Patents

Literature

51 results about "Silybum Marianum Seed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

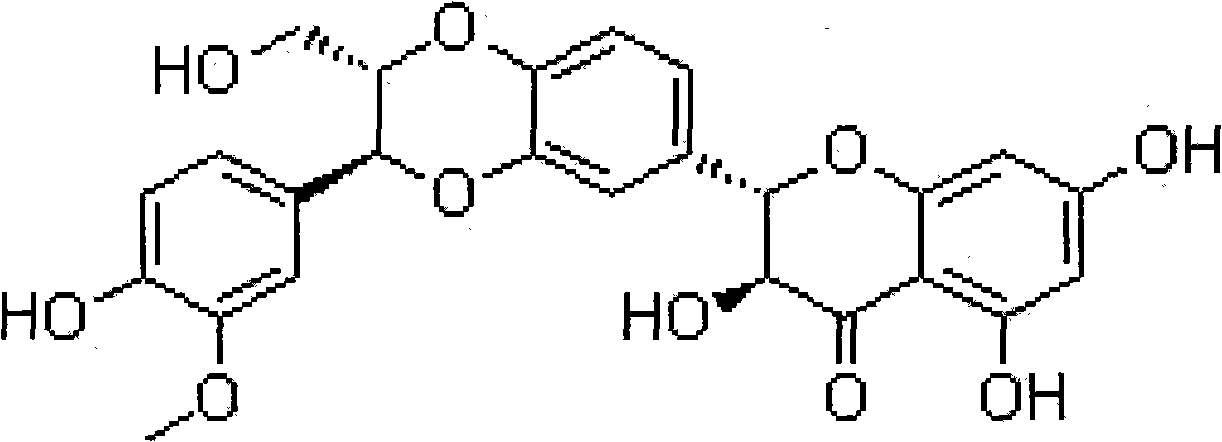

Silybum marianum seeds contain concentrated amounts of a unique group of flavonoids and flavonolignans collectively called silymarin. Silymarin is thought to be the most therapeutically active ingredient of milk thistle. Although concentrated in the seeds, silymarin is also contained throughout the milk thistle plant.

Production method of silymarin

ActiveCN102079745AReduce the amount of fatReduce the use effectOrganic chemistrySilybum Marianum SeedSolvent

The invention provides a production method of silymarin, which comprises the following steps: shelling silybum marianum seeds; filling the silybum marianum shells into a softening tank, and softening the silybum marianum shells with vapor; filling the softened silybum marianum shells into a flat-turn extractor, and adding ethanol to carry out extraction, thereby obtaining an extracting solution; concentrating the extracting solution to a certain degree to obtain a concentrated solution; adding aqueous alkali into the concentrated solution, stirring and standing to precipitate; and filtering the precipitate, drying, pulverizing and screening. In the extraction process, no toxic or harmful reagent is adopted, and no solvent residue which is harmful to the product can be produced; the ultraviolet detection indicates that the total flavone content in the product can be higher than 70%, the contents of silybin and isosilybin can be higher than 30%, and the product yield is 3-4% of the silybum marianum seeds; and therefore, the invention has the advantages of high extraction efficiency, simple technique and low solvent consumption.

Owner:内蒙古昶辉生物科技股份有限公司

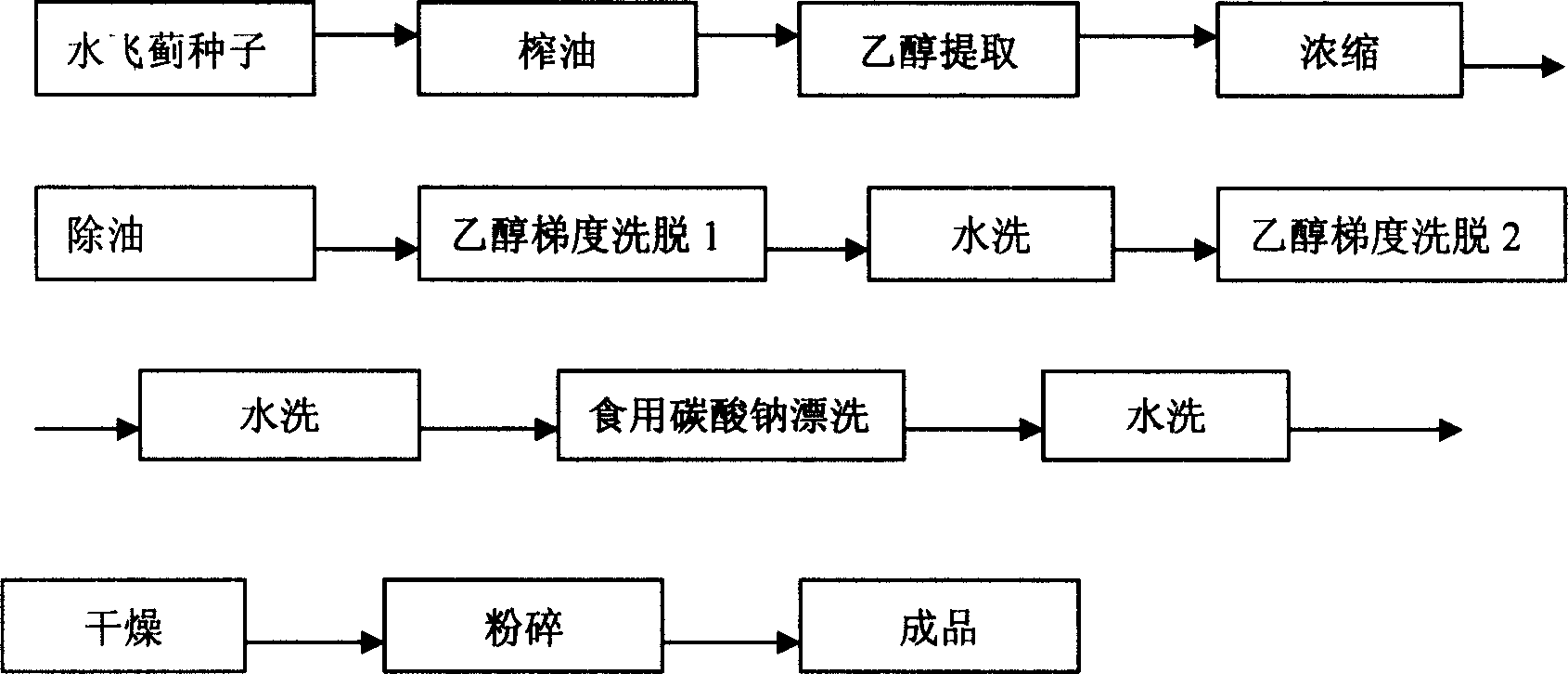

Process for extracting water grind thisvine using alcohole as single organic dissolvent

The invention discloses a process of extracting silymarine by using alcohol as a single organic solvent, adopting edible alcohol to extract silymarine, then adopting alcohol and water to wash twice so as to eliminate oil and impurities, using edible sodium carbonate for elution, drying the silymarine solids obtained by fulling and then crushing and obtaining the final product, where by the UV determination, the total flavone content in the silymarine has mass percent concentration of 70%-90%, the product yield is 2-3% of the quantity of silymarine seeds from which the oil has been extracted. It solves the problem of harmful solvent residues in current silymarine products, and it can obtain the silymarine products without harmful solvent residues.

Owner:XIAN UNIV OF TECH

Method for preparing silybin

The invention relates to a method for preparing silybin. The method comprises the following process steps: crushing silybin seeds into 20 to 40 meshes, and degreasing the crushed silybin seeds thrice by using n-hexane; refluxing and extracting degreased coarse materials by using dilute ethanol; concentrating the extract under reduced pressure till the extract has no ethanol smell, extracting the concentrate by using ethyl acetate, stirring and drying ester phase and silica gel, then injecting a dried product to a column, eluting the dried product by using benzene or benzene-ethyl acetate, collecting the elute by sections, combining the elute to obtain main elute component of the silybin, concentrating the elute under reduced pressure, dissolving the elute in ethanol solution, adding active carbon into the solution, stirring the solution, decolorizing the solution for 0.5 to 1 hour, filtering the active carbon from the decolorized solution, concentrating the decolorized solution under reduced pressure to 40 to 60 percent of the primary volume, cooling the concentrate to separate out crystals, crystallizing the crystals by using hot ethanol, and repeating the crystallization step for 2 to 4 times to obtain the silybin. The method for producing the silybin has the advantages of simple process, low solvent toxicity, low production cost, and easy realization of industrialization.

Owner:NANJING ZELANG MEDICAL TECH

New method for purifying silymarin

The invention belongs to the field of natural organic chemistry, and relates to a method for preparing high purity silymarin by the following steps: adopting biological wall breaking and microwave pretreatment to obtain oil, carrying out microwave countercurrent extraction and macroporous resin purification to obtain the high purity silymarin. The method has the following advantages that: 1, a step-by-step method is adopted to carry out degreasing, seeds are pretreated, microwave countercurrent extraction is performed, and isoelectric point precipitation is performed to remove proteins, such that complete dissolution of effective components of the silymarin is prompted; 2, with the microwave extraction, the extraction time is reduced to 60-80 minutes so as to improve extraction speed and increase effective component content, and reduce herb consumption and energy consumption; 3, the macroporous resin adsorption technology is adopted so as to reduce the amount of the solvent, and the macroporous resin can be conveniently and rapidly regenerated, such that the cost is substantially reduced; and 4, two products of silybum marianum oil and silymarin can be obtained. With the method, the biological wall breaking treatment is performed on the silybum marianum seeds at the early stage so as to shorten the microwave pretreatment time, such that the seed oil can be extracted in just a few minutes; with the two-step microwave extraction, the extraction time is shortened; and the disadvantages of long conventional extraction time, low extract purity and single extract are overcome.

Owner:DAXINGANLING LINGOBERRY BOREAL BIOTECH CO LTD

Supplement composition and method of use in enhancement of methylation process

InactiveUS20070021376A1Increase heightIncrease of methylationBiocideSulfur/selenium/tellurium active ingredientsS-Adenosyl-l-methionineMethylsulfonylmethane

A supplement composition for enhancement of methylation process is provided, which contains vitamin B6 (as pyridoxine HCl), folic acid, vitamin B12 (as cyanocobalamin), betaine HCl, and methylsulfonylmethane; and also contains S-adenosylmethionine. The supplement composition further includes silymarin (from milk thistle seed extract), N-acetyl L-cysteine, and cruciferious blend which includes broccoli (brassica oleracea var. talica), kale (brassica oleracea var. acephala), and radish (raphanus sativus). Further provided is a method of using the supplement composition for enhancement of methylation process.

