Patents

Literature

38results about How to "Firing speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

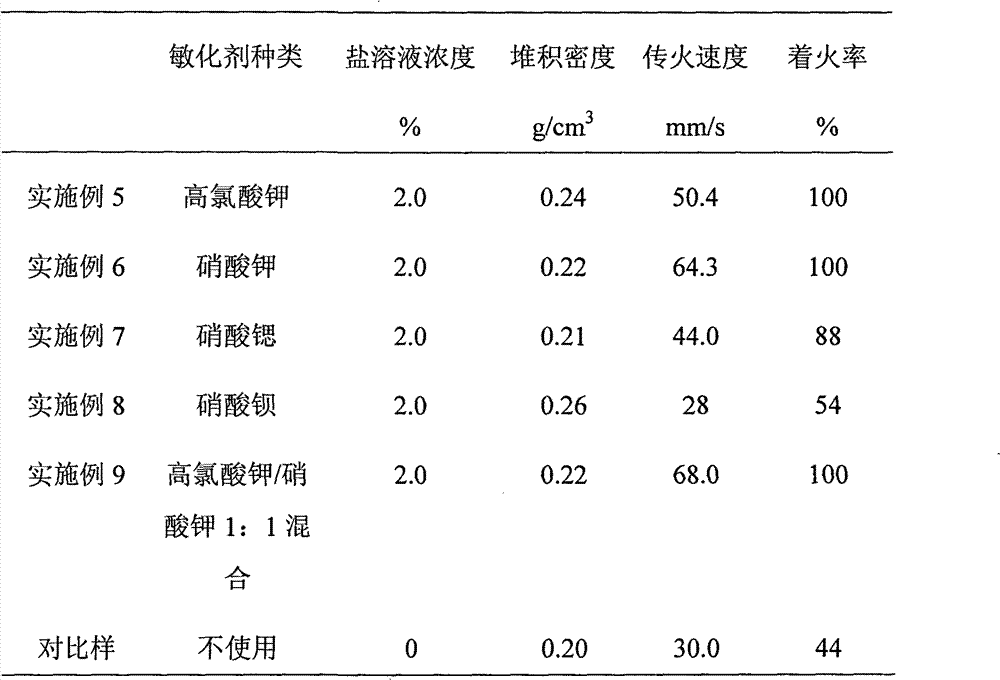

Micro-pore firework powder capable with improved fire ignition and transfer properties and preparation method thereof

ActiveCN101857516AIncreased fire speedImproved ignition capabilityNitrated explosive compositionsSolventChemistry

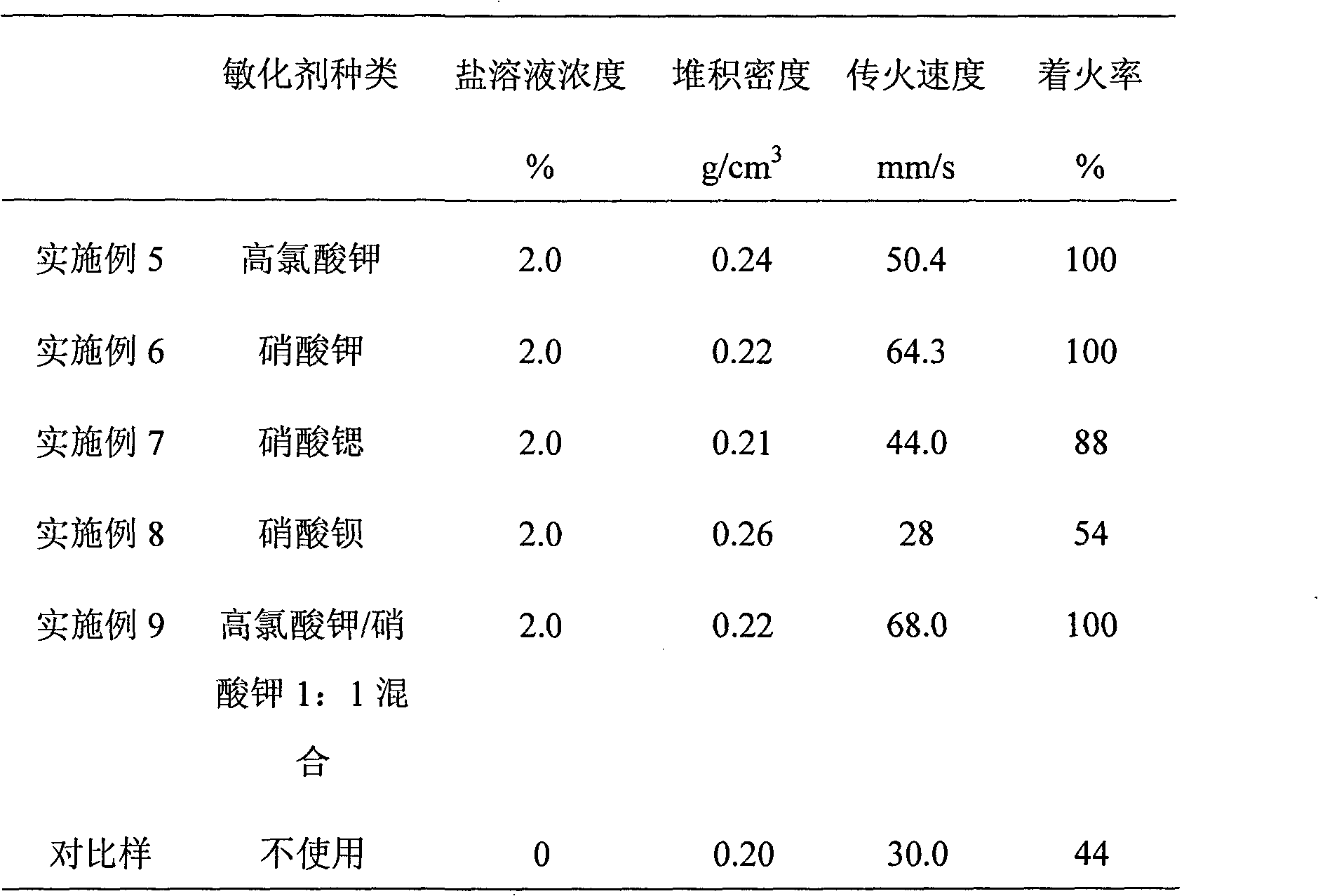

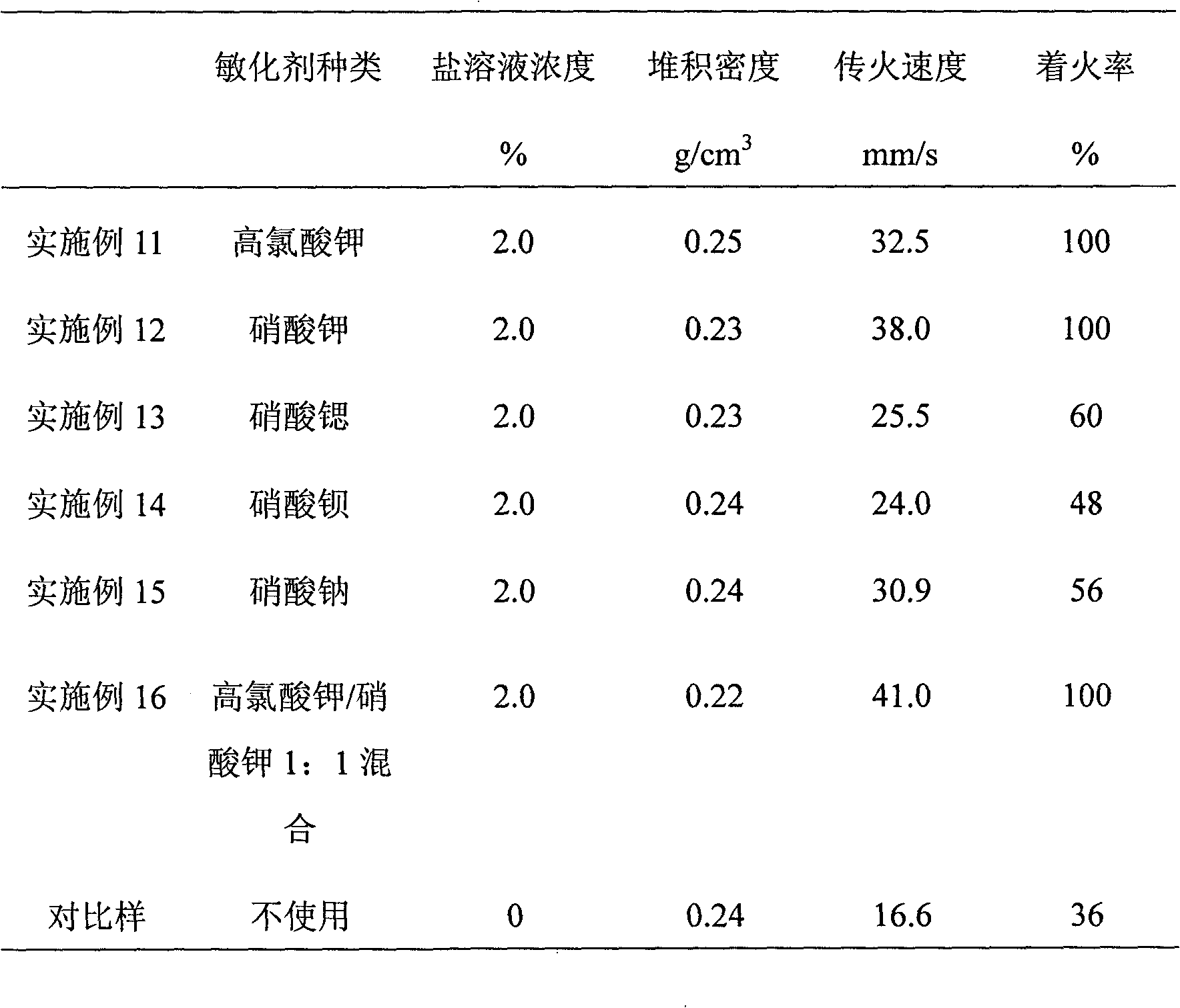

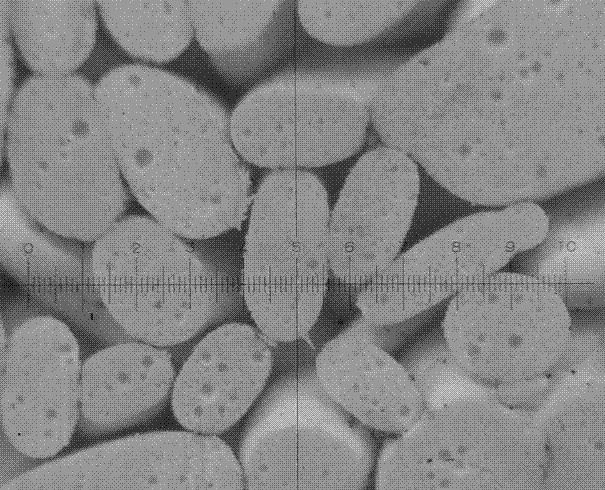

The invention discloses a method for preparing micro-pore firework powder capable with improved the fire ignition and transfer properties, which comprises the following steps of: firstly, dissolving materials, emulsifying, foaming, balling, then removing a solvent, separating the materials, and finally, drying; when the materials are dissolved, emulsified and foamed, adding a water solution of a sensitizing agent; and adding a water solution containing a sensitizing agent and a dispersing agent as a dispersion medium in the balling process, wherein the concentration of the water solutions of the sensitizing agents is the same. The used sensitizing agents can adopt the nitrate, the perchlorate or the mixture thereof of alkali metal or alkali earth metal, and the addition proportion is 0.2 to 10 percent of the mass of raw powder. The sensitizing agents are added in the forming process of the micro-pore firework powder by the form of the water solutions, an extra procedure is not added, a forming medium is recycled in the technological process, environmental pollution and material wastage can not be caused, the distribution of the sensitizing agents in an obtained sample of a finished product is more uniform, and the ignition capability and the normal-pressure fire transfer speed are both enhanced obviously.

Owner:NANJING UNIV OF SCI & TECH

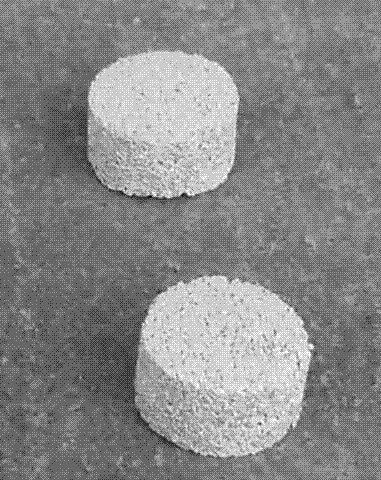

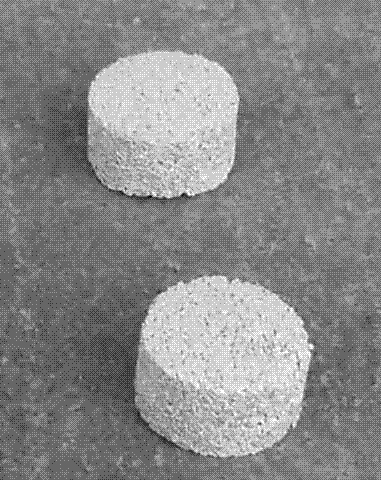

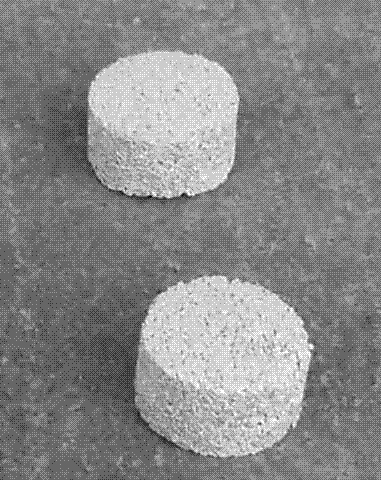

Modularized smokeless firework propellant and preparation method thereof

ActiveCN102219621ASolve residual problemsImprove securityNitrated explosive compositionsPrillFireworks

The invention discloses a modularized smokeless firework propellant which contains nitrocotton, a large quantity of tiny holes are arranged in the propellant and have block shape, and the size and shape of the holes are determined according to the caliber and shape of a firework transmitting barrel. The preparation method of the modularized smokeless firework propellant comprises the following steps: firstly mixing organic bond with granular pore firework powder, secondly preparing block-shaped solid by using the mixed materials through mould pressing, and then expelling volatilizing components in the block-shaped medicine by stoving. Compared with the granular pore firework powder, the modularized smokeless firework propellant can thoroughly solve the problem of propellant residue of granular propellant feeding, and simplifies the operation of transmitting propellant feeding, so that the stability and consistency of an end firework product are better; and in addition, the modularizedsmokeless firework propellant also avoids the mechanical friction action among granules, and improves the safety of manufacture, transmission, and storage of the firework products.

