Process for extracting water grind thisvine using alcohole as single organic dissolvent

A technology of organic solvents and silymarin, which is applied in organic chemistry and other fields, and can solve problems such as solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

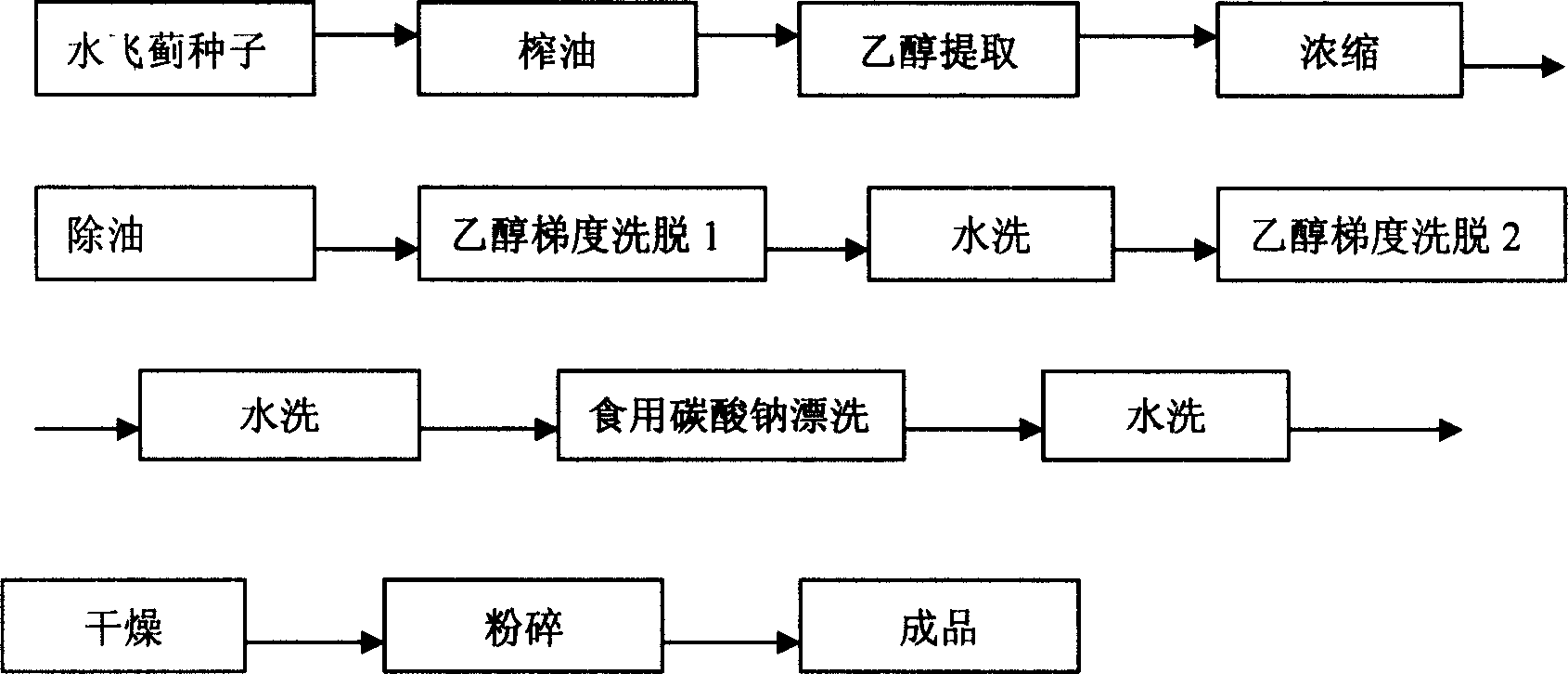

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: first squeeze milk thistle seed into the oil cake that thickness is 1.5mm, pulverize into 20 meshes and sieve, carry out reflux extraction with 85% ethanol of 4 times the amount of oil cake, extract altogether four times, then after the extract is concentrated , cooled to 30 degrees Celsius, and then separated to remove the upper part of the milk thistle oil, the lower part of the precipitated solid matter was added to 3 times the amount of deionized water, heated and stirred to 80 degrees Celsius, kept for 30 minutes, then poured out the upper layer of liquid, and the lower part of the solid Add 3 times the amount of 15% ethanol to the substance, heat and keep it under reflux for 1 hour, then pour out the upper layer of liquid, and then use water for the lower solid to do the aforementioned treatment, and then use the aforementioned ethanol treatment method. Add 0.1%-2% (mass percentage concentration) of edible sodium carbonate solution 3 times, keep at 70...

Embodiment 2

[0021] Embodiment 2: first squeeze milk thistle seed into the oil cake that thickness is 2mm, pulverize 20 meshes and sieve, carry out reflux extraction with 3 times the amount of 90% ethanol, extract altogether three times, then after the extract is concentrated, cool to 35 Celsius, then separate and remove the milk thistle oil in the upper part, add 5 times the amount of deionized water to the solid matter precipitated in the lower part, heat and stir to 85 degrees Celsius, keep for 30 minutes, then pour out the upper liquid, add 3 Double the amount of 25% ethanol, heat and keep reflux for 40 minutes, then pour out the upper layer liquid, and then use water for the lower solid matter to do the aforementioned treatment, add 0.1%-2% (mass percentage concentration) edible sodium carbonate solution in the gained solid matter 4 times, keep at 75 degrees Celsius for 40 minutes, then pour out the upper liquid, and then use water to treat the lower solids, then use the aforementioned...

Embodiment 3

[0022] Embodiment 3: first squeeze milk thistle seed into the oil cake that thickness is 2.5mm, pulverize 20 meshes and sieve, carry out reflux extraction with 4 times the amount of 95% ethanol, extract altogether four times, then after the extract is concentrated, cool to 30 degrees Celsius, then separate and remove the milk thistle oil in the upper part, add 4 times the amount of deionized water to the solid matter precipitated in the lower part, heat and stir to 90 degrees Celsius, keep for 20 minutes, then pour out the upper layer of liquid, in the lower part of the solid matter Add 2.5 times the amount of 25% ethanol, heat and maintain reflux for 30 minutes, then pour out the upper layer of liquid, and then use water for the lower solids to do the aforementioned treatment, and add 0.1%-2% (mass percentage concentration) of edible carbonic acid to the resulting solids 3 times the sodium solution, keep it at 80 degrees Celsius for 30 minutes, then pour out the upper liquid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com