Owner:SURACELL

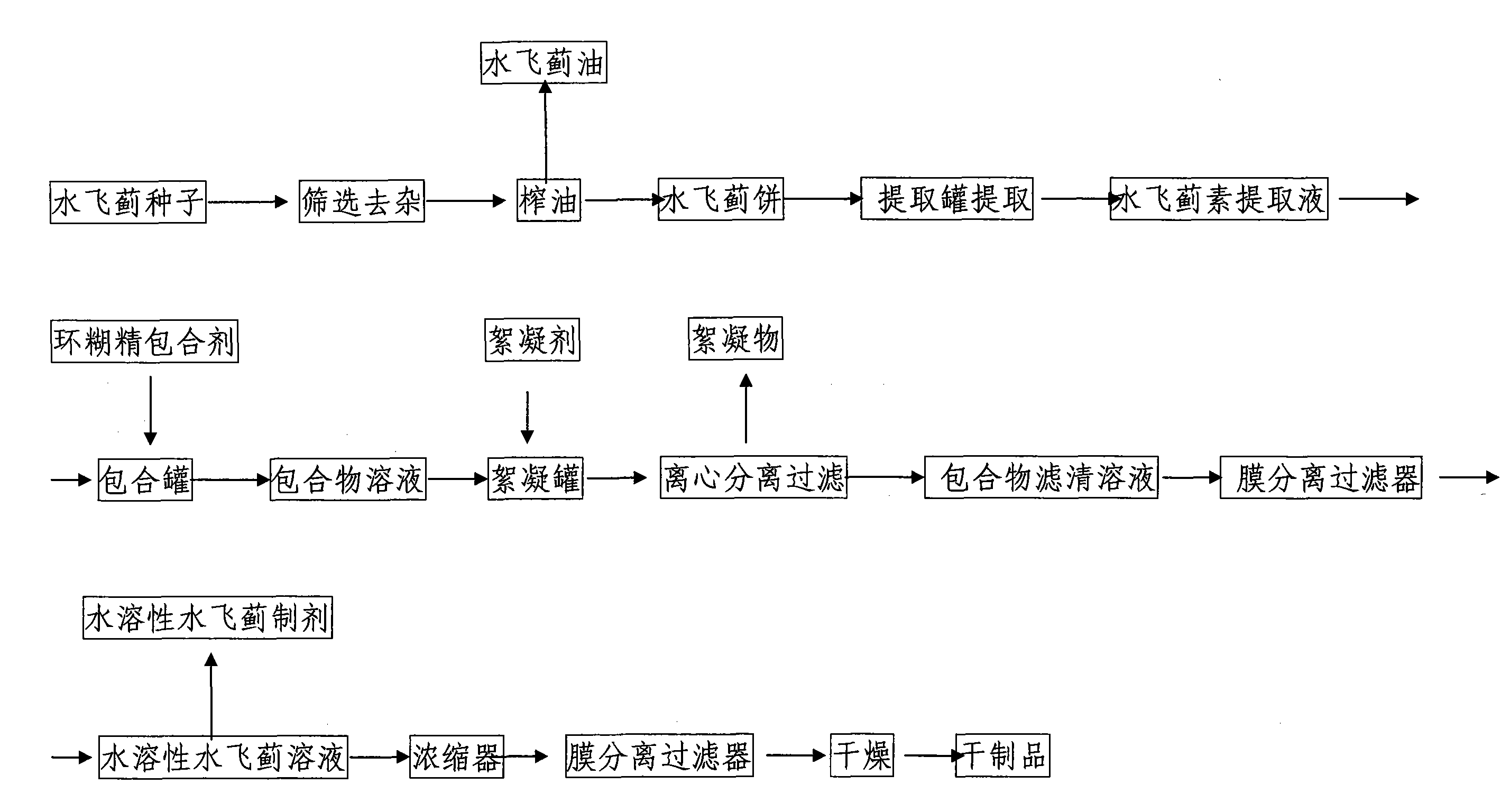

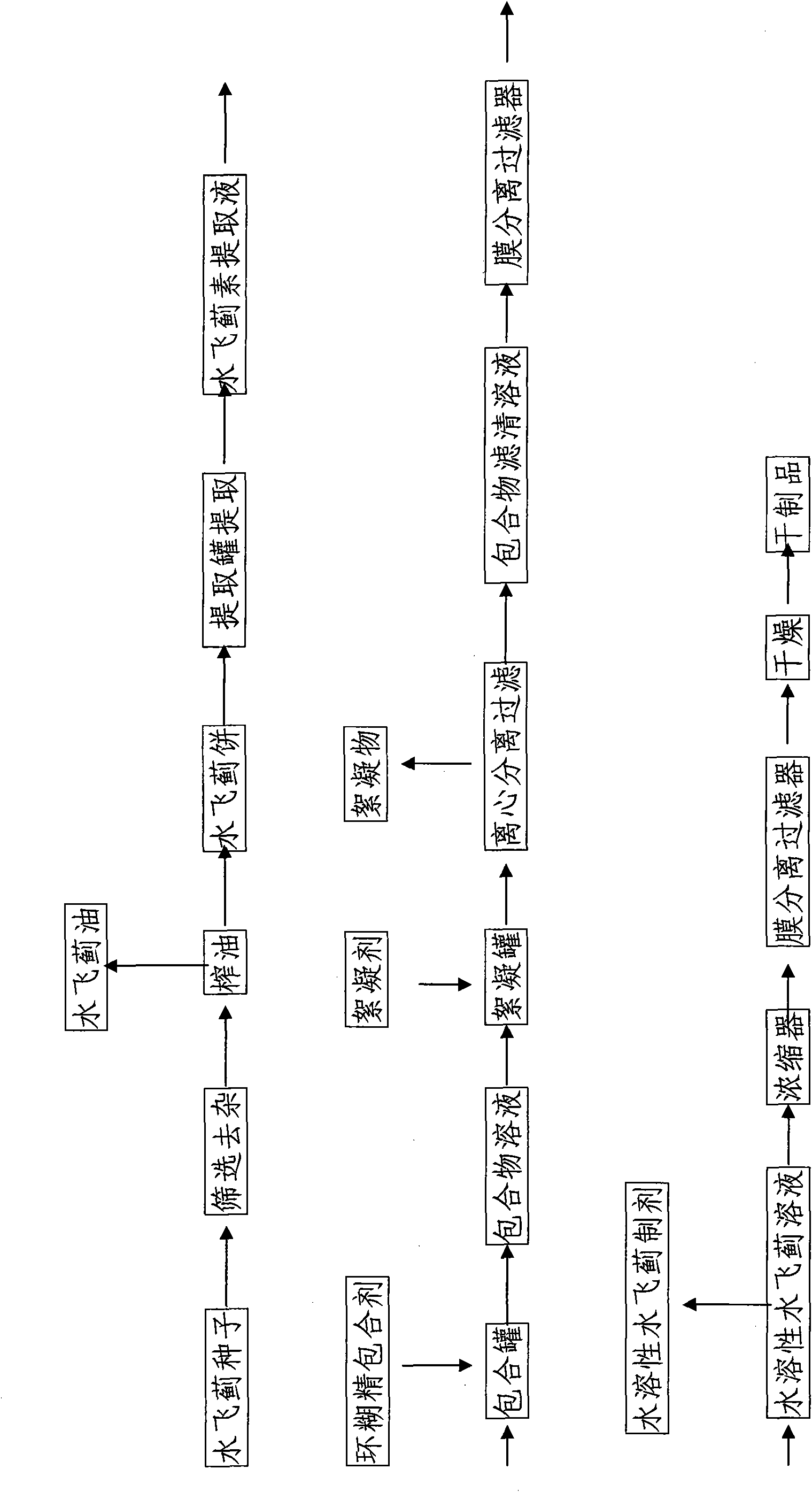

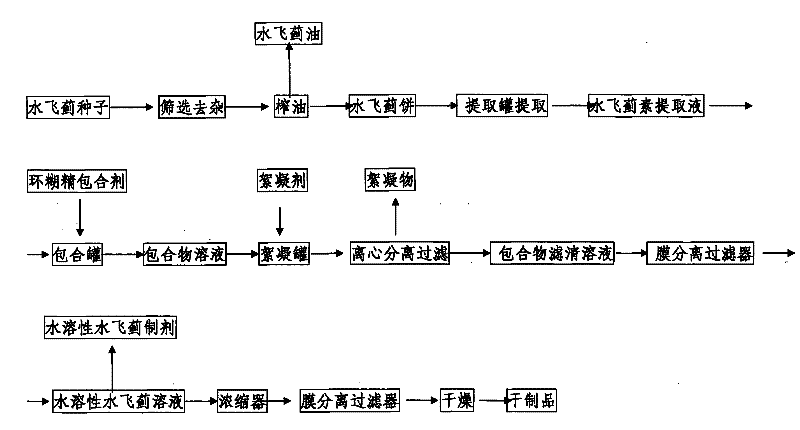

Water-soluble silymarin and preparation method thereof

InactiveCN101810660ANo residueImprove qualityOrganic active ingredientsMetabolism disorderSolubilitySilybum Marianum Seed

The invention discloses water-soluble silymarin, which is an inclusion compound that takes cyclodextrin as main molecules and silymarin as guest molecules; and the inclusion compound contains 12 to 20wt % of silybinin. The preparation method thereof comprises the following steps: silybum marianum seeds are squeezed into silybum marianum cakes; the silybum marianum cakes are added into alkali water ethanol solution and are heated to 75DEG C to 85DEG C, the constant temperature is kept for 1.5-2.5 hours, and silybum marianum extracting solution is prepared after 2-4 times of continuous extraction; the silybum marianum extracting solution is added with the cyclodextrin for inclusion, thus obtaining inclusion compound solution; flocculant is added, standing after being well stirred; after flocculate is filtered out, membrane separation process is carried out, thus obtaining water-soluble silymarin solution; and after the membrane separation process, the water-soluble silymarin solution is concentrated and dried, thus obtaining the dried product of the water-soluble silymarin. The water-soluble silymarin prepared by the method has the advantages of high solubility, good quality, good drug stability and high bioavailability.