Owner:NANJING UNIV OF SCI & TECH

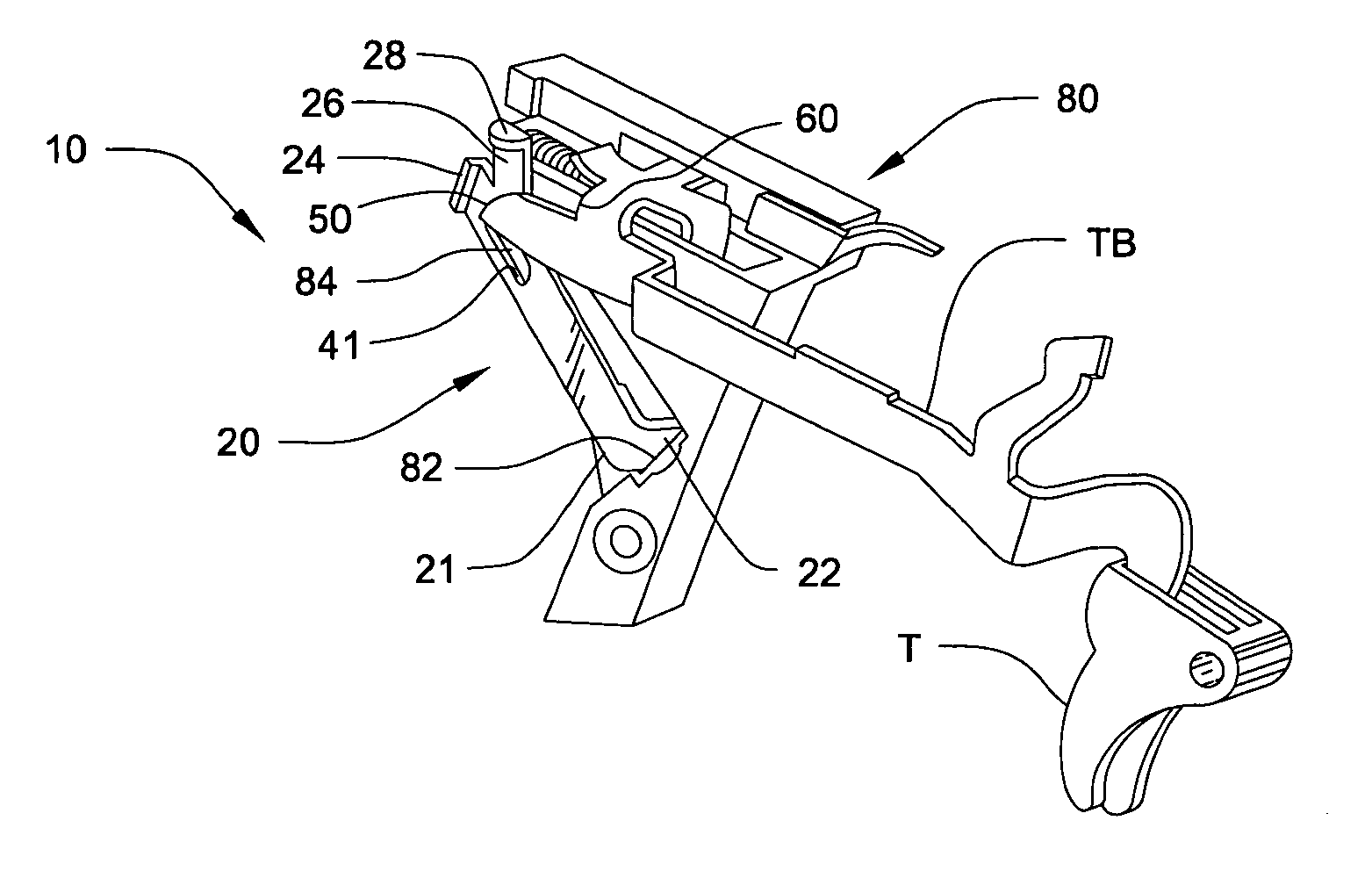

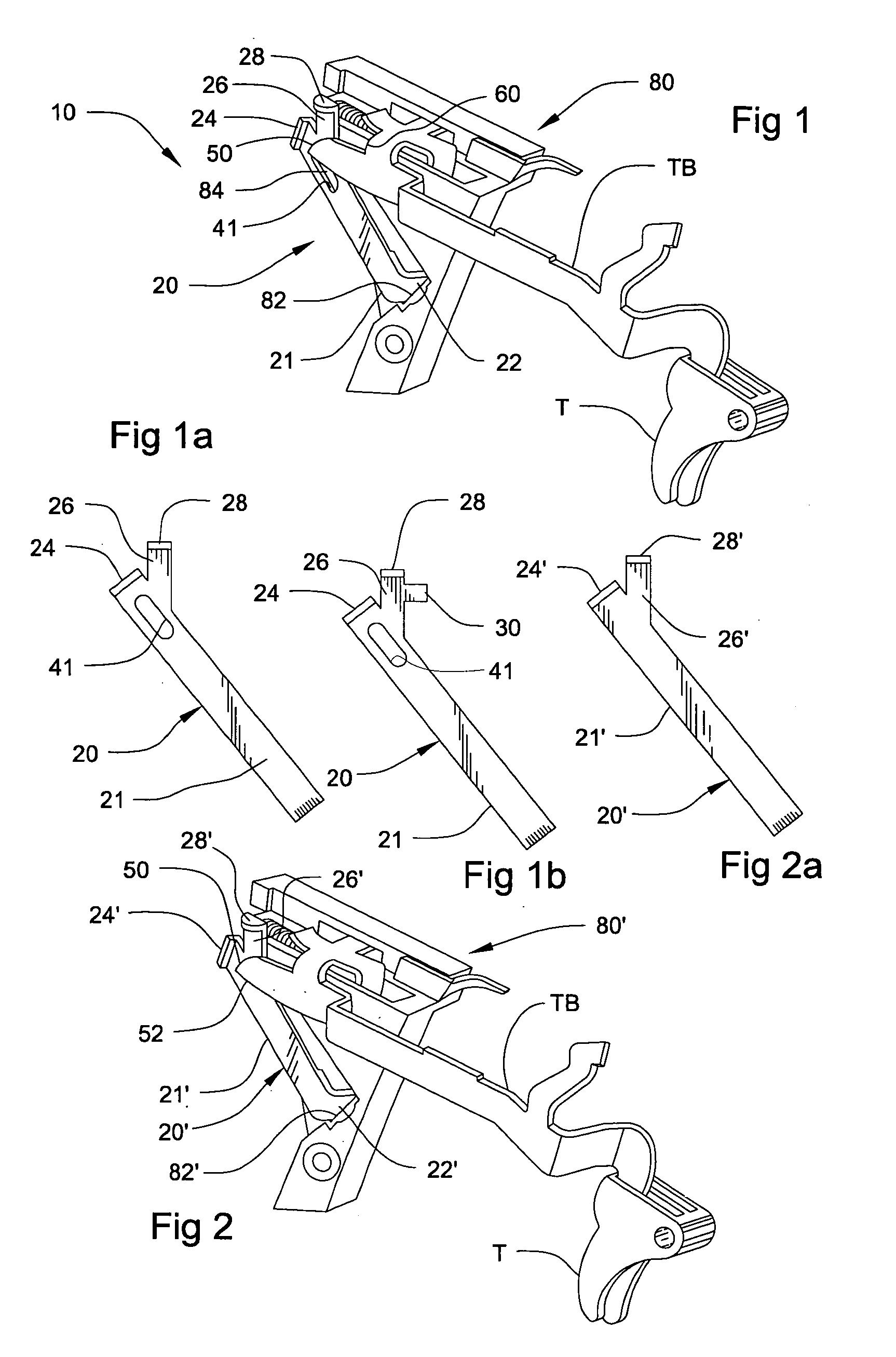

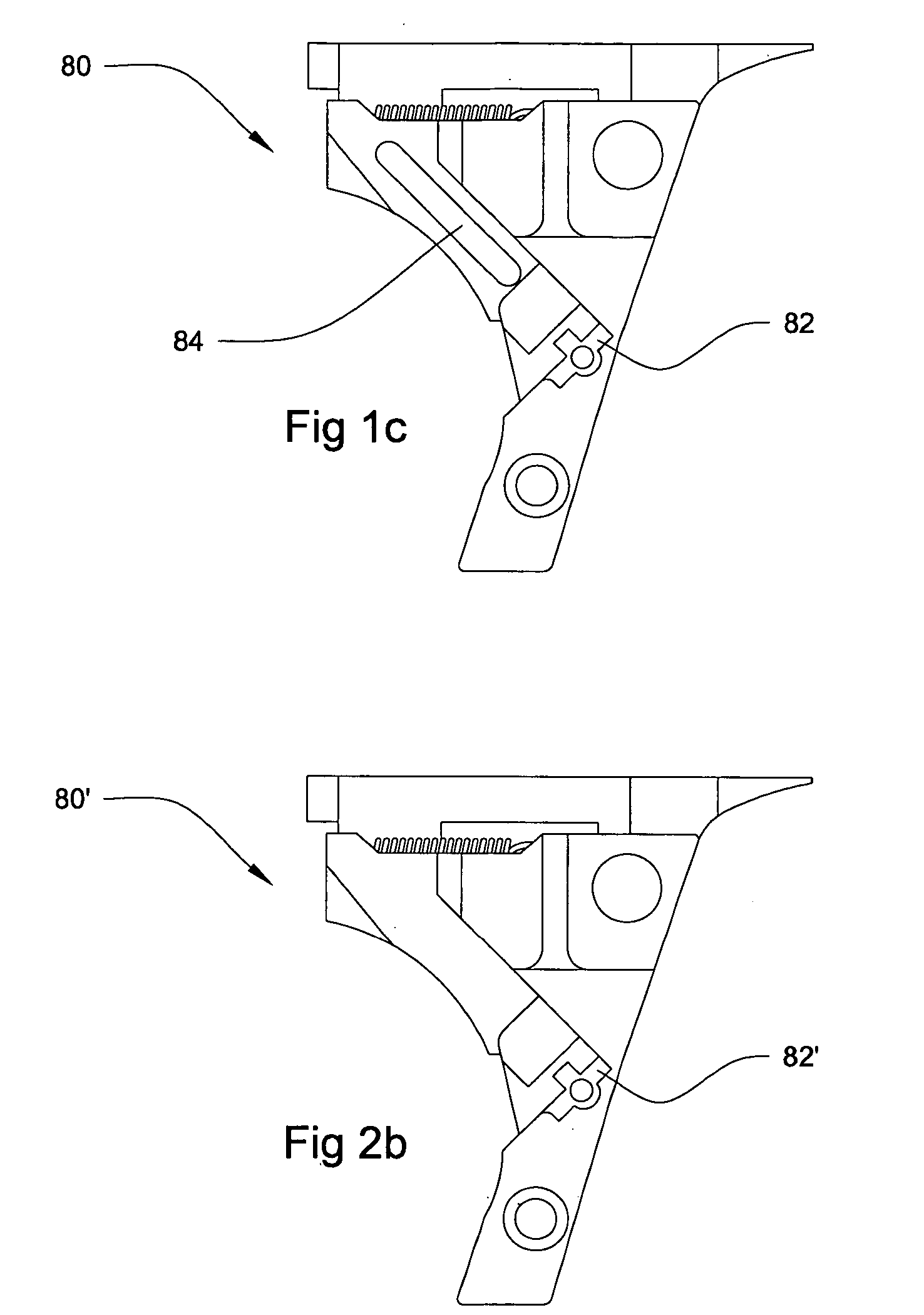

Self-cleaning trigger connector system

InactiveUS20060236581A1Convenient and accurateAvoid manipulationFiring/trigger mechanismsEngineeringLubrication

A self-cleaning trigger connector system resulting in increased reliability comprising a self-cleaning trigger connector and a trigger mechanism housing. The self-cleaning trigger connector is designed with specific contact points to prevent over-travel of the trigger bar when operating in cooperation with the trigger of the firearm. The self-cleaning trigger connector has a first at least one elongated through hole of a predetermined length that allows for a lighter trigger pull and defines a lubrication reservoir. The trigger mechanism housing comprises a second at least one elongated through hole. Debris that accumulates from the interaction between the trigger bar and the self-cleaning trigger connector passes through the first and second at least one elongated through holes. After passing through the first and second at least one elongated through holes, the debris then falls downwardly through a cavity adjacent to the firearm magazine well.

