste are reduced by middle- and low-temperature digestion, constant temperature film concentration and low temperature drying technologies and the like. The preparation method is simple, and the aqueous solution of the extract has a scent and is strong in aroma, smooth to drink, sweet and liquid-engendering, and red and bright in liquor color. The pu'er raw tea extract is similar to the original pu'er tea in tea liquid scent, taste and liquor color.

Owner:SPACE AQUA TECH

Cigar tobacco leaf additive and production method thereof

ActiveCN103070475ARich styleAlcoholic and soft smokeTobacco preparationTobacco treatmentMaillard reactionFlavor

The invention discloses a cigar tobacco leaf additive and a production method thereof. The production method of the cigar tobacco leaf additive comprises the following steps of: smashing natural plants into pulp; adding an enzyme preparation for enzymolysis and then inactivating enzyme; carrying out Maillard reaction within a temperature range of 110 to 150DEG C; distilling a reacted mixture at normal pressure to obtain a first component; heating and extracting residual slag generated by distilling with a compound solvent consisting of ethanol and water to obtain a second component; and mixing 2 to 4 parts of first component with 6 to 8 parts of second component to obtain the cigar tobacco leaf additive. According to the cigar tobacco leaf additive disclosed by the invention, the styles of cigar cigarettes are enriched and the sweet feeling of cigar flavor is added, so that the cigar cigarette is sweet and comfortable in flavor and pure and mild in smoke.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

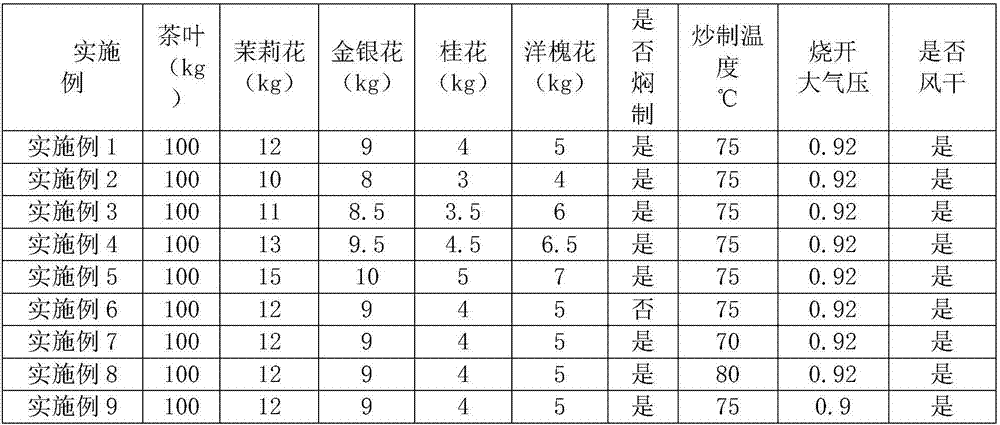

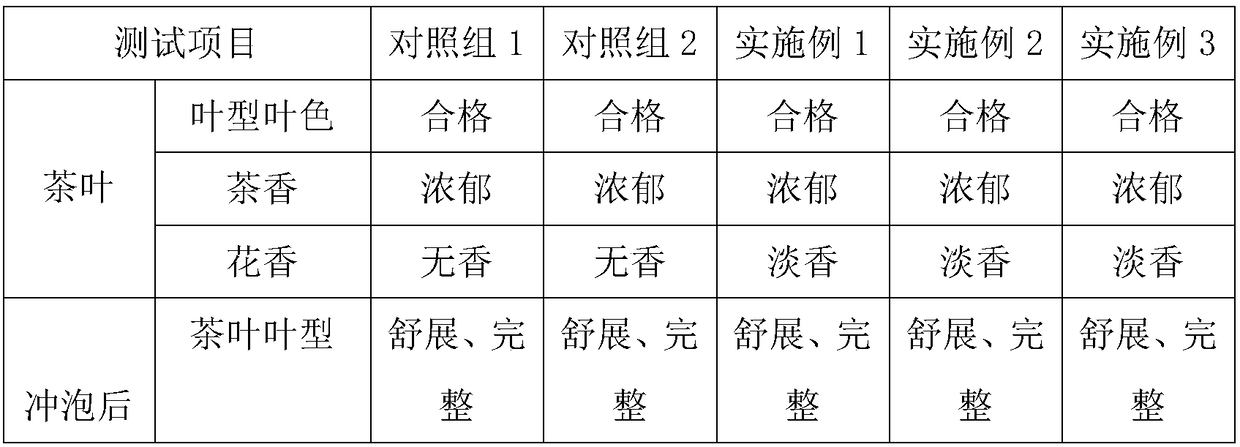

Processing technology of green tea with flower fragrance

InactiveCN106857904AMellow tasteGreat tastePre-extraction tea treatmentOsmanthus Fragrans FlowerProduct processing

The present invention relates to the field of agricultural product processing and discloses a processing technology of green tea with flower fragrance. The processing technology of the green tea with flower fragrance comprises the following steps of fresh leaf treating, juice preparing, green leaf rocking, enzyme deactivating, rolling, drying, etc. Jasmine flowers, honeysuckles, osmanthus fragrans flowers and sophora japonica flowers are mainly used, the raw materials are crushed, the crushed raw materials are fermented, the obtained juice after the fermentation is used to conduct the enzyme deactivating of the tea leaves, and solid residues of the fresh flowers are used to conduct fire curing and drying of the tea leaves. Compared with the prior art, the green tea with flower fragrance is lighter in taste, mellower in taste, and lower in costs.

Owner:ZHENGAN COUNTY FUYAN TEA IND CO LTD

Processing method of broadleaf holly leaves

The invention belongs to the technical field of tea leaf processing and particularly relates to a processing method of broadleaf holly leaves. The method includes: collecting tea leaves, withering, performing fixation, rolling, setting, and drying to obtain a finished product. By the method, the quality, fragrance and taste of the tea leaves are effectively guaranteed by manual operation without the need of special facilities and equipment. In the setting step, the tea leaves are twisted into a funicular shape or rolled into a round square shape or a triangle shape, and the like so as to allow the tea leaves to be exquisite and elegant. After being brewed, the tea leaves restore a green color, show color, fragrance, taste and shape, and maintain the original taste and flavor of the tea leaves. By the method, a finished product after the broadleaf holly leaves are deeply processed can reflect the quality furthest. The method reduces a production cost, and obviously allows the tea leaves to have added-value and high benefit.

