Yunnan black tea essential oil and preparation method thereof

A technology of essential oil and Dianhong tea, applied in the field of natural plant essential oils, can solve the problems such as no reports on the application of supercritical fluid extraction-molecular distillation combined technology, and achieve the effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

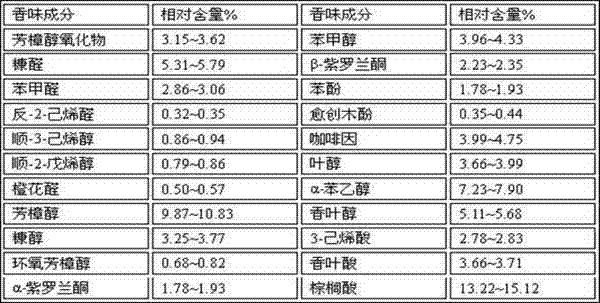

Image

Examples

Embodiment 1

[0022] Take 300g of Dianhong tea powder, add it to a 1000mL supercritical fluid extraction tank, and use CO 2 As a supercritical fluid, the flow rate is 0.5L / h. When the temperature rises to 30°C and the pressure reaches 10MPa, start timing. Keep this condition and run for 10 hours, then stop, and separate crude oil 25g from the separation tank. Add the prepared crude oil into the vacuum degassing tank of molecular distillation, degas for 20 minutes, and then send the material into the continuous evaporator at a uniform rate through the flow meter, the vacuum degree is controlled at 0.1Pa, and the distillation temperature is controlled at 30°C, the condensation temperature is 10°C, the rotation speed is 250 rpm, and 17g of Dianhong tea essential oil is obtained after distillation for 3 hours. The obtained Dianhong tea essential oil is a light red transparent oily liquid, which has the characteristic tea aroma and floral aroma of Dianhong. The aroma quality, intensity, and fr...

Embodiment 2

[0024] Take 400g of Dianhong tea powder, add it to a 1000mL supercritical fluid extraction tank, and use CO 2 As a supercritical fluid, the entrainer is 40% ethanol aqueous solution by mass fraction, the volume ratio of entrainer to Dianhong tea powder is 15:100, the flow rate is 2L / h, and the timing starts when the temperature rises to 40°C and the pressure reaches 15MPa. Keep this condition to run for 5 hours, then stop, and separate crude oil 41g from the separation tank. Add the prepared crude oil into the vacuum degassing tank of molecular distillation, degas for 30 minutes, and then send the material into the continuous evaporator at a uniform rate through the flow meter, the vacuum degree is controlled at 75Pa, and the distillation temperature is controlled at 45 ℃, the condensation temperature is 0 ℃, the rotation speed is 250 rpm, and 31g of Yunnan black tea essential oil is obtained after distillation for 2 hours. The obtained Dianhong tea essential oil The properti...

Embodiment 3

[0026] Take 500g of Dianhong tea powder, add it to a 1000mL supercritical fluid extraction tank, and use NO 2 As a supercritical fluid, the entrainer is 95% ethanol aqueous solution, the volume ratio of entrainer to Dianhong tea powder is 30:100, the flow rate is 5L / h, and the timing starts when the temperature rises to 50°C and the pressure reaches 20MPa. Keep this condition and run for 2 hours, then stop, from the separation tank middle fluid crude oil 66g. Add the prepared crude oil into the vacuum degassing tank of molecular distillation, degas for 40 minutes, and then send the material into the continuous evaporator at a uniform rate through a flow meter, control the vacuum degree at 150Pa, and control the distillation temperature at 60 °C, the condensation temperature is -15 °C, the rotation speed is 250 rpm, and 43 g of Dianhong tea essential oil is obtained after distillation for 1 hour. The properties and quality of the obtained Dianhong tea essential oil are the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com