Owner:VIANI ARTHUR

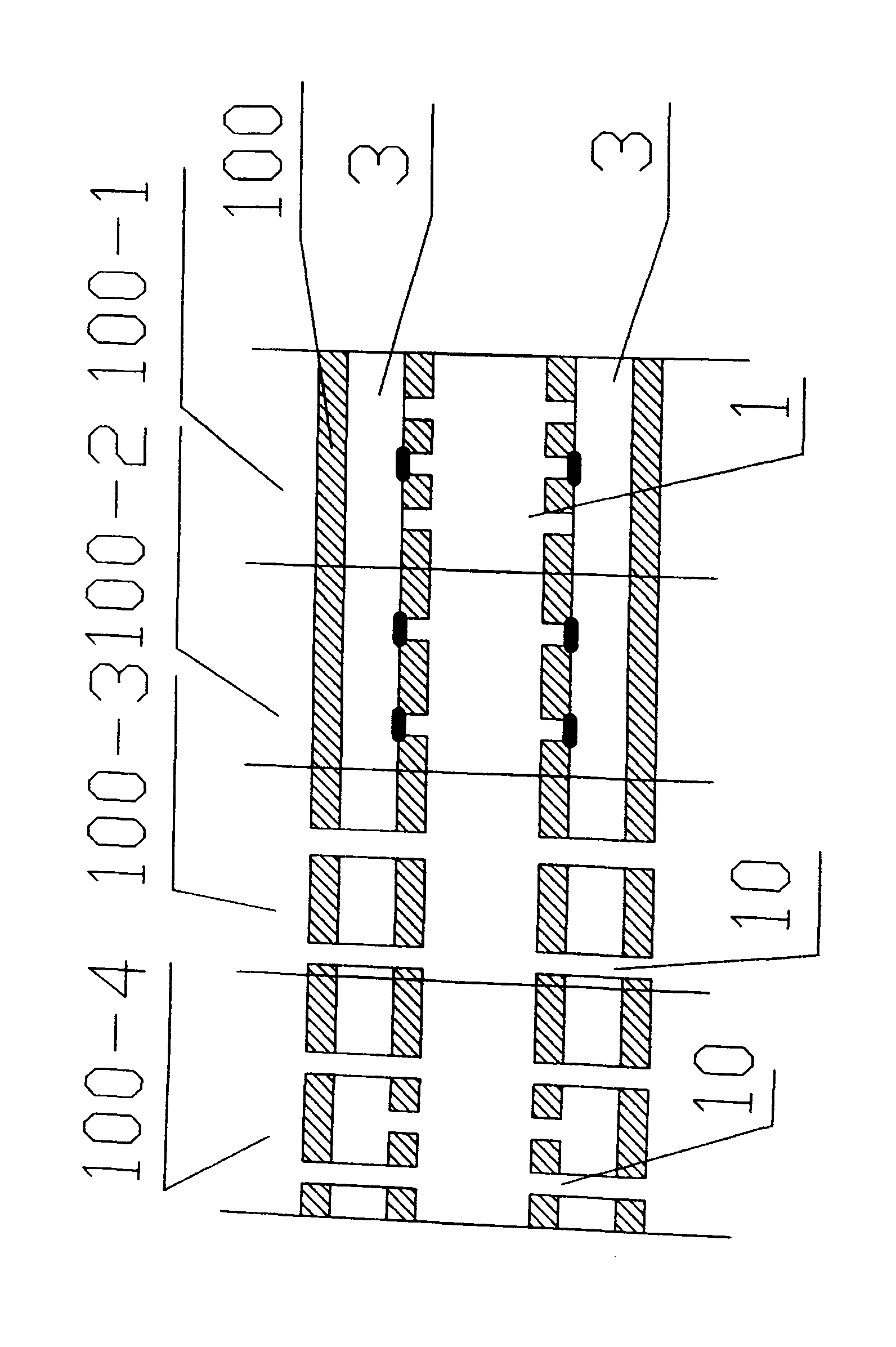

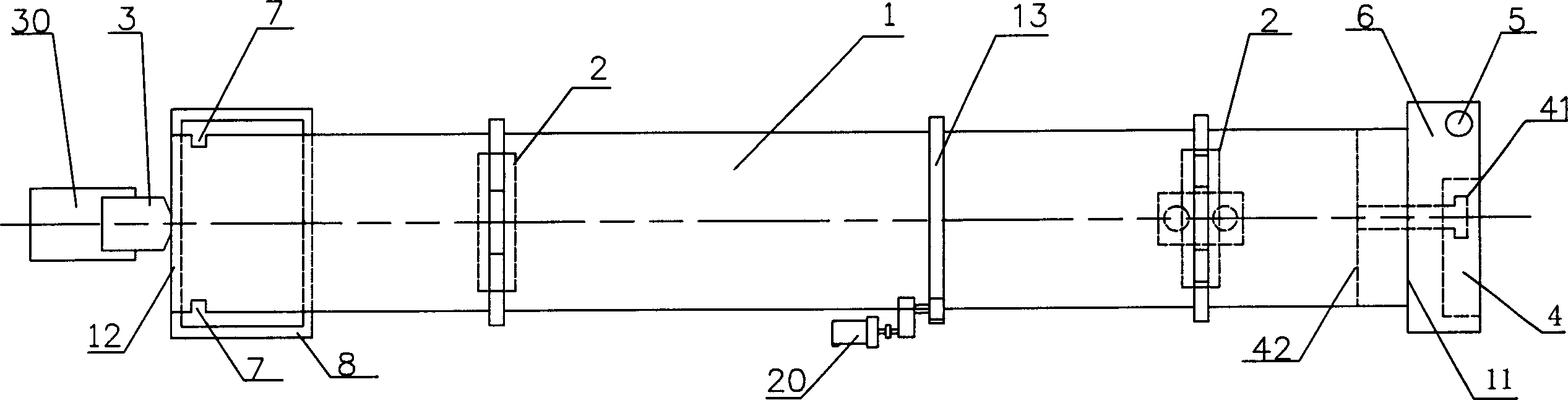

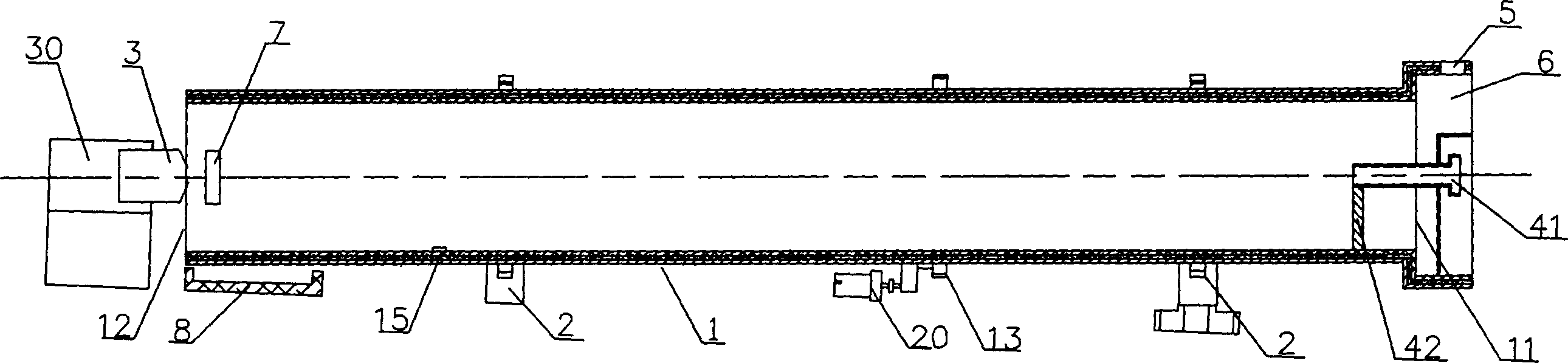

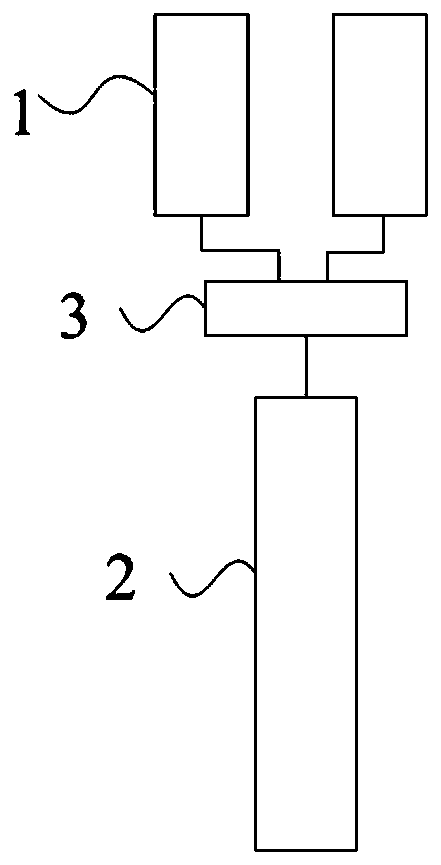

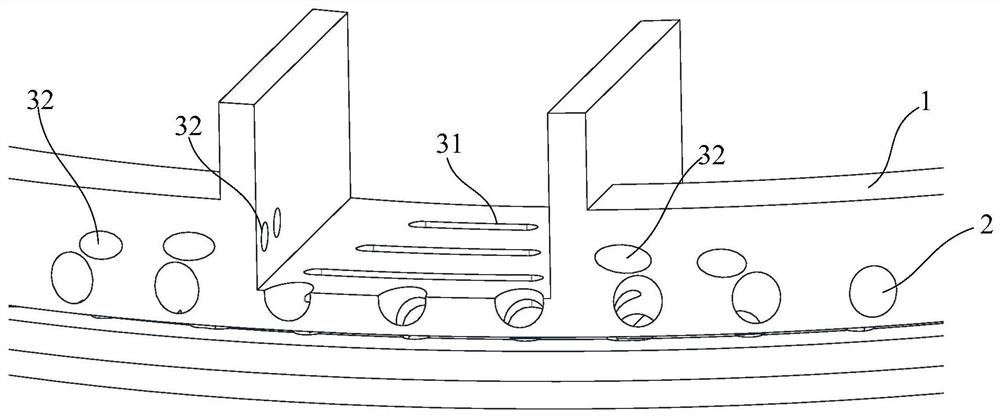

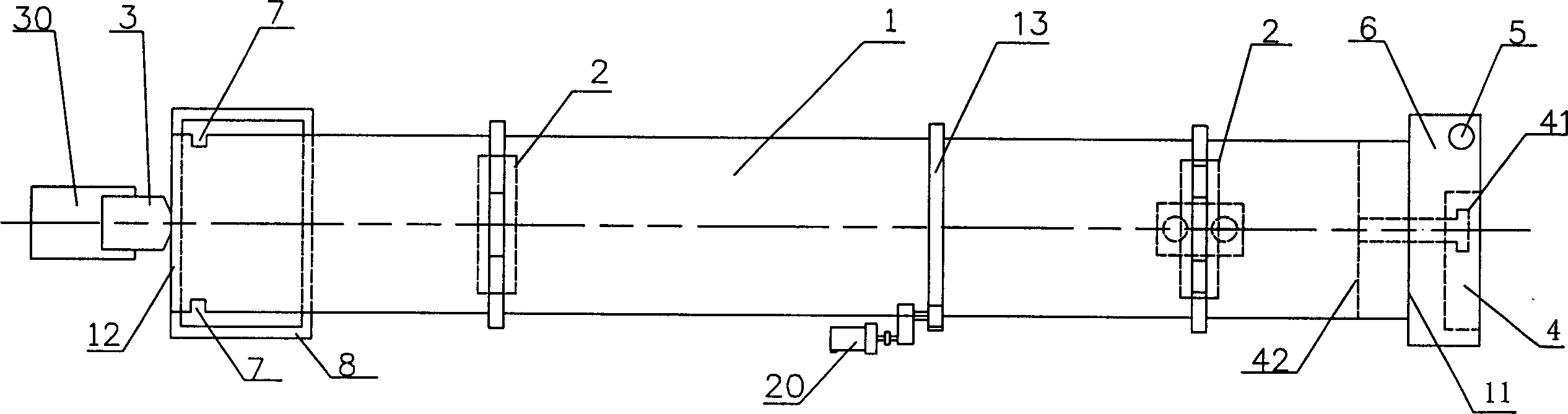

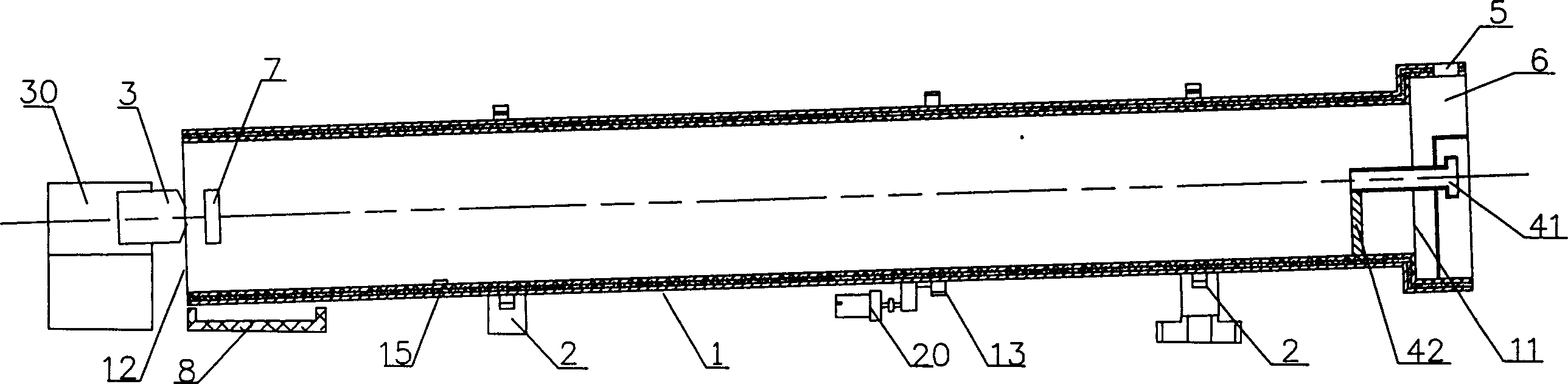

Energy-saving four-duct once-setting firing tunnel kiln

InactiveCN101782322ASimple structureReduce the temperature difference between upper and lowerFurnace typesWaste heat treatmentTunnel kilnPulp and paper industry

The invention discloses an energy-saving four-duct once-setting firing tunnel kiln, which comprises a burning kiln body and a drying kiln body, wherein the burning kiln body and the drying kiln body are provided with a kiln chamber respectively and are communicated through a heat delivery draught fan; the two sides of the kiln chamber of the burning kiln body are symmetrically provided with upper and lower duct layers respectively of which the upper duct layer serves as a residual heat duct and the lower duct layer serves as a draught duct; a plurality of air brakes are arranged in the residual heat duct and the draught duct and are communicated with the kiln chamber of the burning kiln body respectively; the two sides of the kiln chamber of the drying kiln body are also symmetrically provided with the upper and lower duct layers respectively of which the upper duct layer serves as a dehumidifying duct and the lower duct layer serves as a heat delivery duct; the dehumidifying duct is provided with a dehumidifying fan; and a plurality of air brakes are arranged in the dehumidifying duct and the heat delivery duct and are communicated with the drying kiln body respectively. The tunnel kiln can improve yield, reduce the coal consumption and power consumption, reduce the emission of carbon dioxide, ensure difficult kiln collapse when drying wet blanks and easy control in burning and improve the qualification rate of the product.