Owner:廖广千

Production method of calyx canthus flower tea

ActiveCN104222339AEasy to keep fresh and storeMaintain qualityPre-extraction tea treatmentTea leafHorticulture

The invention discloses a production method of calyx canthus flower tea. The production method comprises the following steps: sorting, performing fixation, refrigerating, splicing tea and flowers, scenting at the low temperature, removing flower residues, frying at low temperature, mixing and bagging to obtain the calyx canthus flower tea. The production method has the effects that firstly, the oxidation reaction of fresh calyx canthus flowers is controlled by adopting a fixation process, the fresh calyx canthus flowers are conveniently preserved after being properly dehydrated, the quality and aroma of the fresh calyx canthus flowers are kept to the maximum extent, and the fresh calyx canthus flowers can be stored within a short time; secondly, the scenting process is carried out at low temperature, so that the original high quality of a tea blank cannot be changed and the quality of scented tea leaves is ensured; thirdly, the frying process is carried out at low temperature, so that the flower aromas of the scented tea leaves can be well retained; fourthly, in conclusion, the tea leaves prepared by adopting the method have the characteristics of being elegant in smell, fresh and brisk in taste, and light green and bright in soup color, so that the calyx canthus flower tea is an ideal calyx canthus flower tea product.

Owner:HUBEI YOUHUA XUN TEA FLORICULTURE SCI & TECH

Processing and production method of mulberry-leave tea

InactiveCN105454474AGuaranteed aromaNeat appearancePre-extraction tea treatmentTea substituesFlavorEnzyme

The invention discloses a processing and production method of mulberry-leave tea. The invention is characterized in that the processing and production method comprises the following nine major steps: picking the mulberry leaves, peeling the mulberry leaves, airing the enzymes, deactivating the enzymes, air-drying, kneading, screening and classifying, refining the aroma, dehydrating and the like. The processing and production method has the beneficial effects that the leaf stems and the thick leaf veins of the fresh and tender mulberry leaves which are picked in proper season are peeled, so that the refreshing and pure taste of the mulberry-leave tea can be preserved; enzymes in the leaf stems and the thick leaf veins are further deactivated by water vapor, so that the pure aroma of the mulberry-leave tea can be further ensured; the enzyme deactivation and the air-drying are performed on a conveyer belt so that the shapes of the mulberry leaves are kept and the strips formed by the mulberry leaves are uniform in shape; the kneading is performed when the mulberry leaves are hot, so that the mulberry leaves can be better shaped and the astringent taste of the mulberry leaves is removed; and the astringent taste can be further covered by the step of refining the aroma. The mulberry-leave tea produced according to the processing and production method has the advantages that the mulberry-leave tea is uniform in appearance, jade-green in color, refreshing and thick in aroma, dark-green and transparent in tea-soup color, tender and mellow in tea-soup taste as well as exquisite and fragrant tea-soup flavor. The processing and production method greatly improves quality of the mulberry-leave tea product.

Owner:石爱军

Natural plant composite particles with sweetening and moisture-preserving functions and preparation method and application thereof

InactiveCN108142994AAvoid it happening againImprove filtering effectTobacco smoke filtersEssential-oils/perfumesHazardous substanceLicorice roots

Natural plant composite particles with sweetening and moisture-preserving functions and a preparation method and application thereof are provided. The composite particles which are 30-60 in mesh are prepared by: crushing Poria, Momordica grosvenori fruit, root of Angelica sinensis, florists chrysanthemum, honeysuckle, flowering tobacco, licorice root and Pinellia ternata tuber separately, performing cell disrupting, screening to obtain cell-broken powder, adding auxiliaries to the cell-broken powder, mixing well to obtain a mixture, adding a certain amount of water into the mixture to obtain wet material, subjecting the wet material to rotary granulating, drying at low temperature, stabilizing the size, and screening; based on existing rich plant materials and long-standing studies and application history, the plant materials with sweetening and moisturizing functions added herein feature zero harm, zero additives, zero pollution and good safety and reliability and have the functions,such as aroma enhancing, disinfecting and antioxidation; the plant materials do not combust, so that harm harmful matters are avoided; by adding the prepared composite particles to a cigarette filter,effective active ingredients of plants themselves can be retained.

Owner:YUNNAN SHENBOYUAN BIOLOGICAL TECH

Preparation process of mixed floral fragrance type Liuan guapian tea picked before grain rain

InactiveCN109275733AImprove processing efficiencyIncrease productionPre-extraction tea treatmentTea flavoringChemistry

The invention relates to the technical field of processing of tea leaves, and in particular relates to a preparation process of mixed floral fragrance type Liuan guapian tea picked before grain rain.The preparation process comprises the following steps: 1, selecting tea leaves, 2, performing manual withering, 3, performing de-enzyming, 4, performing mixing and rolling, 5, performing deblocking and strip tidying, 6, performing air separation, 7, performing primary drying, 8, performing stir-frying, 9, performing color selection, and 10, performing fast baking with high-temperature carbon fire,storage and the like; the preparation process improve the processes of de-enzyming, rolling, drying and the like, a proper amount of fresh sweet-scented osmanthus is added in the rolling process, andthe flower fragrance is fused into the tea leaves in a rolling mode; the production efficiency of the green tea is improved, the floral fragrance type Liuan guapian tea is obtained, and the taste, shape and mouthfeel of the tea is not influenced, therefore, the economic benefits of the production of the Liuan guapian tea are improved.

