Low-temperature rapid sintered high-frequency low-consumption glass ceramic and preparation thereof

A glass-ceramic, low-loss technology, applied in the field of ceramic materials, can solve problems such as prolonging the production cycle, and achieve the effects of simple firing system, fast firing speed and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Table 3 shows the content of each component of the specific example 1 of the present invention. Each material was weighed according to the mass percentage, and after 4 hours of mixing, the binder was added to granulate, and pressed at 120MPa. The sample was directly kept at 685°C for 40 minutes, then taken out directly and cooled at room temperature. The performance test of the sintered body is shown in Table 4.

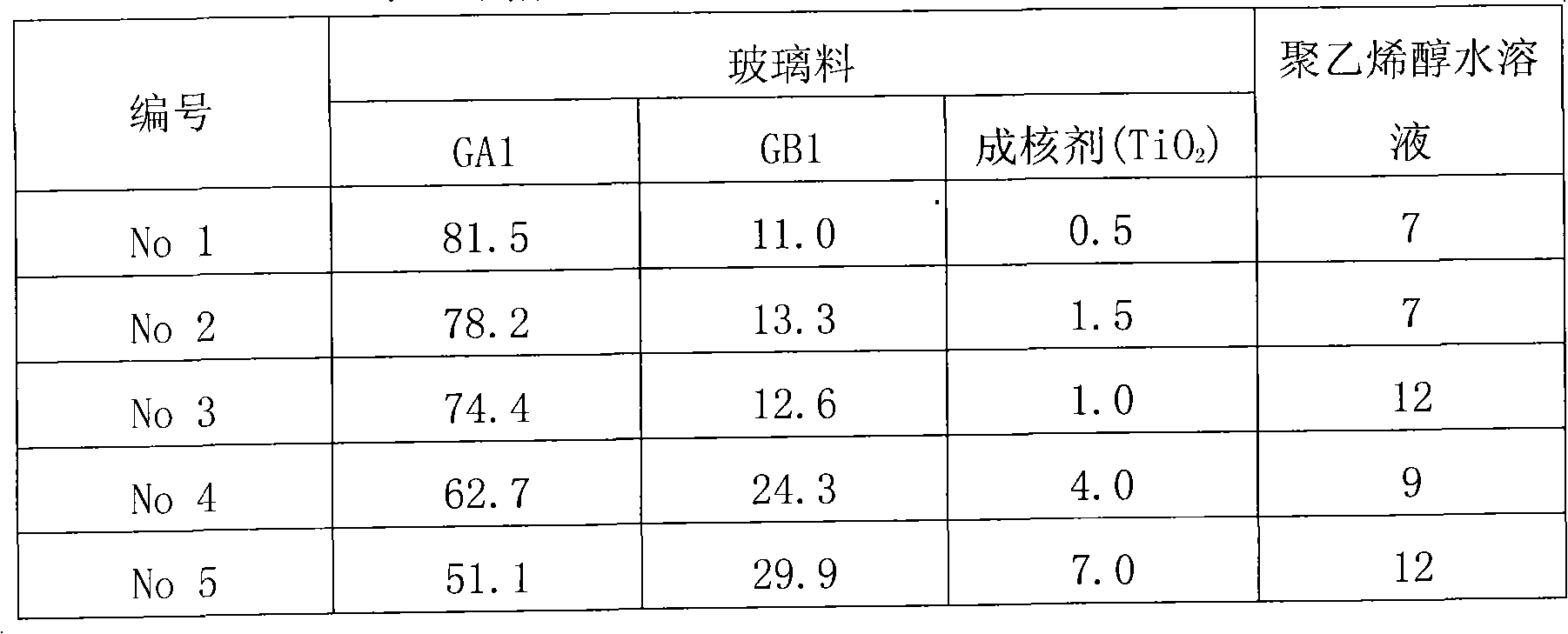

[0029] Table 3 High-frequency low-loss glass ceramic components content (wt%)

[0030]

[0031] Table 4 Properties of High Frequency Low Loss Glass Ceramics

[0032] serial number

Embodiment 2

[0034] Table 5 shows the content of each component of the specific example 2 of the present invention. Weigh each material according to mass percentage, mix uniformly after 4 hours, add binder to granulate, and press to form under 150MPa. The sample was directly kept at 685°C for 40 minutes, then taken out directly and cooled at room temperature. The performance test of the sintered body is shown in Table 6.