Owner:江苏健佳药业有限公司

Method for extracting silybum marianum protein

InactiveCN103242423AGet rid of the bondagePromote dissolutionPeptide preparation methodsWater bathsFreeze-drying

The invention discloses a method for extracting silybum marianum protein and belongs to the technical field of application of biotechnology in foods. The method comprises the following steps: dissolving silybum marianum seed kenel spent meal in distilled water, adding mixed enzyme of cellulose and amylase according to a mass ratio of the enzyme to the substrate of 4.5-12 percent so as to carry out enzymolysis for 0.5-3 hours under the conditions of the pH of 4-7 and the temperature of 40-70 DEG C, heating and inactivating the enzymes, regulating the pH value of the solution to be 10 at the water bath temperature of 50 DEG C, leaching for 60 minutes, centrifuging, regulating the pH value of the liquid supernatant to be 5.5 by using hydrochloric acid, centrifuging and collecting the precipitate, dissolving the precipitate by using water, regulating the pH to be neutral, and performing vacuum freeze drying to obtain the silybum marianum protein powder. The silybum marianum seed kenel spent meal is treated by employing cellulose and amylase, and the cellulose and amylase can hydrolyze cellulose, starch and other polysaccharide components, so that the constraint of the polysaccharide on the protein can be relieved, the dissolution of the protein is promoted, and the protein extracting rate is improved.

Owner:JIANGSU UNIV

Method for refining silybum marianum seed oil by enzymic-method degumming

InactiveCN102936533AReduce oil lossReduce lossFatty-oils/fats refiningSILYBUM MARIANUM SEED OILPhospholipin

The invention discloses a method for refining silybum marianum seed oil by enzymic-method degumming and relates to the technical field of oil refining. The method includes the following steps: squeezing or leaching silybum marianum seeds to prepare silybum marianum seed oil, utilizing the principle that suspension impurities and oil have different densities to separate the impurities and the oil under the standing state or placing the silybum marianum seed oil into a 50 DEG C drying box for 1h, filtering to prepare crude oil, degumming the silybum marianum seed oil through phospholipase and conducting deacidification, decoloration and deodorization to obtain the refined silybum marianum seed oil. The enzymic-method degumming method adopts key technology for refining of the silybum marianum seed oil, remarkably reduces phospholipid content in the degummed silybum marianum seed oil, and is high in degumming efficiency, mild in reaction condition, low in energy consumption and easy to control. Silica gel is utilized as adsorbent to conduct decoloration and deodorization processing, high temperature vacuum decoloration and high temperature vacuum deodorization processing in the prior art are avoided, loss of effective components in the silybum marianum seed oil is reduced, and process flow is shortened.

Owner:JIANGSU UNIV

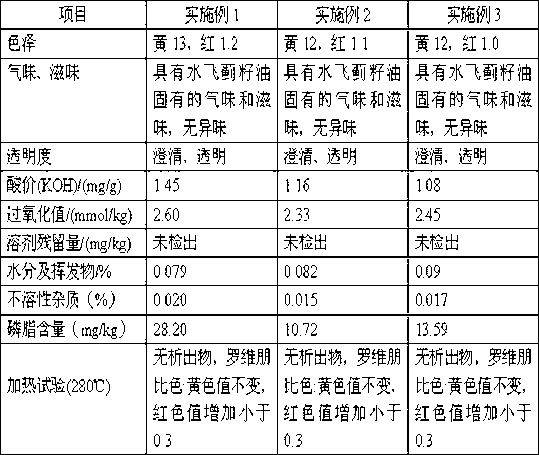

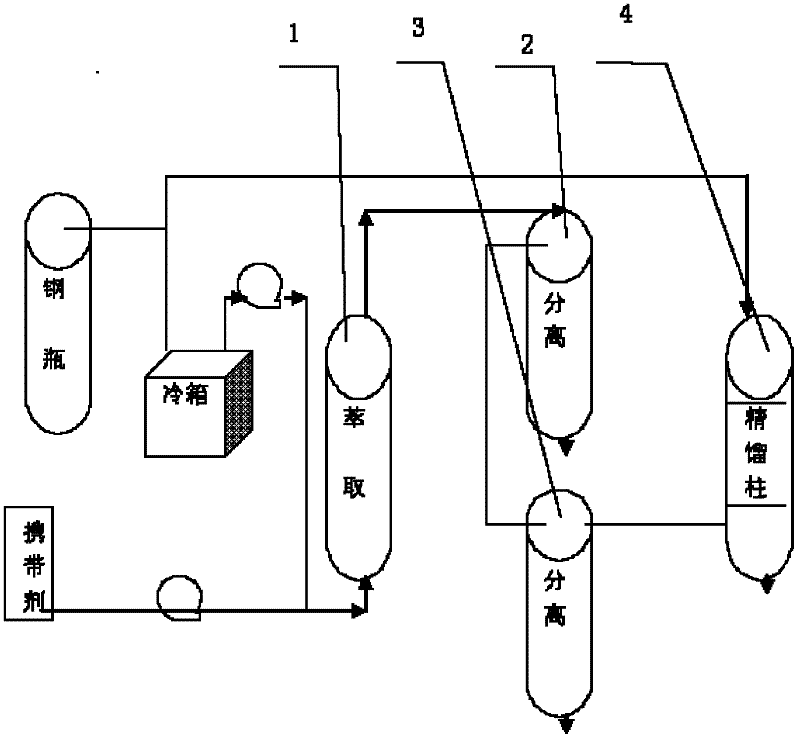

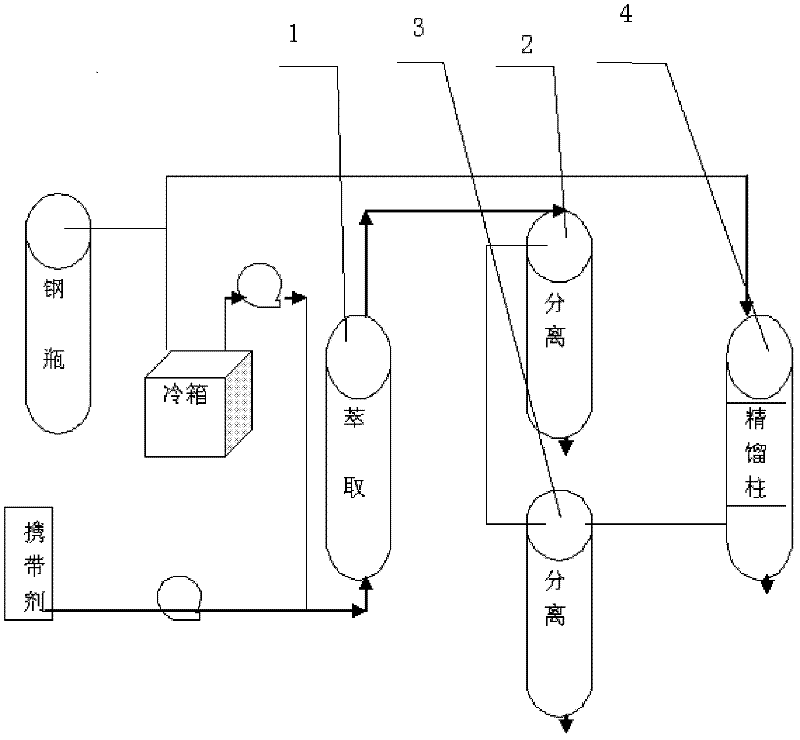

A kind of preparation method of milk thistle oil

InactiveCN102260589AImprove extraction efficiencyImprove qualityFatty-oils/fats refiningFatty-oils/fats productionSilybum Marianum SeedDistillation

The invention relates to a method for extracting milk thistle oil from milk thistle seeds, belonging to the extraction technology of milk thistle oil, comprising the following steps: (1) selecting milk thistle seed powder as a raw material, and conducting physical properties by alcohol After granulation, mix a certain amount of filler, the mixing ratio is milk thistle seed powder:filler=10:1, (2) the mixed raw material is filled in the extraction kettle, and supercritical CO2 fluid and carrier are introduced , control the extraction pressure and temperature for extraction, (3) control the primary and secondary separation temperature and pressure for separation, (4) control the temperature and pressure of the rectification column for supercritical CO2 rectification to remove impurities and water. The milk thistle oil prepared by the method of the invention is clear and translucent, with high extraction rate and high quality.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

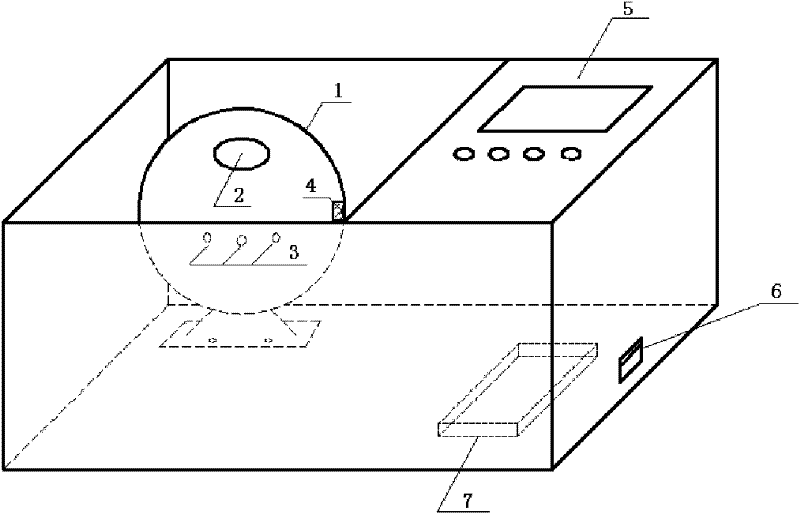

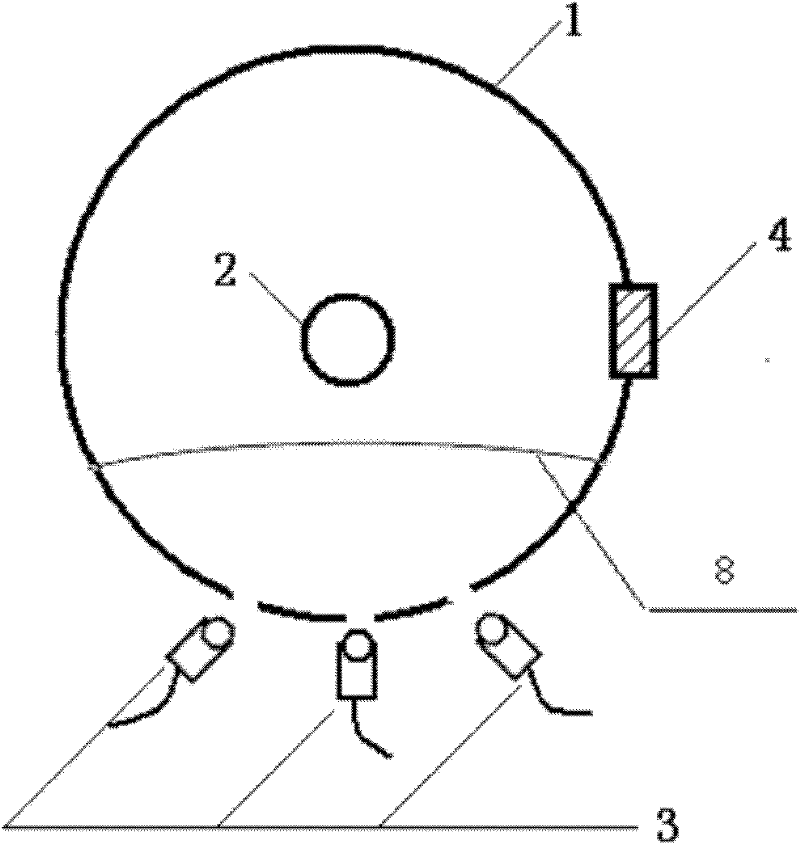

Device for detecting quality of Silybum marianum seed and detecting method thereof

