Micro-pore firework powder capable with improved fire ignition and transfer properties and preparation method thereof

A micro-porosity and performance technology, applied in explosives, offensive equipment, nitrification explosive components, etc., can solve the problems of no hot solid products, low ignition and fire transfer ability, etc., and achieve the effect of improving fire transfer speed and ignition ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

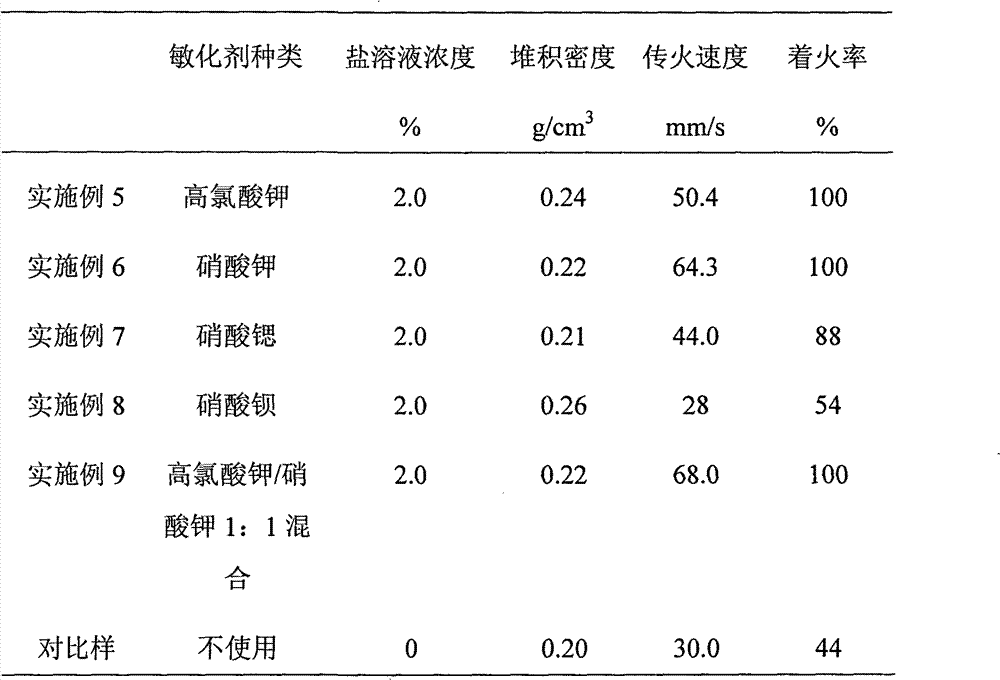

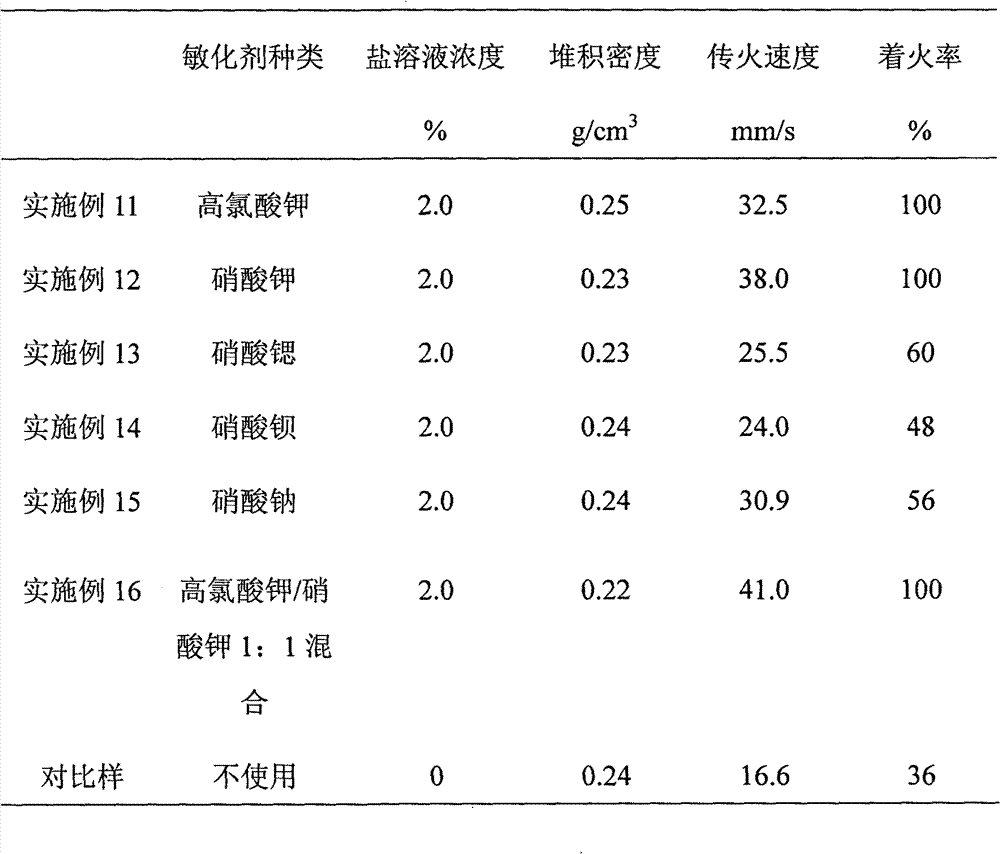

Examples

preparation example Construction

[0010] A method for preparing a microporous firework drug with improved point-to-fire performance, comprising the following steps: first dissolving materials, emulsifying and foaming, forming balls, then removing solvents, separating materials, and finally drying; dissolving and emulsifying materials When foaming, add the aqueous solution of the sensitizer; during the ball forming process, add the aqueous solution containing the sensitizer and the dispersant as the dispersion medium; the concentration of the aqueous solution of the sensitizer is the same. The sensitizer is one or more mixtures of nitrates and perchlorates of alkali metals or alkaline earth metals; it can be one of sodium nitrate, potassium nitrate, barium nitrate, strontium nitrate, sodium perchlorate, and potassium perchlorate one or a mixture of several. The concentration of the sensitizer in the sensitizer aqueous solution is 0.1-5.0%, and the mass of the sensitizer is 0.2-10% of the mass of the crude drug....

Embodiment 1

