Rotary kiln and method for producing calcining color frit using rotary kiln

A rotary kiln and calcining technology, applied in rotary drum furnaces, lighting and heating equipment, furnace types, etc., can solve the problems of large saggar loss, high labor intensity of pouring pots, long calcination time, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

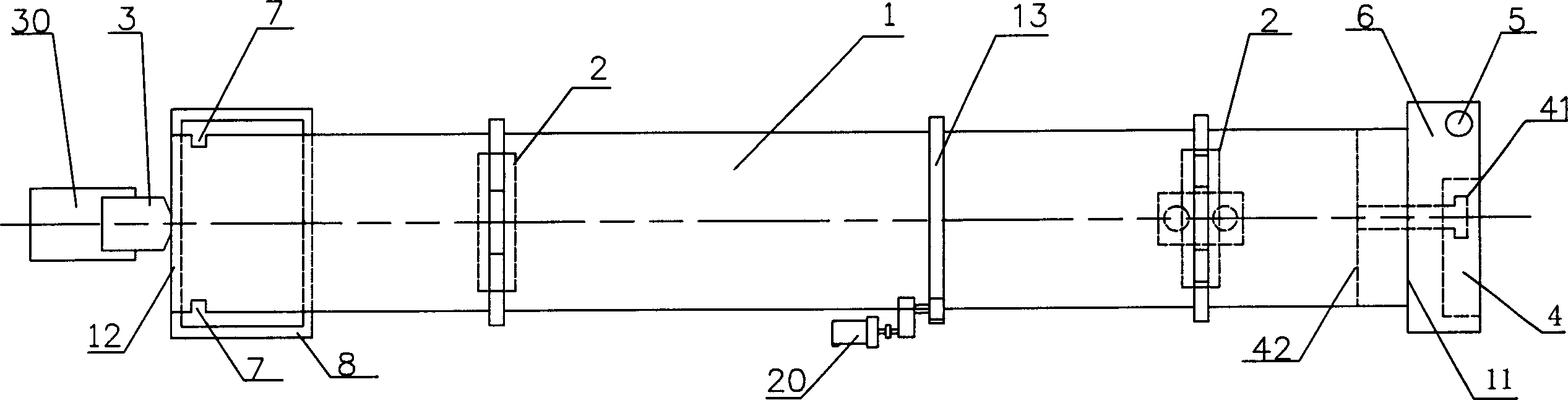

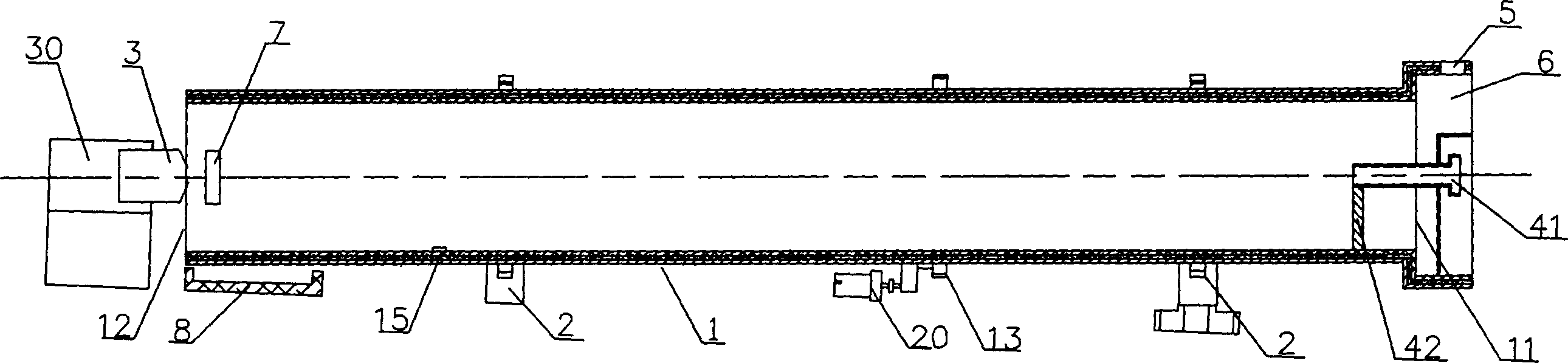

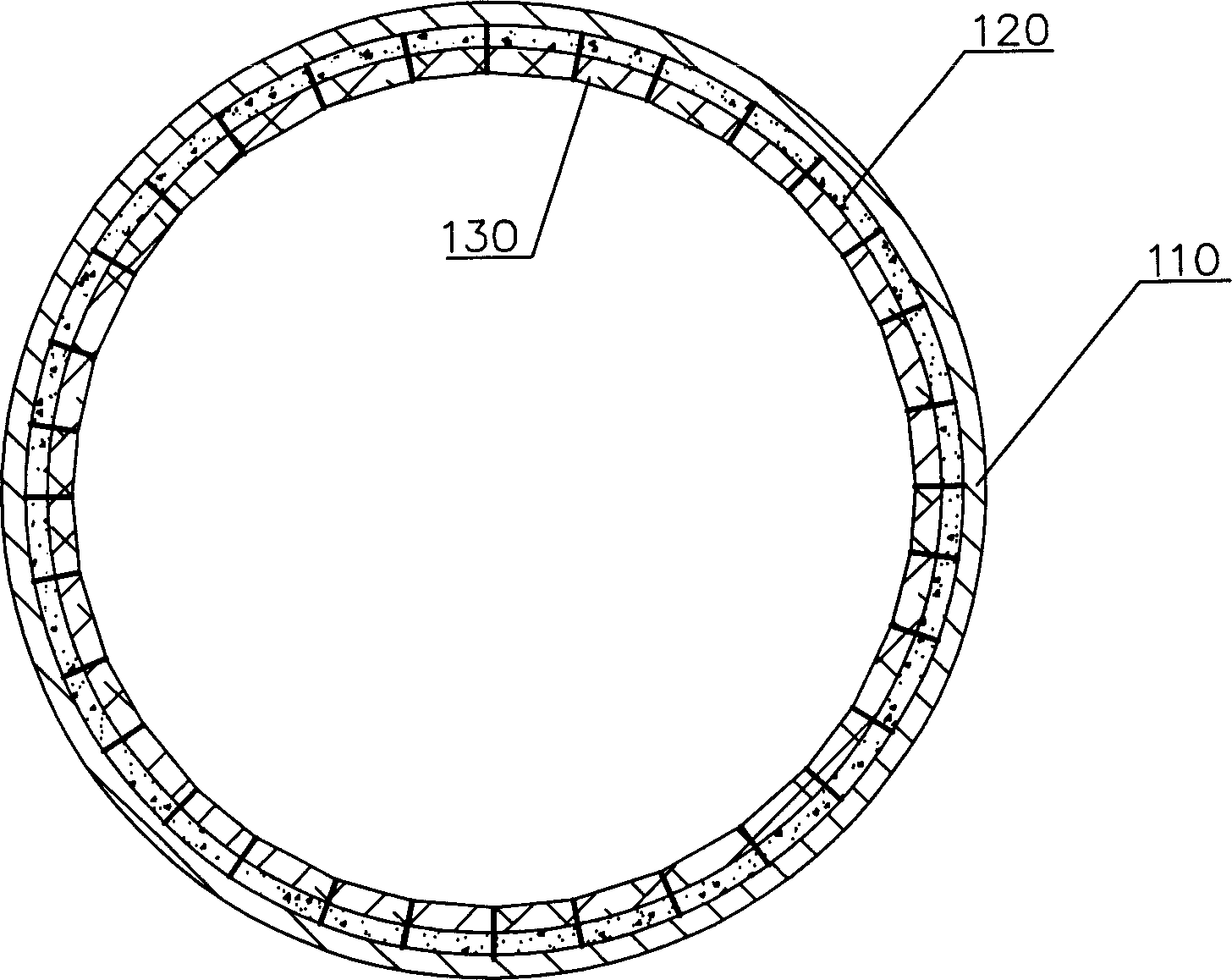

[0016] refer to figure 1 , figure 2 , a rotary kiln for calcining colored glazes according to the present invention, comprising a cylinder body 1, the cylinder body 1 has an inner chamber passing through the kiln head 11 and the kiln tail 12, and the bottom of the cylinder body 1 has a power system and is connected with the rim There is an inclination angle of 1° to 7° between the cylinder body 1 and the horizontal plane, the kiln head 11 is high, the kiln tail 12 is low, the power system is connected with the cylinder gear 13 on the cylinder body 1, and the kiln head 11 is set There is a feed inlet 4 and a flue 6 with a chimney 5 , a temperature measuring device is installed in the inner chamber of the cylinder body 1 , a heat source generating device is installed outside the kiln tail 12 , and the kiln tail 12 has a discharge outlet 7 .

[0017] Wherein, the inclination between the cylinder body 1 and the horizontal plane can be achieved by adjusting the height of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com