ActiveCN102507491ACompact structure and miniaturizationImprove objectivityColor/spectral properties measurementsElectricityNon destructive

The invention discloses a device for detecting the quality of a Silybum marianum seed, which belongs to non-destructive testing technology for the quality of raw material of traditional Chinese medicine. The device comprises a spectrum signal collecting system and a microprocessor electrically connected with the spectrum signal collecting system; wherein the spectrum signal collecting system is used for spectral scan for Silybum marianum seeds to be tested, collecting diffuse reflection near-infrared signals of the Silybum marianum seeds to be tested and then transmitting the signals to the microprocessor. The invention further discloses a method for detecting the quality of Silybum marianum seeds. The invention applies the near-infrared optical detection means to the process of non-destructive testing technology for the quality of raw material of traditional Chinese medicine, therefore the method has the advantages of high detecting precision, good consistency of results and high automation degree. The time for conducting one-time detection would not exceed one minute, therefore the invention can be conveniently applied to on-site quality detection of the primary raw material of tradition Chinese medicine so as to comprehensively evaluate the quality of the Silybum marianum seeds with great efficiency.

Owner:ZHONGXING PHARM CO LTD JIANGSU

Production method of high-purity silibinin

InactiveCN103408539AReduce usageReduce pollutionOrganic chemistrySilybum Marianum SeedOrganic solvent

The invention provides a production method of high-purity silibinin. Silybum marianum seed is used as a raw material according to the method. The method comprises the steps of husking silybum marianum seeds, extracting by using an organic solvent aqueous solution, carrying out reduced-pressure concentration for recovering the solvent, diluting with water, removing precipitate, absorbing by using gel-type hydrogen bond adsorbent resin, washing for removing impurities, desorbing through a high-concentration organic solvent aqueous solution, decolorizing the desorption solution, concentrating and crystallizing the solution, recrystallizing and drying the solution to obtain a high-purity silibinin product, wherein the content of silibinin is more than 95%. The product is applicable to development of healthcare products, functional food and medicines. The method has the advantages that the product has high purity and stable quality and is free of residue of toxic and harmful solvent; the process is simple, convenient and rapid, and production cost is low; no toxic organic solvent is used in the processes; the production process is safe and environment-friendly.

Owner:天津普拉德生物科技有限公司

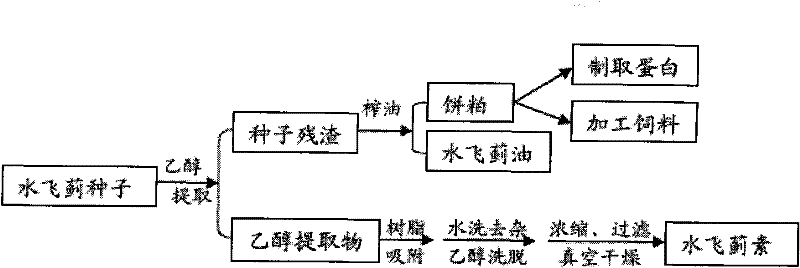

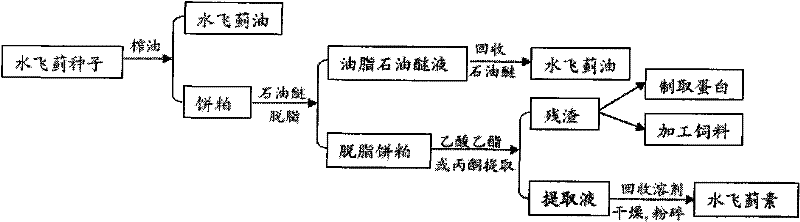

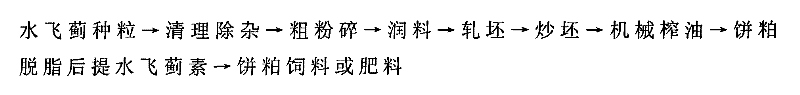

An optimized scheme for the comprehensive utilization of milk thistle

InactiveCN102293804AReduce pigmentIncrease valueFood processingProtein composition from vegetable seedsSilybum Marianum SeedOrganosolv

The invention relates to the field of application of plant products, particularly an optimized scheme for comprehensively utilizing silybum mariamum. The invention solves the problems of poor comprehensive utilization effect of silybum mariamum, complex technique, high organic solvent consumption, low production efficiency, great potential safety hazard and the like, breaks through the restriction of the existing technical field; and the scheme of oil pressing after drying seeds extracted by ethanol simplifies the technique, enhances the production efficiency, improves the product quality, and is suitable for popularization.

Owner:北京京卫燕康药物研究所有限公司

Preparation method of silymarin

ActiveCN105503843AAvoid influenceSimple manufacturing methodOrganic chemistrySilybum Marianum SeedAlcohol

The invention relates to a preparation method for extracting high-purity silymarin from silybum marianum seed husk. The preparation method comprises the following steps: separating silybum marianum seeds from seed husk, radiating by ultraviolet, carrying out the enzymolysis, extracting by absolute ethyl alcohol, volatilizing a solvent in an extracting solution, and washing solids to obtain a silymarin crude product; dissolving in absolute ethyl alcohol, obtaining supernatant, treating by adopting the reversed phase partition chromatography, carrying out the gradient elution by using water-ethyl alcohol, collecting eluate of the absolute ethyl alcohol part, concentrating the eluate, and vacuum-drying by virtue of microwaves to obtain a product. The method is simple in process, high in production efficiency and simple to operate, the product purity can reach up to 93 percent or more, and basically no solvent remains.

Owner:内蒙古昶辉生物科技股份有限公司

Method for synchronously extracting silybum marianum oil and hydrolyzed protein

InactiveCN109266432ARelease fullyHigh yieldProtein composition from vegetable seedsFatty-oils/fats refiningSocial benefitsSilybum Marianum Seed

The invention discloses a method for synchronously extracting silybum marianum oil and hydrolyzed protein and belongs to the technical field of biological processing. The method comprises the following steps: taking silybum marianum seeds as raw materials; carrying out crushing, enzymolysis and carrying out high-temperature enzyme killing; centrifuging and separating an oil-water mixture obtainedby the enzymolysis; then preparing the silybum marianum oil and hydrolyzed protein powder respectively. The method disclosed by the invention has the advantages of moderate processing conditions, lowextraction temperature, high oil yield and uneasiness of denaturing the protein; two high-quality products including the silybum marianum oil and the hydrolyzed protein can be synchronously obtained;the prepared hydrolyzed protein can be used as a nutrient enhancing agent or a material of a health-care food, and has remarkable economic and social benefits.