Owner:金寨县徽味香生态茶叶有限公司

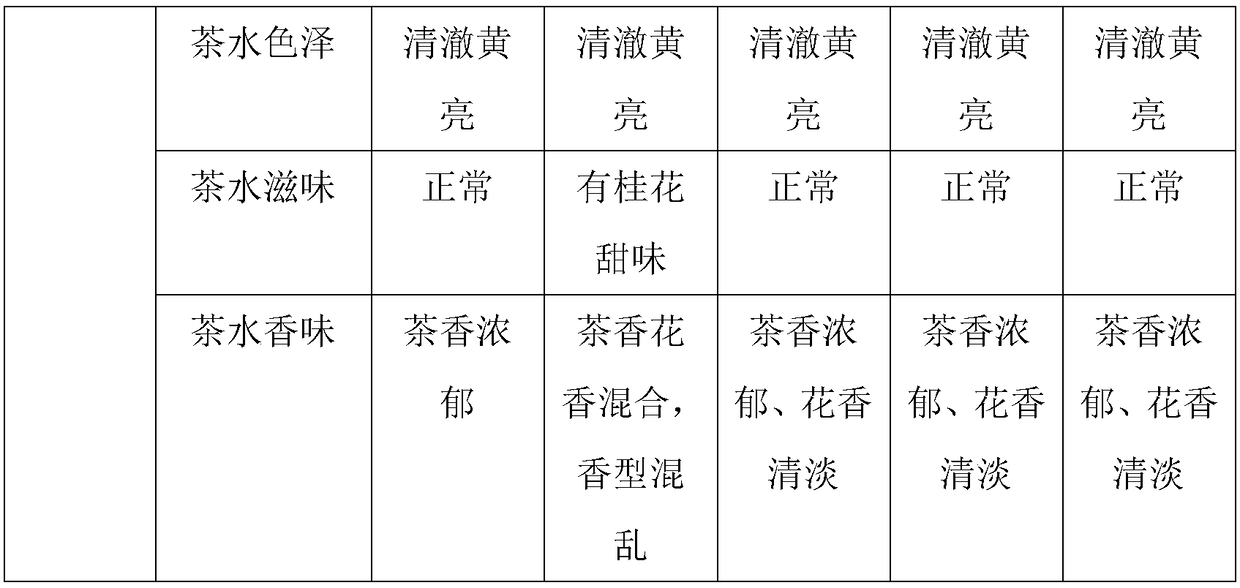

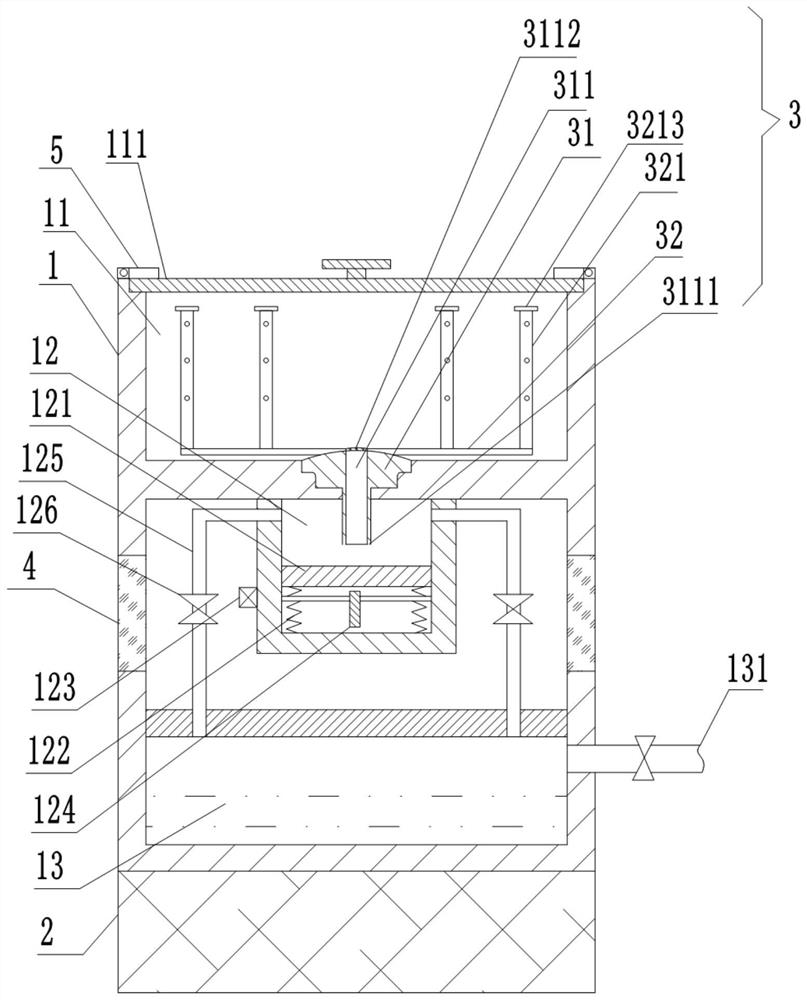

Concentrated fragrance-type edible oil hot-squeezing refining small-set

InactiveCN103966016AAvoid affecting the oil yieldSimple processFatty-oils/fats refiningFatty-oils/fats productionFiltrationEdible oil

The invention discloses a concentrated fragrance-type edible oil hot-squeezing and refining small-set. The concentrated fragrance-type edible oil hot-squeezing and refining small-set realizes combination of a hot-squeezing process and a refining process. The concentrated fragrance-type edible oil hot-squeezing and refining small-set utilizes edible oil squeezing special-purpose filters, simplifies a technical process and reduces an equipment cost. The concentrated fragrance-type edible oil hot-squeezing and refining small-set utilizes a combined frame and removable support legs are connected to the frame by bolts and are arranged on a chassis so that transport is convenient and installation difficulty is simplified. An oil press is arranged below a stir-frying pan. A processed oil material is directly added into the oil press so that heat dissipation-caused influence on an oil extraction rate is avoided and continuous production is realized. A separator is arranged above a drying tank and a water-ring vacuum pump is arranged below the drying tank. Through effects of the vacuum pump, a vacuum environment in the drying tank is formed and low-temperature vacuum dehydration of edible oil in the drying tank is realized. The concentrated fragrance-type edible oil hot-squeezing and refining small-set guarantees a concentrated fragrance degree and volatile impurities can be separated by the separator. The concentrated fragrance-type edible oil hot-squeezing and refining small-set utilizes the two special-purpose filters to realize alternative filtration, can produce the high-quality concentrated fragrance-type edible oil and can guarantee continuous production effects.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