Owner:吴宏信

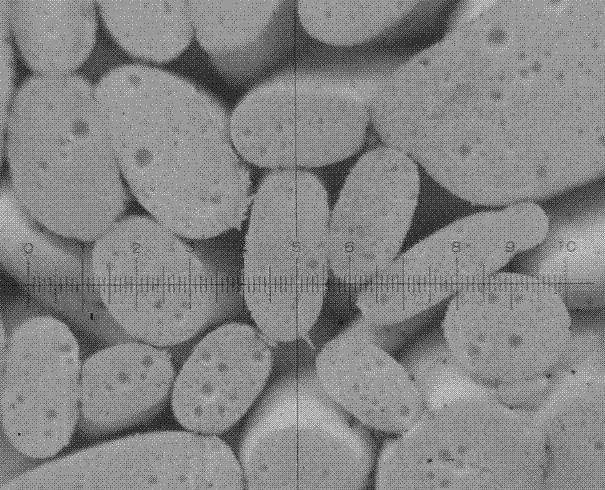

Method for sensitizing microporous smokeless firework explosive

InactiveCN101844955AFiring speed is fastImprove ignition performanceNitrocellulose explosive compositionsInorganic oxygen-halogen salt explosive compositionsNon solventCellulose

The invention discloses a method for sensitizing microporous smokeless firework explosive, which comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent to obtain explosive particles suspended in the solution and provided with micropores, separating the explosive particles suspended in the solution and provided with micropores, sensitizing the explosive particles separated from the solution of the suspended explosive particles and provided with micropores, and drying the explosive particles to obtain an explosive particle finished product, wherein the sensitizing mode is to add a sensitizing agent into the explosive particles separated from the solution of the suspended explosive particles in a form of aqueous solution or solid. The sensitizing process improves the fire transfer speed of the explosive particles and improves the ignition performance thereof, and the fire transfer speed of the explosive particles is improved by 10 to 200 percent under a normal pressure condition.

Owner:NANJING UNIV OF SCI & TECH

Jun porcelain fancy glaze and preparation method thereof

The invention discloses jun porcelain fancy glaze and a preparation technology thereof. Prepared fancy glaze porcelain has a high yield, manufacturing cost is reduced, and the prepared fancy glaze porcelain has very high artistic value and economical value. Used spodumene can react with kaolin and quartz in a firing process to form a little mullite crystal, and the mullite crystal can greatly improve the mechanical strength of jun porcelain; the spodumene is added into a formula, so that a firing speed is improved, and product crack is avoided; thus, energy consumption is reduced, a yield is about 85%, and the manufacturing cost is reduced.

Owner:杨鹏飞

Novel mixed-fuel calcination limekiln

At present, in China, the existing methods for producing quicklime by sedimentary rock calcination mainly adopt a coal-fired energy-saving machinery shaft kiln, a gas-fired energy-saving machinery shaft kiln, a coal-fired (powder-injection) rotary kiln and a gas-fired rotary kiln. The existing methods have limitation. The invention provides a novel mixed-fuel calcination limekiln. The novel mixed-fuel calcination limekiln can produce quicklime simultaneously by gas and coal calcination of sedimentary rock. The novel mixed-fuel calcination limekiln has the advantages of manufacture easiness, air distribution reasonability, combustion easiness, advantage and disadvantage complementation, and energy-saving easiness. The novel mixed-fuel calcination limekiln provides a novel and feasible scheme for energy saving, environmental protection, production cost reduction and product quality improvement of sedimentary rock calcination-based production of quicklime at home and abroad.

Owner:刘丽颖 +1

Microcrystal glass combined plate material and its production technology

A microcrystal glass compounded vitrified plate is composed of surfacial layer (microcrystal glass) and bottom layer (vitrified tile), and is prepared through preparing raw materials, die pressing, smelting, vitrifying, cutting edge, coarse grinding, further grinding, fine grinding, coarse polishing, fine polishing, chamfer, drying and classifying. Said vitrified tiles are prepared from clay, quartz, feldspar sand, and talc. Said microcrystal glass is prepared from quartz, feldspar and calcite. Its advantages include high adhesion, high strength and lustre, moderate cost, and high antiwear and anticorrosion performance.

Owner:东莞市唯美陶瓷有限公司

Jun porcelain celeste blue glaze and preparation method thereof

The invention discloses a jun porcelain celeste blue glaze which is prepared from the following raw materials in parts by weight: 32-40 parts of melilite, 14-18 parts of quartz, 10-14 parts of calcite, 10-14 parts of herb drug, 4-6 parts of spodumene, 3-5 parts of talc, 0.5-1.5 parts of ferric oxide, 4-6 parts of copper ore, 0.5-1.5 parts of tin oxide and 6-10 parts of wood ash. A preparation method for the jun porcelain celeste blue glaze comprises the following steps: (1) crushing the raw materials, mixing and putting into a ball mill for milling, adding water till the mass concentration ofthe glaze reaches up to 56-58%, wetly milling for 6-8 hours and using a 200-300 mesh sieve for sieving the wetly milled slurry, thereby acquiring glaze slip; (2) soaking the blank into the glaze slipfor 1-2 times; (3) sintering under the sintering temperature of 1260-1290 DEG C.

Owner:禹州市锦丰源瓷业有限公司

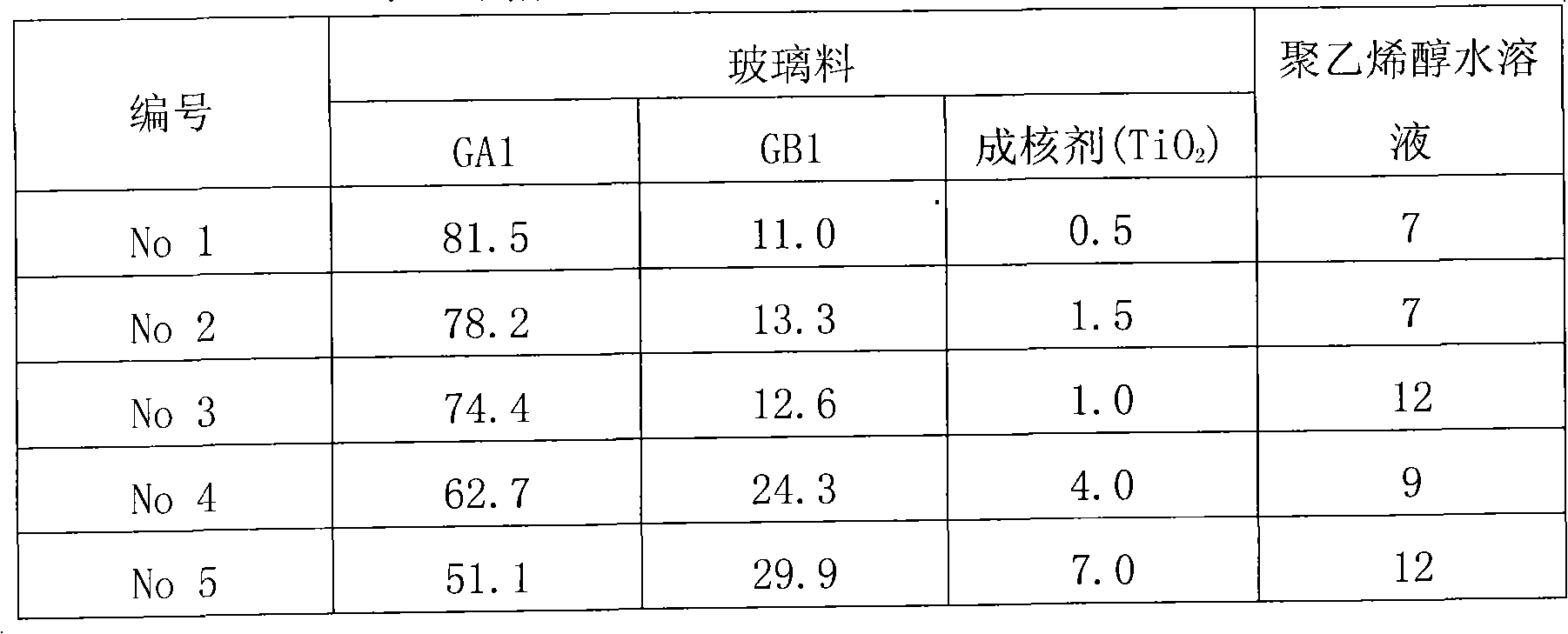

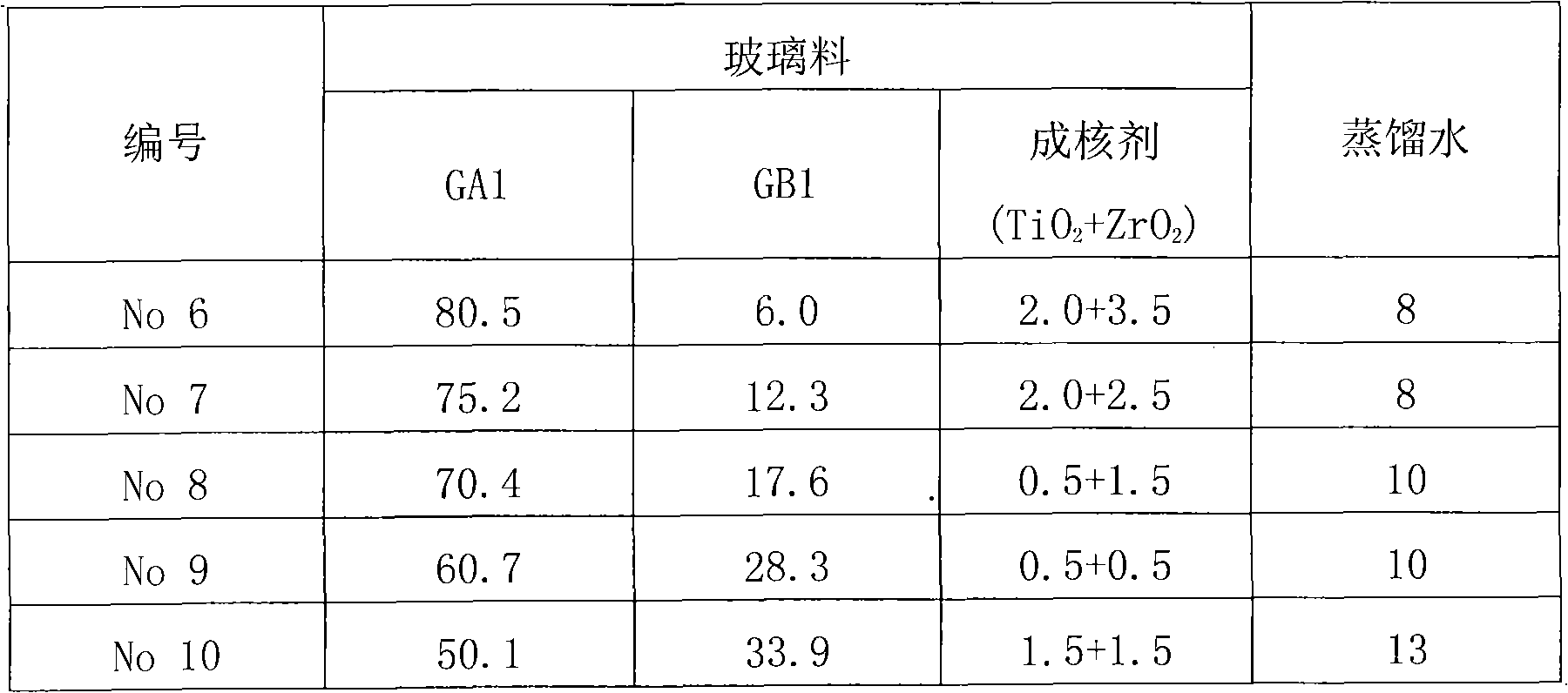

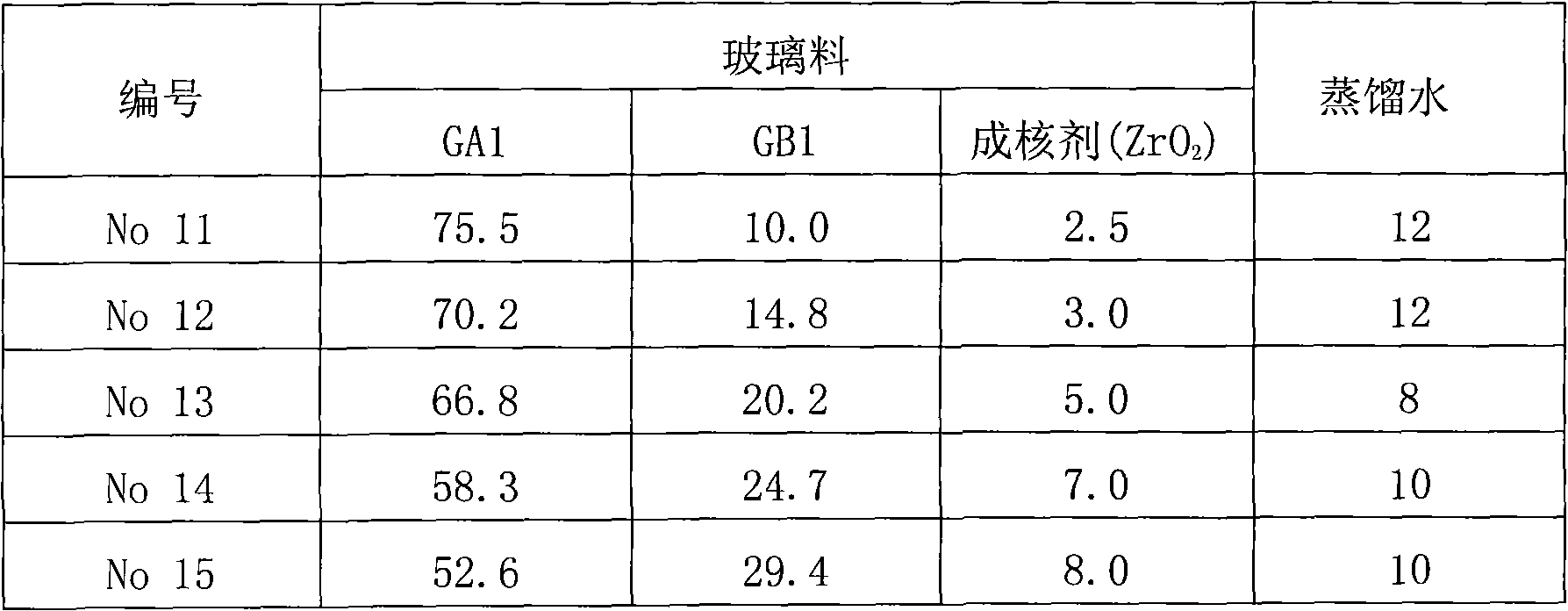

Low-temperature rapid sintered high-frequency low-consumption glass ceramic and preparation thereof

The invention relates to a high frequency low-loss glass ceramic that is sinterd rapidly under low temperature and a production method thereof. The glass ceramic is sintered by silicon, boron, borosilicate glass, and nucleating agent and agglomerant. The ingredients provided by the invention can realize the low-temperature smelting of the calcium, silicon, boron and borosilicate glass, the glass materials can be sintered at about 680 DEG C and the sintered body has excellent dielectric property (Epsilon[r] is 6-8 and the tanDelta is less than 0.000525 MHz).

