Energy-saving four-duct once-setting firing tunnel kiln

A four-air duct, energy-saving technology, applied in the furnace type, waste heat treatment, furnace, etc., can solve the problems of difficult control of overburning, low product qualification rate, and low output, so as to save fan power consumption and improve product qualification rate , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

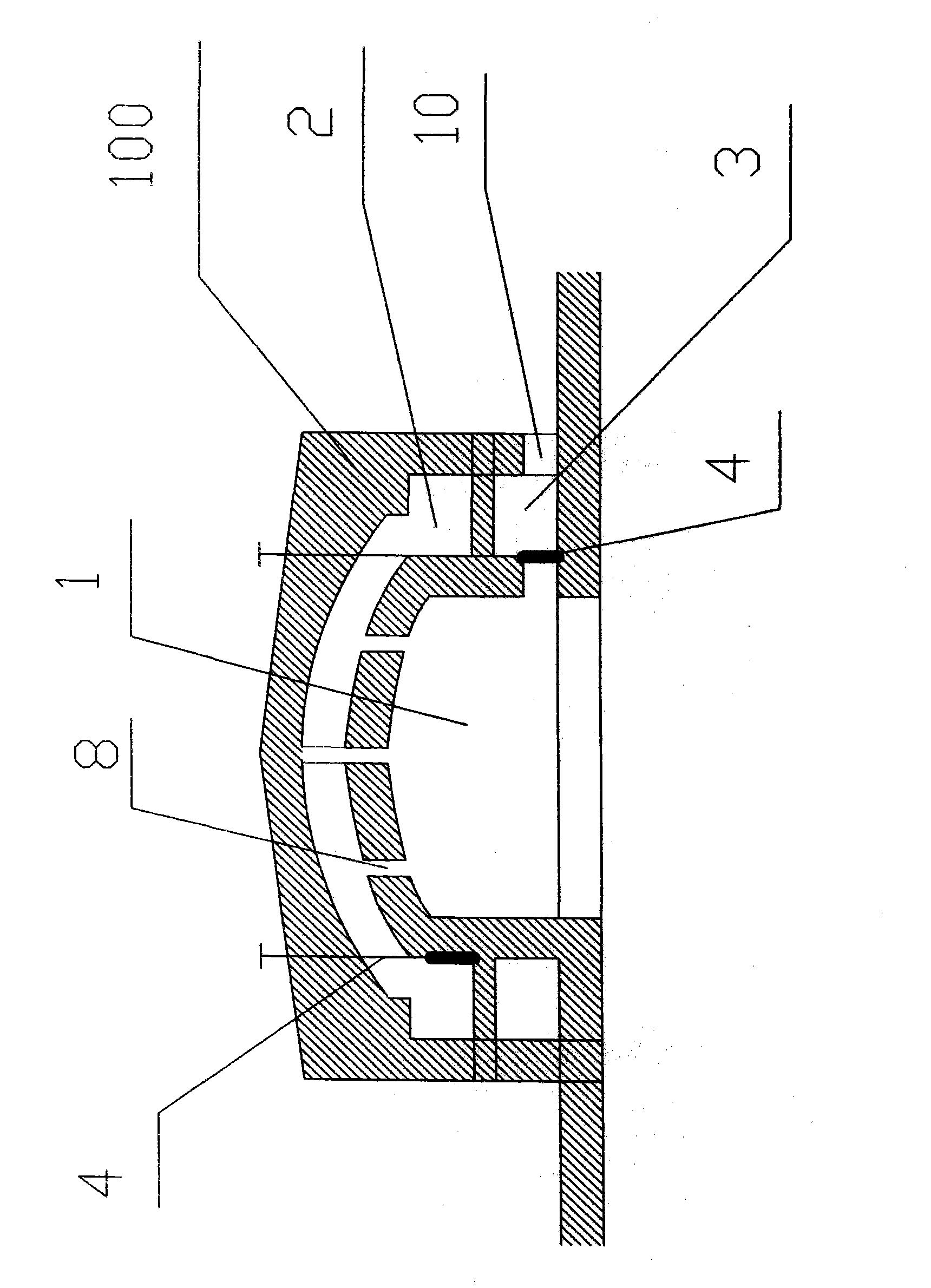

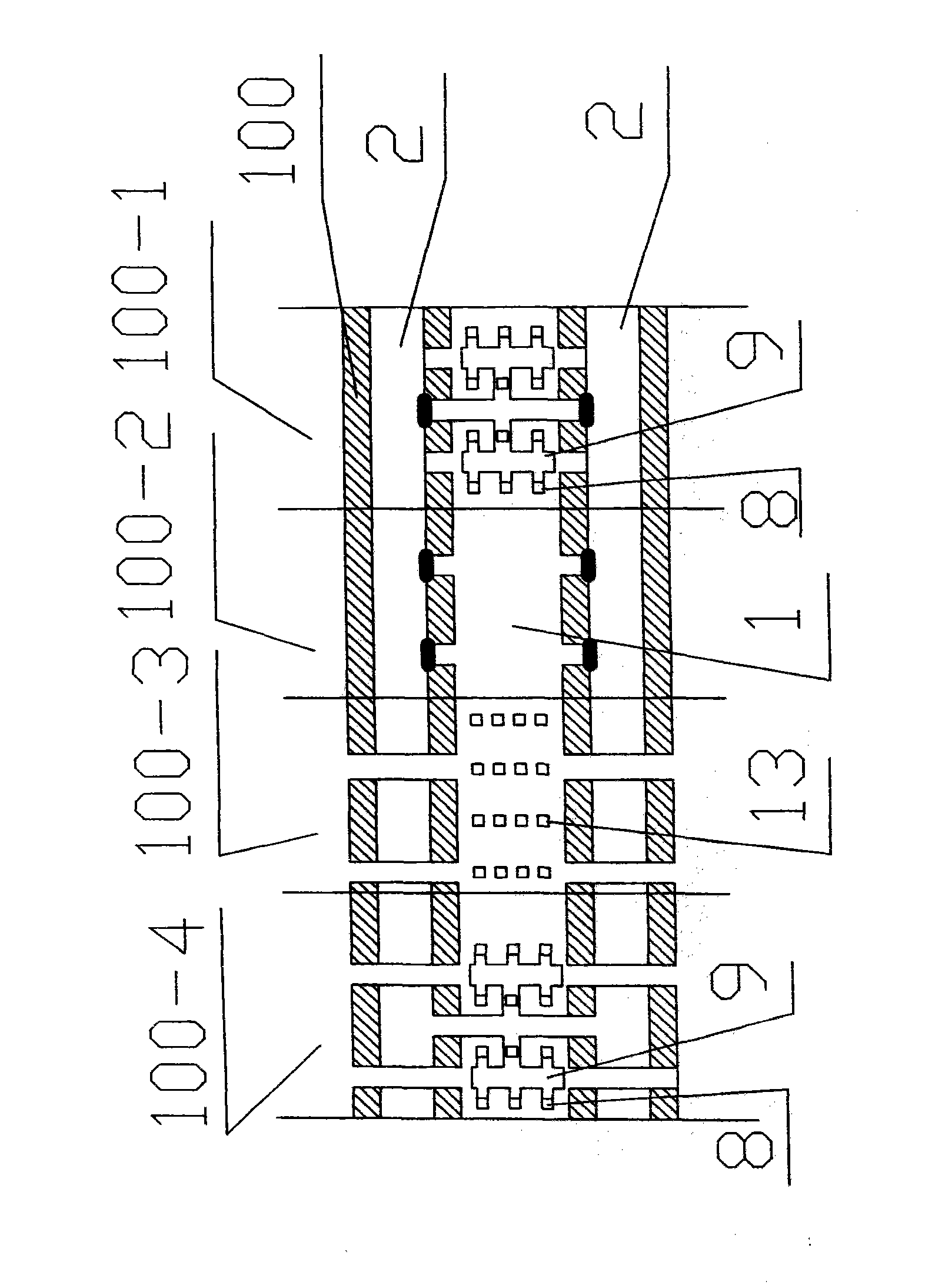