Owner:JIANGSU UNIV

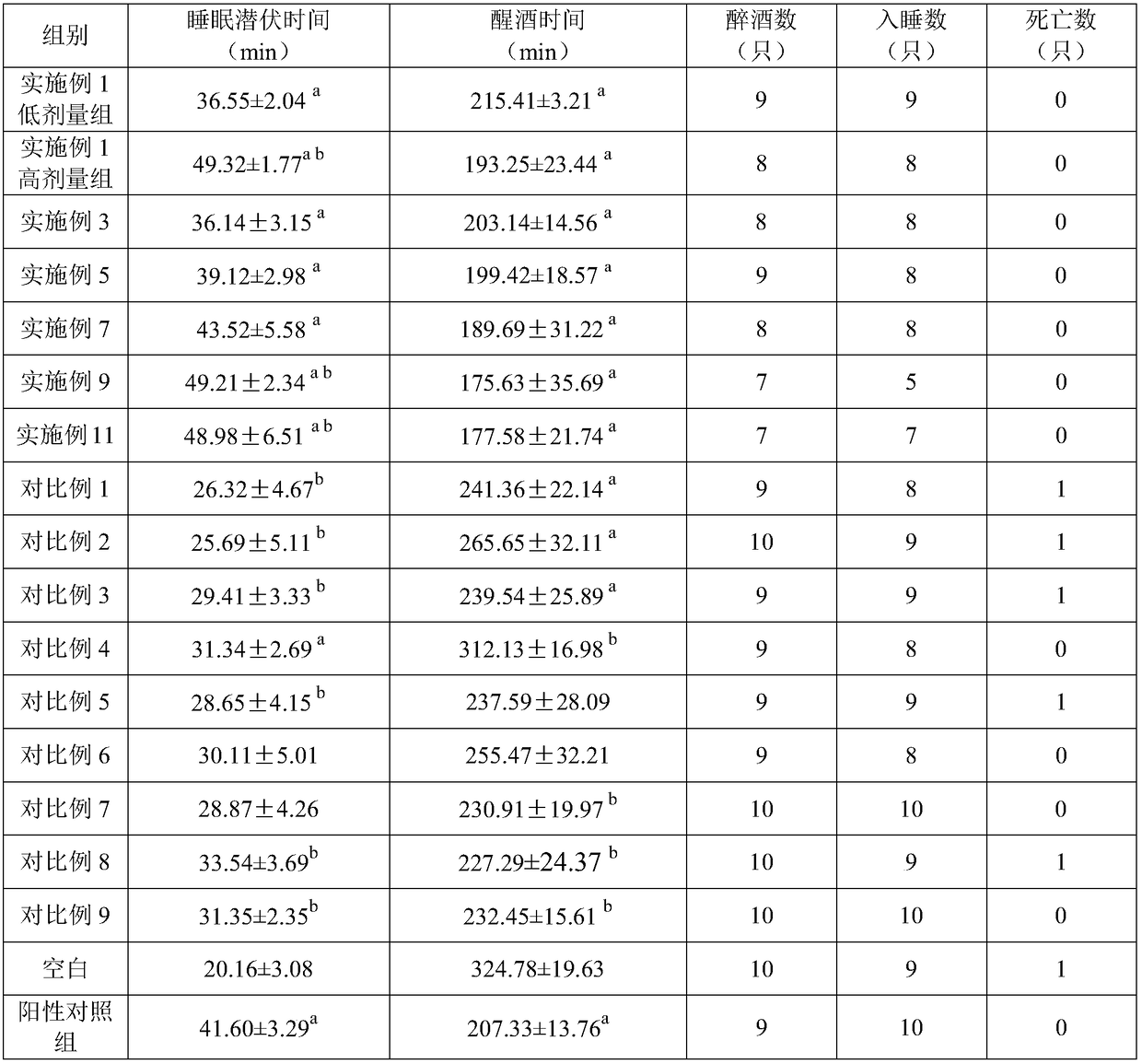

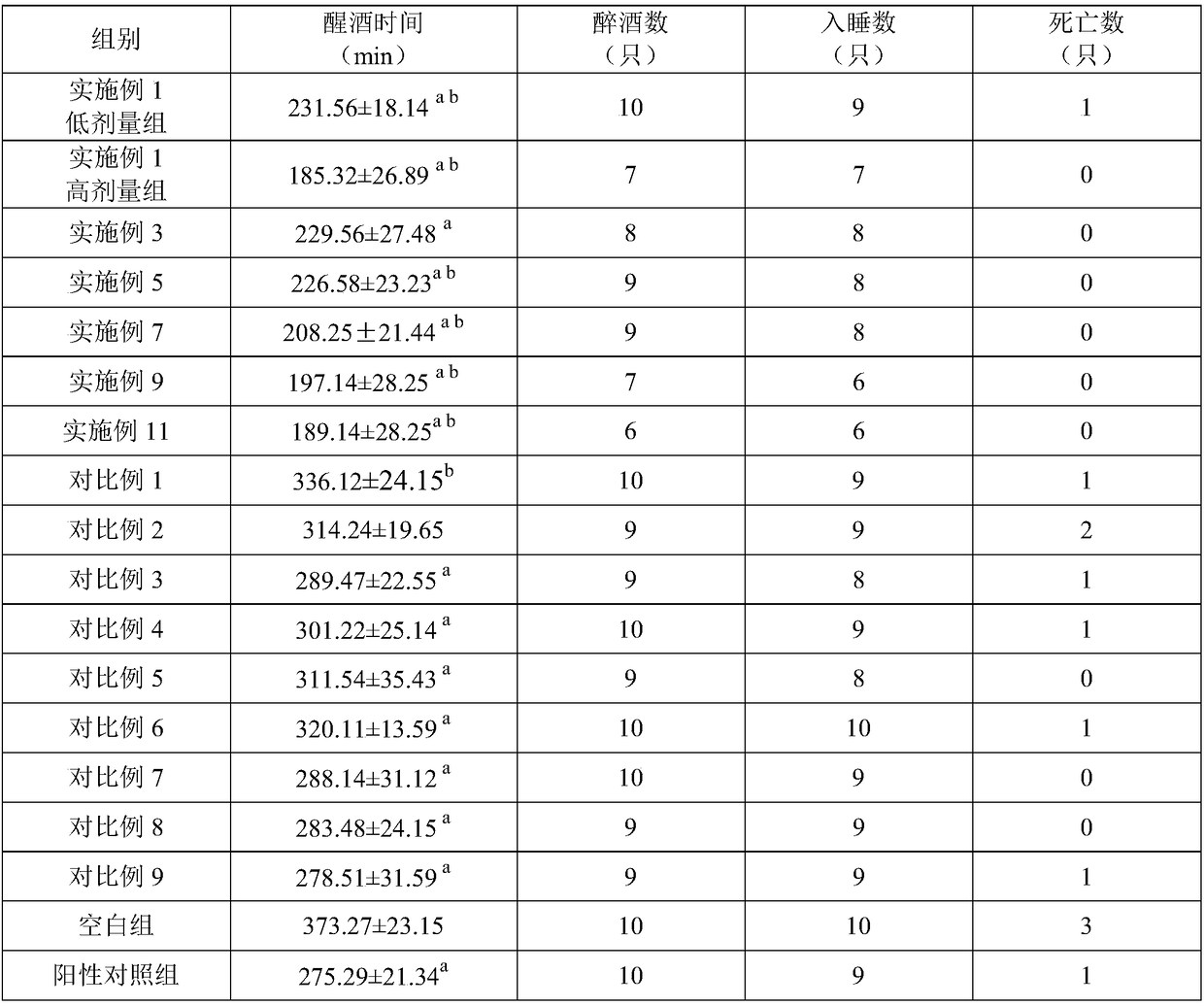

Food composition having health-care effects of protecting liver and neutralizing effect of alcoholic drinks

PendingCN109170900AImprove immunityEnhance detoxification functionLipidic food ingredientsNatural extract food ingredientsSide effectSilybum Marianum Seed

The invention belongs to the field of foods or health-care products, and particularly relates to a food composition having the health-care effects of protecting the liver and neutralizing the effect of alcoholic drinks. The components of the food composition comprise substances of silybum marianum seeds, cortex eucommiae male flowers, dandelions, hoveniae semoveniae semen, roselle, hyriopsis cumingii polysaccharide and the like. Through extraction of effective components, mixing and drying, paste is made and can be eaten. A food made from the food composition having the health-care effects ofprotecting the liver and neutralizing the effect of alcoholic drinks provided by the invention utilizes the advantage of each component, on one hand, through mutual synergistic reaction of the components, the food has the effects of neutralizing the effect of alcoholic drinks, removing toxicity and protecting the liver, and on the other hand, the immunity of bodies can be enhanced. Besides, all the components are food raw materials, so that the food composition is healthy, free from toxic and side effects, and suitable for people to take for a long time.

Owner:丽睿客信息科技(北京)有限公司

Method for extracting silybum marianum oil

ActiveCN105623839AClear oilFull of aromaFatty-oils/fats refiningFatty-oils/fats productionSilybum Marianum SeedFreeze-drying

The invention relates to a method for extracting silybum marianum oil from silybum marianum seeds. By adopting a method of immersing, freeze drying and ultrasonic extraction, the product yield is greatly increased; moreover, the content of unsaturated fatty acid in the oil product reaches more than 50 percent, the loss is basically avoided, and the yield reaches up to more than 95 percent; and moreover, the oil is clear in color, full in fragrance and very suitable for industrialized production. The product can be directly used as healthy edible oil or can be applied to a health product.

Owner:内蒙古昶辉生物科技股份有限公司

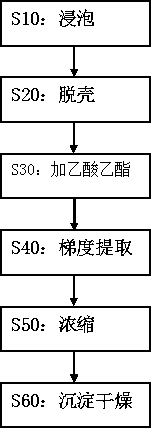

Method for extracting silymarin

InactiveCN107698572AAvoid the effects of extractionHigh extraction rateOrganic chemistryAcetic acidSilybum Marianum Seed

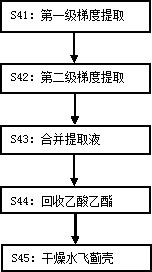

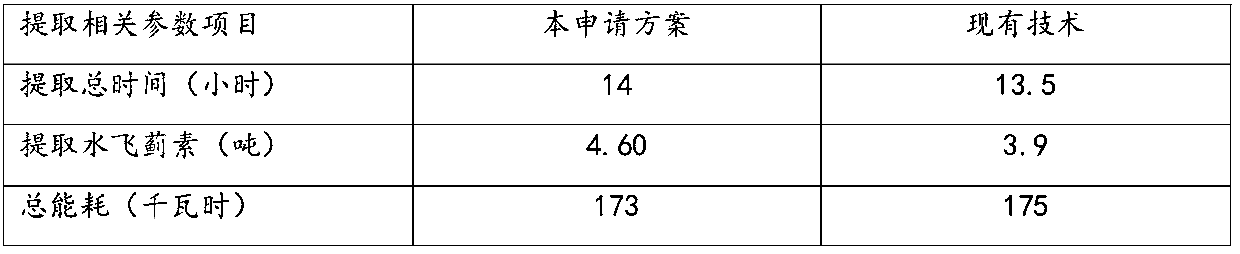

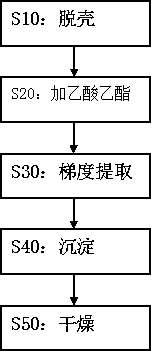

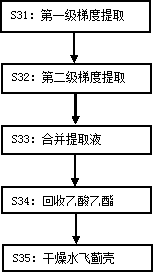

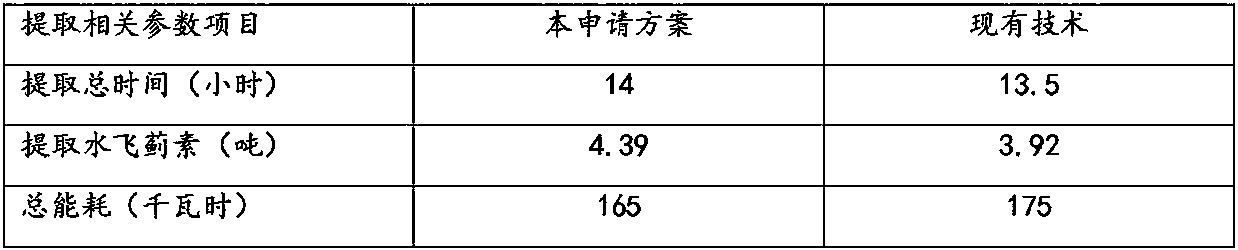

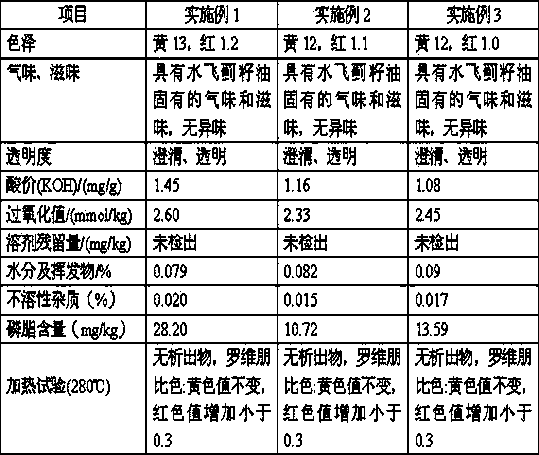

The invention relates to a method for extracting silymarin. The method is characterized by comprising the following steps: soaking silybum marianum seeds in ethyl acetate for a preset time; taking thesoaked silybum marianum seeds out from the ethyl acetate, adding the soaked silybum marianum seeds into a hulling machine, and shelling the silybum marianum seeds; putting the silybum marianum shellinto an extraction tank of tank group type gradient extraction equipment, and adding ethyl acetate and a diluent into the extraction tank; performing gradient extraction on the silybum marianum shellto obtain a primary extracting solution of silymarin; concentrating the primary extracting solution to obtain a silybum marianum concentrated solution; and adding an alkaline aqueous solution into theconcentrated solution and performing stirring, then performing standing, precipitating and drying, and performing crushing and sieving so as to obtain the silymarin. According to the scheme providedby the invention, a gradient extraction mode is used, so that the extraction rate of the silymarin is increased, and the production energy consumption and the production cost are reduced.