Owner:NANJING UNIV OF TECH

Formula for low temperature sintering of 95% resistor ceramic substrate

The invention provides a preparation method for a 95% resistor ceramic substrate raw material capable of being rapidly sintered at a low temperature of 1250 DEG C. The raw material is prepared from 94 to 96 wt% of a-alumina (Al2O3), 2 to 3 wt% of barium pyroborate (BaO.2B2O3), 1.5 to 3 wt% of manganese oxide (MnO2), 1 to 1.5 wt% of magnesium carbonate (MgCO3) and 0.5 to 1.5 wt% of titanium oxide (TiO2). The raw material provided by the invention has the characteristics of a low sintering temperature, a fast sintering speed and obvious energy saving and emission reduction effects, has thermal conductivity of 21 to 25 W / m.K and density of 3.75 g / cm<3>, has the advantages of high dielectric strength and high breaking strength, totally satisfies requirements of performance of a subminiaturized resistor and is mainly used for production of electronic ceramic products like a subminiaturized 95% resistor ceramic substrate, a 95% semiconductor integrated circuit package shading ceramic substrate and an electronic Nixie tube alumina ceramic plate.

Owner:DONGGUAN CITY GRT ELECTRONICS MATERIAL

Trigger linkage mechanism for use in toy gun

ActiveUS9250033B1Firing speed is fastImprove user experienceFiring/trigger mechanismsAmmunition loadingRadianEngineering

A trigger linkage mechanism for use in toy gun includes: a trigger pivoted to a gun frame and formed with a push block; a linkage member having one end formed with a first pivotal part and the other end formed with a second pivotal part. The linkage member is formed with an abutting part disposed between the two pivotal parts and abutted against the push block; a pull member pivoted to the second pivotal part and formed with a pawl part capable of being correspondingly buckled with the buckle part; a first recovery spring clamped between the gun frame and the linkage member; and a second recovery spring clamped between the linkage member and the pull member. Accordingly, the rotation radian and speed of the pawl part is able to be controlled and adjusted.

Owner:WEI HO SHENG

Green glaze for wood-fired porcelains

The invention relates to green glaze for wood-fired porcelains. The green glaze is prepared by the following components in parts by weight: 21.26 parts of quartz, 33.11 parts of feldspar, 12.35 parts of calcite, 20.85 parts of graphite, 3.58 parts of phosphorus bone powder, 3.60 parts of agate, 2.25 parts of water bone stone and 3.00 parts of black golden earth, wherein the quartz is quartz sand, the feldspar is one or combination of sodium feldspar and potassium feldspar, the content of ferric oxide in the black golden earth is 30%-35%, and the content of manganese oxide in the black golden earth is 8%-10%. A preparation method of the green glaze for the wood-fired porcelains comprises the following steps: (a) carrying out batching according to all the components and the mass proportion thereof; (b) mixing all the components uniformly, adding 20-22 parts of water, carrying out wet-process ball grinding for 16-20 hours, filtering the ball-ground glaze by a sieve of 250 meshes, mixing into glaze slip with baume degrees of 60-65, then spraying the glaze slip onto incense ash base, rising temperature from normal temperature to 1180-1250 DEG C, cooling, drawing out of a kiln and standing for about 15 hours. The green glaze has the advantages of fast firing at a medium temperature, lower cost, uniform and clean glaze layer, good glossiness and strong decorative conception.

Owner:马聚魁

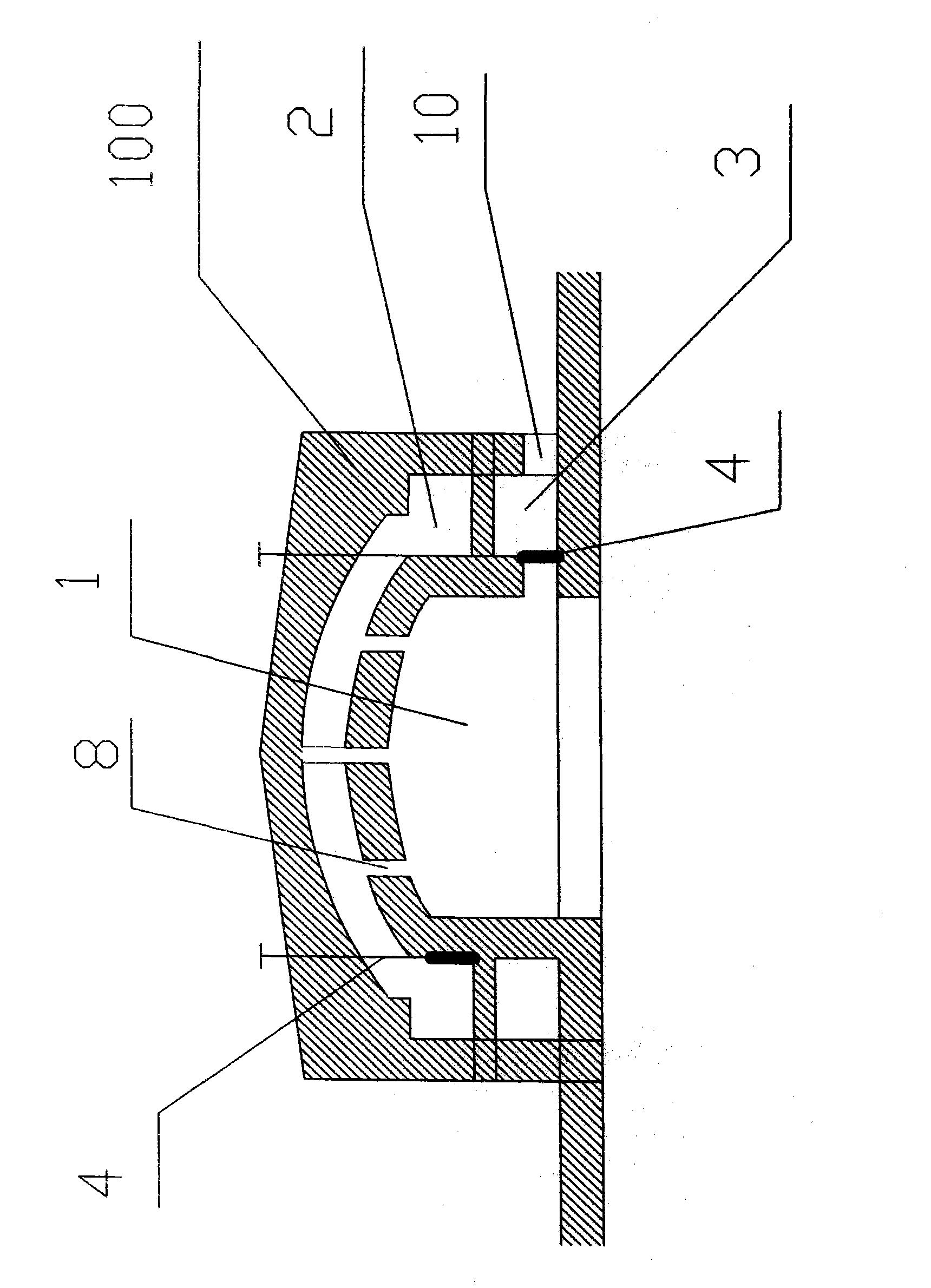

Modularized smokeless firework propellant and preparation method thereof

ActiveCN102219621BSolve residual problemsSimplify the charging processNitrated explosive compositionsNitrocelluloseFireworks

The invention discloses a modularized smokeless fireworks propellant, which contains nitrocellulose, has a large number of tiny pores inside, and has a block shape. The size and shape of the propellant are determined according to the caliber and shape of the firework launching tube. The preparation method of this modular smokeless fireworks propellant is firstly to mix the organic binder and the granular micro-pore fireworks, and then the mixed material is prepared into a block solid by molding, and then dried Methods to drive out the volatile components in the block medicine. Compared with the granular micro-pore fireworks powder, this modular smokeless firework propellant completely solves the problem of the launch residue of the granular charge, simplifies the operation of the propellant charge, and makes the finished product more stable and consistent. , In addition, the mechanical friction between particles is avoided, and the safety of the manufacture, transportation and storage of fireworks products is improved.

Owner:NANJING UNIV OF SCI & TECH

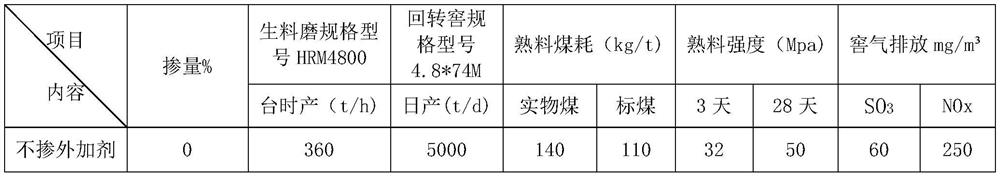

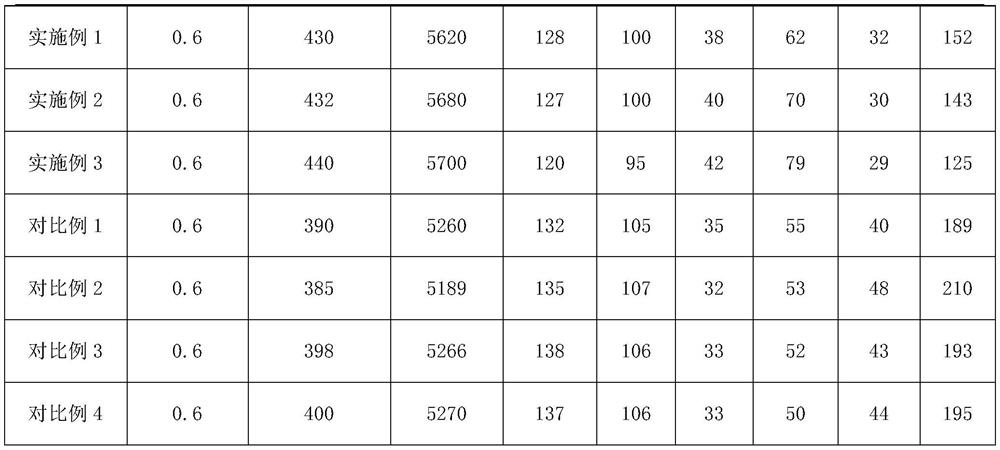

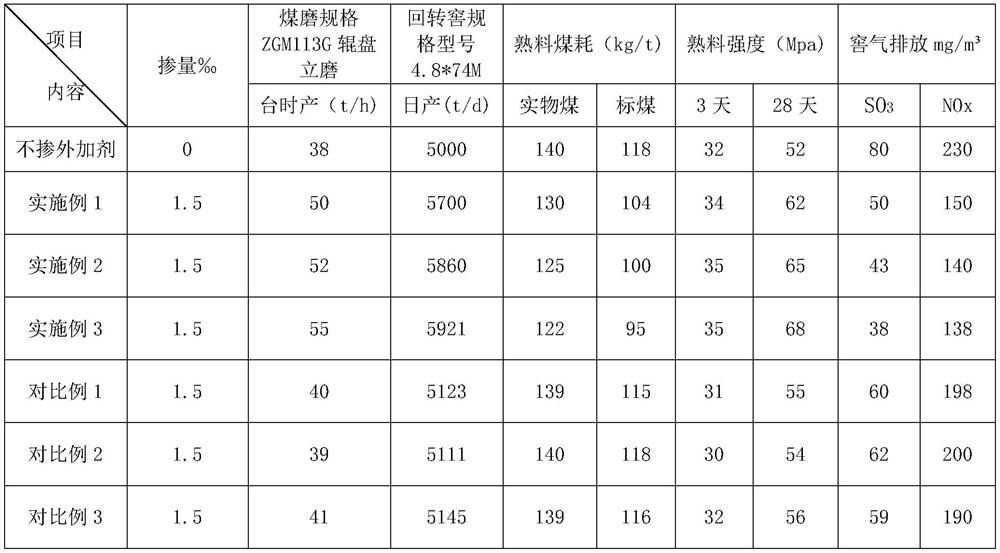

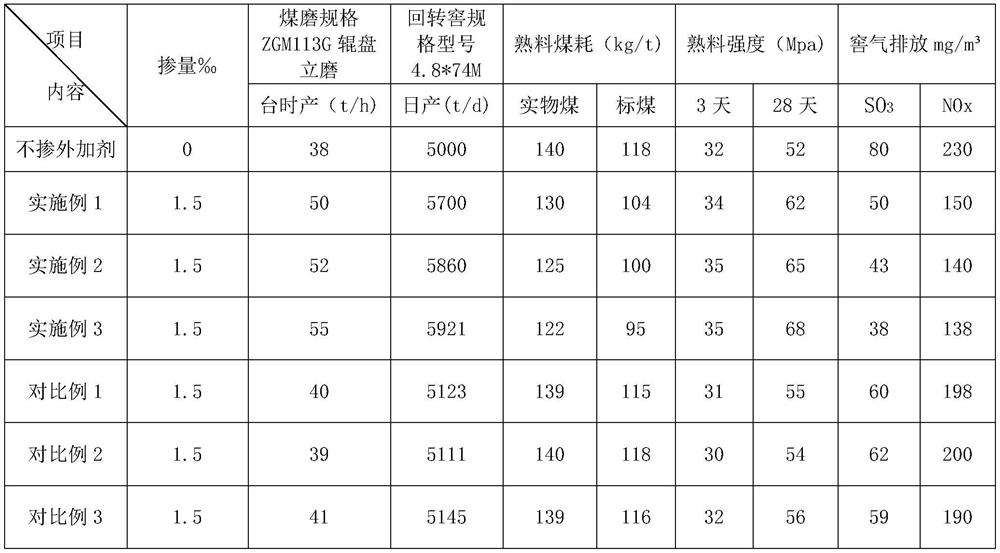

Admixture for dry-process cement kiln clinker production

The invention discloses an admixture for dry-process cement kiln clinker production, and belongs to the technical field of building material admixtures. The admixture disclosed by the invention is prepared from the following raw materials in parts by weight: 3-10% of rare earth, 20-40% of fluorite, 3-10% of nano metal powder, 30-60% of gypsum, 5-10% of modified steel slag powder and 1-5% of glycerol. The rare elements are hybridized and doped in clinker combustion, so that the eutectic point can be reduced, and the effects of destroying the crystal structure and improving the activity of the clinker are achieved. Fluorite and gypsum are added to achieve a mineralization effect, and metal nano powder is doped to catalyze clinker combustion, so that the firing speed is increased. The nano metal powder and the modified steel slag are matched with each other, so that efficient combustion of the clinker is jointly realized. The additive disclosed by the invention is 0.6-1% in doping amount,can remarkably improve the yield of a raw mill, improve the strength of clinker, fix sulfur and denitrate, comprehensively reduce the cost and realize efficient reutilization of waste resources, andhas wide economic benefits and social benefits.