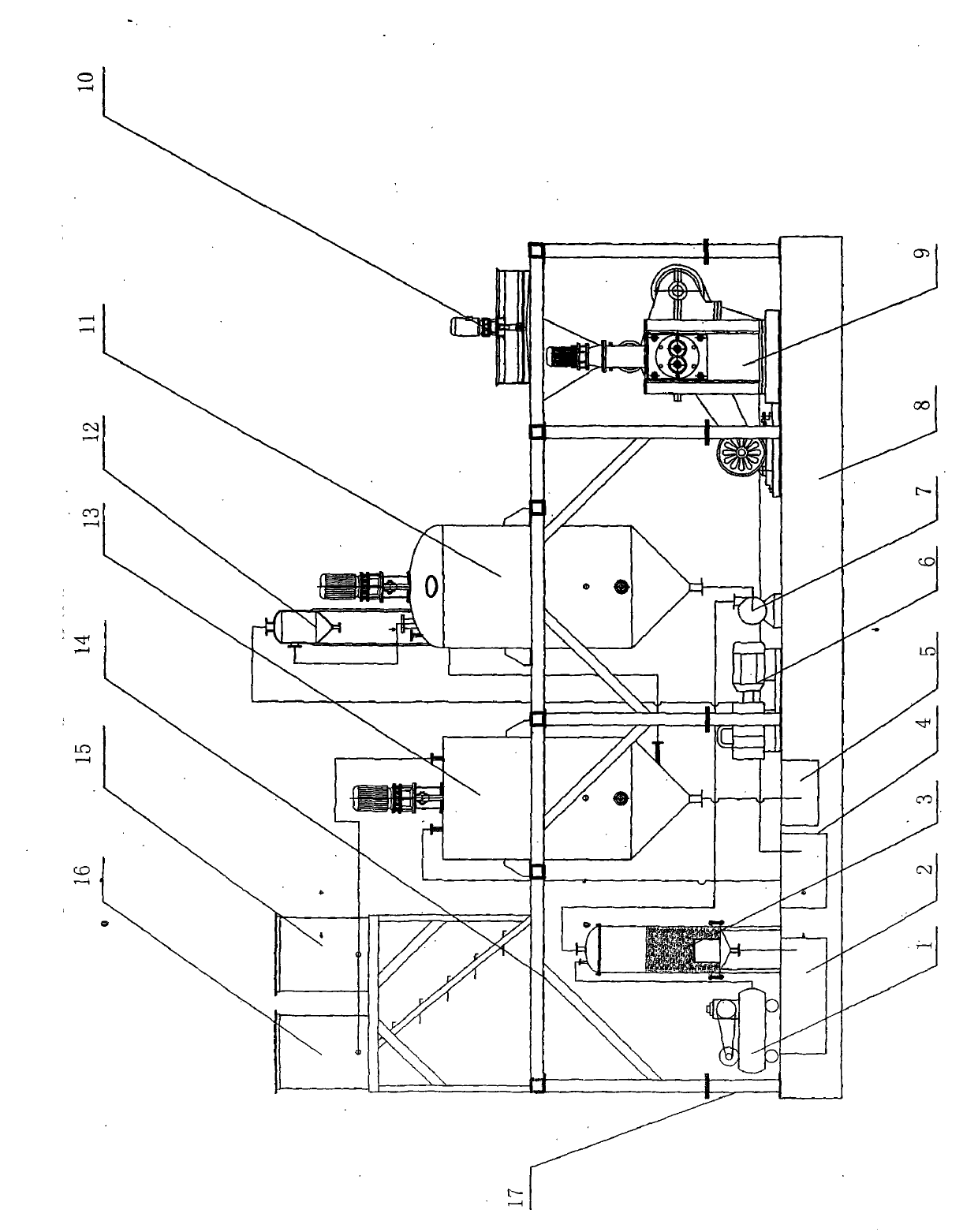

Sesame salt processing technology

The present invention discloses a sesame salt processing technology which includes the following eight steps: impurities removing, water washing, wok heating, fire frying, cooling, grinding, salt adding, and sealing and packaging. The sesame salt processing technology has reasonable processing technology, and simple and accurate operation step by step, and the prepared sesame salt has bright color and luster, and is fragrant all around, clean, fresh and bright. The processing technology has high production efficiency and the fragrant and mellow degree of the sesame salt is ensured.

Owner:ANHUI XINQIAO IND & TRADE

Preparation method of health-preserving red yeast rice white spirit

PendingCN113493726AWide audienceGuaranteed aromaAlcoholic beverage preparationMicroorganism based processesBiotechnologyRed yeast rice

The invention discloses a preparation method of health-preserving red yeast rice white spirit. Raw materials include water, red yeast rice, a sorghum mixture, distiller's yeast and a material tank. The preparation method is characterized in that the raw materials include 20% of the water, 10% of the red yeast rice, 69% of the sorghum mixture comprising sorghum, rice, sticky rice, wheat and maize, 0.5% of the distiller's yeast and 0.5% of the material tank. According to the preparation method of the health-preserving red yeast rice white spirit, the red yeast rice is added into a traditional white spirit process as the raw material, so that the mouth feel can be softened and the whole finished white spirit has health-preserving and health-care effects under the influence of no texture change on the finished white spirit.

Owner:陈康君

Preparation method of mushroom bran freshwater shrimp feed

InactiveCN105124304AReduce pollutionIn line with growth needsAnimal feeding stuffYeastAnimal science

The invention relates to the field of feed, particularly to a preparation method of mushroom bran freshwater shrimp feed. The mushroom bran freshwater shrimp feed is prepared by selecting 60 to 80 parts of mushroom bran, 10 to 15 parts of fish meal, 10 to 15 parts of spirulina powder, 10 to 25 parts of waste or damaged edible mushroom, 1 to 5 parts of corn oil, 2 to 4 parts of composite vitamins, 2 to 4 parts of beer yeast and 8 to 12 parts of rape seed cake through the steps such as raw material processing, boiling and fermenting. The mushroom bran and the waste or damaged edible mushroom are used as raw materials, so that the value of the mushroom bran and the waste edible mushroom is effectively utilized, and the probability of environmental pollution is reduced; the freshwater shrimp feed is prepared by adopting semi-cooked materials in a fermenting manner, so that the nutrition of various components in the raw material is guaranteed; moreover, the nutrition is balanced, and the growth requirement of the freshwater shrimp can be met, and the aromatic smell and good palatability of the feed can be guaranteed.