Owner:内蒙古昶辉生物科技股份有限公司

Silybin purification method

The invention discloses a silybin purification method. The silybin purification method comprises the following steps: taking silybum marianum seed skins, crushing the material, adding ethanol according to the solid-liquid ratio of 1 kg: 2L, and performing ultrasonic extraction for 2 h at the temperature of 40 DEG C; then transferring the material liquid into a soxhlet extractor, adding an ethyl alcohol solution of 5-7 BV, performing extraction for 4 h at the temperature of 60 DEG C, performing water-bath rotary evaporation on an extract at the temperature of 50 DEG C for 2-4 hours, then placing the material under room temperature, filtering the material, and dissolving the material by 2-4 BV methanol, placing the material at the temperature of 5-10 DEG C for crystallization for 48-72 h, refiltering the material, performing cold water washing on a filter cake, and then performing vacuum drying at the temperature of 50 DEG C for 8 hours to obtain silybin with purity being greater than or equal to 97%. The method has the advantages of simple required equipment, clear process, easy realization, and low production cost, and the prepared silybin has the advantages of good quality, high purity, and obvious economic benefit.

Owner:JIANGSU TIANSHENG PHARMA

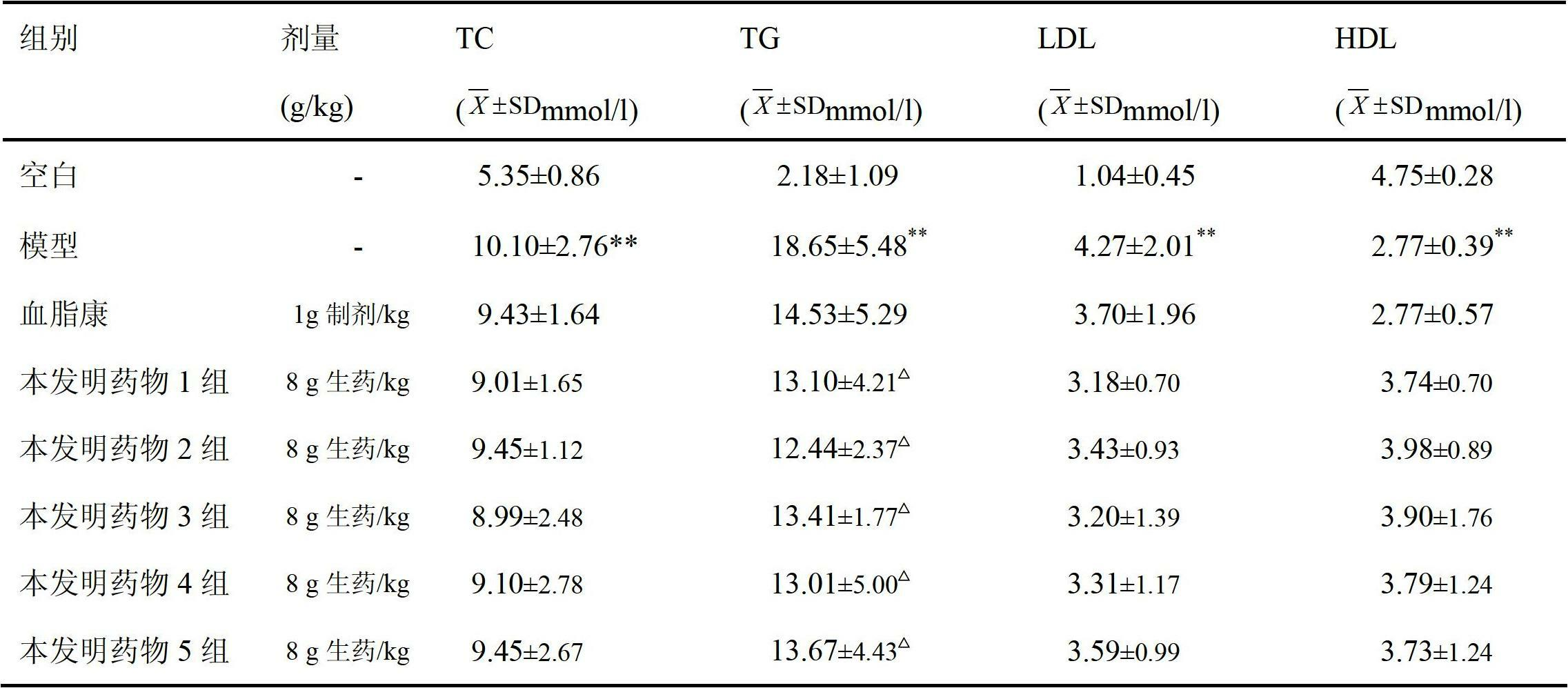

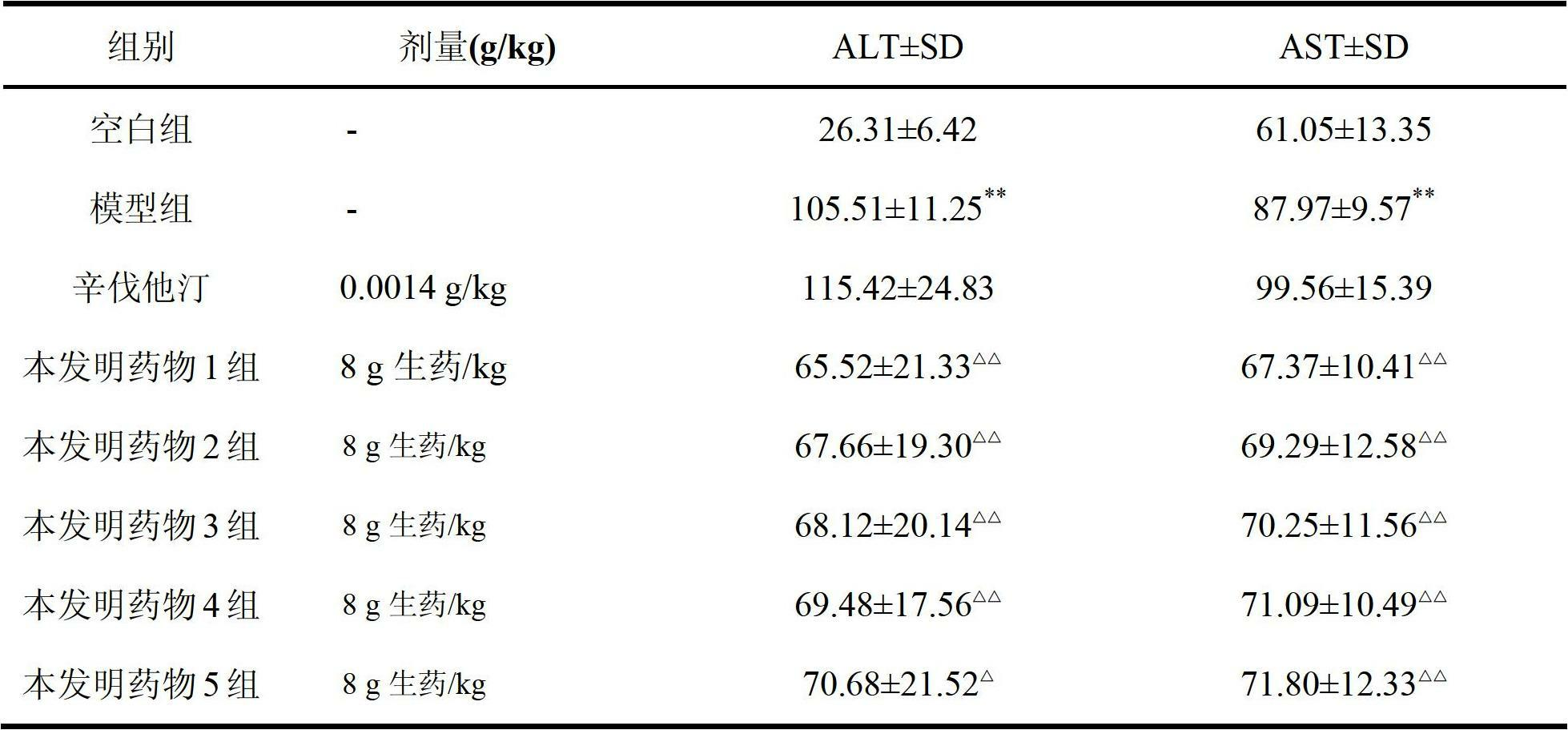

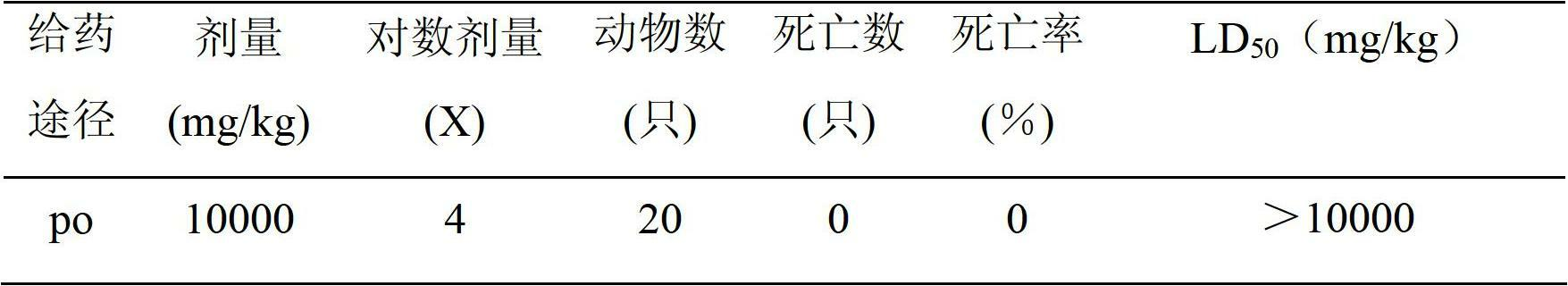

Chinese medicine composition with effect of reducing blood fat as well as preparation method and application thereof

ActiveCN102688296AQuick effectMetabolism disorderDigestive systemSilybum Marianum SeedSilybum marianum

The invention relates to a Chinese medicine composition with an effect of reducing blood fat as well as a preparation method and application thereof. The Chinese medicine composition is prepared from the following raw materials: lotus leaves, scutellaria baicalensis, uniflower swisscentaury root and silybum marianum oil at a weight ratio of (1-5):(1-5):(1-5); the ratio of the silybum marianum oil to the lotus leaves, the scutellaria baicalensis and the uniflower swisscentaury is 1:(2-4) ml / g; and the silybum marianum oil is fat extracted from silybum marianum seeds. The Chinese medicine composition with the effect of reducing blood fat has the remarkable effect of reducing the blood fat and concurrently treating liver injury, and is safe and quick in effectiveness.