Owner:临沂德艺科技发展有限公司

Jun porcelain pea green glaze and preparation method thereof

The invention discloses a Jun porcelain pea green glaze, which is prepared from the following raw materials in parts by weight: 28 to 36 parts of melilite, 18 to 24 parts of glaze stone, 14 to 18 parts of quartz, 8 to 12 parts of calcite, 4 to 6 parts of spodumene, 4 to 6 parts of talc, 1.5 to 2.5 parts of iron ore, 3 to 5 parts of Datong soil, 0.5 to 1.5 parts of tin oxide and 3 to 5 parts of wood ash. The preparation method of the Jun porcelain pea green glaze comprises the following steps: (1) smashing and mixing the raw materials, placing into a ball mill for ball milling, adding water tomake the mass concentration of the glaze reach 56-58%, performing wet-milling for 9-10 hours, and screening, through a 200 to 300 mesh, the slurry subjected to the wet milling to obtain glaze slip; (2) soaking a green body in the glaze slip for 1 or 2 times; (3) firing with the firing temperature of 1280 to 1300 DEG C.

Owner:禹州市锦丰源瓷业有限公司

Rotary kiln and method for producing calcining color frit using rotary kiln

InactiveCN1554605ASimple structureLess investment in infrastructureGlass furnace apparatusRotary drum furnacesFritEngineering

The present invention discloses a rotary kiln and method for producing calcined color frit therewith. The rotary kiln includes inclined lined cylinder with material feeding port in the head, drive system, flue with chimney, temperature metering unit inside the cylinder, heat source in the tail and discharge port in the tail. During production, the mixed raw material is fed to the inner hearth and rolled from head to tail while the cylinder is rotated and the high temperature gas flows from tail to head, so that the material is preheated and high temperature calcined to become color frit, which is discharged from the tail and cooled. The present invention has high yield and low cost.

Owner:贺建彪 +1

Preparation method, production system and application of foamed ceramic and foamed ceramic

ActiveCN110317076AFiring speed is fastIncrease productionCeramic shaping apparatusCeramic materials productionStructural waterSulfate

The invention relates to the field of foamed ceramics, and particularly provides a preparation method, production system and application of a foamed ceramic and the foamed ceramic. The preparation method of the foamed ceramic comprises the steps that firstly, foamed ceramic powder is subjected to biscuit firing and then fired to obtain the foamed ceramic. The method is scientific and reasonable inprocess, structural water, combined water, organic matter, carbonate, sulfate and other substances in the powder can be decomposed in the biscuit firing stage, gas which is not conducive to the production of the foamed ceramic is fully discharged, the firing process of the material can be quickly completed, the method is beneficial to increasing the firing speed, increasing the yield and ensuringthe product quality, and moreover, the thicker product can be produced.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