Owner:成都圣灵生物科技有限公司

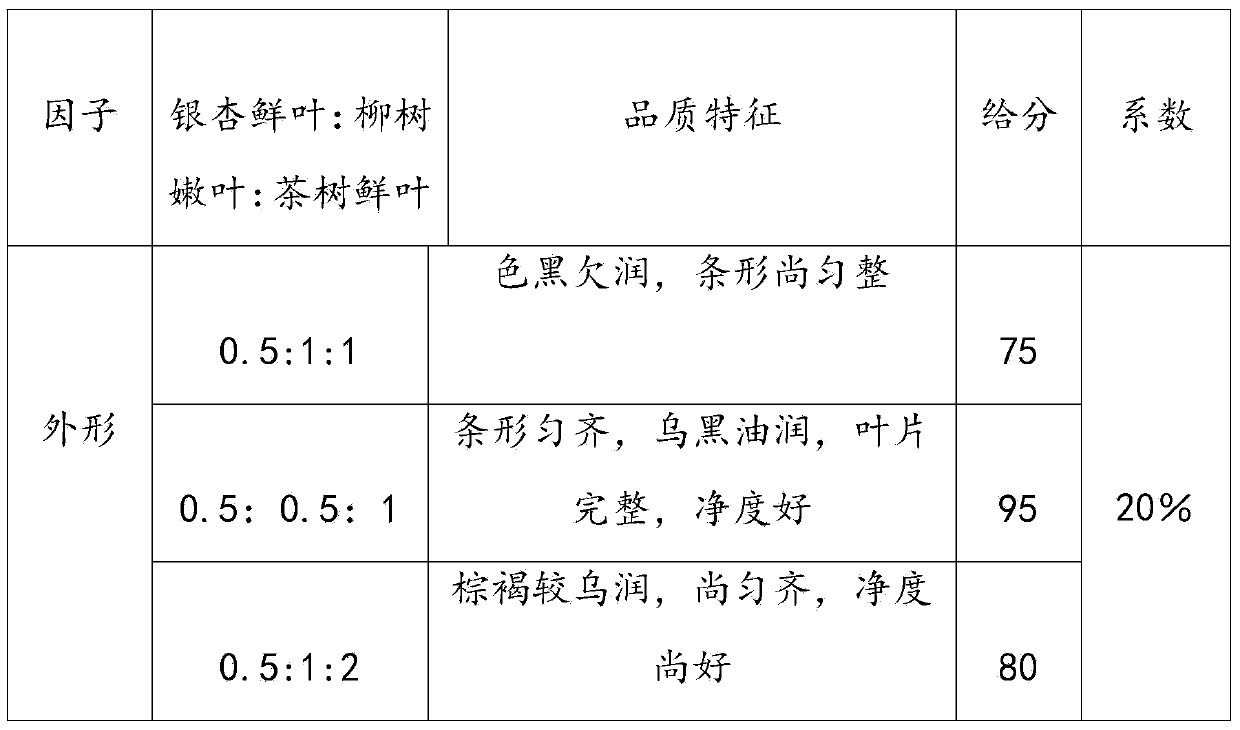

Processing method of black tea with leaves

The invention relates to a processing method of black tea with leaves. The method includes following steps: picking fresh gingko leaves, tender willow leaves and fresh tea leaves with a weight ratio of the fresh gingko leaves, the tender willow leaves and the fresh tea leaves being 0.5:0.5-1:0.5-1; removing petioles from the fresh gingko leaves and the tender willow leaves; cutting the fresh gingko leaves and the tender willow leaves into bars with a width being about two fingers and a length being 0.5-2.5 cm; enabling the fresh tea leaves to has two leaves on one bud; spreading out the fresh gingko leaves, the tender willow leaves and the fresh tea leaves for 8-14 hours; withering the fresh gingko leaves, the tender willow leaves and the fresh tea leaves until the fresh gingko leaves, the tender willow leaves and the fresh tea leaves are fully soft with a moisture content being 65-75%; uniformly mixing the withered fresh gingko leaves, tender willow leaves and fresh tea leaves; performing a rolling process; performing a fermenting process in stacks; and performing a drying process. The black tea has obvious fresh flavors of the gingko leaves and the willow leave, is uniform in the bar shape, is black and glossy, is good in appearance, is rich in nutrition, and has effects of clearing and dispersing, promoting urination, eliminating inflammation and removing toxin.

Owner:宋锦谋

Novel grape wine made by using double-feeding and double-bacterium compound fermentation process and making method thereof

The invention provides novel grape wine made by using a double-feeding and double-bacterium compound fermentation process and a making method thereof. The making method comprises the following steps of: laying and airing mature grapes, and when the sugar degree of the grapes is up to 28 to 36 percent, sorting, stemming and crushing the grapes, so as to obtain grape syrup; preparing double-bacterium yeast by using wine yeast and rice wine yeast; adding the prepared double-bacterium yeast into the grape syrup for fermentation; complementing the laid and aired grapes and partial raisins of the same type with the grapes into fermented juice of which the sugar degree is reduced, increasing the degree of the fermented juice so as to gradually increase the fermented raw alcohol content, so that the final fermented alcohol content is more than or equal to 18 percent_vol, and performing post-fermentation; after the post-fermentation is finished, adding distilled grape wine and the raisins intopost-fermented juice; standing and soaking for at least six months; and squeezing and separating grape peels and grape seeds from alcohol liquid, clarifying and filtering the alcohol liquid, so as toobtain the novel grape wine. The shelf life of the grape wine is stable; and the grape wine does not contain preservative, so that the safety of drinking the wine is improved.

Owner:甘肃省轻工研究院有限责任公司

Heating cigarette capable of uniformly releasing esters

ActiveCN113455700AGuaranteed aromaStable aromaTobacco preparationCigar manufactureEngineeringFood science

The invention relates to a heated cigarette capable of uniformly releasing esters, which is characterized in that a tobacco shred part of the heated cigarette consists of three parts, namely a middle area, a transition area and a peripheral area, and the concentrations of ester monomer flavors contained in sheet tobacco shreds in the three areas are different, so when a heating smoking set is used for heating the peripheral area, as the perfume concentration in the middle area and the transition area is high, firstly, part of the perfume is supplemented to the peripheral area, the amount of the perfume in the smoke of the first puff is guaranteed, the tobacco shreds in the middle area are fully heated along with the increase of the heating time, and at the moment, the perfume attached to the sheet tobacco shreds in the middle area is supplemented to the smoke so as to maintain the amount of the perfume in the smoke of the second puff; when the heating smoking set is heated from the middle of the tobacco shred part, the fragrance concentration of the middle area is lower than that of the peripheral area, so the fragrance amount in smoke can be kept stable in the smoking process, and the smoking quality is improved.

Owner:CHINA TOBACCO HENAN IND

Black tea wine and preparation method thereof

ActiveCN103627613BReduce outputIncrease contentAlcoholic beverage preparationAlcohol contentPhenolic content in tea

The invention relates to the field of foods, and particularly relates to black tea wine and a preparation method thereof. Particularly, the preparation method comprises the steps: processing sorghum, black tea and fragrant grains, and auxiliary materials such as rice hull and rice bran meal, then soaking, primarily steaming, stewing, re-steaming, discharging from a rice steamer, spreading for cooling, discharging yeast, cultivating, adding the black tea, preparing distiller grains, mixing, feeding a pool for fermenting, distilling, storing, and blending so as to obtain the black tea wine. The black tea wine is cool and transparent in vinosity, pure in faint scent, grace in tea perfume, mellow and clean, long in remaining taste, higher in polyphenol content and low in alcohol content, and has the remarkable black tea fragrance and taste, and a wine body is soft and harmonious.

Owner:GUIZHOU MEITAN DIANXI TEA WINE

Preparation process of honeysuckle tea

InactiveCN108432910BGuaranteed nutritionGuaranteed curative effectPre-extraction tea treatmentTea flavoringHeating effectTea leaf

Owner:安徽百味堂药业有限公司

Footbath liquid and preparation method thereof

InactiveCN106420542APromote circulationEasy to openCosmetic preparationsAntimycoticsAngelica dahuricaBULK ACTIVE INGREDIENT

The invention discloses a formula for footbath liquid. The formula is characterized by comprising 10 to 15 parts of angelica sinensis, 10 to 15 parts of ligusticum wallichii, 10 to 15 parts of angelica dahurica, 10 to 15 parts of notopterygium and 45 to 55 parts of dried ginger. The preparation method of the footbath liquid of the invention includes extracting the active ingredients by ethanol and water extraction, and adding a certain proportion of the original medicine powder to ensure the aromatic smell of the formula. The formula is simple and practical. The footbath liquid can clean feet and also is especially used for treating diseases caused by excessive of dampness of the human body, and suitable for widespread use.

Owner:杨凌萃健生物工程技术有限公司

Production method of honey lemon slices

PendingCN113729185AImprove food safetyPrevent compromising flavor qualityFood thermal treatmentBiotechnologyNutrition

The invention relates to a production method of honey lemon slices. The production method comprises the following steps of: pickling fresh lemons with salt, cleaning, draining, treating and slicing; adding the lemon slices into a cooking container, heating for 1-30 hours, and draining juice for 2-5 times during heating; stopping heating, cooling to normal temperature, adding honey into the cooking container, and uniformly stirring; standing at normal temperature for 4-8 hours; continuously heating for 2-10 hours; and stopping heating, cooling to normal temperature, air-drying, sterilizing and subpackaging to obtain finished products. The honey lemon slices produced by the production method disclosed by the invention are good in flavor, free of bitter aftertaste, moderate in sour and sweet taste and mild in preparation conditions, can keep nutrient substances in the lemons and the honey to the greatest extent, and ensure the nutrition of the honey lemon slices; and moreover, no other additives are added, so that the original taste and aroma of the honey and the lemons can be ensured to the greatest extent, and the honey lemon slices are healthy and safe.