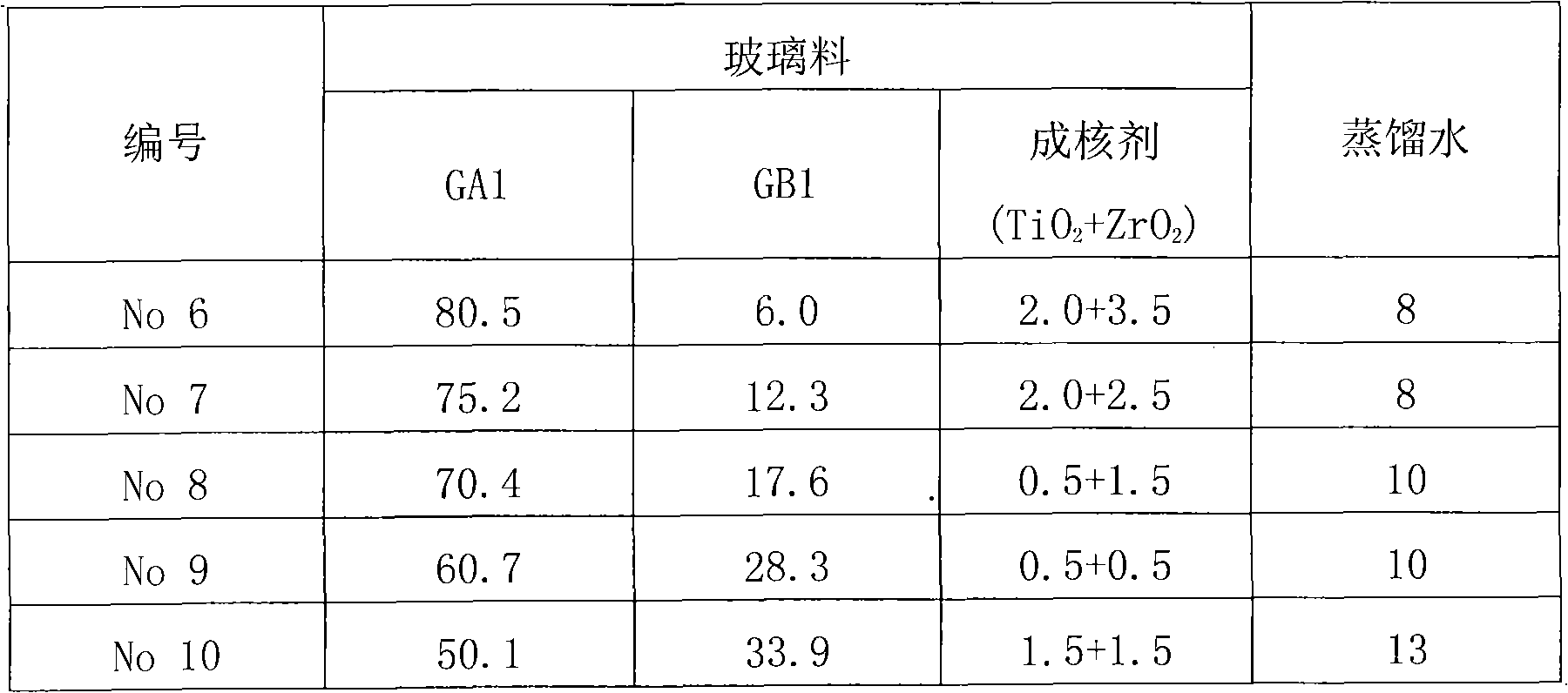

[0035] Table 5 Contents of each component of high-frequency low-loss glass ceramics (wt%)