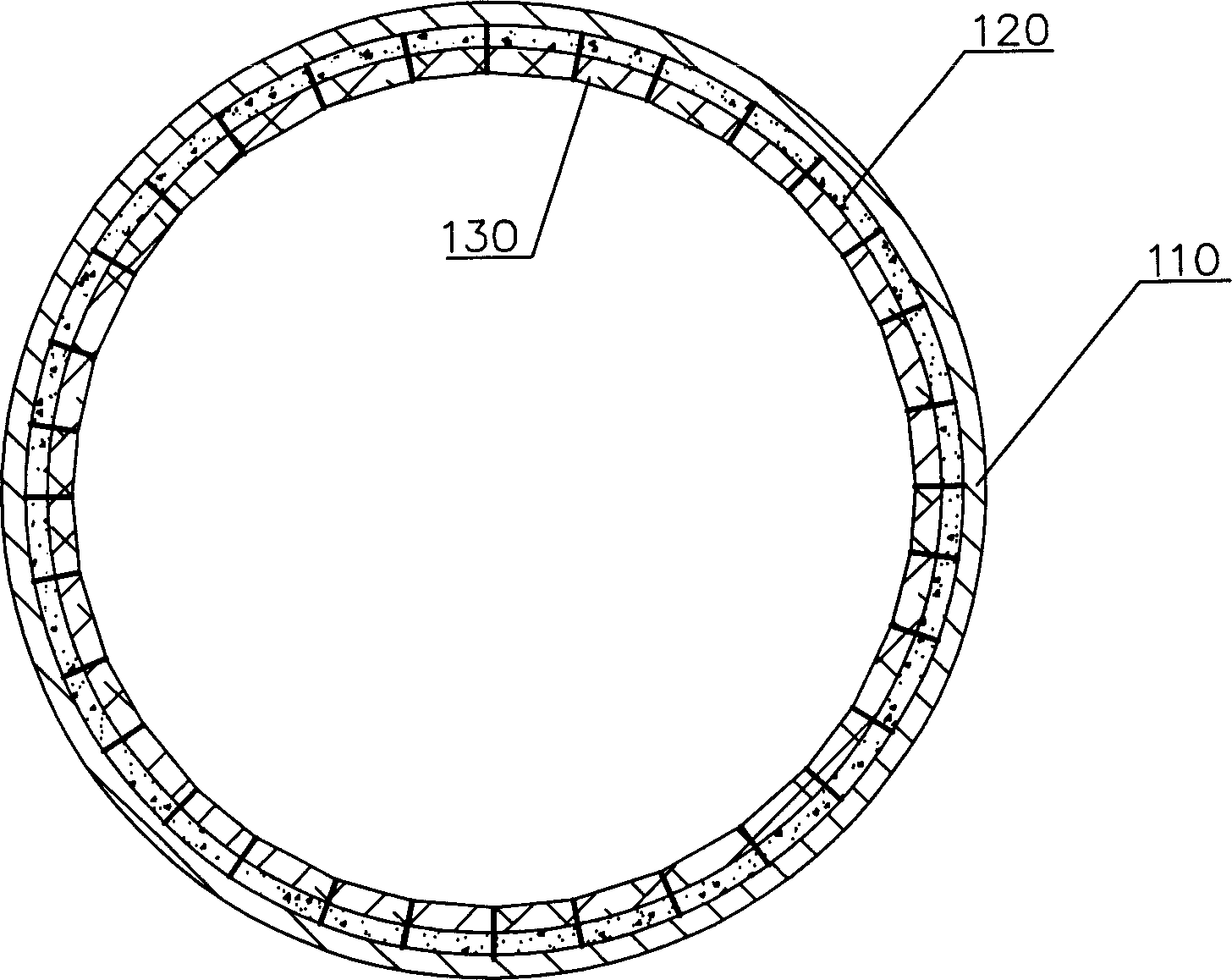

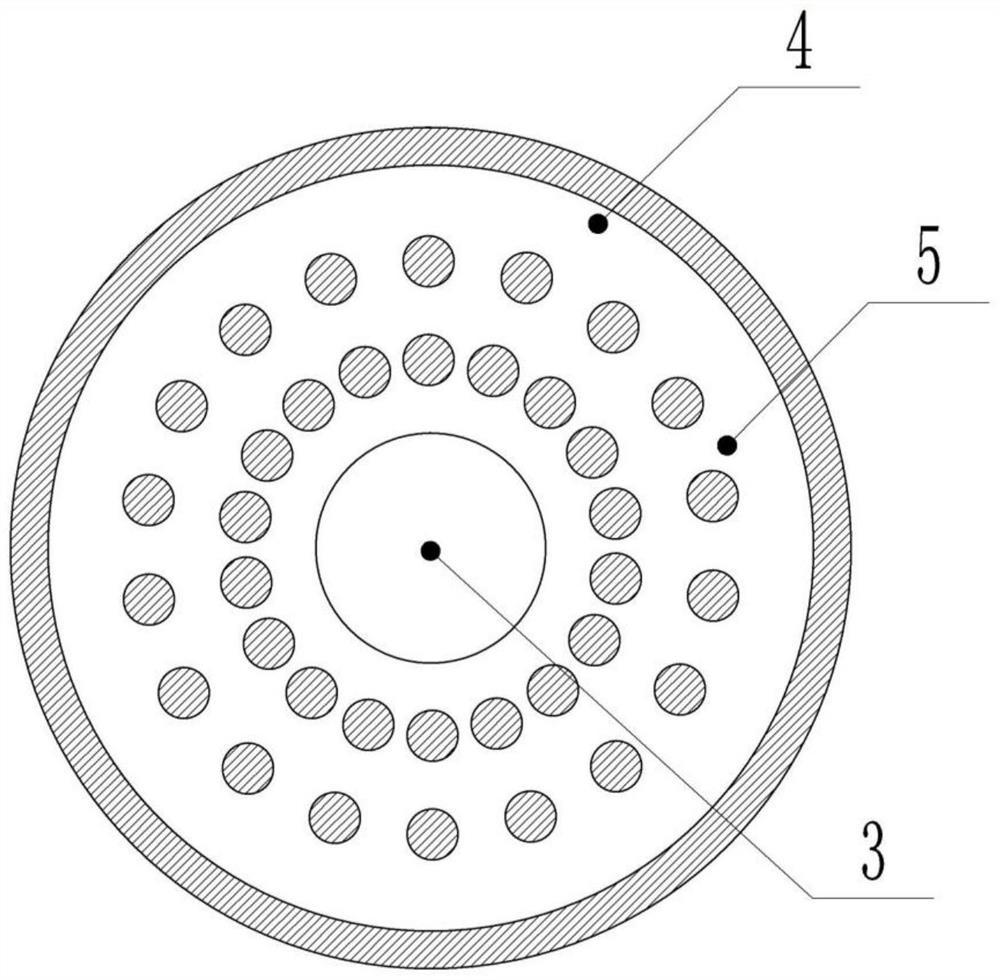

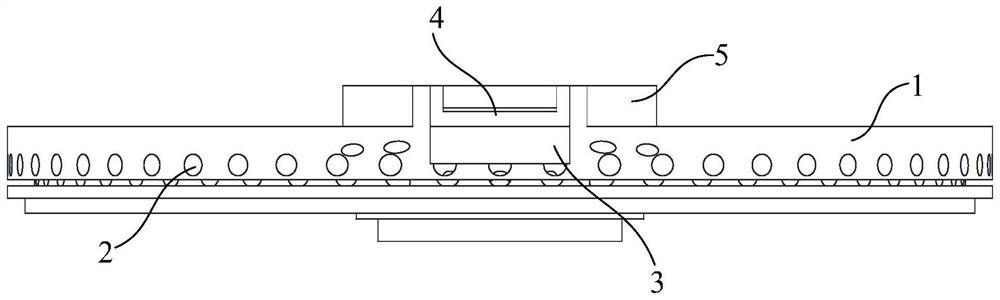

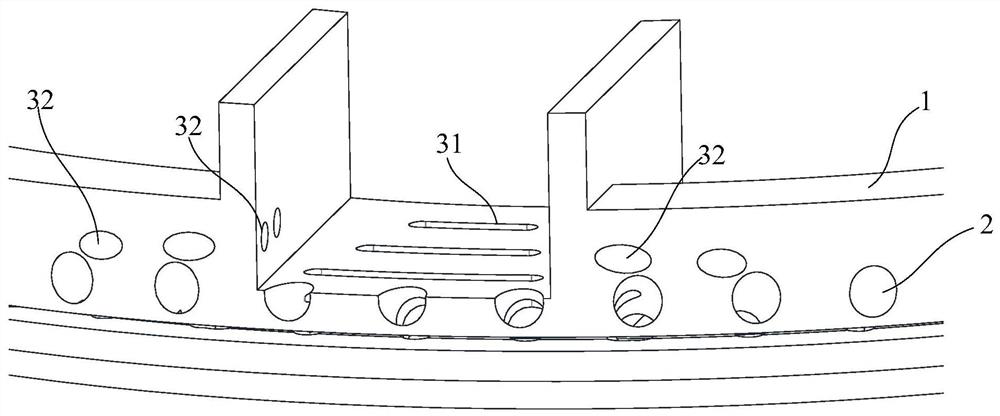

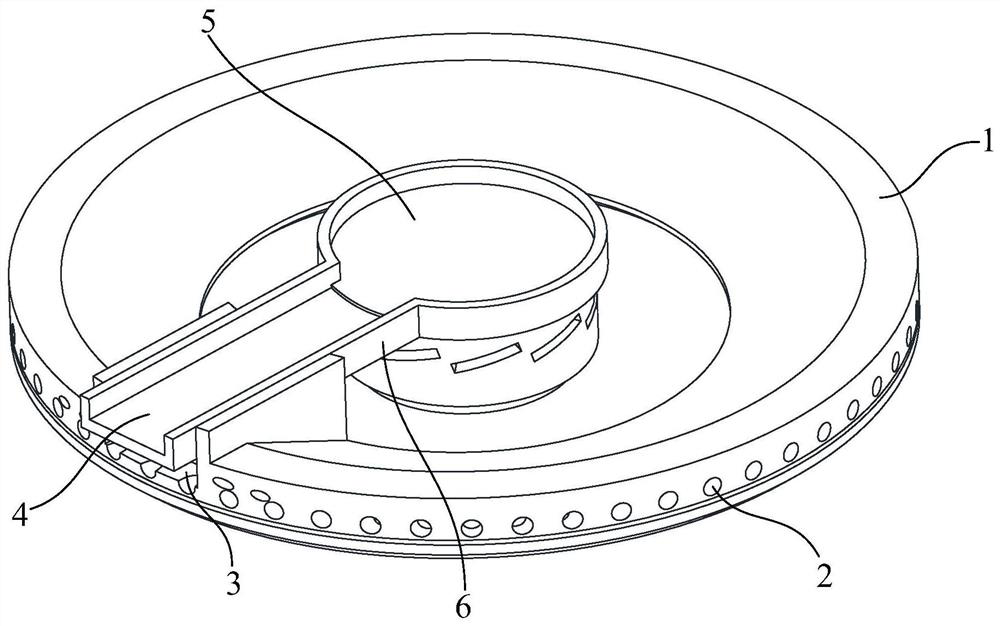

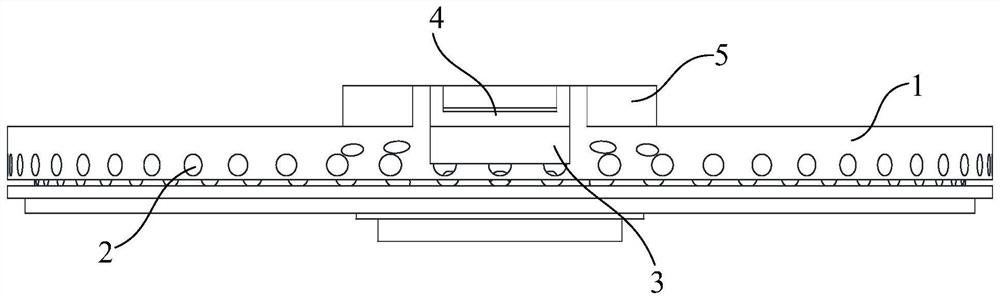

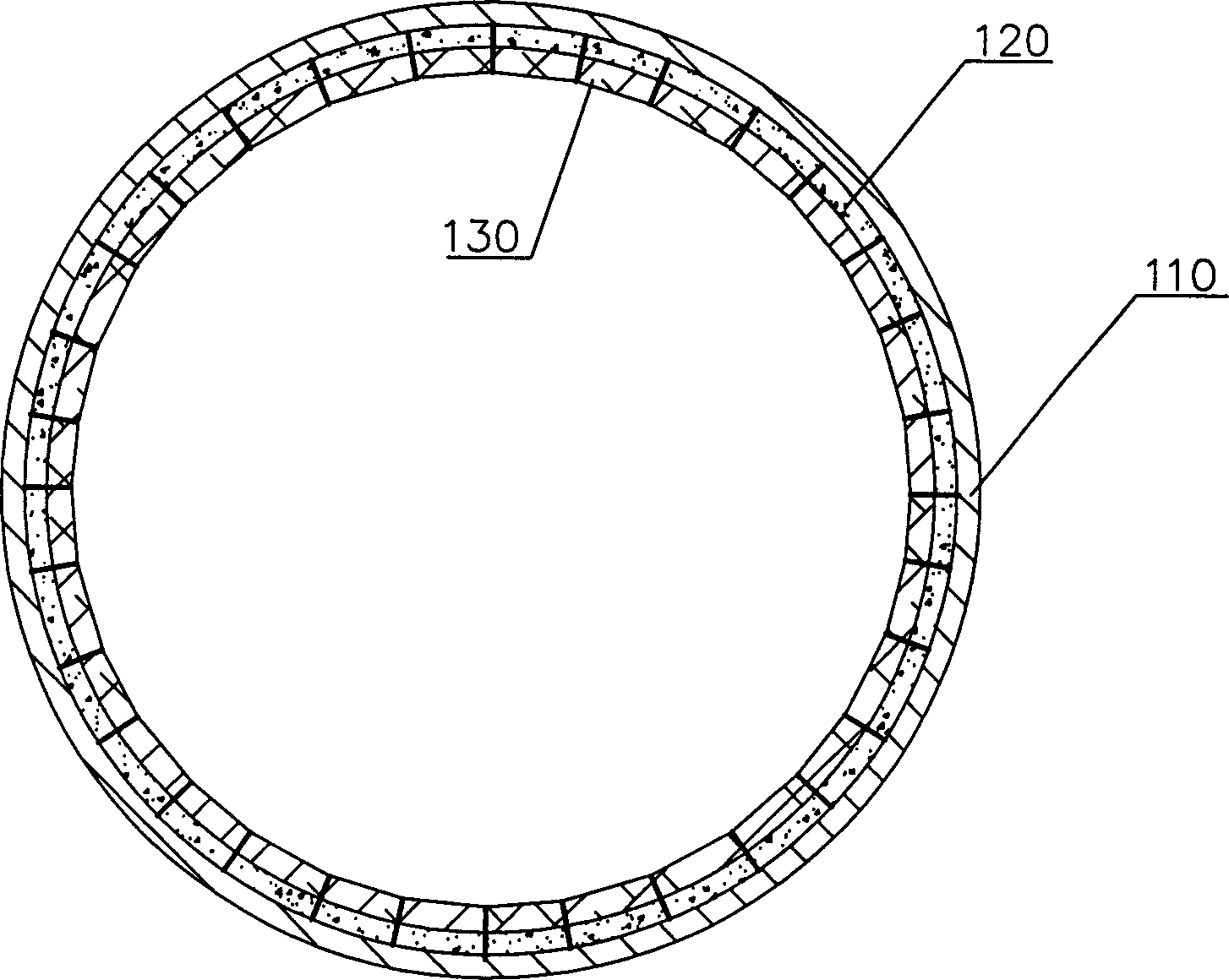

Disc type ceramic membrane and one-step forming method thereof

PendingCN114452830AStable structureExtended service lifeSemi-permeable membranesCeramic membraneDry pressing

The invention belongs to the technical field of ceramic membranes, and particularly relates to a disc type ceramic membrane and a one-time forming method thereof.The one-time forming method specifically comprises the following steps that firstly, ceramic membrane supporting body raw materials are laid on a mold, and a first supporting layer is formed; 2, a loose body is laid on the first supporting layer, and the loose body comprises combustible materials; 3, laying a ceramic membrane support body raw material on the first support layer and the loose body to form a second support layer; 4, performing dry pressing to form a ceramic membrane semi-finished product; 5, drying and calcining the ceramic membrane semi-finished product to form a ceramic membrane support body finished product; and 6, coating the surface of the support body, drying and calcining to form a ceramic membrane finished product. By adopting a support body integrated dry pressing molding technology, the whole structure of the disc-type ceramic membrane support body is firmer, and the service life of the ceramic membrane is prolonged; deformation of the ceramic membrane is integrally reduced, the sintering speed is high, the filtering effect of the ceramic membrane is better, and the cost is lower.

Owner:重庆兀盾纳米科技有限公司

Cement clinker production admixture

ActiveCN112062487AHigh mechanical strengthHigh strengthNitrogen compoundsNanotechnologyIron sulfateEconomic benefits

The invention discloses a cement clinker production admixture, and belongs to the technical field of building material admixtures. The admixture is prepared from the following raw materials in percentage by weight: 1-5% of ferric chloride, 1-10% of ferric sulfate, 5-10% of urea, 3-5% of glycerol, 5-10% of composite anhydrous sodium sulphate, 5-10% of ammonium nitrate and the balance of water. Thecombustion efficiency and the cement clinker quality can be effectively improved by adding 1.4-1.6 per mill of the admixture disclosed by the invention into the pulverized coal mill. The admixture, urea and ammonium nitrate play a role in denitration and forging assistance, glycerin plays a role in increasing heat of the grinding aid, and ferric chloride catalyzes calcination of the cement clinker. Besides, anhydrous sodium sulphate and modified boron nitride achieve synergistic interaction, the purposes of energy conservation, emission reduction and efficiency improvement are achieved together, and the high-strength cement clinker is obtained. Meanwhile, the technical purposes of accelerating the firing speed, increasing the yield, saving the coal consumption, fixing sulfur, denitrating and reducing the cost are achieved, and wide economic benefits and social benefits are achieved.

Owner:临沂德艺科技发展有限公司

Full-penetration polished ceramic tiles and preparation method thereof

InactiveCN108358601ARealistic stone-like effectImprove penetration resistanceClaywaresPotassiumSurface level

The invention discloses full-penetration polished ceramic tiles and a preparation method thereof. The full-penetration polished ceramic tiles are mainly prepared from the following components in partsby weight: 22 to 42 parts of ball clay, 12 to 18 parts of soda feldspar, 5 to 12 parts of ground quartz, 8 to 15 parts of wollastonite, 4 to 7 parts of water milled potassium feldspar powder, 1 to 4parts of sodium silicate, 0.4 to 0.8 part of water reducing agent, 0.3 to 0.6 part of blank enhancing agent and 44 to 70 parts of de-ionized water. The preparation method comprises the following steps: preparing raw materials, carrying out ball milling, spraying and granulating, punching and molding, calcining and polishing. According to the full-penetration polished ceramic tiles prepared by thepreparation method, the problems of traditional polished tiles that the surface level, stereoscopic performance and stone-imitating effect are fuzzy and unclear are solved; application of ultra-penetration materials is researched and developed so that the stone-imitating effect is more vivid; meanwhile, the full-penetration polished ceramic tiles have relatively good anti-penetration performance and color and luster; the preparation method is simple and is suitable for industrial production.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

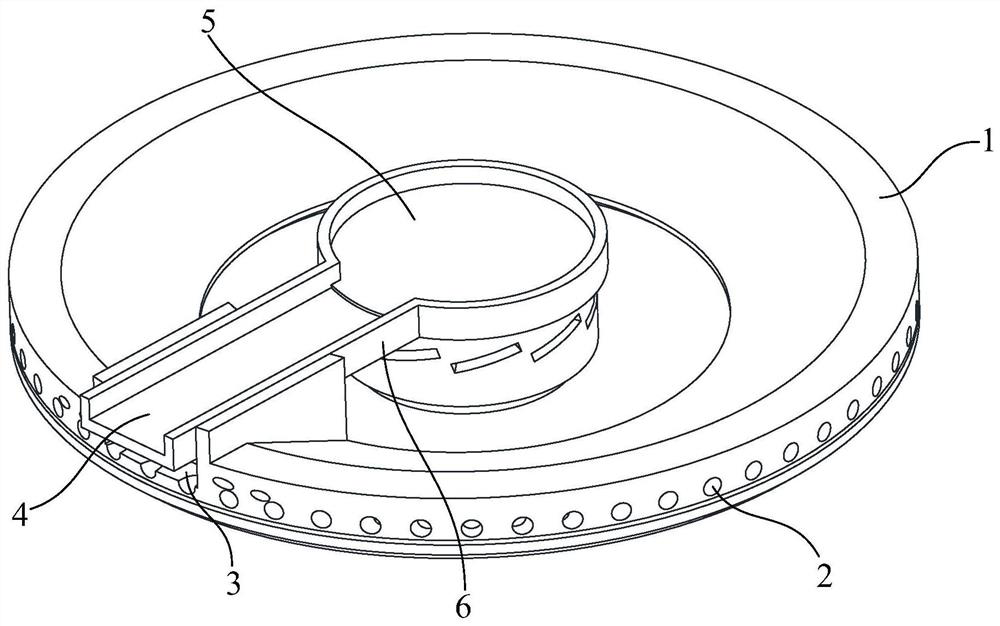

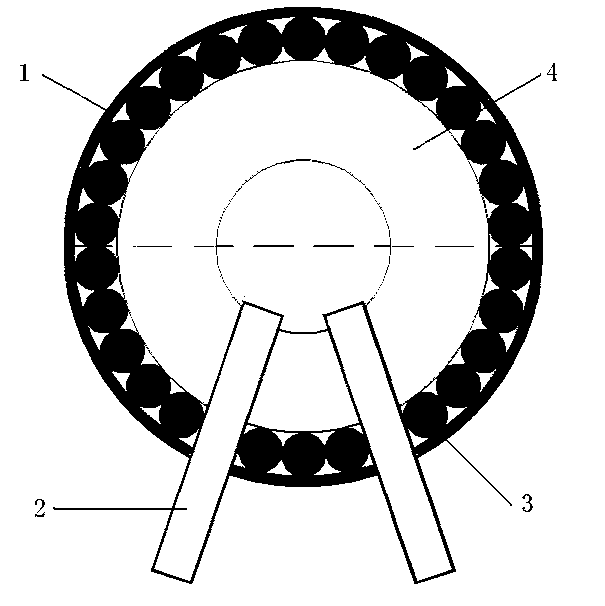

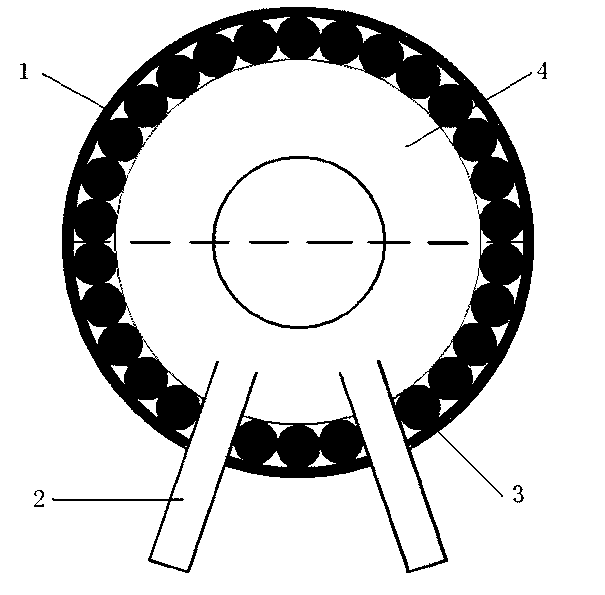

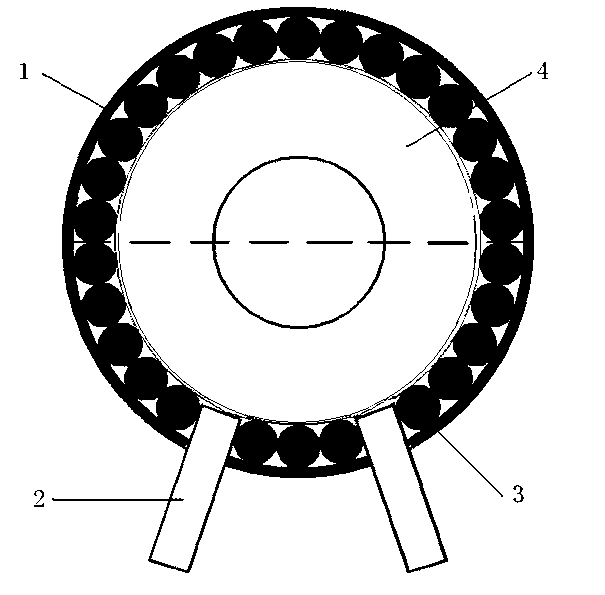

stove cover

ActiveCN112648615BIncrease success rateFiring speed is fastGaseous fuel burnerStructural engineeringOpen fire

The invention discloses a cooker fire cover, which comprises an outer ring fire cover, a plurality of main fire holes are arranged on the outer ring fire cover, and a fire transmission groove is arranged on the upper surface, and the two ends of the fire transmission groove respectively extend to the outer ring fire cover The inner wall and the outer wall of the cooker fire cover also include a top cover, which is arranged on the top of the fire transfer tank and is detachably connected with the fire transfer tank. The top cover and the fire transfer tank together form a top-closed fire transfer channel. The cooker fire cover provided by the present invention provides a detachable top cover on the top of the fire transmission tank, so that the cooker fire cover has two fire transmission modes, hidden and open, and the design of the detachable top cover is also convenient. The interior of the fire cover is cleaned. In addition, the connection between the top cover and the inner ring fire cover is convenient for positioning the inner ring fire cover. The setting of the fire transmission hole improves the success rate of fire transmission. The connecting hole and the end of the fire transmission groove are tangent to the fire hole. The fire transmission of the cooker fire cover is quicker and more effective, and the success rate and speed of fire transmission from the inner ring to the outer ring of the cooker fire cover are significantly increased, and the utility model has strong practicability.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method for sensitizing microporous smokeless firework explosive

InactiveCN101844955BFiring speed is fastImprove ignition performanceNitrocellulose explosive compositionsInorganic oxygen-halogen salt explosive compositionsCelluloseNon solvent

The invention discloses a method for sensitizing microporous smokeless firework explosive, which comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent to obtain explosive particles suspended in the solution and provided with micropores, separating the explosive particles suspended in the solution and provided with micropores, sensitizing the explosive particles separated from the solution of the suspended explosive particles and provided with micropores, and drying the explosive particles to obtain an explosive particle finished product, wherein the sensitizing mode is to add a sensitizing agent into the explosive particles separated from the solution of the suspended explosive particles in a form of aqueous solution or solid. The sensitizing process improves the fire transfer speed of the explosive particles and improves the ignition performance thereof, and the fire transfer speed of the explosive particles is improved by 10 to 200 percent under a normal pressure condition.