Owner:元气密语机能性(广东)生物科技有限公司

Novel grape wine made by using double-feeding and double-bacterium compound fermentation process and making method thereof

The invention provides novel grape wine made by using a double-feeding and double-bacterium compound fermentation process and a making method thereof. The making method comprises the following steps of: laying and airing mature grapes, and when the sugar degree of the grapes is up to 28 to 36 percent, sorting, stemming and crushing the grapes, so as to obtain grape syrup; preparing double-bacterium yeast by using wine yeast and rice wine yeast; adding the prepared double-bacterium yeast into the grape syrup for fermentation; complementing the laid and aired grapes and partial raisins of the same type with the grapes into fermented juice of which the sugar degree is reduced, increasing the degree of the fermented juice so as to gradually increase the fermented raw alcohol content, so that the final fermented alcohol content is more than or equal to 18 percent_vol, and performing post-fermentation; after the post-fermentation is finished, adding distilled grape wine and the raisins intopost-fermented juice; standing and soaking for at least six months; and squeezing and separating grape peels and grape seeds from alcohol liquid, clarifying and filtering the alcohol liquid, so as toobtain the novel grape wine. The shelf life of the grape wine is stable; and the grape wine does not contain preservative, so that the safety of drinking the wine is improved.

Owner:甘肃省轻工研究院有限责任公司

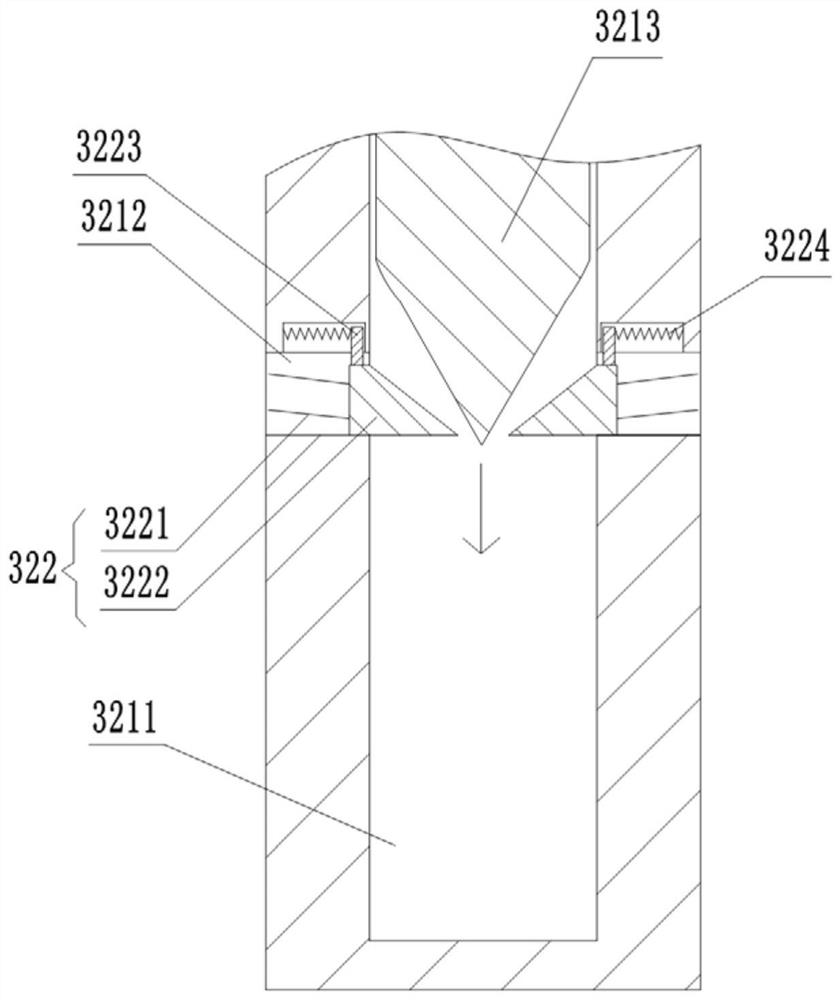

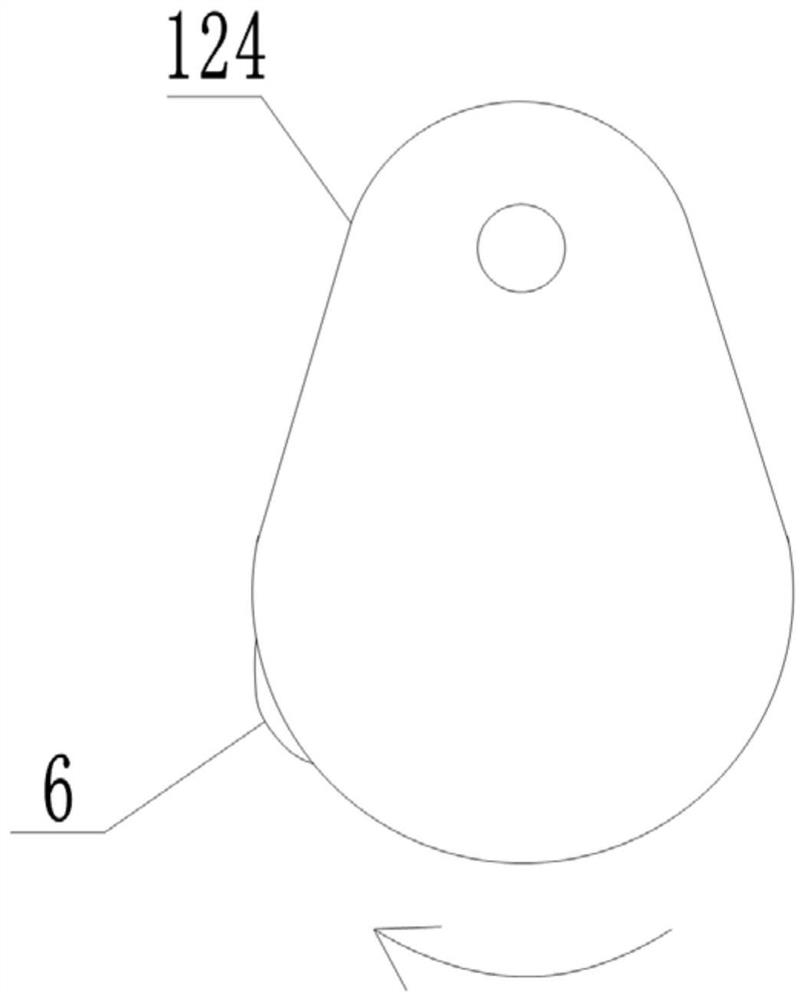

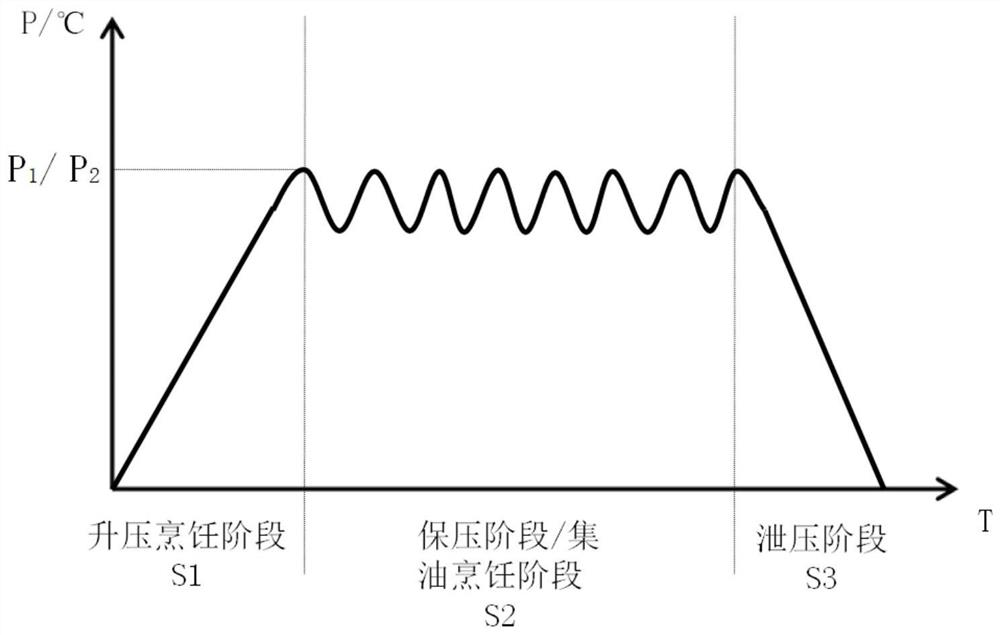

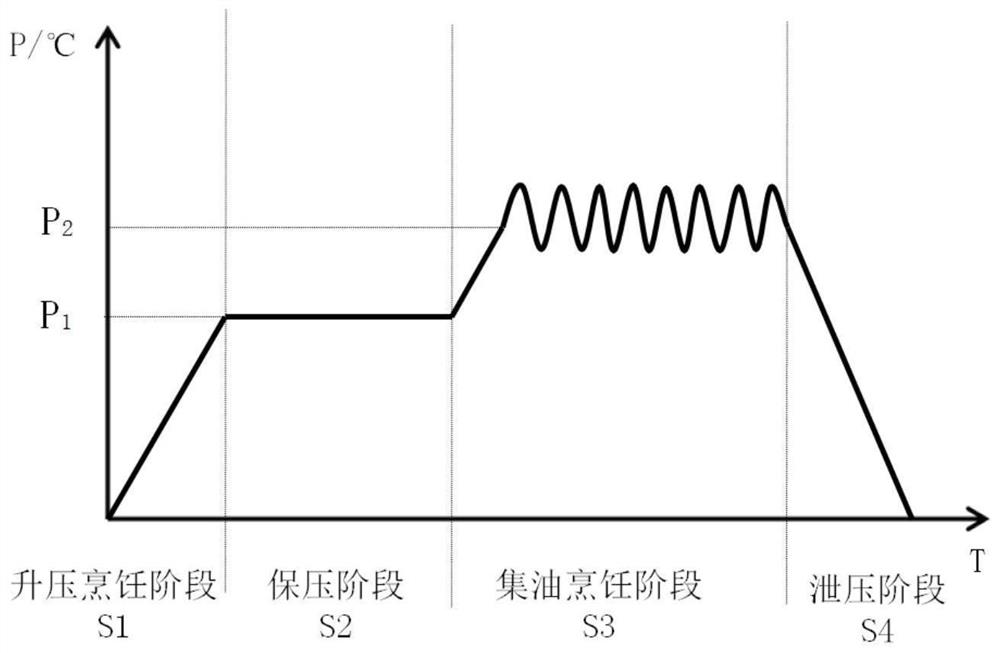

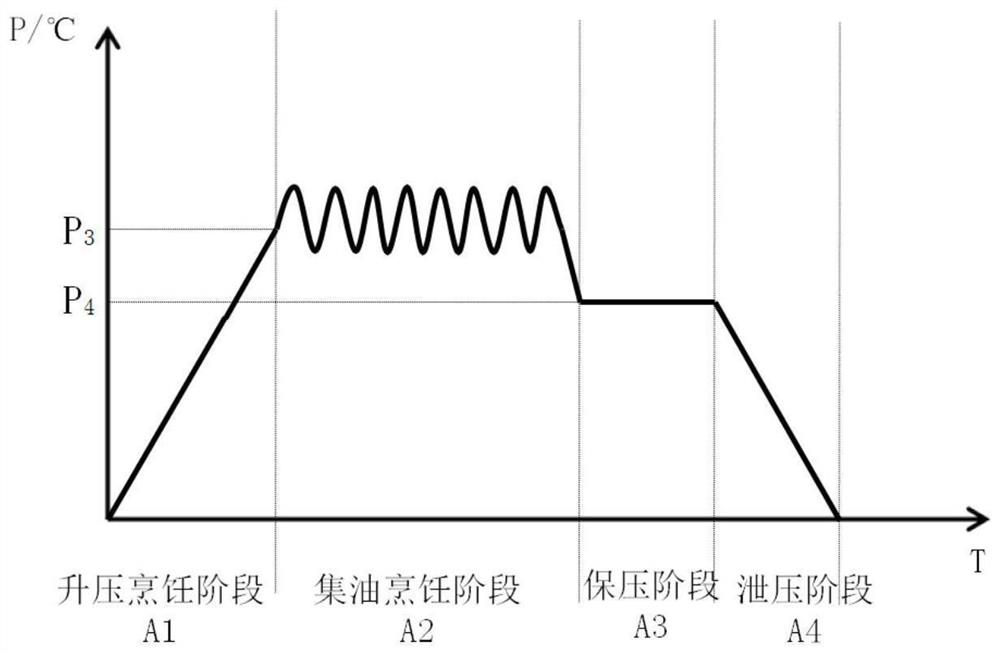

Fat draining cooking control method of pressure cooker

PendingCN114668298AEven boilingGuaranteed tasteCooking insertsTime-controlled ignitorsOil and greaseThermodynamics

The invention discloses a fat draining cooking control method of a pressure cooker. A fat draining kettle is arranged in an inner container of the pressure cooker; the inner container is divided into an oil collecting cavity and a heated cavity by the grease draining kettle; the control method comprises a pressure boosting cooking stage, a pressure maintaining stage and a pressure relief stage. The method further comprises an oil collecting cooking stage. In the oil collection cooking stage, a heating device of the pressure cooker is in a working state, an exhaust valve device of the pressure cooker is in an open state, liquid in the heated cavity is continuously boiled under the dual effects of heating and pressure releasing, the liquid level of the liquid rises to drive grease to enter the oil collection cavity, and therefore rapid cooking of low-fat food materials is achieved.