Owner:石洪波

Silymarin extracting method

InactiveCN107759578ALoose cell structureEasy extractionProductsOrganic chemistrySilybum Marianum SeedSolvent

The invention discloses a silymarin extracting method. The silymarin extracting method comprises the following steps: (1) washing silybum marianum seeds to be extracted; draining off; and microwave drying until the water content is reduced to be less than 10%; (2) crushing the silybum marianum seeds; sieving through a sieve with 40-80 meshes; and expanding; (3) performing supercritical CO2 refining, namely, feeding the silymarin seeds into a supercritical CO2 device; extracting twice; and collecting extracting solution to obtain rough silymarin product; and (4) freezing and centrifuging; centrifuging the frozen rough silymarin product for 20-30 minutes through a high-speed freezing centrifuging machine; purifying; washing under the temperature of 40-50 DEG C; and drying to obtain silymarin. The method is high in yield, quick, efficient, free from any solvent residues, and free from pollutions on extracted substances; the whole process is simple, complete in separation, green and environmentally friendly.

Owner:江苏健佳药业有限公司

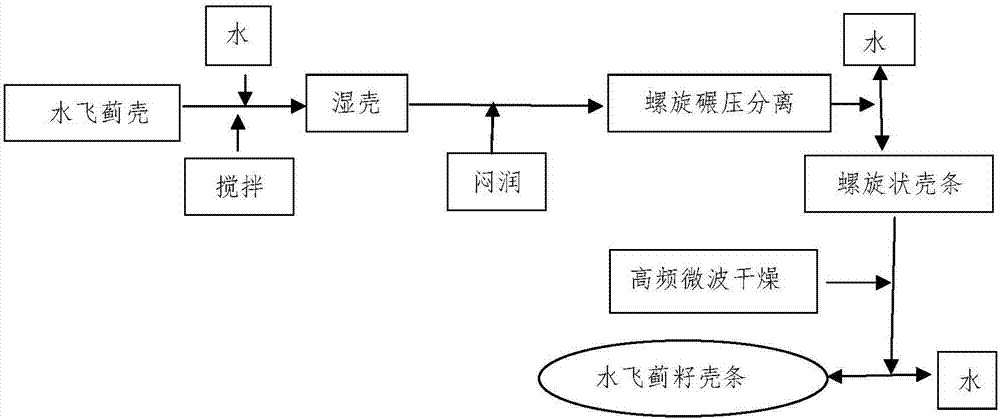

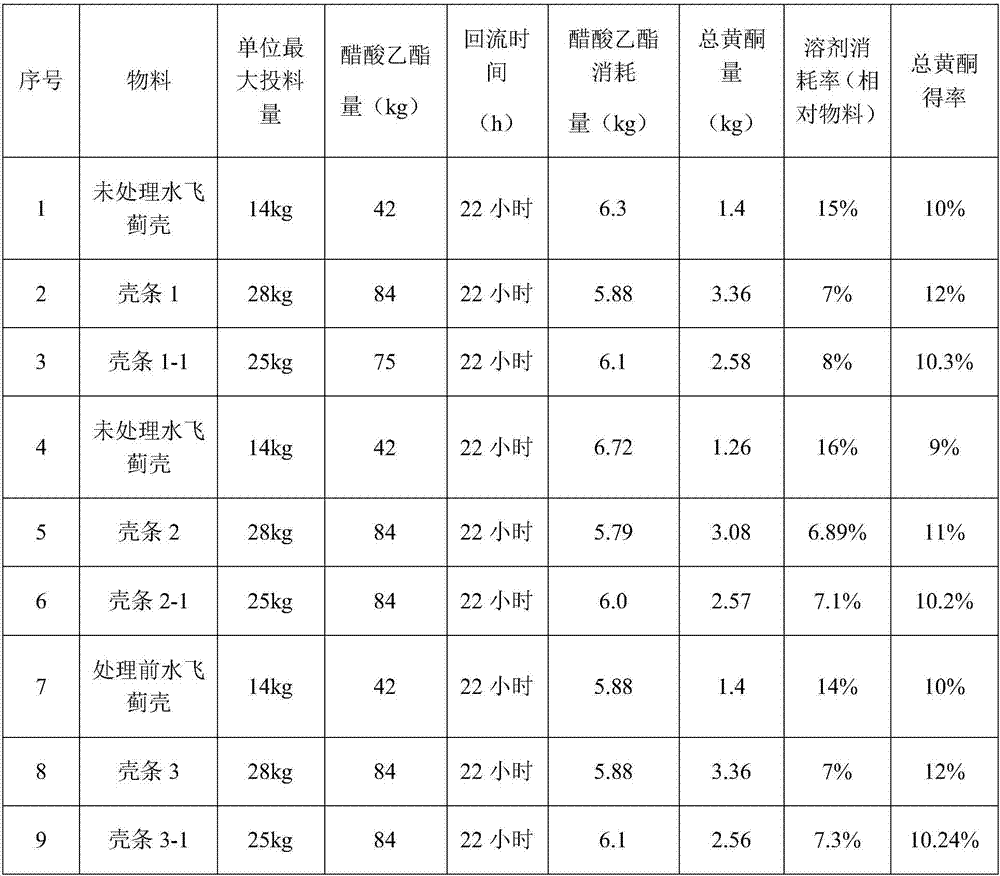

Method for improving dissolution of effective ingredients of silybum marianum shells

The invention provides a method for improving dissolution of effective ingredients of silybum marianum shells. The method comprises the following steps: adding water in silybum marianum seed shells and stirring, and then stopping stirring and moistening to enable the silybum marianum shells to fully absorb water and then to be in a softened state; enabling the moistened silybum marianum shells to pass through a spiral rolling and separating device to enable the water content in the shells to be controlled to be 5% or below so that scattered silybum marianum seed shells are changed into spiral shell strips; feeding the shell strips into a closed high-frequency microwave drying device through a conveying belt and drying for 2-3 minutes, controlling water to be 3% or below, and keeping the shell strips spiral to obtain the treated silybum marianum shell strips; and (4) carrying out solvent extraction on the treated silybum marianum shells according to the conventional method. The general flavone is extracted by the silybum marianum seed shells, the feeding amount of the treated silybum marianum seed shells treated by the same extracting equipment is two times greater than the original feeding amount, the energy consumption is halved, the relative production period is also halved, and the yield of the general flavone of the silybum marianum relative to shells is improved by about 2%.

Owner:ZHONGXING PHARM CO LTD JIANGSU

Silymarin extraction method

The invention provides a silymarin extraction method. The method comprises the following steps: 1, carrying out crude extraction: placing greaseless milk thistle seeds and an organic solvent in an extraction container, cutting and stirring the greaseless milk thistle seeds to break the greaseless milk thistle seeds and form a negative pressure in order to make a silymarin extract product rapidly ooze out of cells of the greaseless milk thistle seeds and be uniformly dispersed in the organic solvent, and filtering to obtain a silymarin crude extract filtrate; 2, concentrating the crude extract filtrate: concentrating the silymarin crude extract filtrate to obtain a silymarin total extract product; and 3, carrying out fine extraction: separating finished silymarin from the silymarin total extract product. The extraction method has the advantages of rapidness, high efficiency, normal temperature extraction, no destroy to effective components of silymarin, energy saving, consumption reduction and simplicity.

Owner:河南智晶生物科技股份有限公司

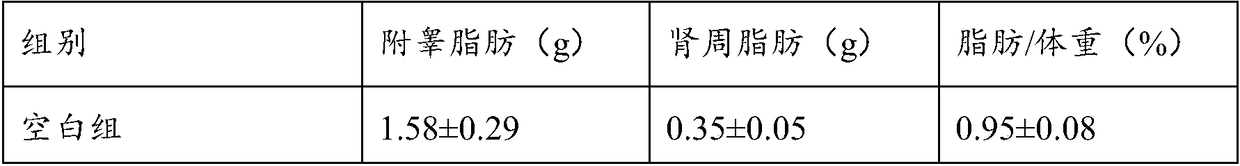

Composition for expelling phlegm and dampness, and preparation method and application thereof