Owner:NANJING UNIV OF SCI & TECH

Imitating fancy glaze for jun porcelain light fixtures and preparation process of imitating fancy glaze

The invention discloses imitating fancy glaze for jun porcelain light fixtures and a preparation process of the imitating fancy glaze. Prepared imitating fancy glaze porcelain has high yield, reducedproduction cost and very high artistic value and economic value. Spodumene reacts with kaolin and quartz in the firing process, produced mullite still keeps the appearance of kaolinite. The spodumeneadded to the formula can increase the firing speed and cannot cause product cracking, so that energy consumption can be reduced, the yield is about 88%, and the production cost can be reduced.

Owner:杨鹏飞

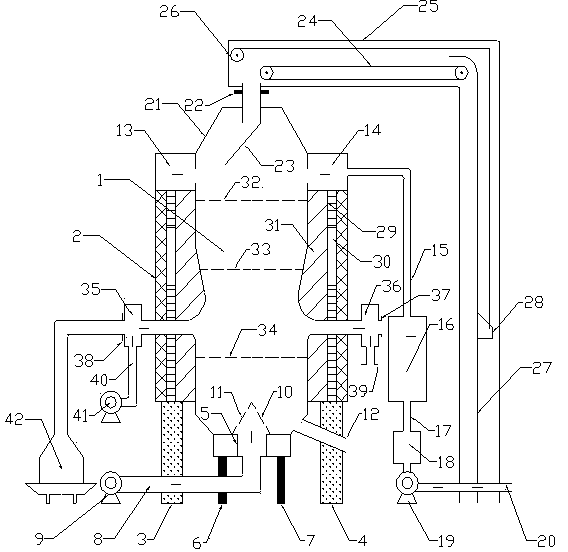

Cooker burner cap

ActiveCN112648615AFast and effective fire transferEasy to locate and installGaseous fuel burnerEngineeringOpen fire

The invention discloses a cooker burner cap which comprises an outer ring burner cap body. A plurality of main fire holes are formed in the outer ring burner cap body, a fire transmission groove is formed in the upper surface of the outer ring burner cap body, and the two ends of the fire transmission groove extend to the inner wall and the outer wall of the outer ring burner cap body respectively; and the stove burner cap further comprises a top cover which covers the top of the fire transmission groove and is detachably connected with the fire transmission groove, and the top cover and the fire transmission groove jointly form a fire transmission channel with the closed top. According to the cooker burner cap provided by the invention, the detachable top cover is arranged at the top of the fire transmission groove, so that the stove burner cap has a hidden fire transmission manner and an open fire transfer manner at the same time; the interior of the burner cap is convenient to clean due to the design of the detachable top cover; in addition, the top cover is connected with an inner ring burner cap body to conveniently position the inner ring burner cap body; and the fire transmission success rate is increased through the arrangement of fire transmission holes, one end of each communicating hole and one end of the fire transmission groove are tangent to the corresponding fire transmission hole, so that fire transmission of the stove burner cap is faster and more effective, the fire transmission success rate and the fire transmission speed from an inner ring to an outer ring of the stove burner cap are remarkably increased, and practicability is high.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Chai Porcelain Bean Green Glaze

The invention relates to Chai kiln porcelain yellowish pea green glaze which is prepared from the following ingredients in parts by weight: 20.18 parts of quartz, 35.28 parts of feldspar, 11.26 parts of calcite, 18.83 parts of slate gray, 5.58 parts of phosphorous bone powder, 3.48 parts of agate, 2.56 parts of hydrotalcite and 2.83 parts of white metal soil, wherein quartz sand serves as the quartz, the feldspar is a combination of one or two of sodaclase and potassium feldspar, the content of ferric oxide in the white metal soil is 30-35%, the content of manganese oxide is 8-10%, the used preparation method of Chai kiln porcelain green glaze comprises the following steps: a. carrying out burdening according to various ingredients and the proportion by weight of the various ingredients; and b. mixing the various ingredients uniformly, adding 20-22 parts of water, ball-milling for 16-20 hours by using a wet method, enabling ball-milled glaze to pass through a 250-mesh screen, then turning the glaze into glaze slip with 60-65 baume degrees, then spraying the glaze slip on a incense ash tire, afterwards, heating the glaze slip at normal temperature to 1,180-1,250 DEG C, then cooling, and drawing for 15 hours or so. The Chai kiln porcelain yellowish pea green glaze has the advantages of fast firing at medium temperature, lower cost, even and clean enamel layer, good glossiness and strong decorative perception.

Owner:马聚魁

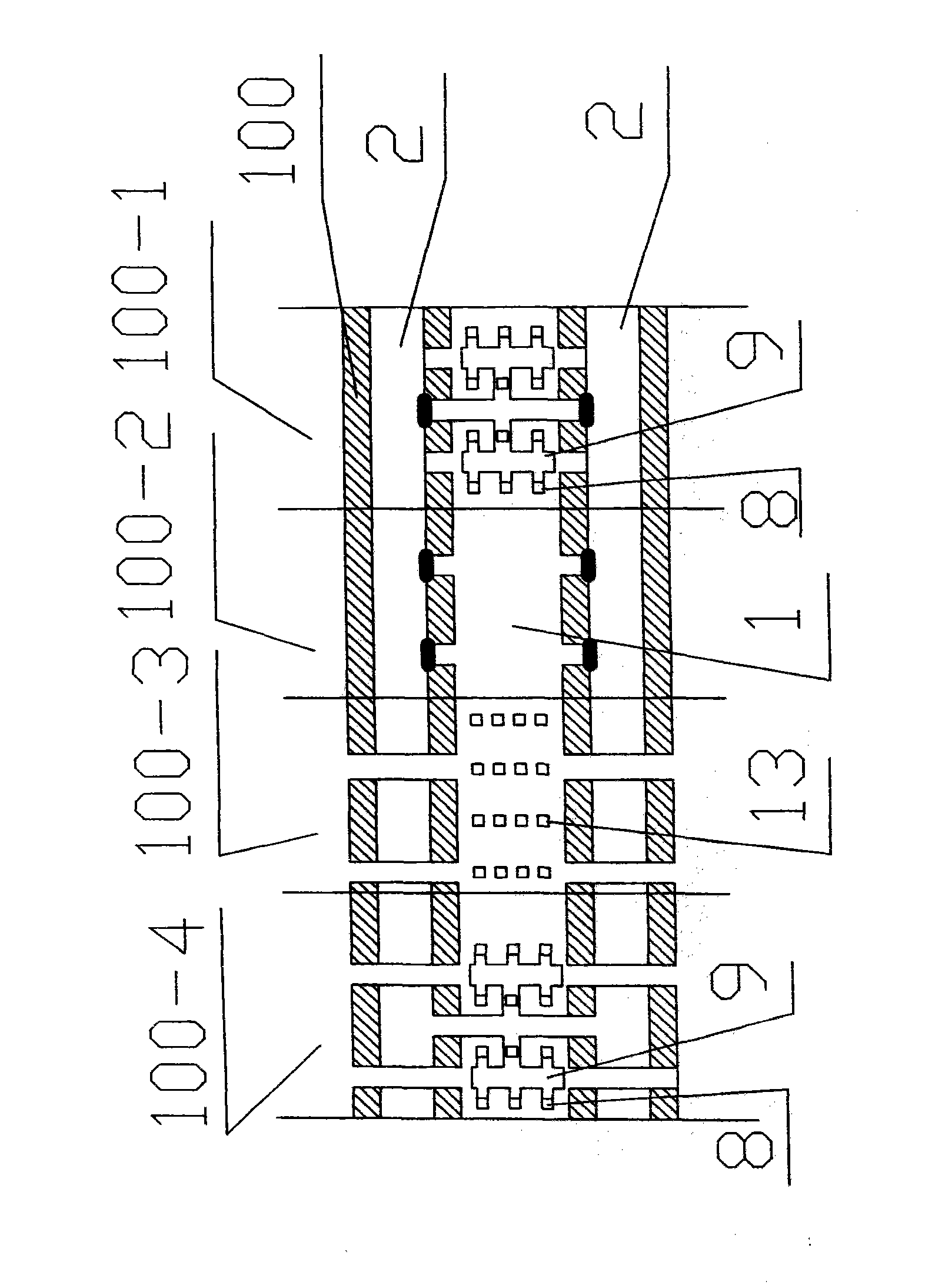

Display shell with modular open-bud charging structure and preparation method thereof

ActiveCN102192684BEasy to operateResolve Insufficient CombustionFireworksStructural engineeringProcess engineering

The invention discloses a display shell with a modular open-bud charging structure. The display shell comprises an outer shell, a delay ignition harness, bright beads and open-bud powder blocks, wherein the outer shell, the delay ignition harness and the bright beads can be made of traditional materials and have traditional structures; and the open-bud powder blocks are combined and charged in a ball shell, and a hollow structure is formed in the center of the open-bud charging structure. A preparation method of the display shell with the modular open-bud charging structure comprises the following steps of: arranging bright beads to the inner side of the ball shell of the display shell; directly charging the prepared modular powder blocks into one semi-ball shell; charging powder into theother semi-ball shell with the same powder charging sequence; and buckling the two semi-modular blocks with each other, and applying paper to the surface of the shell and drying. The display shell structure and the preparation method contribute to overall ignition, the problem of insufficient combustion or powder residue when particular microporous firework powder is taken as open-bud powder can be completely solved, and the enjoyment effect and environmentally friendly performance are improved. Furthermore, the operation of the display shell production process is simplified, and the safety of manufacture process and storage and transportation process of firework products is improved.

Owner:NANJING UNIV OF SCI & TECH

A kind of cement clinker production admixture

ActiveCN112062487BHigh mechanical strengthHigh strengthNitrogen compoundsNanotechnologyIron sulfateSocial benefits

The invention discloses an admixture for cement clinker production, which belongs to the technical field of building material admixtures. The admixture of the present invention is composed of the following raw materials in percentage by weight: 1-5% ferric chloride, 1-10% ferric sulfate, 5-10% urea, 3-5% glycerin, 5-10% compound sodium sulfate, nitric acid Ammonium 5-10%, the balance is water. The combustion efficiency and the quality of cement clinker can be effectively improved by adding 1.4-1.6‰ of the additive of the present invention to the coal pulverizer. The admixture of the present invention, urea and ammonium nitrate act as a denitrification aid for forging, glycerin acts as a grinding aid to increase heat, ferric chloride catalyzes the calcination of cement clinker, and in addition, sodium sulfate and modified boron nitride, the two synergize, Jointly achieve the purpose of energy saving, emission reduction and efficiency increase, obtain high-strength cement clinker, and at the same time achieve the technical goals of accelerating firing speed, increasing production, saving coal consumption, fixing sulfur and denitrification, and reducing costs, which has broad economic and social benefits.

Owner:临沂德艺科技发展有限公司

Micro-pore firework powder capable with improved fire ignition and transfer properties and preparation method thereof

ActiveCN101857516BFiring speed is fastImprove ignition performanceNitrated explosive compositionsAlkaline earth metalNitrate

The invention discloses a method for preparing micro-pore firework powder capable with improved the fire ignition and transfer properties, which comprises the following steps of: firstly, dissolving materials, emulsifying, foaming, balling, then removing a solvent, separating the materials, and finally, drying; when the materials are dissolved, emulsified and foamed, adding a water solution of a sensitizing agent; and adding a water solution containing a sensitizing agent and a dispersing agent as a dispersion medium in the balling process, wherein the concentration of the water solutions of the sensitizing agents is the same. The used sensitizing agents can adopt the nitrate, the perchlorate or the mixture thereof of alkali metal or alkali earth metal, and the addition proportion is 0.2 to 10 percent of the mass of raw powder. The sensitizing agents are added in the forming process of the micro-pore firework powder by the form of the water solutions, an extra procedure is not added, a forming medium is recycled in the technological process, environmental pollution and material wastage can not be caused, the distribution of the sensitizing agents in an obtained sample of a finished product is more uniform, and the ignition capability and the normal-pressure fire transfer speed are both enhanced obviously.

Owner:NANJING UNIV OF SCI & TECH

Rotary kiln and method for producing calcining color frit using rotary kiln

InactiveCN1226208CSimple structureLess investment in infrastructureGlass furnace apparatusRotary drum furnacesFritProcess engineering

The present invention discloses a rotary kiln and method for producing calcined color frit therewith. The rotary kiln includes inclined lined cylinder with material feeding port in the head, drive system, flue with chimney, temperature metering unit inside the cylinder, heat source in the tail and discharge port in the tail. During production, the mixed raw material is fed to the inner hearth and rolled from head to tail while the cylinder is rotated and the high temperature gas flows from tail to head, so that the material is preheated and high temperature calcined to become color frit, which is discharged from the tail and cooled. The present invention has high yield and low cost.

Owner:贺建彪 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com