Concentrated fragrance-type edible oil hot-squeezing refining small-set

A strong aroma type, small unit technology, applied in the project field, can solve problems such as the decline of strong aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

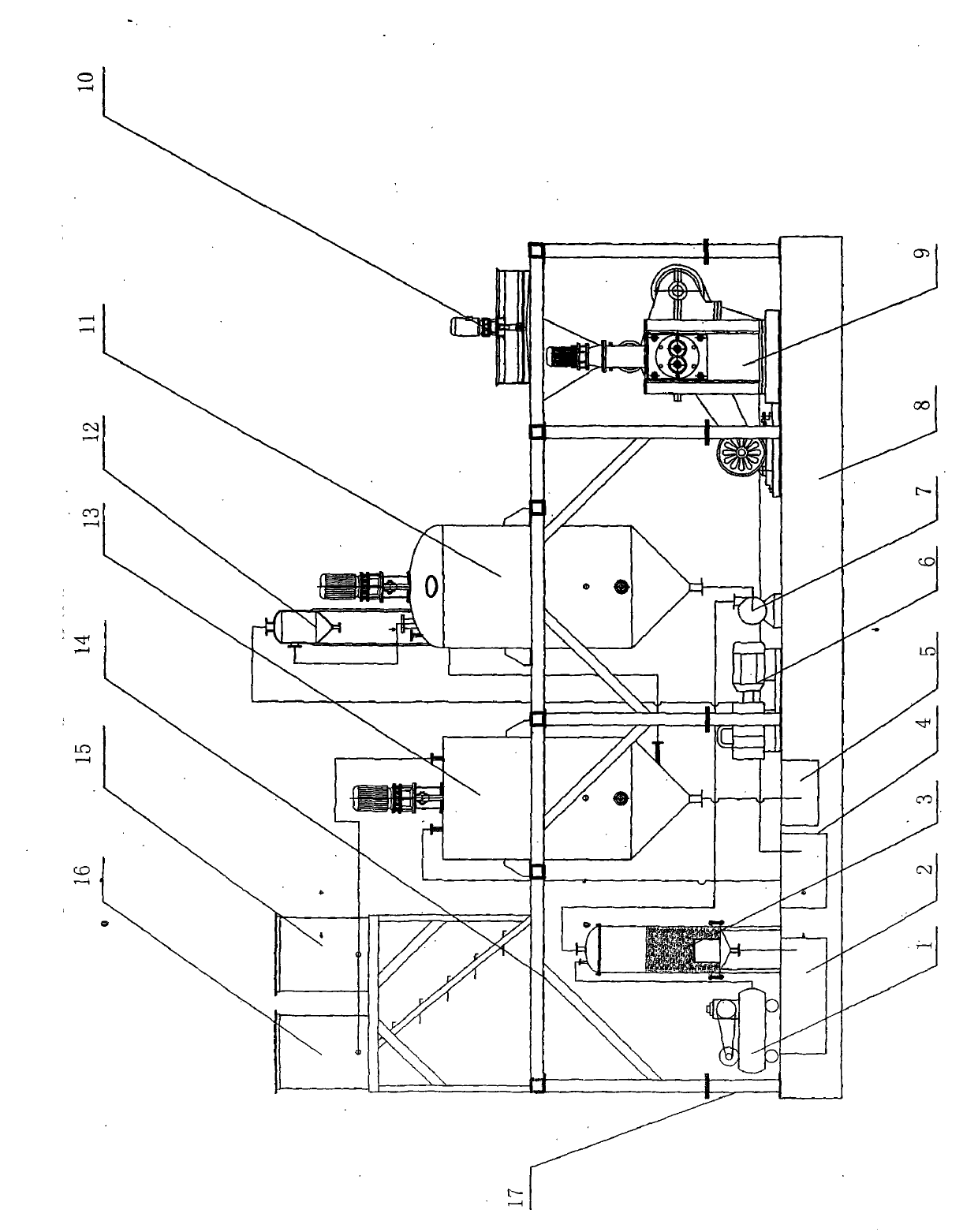

[0009] like figure 1 As shown in the products involved in this project, the frame 14 is connected with the chassis 8 with bolts through the movable legs 17; The top of the frame 14 is provided with a frying pan 10, a drying tank 11, an oil refining pot 13, an alkaline water tank 15, and a salt water tank 16, and the bottom of the frame 14 is provided with an air compressor 1, a special filter 3, a water ring vacuum pump 6, and a drying pump 7. Oil press9. The oil press 9 is arranged under the frying pan 10, and the oil is processed and directly enters the oil press 9; to avoid heat emission from affecting the oil yield. A separator 12 is provided above the drying tank 11, and a water ring vacuum pump 6 is provided below; a vacuum environment is formed in the drying tank 11 through the action of the vacuum pump, and edible oil is dehydrated in a low-temperature vacuum in the drying tank; 14, the outlet pipes of the alkaline water tank 15 and the salt water tank 16 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com