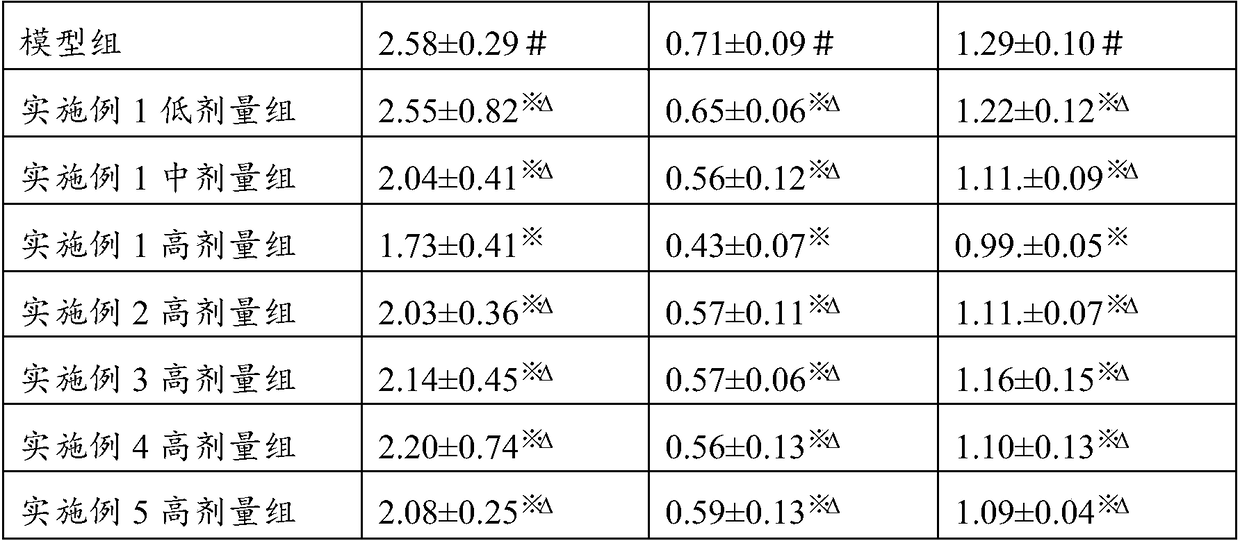

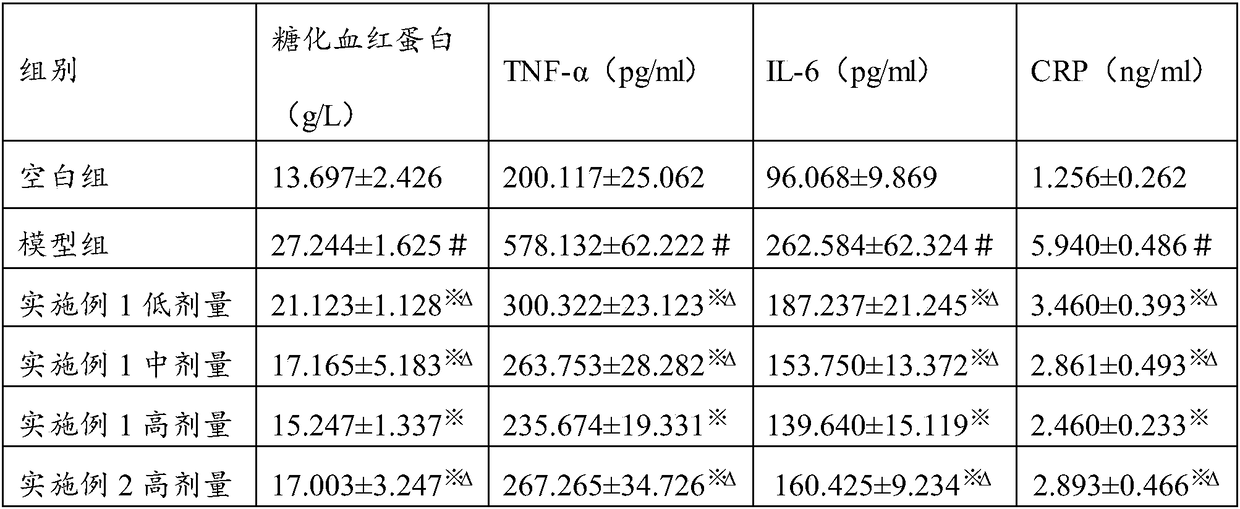

InactiveCN108926627ALose weightReduce body fat massAntipyreticMetabolism disorderSILYBUM MARIANUM SEED OILInflammatory factors

The invention relates to the technical field of health food, and discloses a composition for expelling phlegm and dampness, and a preparation method and an application thereof. The composition for expelling phlegm and dampness is composed of silybum marianum seed oil and tomato seed oil. An oil product is prepared with edible oil plant silybum marianum seeds and tomato seeds as raw materials. Thetwo components constitute the green and safe composition with effects of expelling phlegm and dampness and with simple components, and the composition is capable of reducing body weight, weight gain,in-vivo fat weight, fat / weight ratio, glycosylated hemoglobin and inflammatory factors (TNF-alpha, IL-6 and CRP), improving blood lipids (TC, TG, LDL and HDL) and the like, and can be used in relateddrugs or health food.

Owner:INFINITUS (CHINA) CO LTD

Water-soluble silymarin and preparation method thereof

InactiveCN101810660BNo residueImprove qualityOrganic active ingredientsMetabolism disorderSolubilitySilybum Marianum Seed

The invention discloses water-soluble silymarin, which is an inclusion compound that takes cyclodextrin as main molecules and silymarin as guest molecules; and the inclusion compound contains 12 to 20wt % of silybinin. The preparation method thereof comprises the following steps: silybum marianum seeds are squeezed into silybum marianum cakes; the silybum marianum cakes are added into alkali water ethanol solution and are heated to 75DEG C to 85DEG C, the constant temperature is kept for 1.5-2.5 hours, and silybum marianum extracting solution is prepared after 2-4 times of continuous extraction; the silybum marianum extracting solution is added with the cyclodextrin for inclusion, thus obtaining inclusion compound solution; flocculant is added, standing after being well stirred; after flocculate is filtered out, membrane separation process is carried out, thus obtaining water-soluble silymarin solution; and after the membrane separation process, the water-soluble silymarin solution isconcentrated and dried, thus obtaining the dried product of the water-soluble silymarin. The water-soluble silymarin prepared by the method has the advantages of high solubility, good quality, good drug stability and high bioavailability.

Owner:江苏健佳药业有限公司

Composition including superoxide dismutase and prickly-pear cactus for minimizing and preventing hangovers

InactiveUS7879374B2Minimize impactOvercome disadvantagesBiocideNervous disorderPantothenic acidTherapeutic effect

A composition including superoxide dismutase (SOD) and prickly pear cactus (OFI) protects against, minimizes the effects of, and hastens recovery from the typical symptoms associated with an alcohol induced hangover. In addition, sesamin and alpha-lipoic acid work with the SOD and OFI for enhanced antioxidant and therapeutic effects. Thiamine, niacin, vitamin B6, folate, vitamin B12, pantothenic acid, milk thistle seed extract, flower pollen extract, eleuthero root extract, guggulsterones EZ, white willow bark extract, sclareolide, ginkgo biloba extract, caffeine, and boswellia serrata extract can be added to the composition for additional treatment of symptoms.

Owner:CELLUTIONS

Ethyl acetate based gradient extraction method for silymarin

InactiveCN107663200AHigh extraction rateImprove extraction efficiencyOrganic chemistryAcetic acidSilybum Marianum Seed

The invention relates to an extraction method for silymarin. The method is characterized by comprising steps as follows: silybum marianum seeds are added to a huller for hulling; silybum marianum hulls and ethyl acetate are added to pot group type gradient extraction equipment; the silybum marianum hulls are subjected to gradient extraction, and a primary extraction solution of silybum marianum isobtained; the primary extraction solution is concentrated, and a silybum marianum concentrated solution is obtained; aqueous alkali is added to the concentrated solution, and a mixed solution is stirred and left to stand for precipitation; precipitates are filtered, a product is dried, smashed and screened, and silymarin is obtained. According to the scheme, the gradient extraction is adopted, sothat extraction rate of silymarin is increased, and production energy consumption and production cost are reduced.

Owner:内蒙古昶辉生物科技股份有限公司

Method for extracting silymarin by using ethyl acetate as extraction solvent

The invention provides a method for extracting silymarin by using ethyl acetate as an extraction solvent. The method is characterized by comprising the following steps: (1) removing fatty oil from silybum marianum seeds; (2) grinding oil-pressed cake, and putting into an extraction tank; (3) injecting a proper amount of ethyl acetate from the top end of the extraction tank; (4) putting an extracting solution which is immersed with cake powder into an evaporation tank after static immersion, and injecting a fresh solvent into the charge layer in the extraction tank from the top end of the extraction tank to dynamically balance solvents flowing in and out of the extraction tank; (5) dynamically extracting; (6) concentrating; (7) stopping concentrating until the density is 1.2g / ml, and transferring fluid extract obtained by concentration into an extract washing machine; (8) degreasing for the second time; (9) baking; (10) grinding, and screening products with different specifications for users. According to the method, the existing ethyl acetate process is improved, the operation is simplified, and raw materials of high-content liver-protecting medicines can be provided to clients, so that the method has considerable social and economic benefits.

Owner:辽宁沃德药业有限公司

Method for refining silybum marianum seed oil by enzymic-method degumming

InactiveCN102936533BLow degumming temperatureQuality improvementFatty-oils/fats refiningSILYBUM MARIANUM SEED OILPhospholipin

The invention discloses a method for refining silybum marianum seed oil by enzymic-method degumming and relates to the technical field of oil refining. The method includes the following steps: squeezing or leaching silybum marianum seeds to prepare silybum marianum seed oil, utilizing the principle that suspension impurities and oil have different densities to separate the impurities and the oil under the standing state or placing the silybum marianum seed oil into a 50 DEG C drying box for 1h, filtering to prepare crude oil, degumming the silybum marianum seed oil through phospholipase and conducting deacidification, decoloration and deodorization to obtain the refined silybum marianum seed oil. The enzymic-method degumming method adopts key technology for refining of the silybum marianum seed oil, remarkably reduces phospholipid content in the degummed silybum marianum seed oil, and is high in degumming efficiency, mild in reaction condition, low in energy consumption and easy to control. Silica gel is utilized as adsorbent to conduct decoloration and deodorization processing, high temperature vacuum decoloration and high temperature vacuum deodorization processing in the prior art are avoided, loss of effective components in the silybum marianum seed oil is reduced, and process flow is shortened.

Owner:JIANGSU UNIV

A kind of silymarin extraction method using edible grade ethanol as extraction solvent

The invention provides a method for extracting silymarin by using food-grade ethanol as an extracting solvent. The method is characterized by comprising the following steps: (1) removing fatty oil from silybum marianum seeds; (2) grinding oil-pressed cake, and putting into an extraction tank; (3) injecting a proper amount of food-grade ethanol from the top end of the extraction tank; (4) putting an extracting solution which is immersed with cake powder into an evaporation tank after static immersion, and injecting a fresh solvent into the charge layer in the extraction tank from the top end of the extraction tank to dynamically balance solvents flowing in and out of the extraction tank; (5) dynamically extracting; (6) concentrating; (7) stopping concentrating until the density is 1.2g / ml, and transferring fluid extract obtained by concentration into an extract washing machine; (8) degreasing for the second time; (9) baking; (10) grinding, and screening products with different specifications for users. According to the method, food-grade ethanol is used as an extracting agent instead of chemical raw materials in the prior art, so that obstacles in the march of silymarin forward to the field of health foods are cleared.

Owner:辽宁沃德药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com