Modularized smokeless firework propellant and preparation method thereof

A modular and propellant technology, which is applied in the direction of nitration explosive components, explosives, offensive equipment, etc., can solve the problem that particles are easy to adhere to the inner and outer walls of the launch tube, powder particles are easy to fly to the outside of the launch tube, and the discharge process is safe and secure. Unfavorable environmental protection and other issues, to achieve the effect of simplifying the charge process, facilitating automation and standardization, and improving the consistency of charge ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

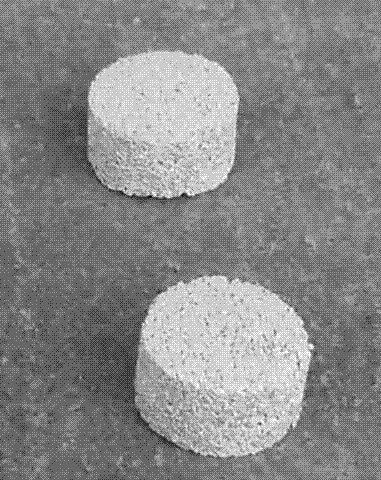

[0019] A method for preparing a modular smokeless fireworks propellant, which is to mix an organic binder with a granular micropore firework medicine, and then prepare the mixed material into a block solid by molding, and then use a drying method Drive off volatile components in bulk solids. Specifically include the following steps:

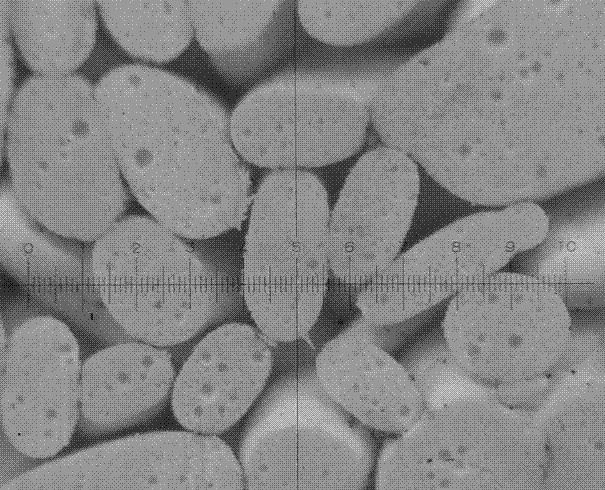

[0020] Step 1. Preparation of granular micro-pore fireworks medicine; dissolving, emulsifying and foaming the pre-prepared raw materials containing nitrocellulose, and forming into balls, followed by solvent removal, material separation, and finally drying to obtain granular micro-pores Fireworks medicine; when the material is dissolved and emulsified and foamed, an aqueous solution of an ignition performance enhancer is added; during the ball forming process, an aqueous solution containing an ignition performance enhancer and a dispersant is added as a dispersion medium; the ignition performance enhancement used in the above two processes The a...

Embodiment 1

[0034]Granular microporous fireworks were prepared from single-base waste propellant powder containing 97.0% nitrocellulose and 1.0% diphenylamine (stabilizer). The single-base waste gunpowder is preliminarily crushed, and the diameter of the particles is controlled to be no more than 3mm. The wet powder with water is added to the molding equipment, and ethyl acetate solvent 10 times the mass of the powder is added under stirring, and the temperature is 45°C-50°C Stir and dissolve under temperature for 30-60min, then continuously add the aqueous solution of 0.5% potassium nitrate (as ignition performance enhancer) to the system; Aqueous solution, the amount of potassium nitrate aqueous solution added is 6 times the mass of the drug granules, then continue to stir at a temperature of 50-60°C for 30min to 60min, and when the temperature of the system is adjusted to 65°C-68°C, add 6 times the mass of the raw drug The aqueous solution containing dispersant and 0.5% potassium nitra...

Embodiment 2

[0040] Granular micro-pore fireworks were prepared from raw materials with nitrocellulose content of 99% and diphenylamine (stabilizer) content of 0.5%. Add ethyl acetate solvent 10 times the mass of the pellets under stirring, stir and dissolve at 45°C-50°C for 30-60min, then continuously add 0.5% potassium nitrate aqueous solution to the system, potassium nitrate as ignition performance Strengthening agent: carry out emulsification and foaming operation under agitation, continue to add 0.5% potassium nitrate aqueous solution in this step, the amount of potassium nitrate aqueous solution added is 6 times of the mass of the medicine grain, and then continue at a temperature of 50-60°C Stir for 30min to 60min, when the temperature of the system is adjusted to 65°C-68°C, add an aqueous solution containing dispersant and 0.5% potassium nitrate 6 times the mass of the raw material drug into the system to disperse into balls, gelatin is used as the dispersant, and the dispersant Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com