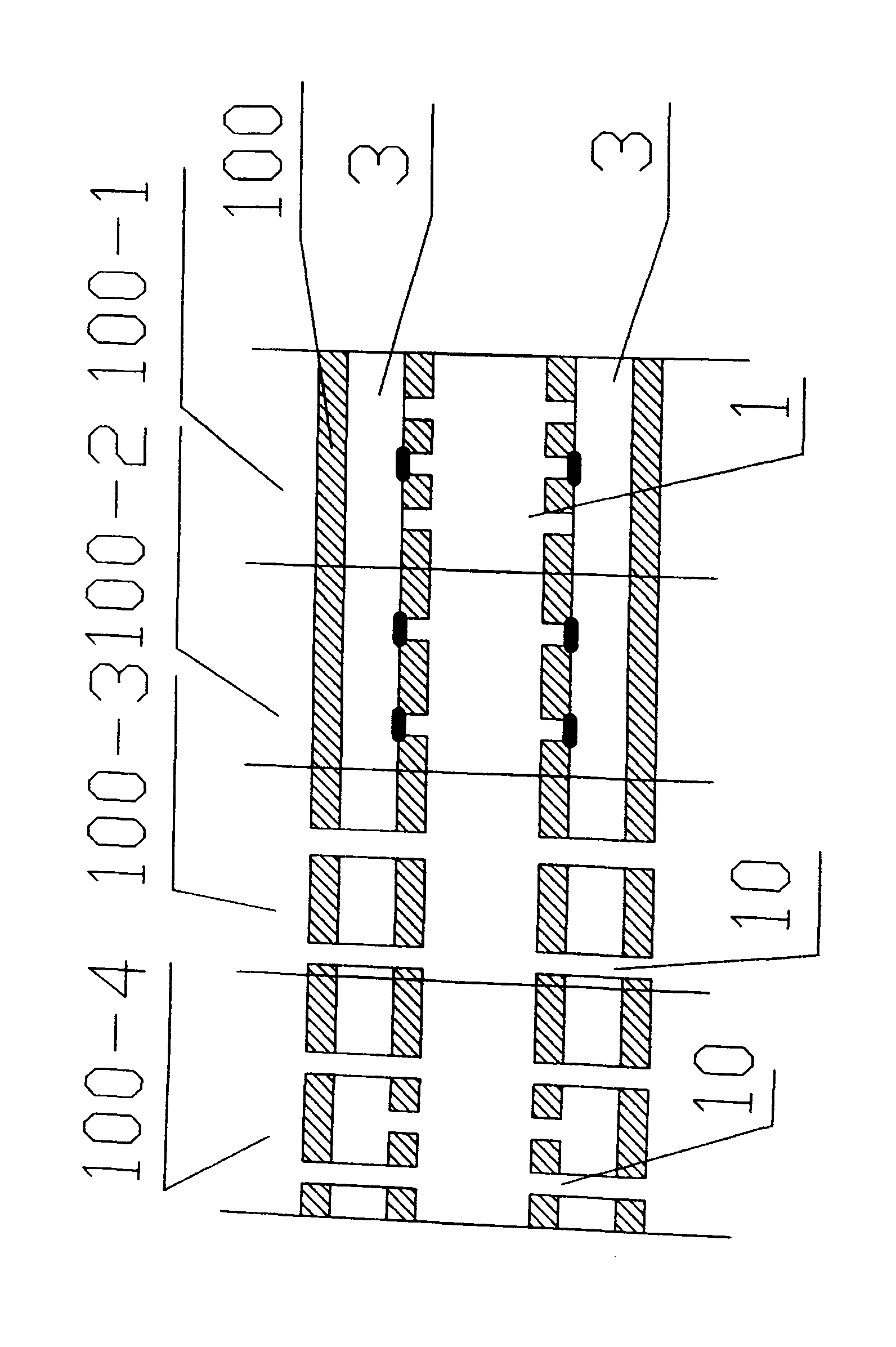

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention is an energy-saving four-air passage one-time code-fired tunnel kiln, which includes a roasting kiln body 100 and a drying kiln body 200. Both the roasting kiln body and the drying kiln body are provided with a kiln chamber 1, and the roasting kiln body It is connected with the drying kiln body through the induced air blower; the upper and lower air ducts are symmetrically arranged on both sides of the kiln chamber of the roasting kiln body, the upper air duct is the waste heat air duct 2, and the lower air duct is the induced air duct 3. A plurality of air dampers 4 are set in the waste heat air duct and the induced air duct, and they are respectively connected with the kiln chamber of the roasting kiln body; the upper and lower air ducts are symmetrically arranged on both sides of the kiln chamber of the drying kiln body, and the upper air duct It is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com