Owner:JOYOUNG CO LTD

Roasted famous high-quality green tea and production process thereof

InactiveCN102669313BGuaranteed qualityPromote hydrolysisPre-extraction tea treatmentTemperature controlGreen tea

Owner:中国测试技术研究院生物研究所

A kind of Dianhong essential oil and preparation method thereof

ActiveCN103087828BNo environmental pollutionNo pollutionEssential-oils/perfumesGreen environmentDistillation

The invention relates to a Yunnan black tea essential oil and a preparation method thereof. The essential oil is prepared by a supercutical fluid extraction-molecular distillation combination technique. The preparation method comprises the following steps: carrying out supercritical extraction on Yunnan black tea, and carrying out molecular distillation to obtain the Yunnan black tea extract. Compared with the traditional extraction method, the invention adopts the newest supercutical fluid extraction-molecular distillation combination technique, has the advantage of high extraction efficiency, does not introduce any harmful organic reagent, and obtains the Yunnan black tea essential oil with no solvent residue and with good scent and quality under the conditions of low temperature and low pressure. The method is simple to operate, has the advantages of high extraction rate and no pollution, and provides an efficient green environment-friendly extraction separation method for preparing Yunnan black tea essential oil.

Owner:云南天宏香精有限公司

Simple, quick and economical sweet beer brewing method

PendingCN112175761AGuaranteed fragranceGuaranteed tasteMicroorganism based processesHops treatmentChaptalizationProcess engineering

The invention provides a simple, quick and economical sweet beer brewing method. A brewing process method which not only saves equipment cost and time cost, but also is simple and practical and ensures the taste and aroma of beer is created by using temperature-controlled saccharification of a controllable vacuum cup, permeability of a tea bag and bitterness of isomerized alpha acid hop extract, and the method has very wide application value. The method belongs to the field of beer brewing.

Owner:MOUTAI INST

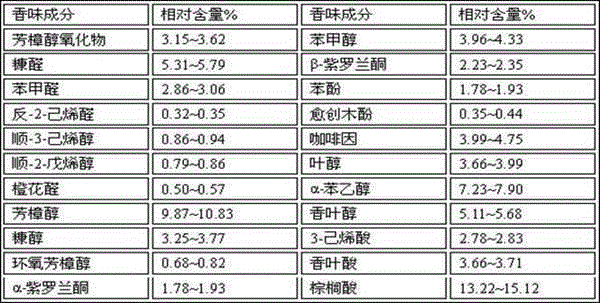

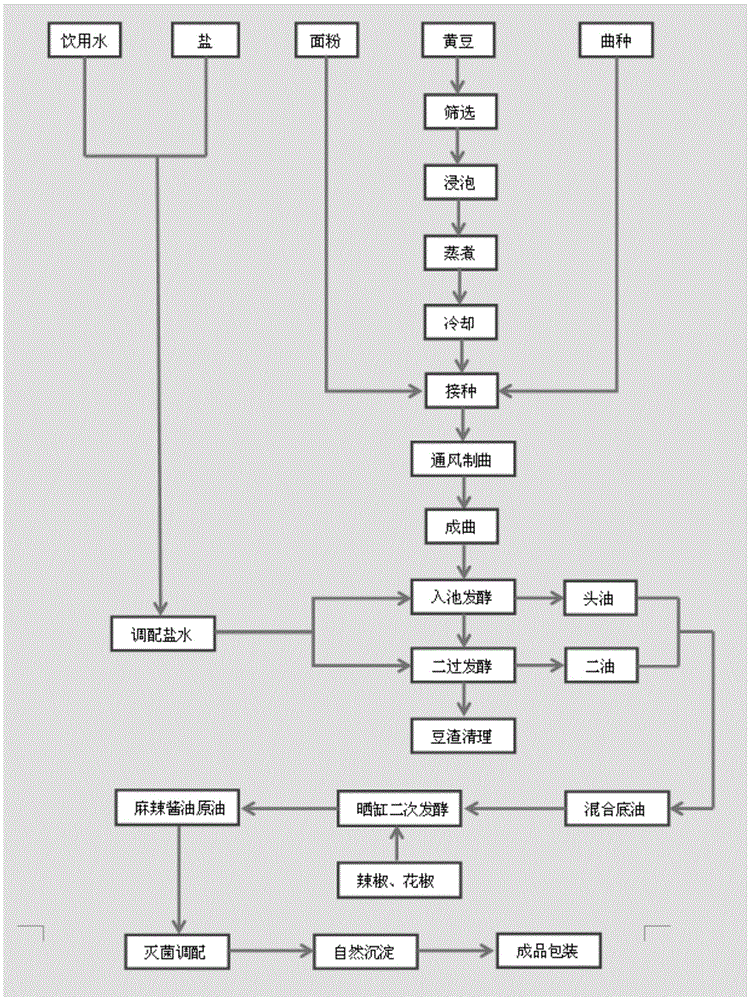

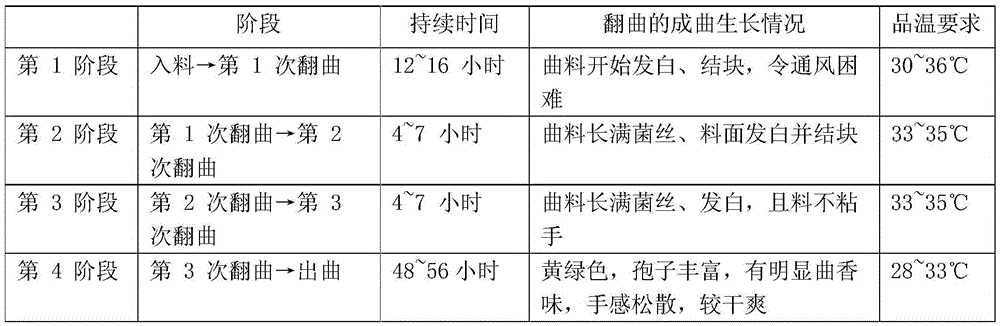

A kind of production method of spicy soy sauce

The invention provides a production method of spicy and hot soybean sauce. The production method comprises two-time fermentation, wherein before second fermentation, chilies and pepper are added to base oil after first fermentation for second fermentation, and a cylinder is exposed under the sun for second fermentation; and during fermentation, the cylinder is exposed under the sun for 60-90 days, opened under sunlight and sealed in the other time. The prepared soybean sauce has uniform reddish brown color, has heavy flavor of fermented soybeans, has heavy pepper and chili flavor and tastes hot and spicy. Spicy and hot substances are uniformly blended with soybean sauce, the layering phenomenon is prevented, the spicy and hot taste and sauce flavor are perfectly integrated, and the spicy and hot soybean sauce has lasting flavor.

Owner:CHONGQING DUOBANG FOOD

Houttuynia cordata sauce and preparation method thereof

The invention relates to houttuynia cordata sauce and a preparation method thereof, the houttuynia cordata sauce comprises the following components in parts by weight: 3-5 parts of houttuynia cordatapowder, 80-85 parts of soybean sauce, 3-5 parts of salt, 8-10 parts of glutinous rice flour and 4-6 parts of tea polyphenol. According to the houttuynia cordata sauce, houttuynia cordata resources arefully utilized, various requirements of people for sauce tastes are met, and the houttuynia cordata sauce has the flavor of houttuynia cordata and strong sauce fragrance, and is a new choice for eating together with rice and cooking.

Owner:CHONGQING UNIV OF EDUCATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com