[0036]

[0037] Table 6 Properties of high-frequency low-loss glass ceramics

[0038] serial number

Embodiment 3

[0040] Table 7 shows the content of each component of the specific example 3 of the present invention. Weigh each material according to the mass percentage, mix evenly after 4 hours, add binder to granulate, and press to form under 180MPa. The sample was directly kept at 685°C for 40 minutes, then taken out directly and cooled at room temperature. The performance test of the sintered body is shown in Table 8.

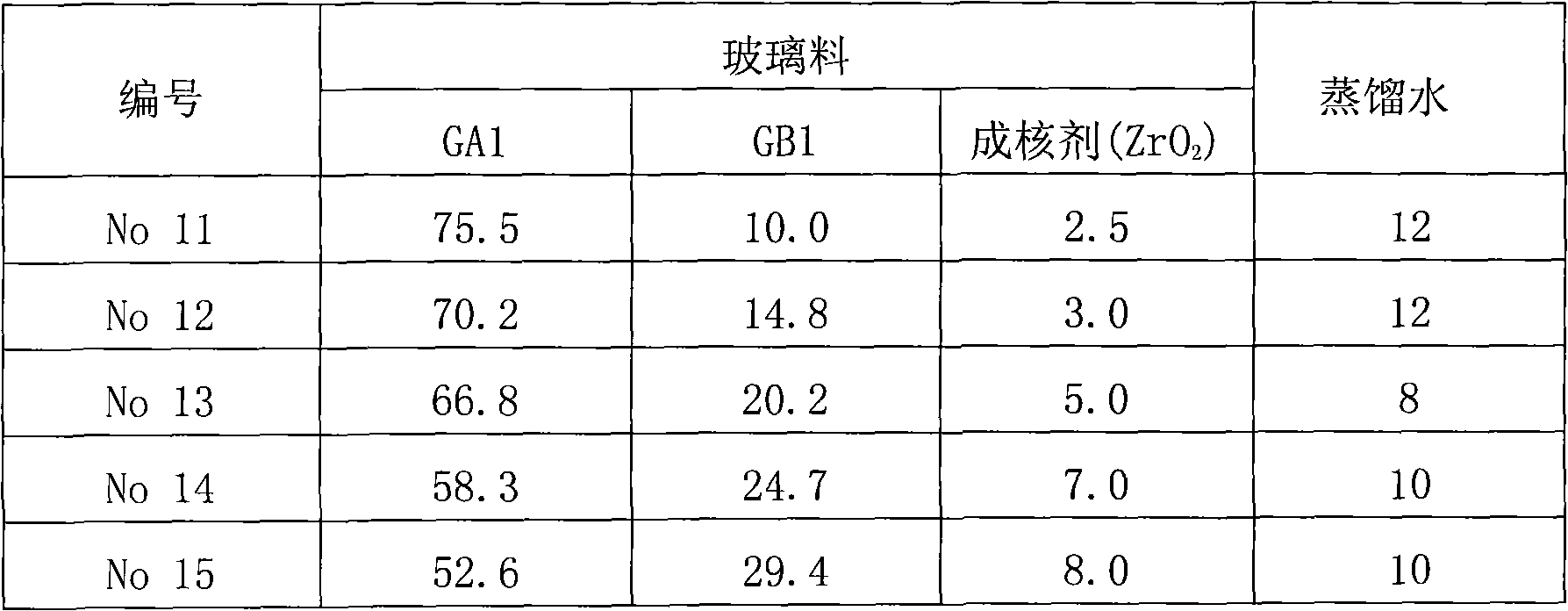

[0041] Table 7 High-frequency low-loss glass ceramic components content (wt%)

[0042]

[0043] Table 8 Performance of high-frequency low-loss glass ceramics

[0044] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com