[0022] Single-base waste powder with a nitrocellulose content greater than 85% is used as the raw material drug. After preliminary crushing, the particle diameter is controlled to be no more than 3mm. The wet drug granules with water are added to the molding equipment, and 10 times the drug granules are added under stirring. High quality ethyl acetate solvent, stir and dissolve at 45°C-50°C for 30-60min, then continuously add 1% potassium nitrate aqueous solution to the system, potassium nitrate as a sensitizer; emulsify and foam under stirring Operation, in this step, continue to add 1% potassium nitrate aqueous solution, the amount of potassium nitrate aqueous solution added is 6 times the mass of the pellets, then continue to stir at 50-60°C for 30min-60min, and adjust the system temperature to 65 At -68°C, add 6 times the mass of the raw material drug containing dispersant and 1% potassium nitrate aqueous solution into the system to disperse into balls, gelatin is used as d...

Embodiment 2

[0024] Using the same process as in Example 1, adopting single-base waste gunpowder with a nitrocellulose content greater than 85% as a raw material, using potassium nitrate as a sensitizer, only dissolving and emulsifying foaming and using potassium nitrate as a ball-forming medium The concentration of the solution is all reduced to 0.1%, and the bulk density of the obtained sample is 0.21g.cm -3 . The test result of potassium nitrate content in the sample was 0.20%. The particle size is mainly concentrated in 300-2000um. After drying, the 20-40 mesh part is screened out, and the fire transmission speed is 35mm / s. Using a firework bomb with an inner diameter of 25mm, put 25 red bright beads and 3 grams of microporous powder into the explosion test to test the ignition rate of the bright beads. The ignition rate of the sample prepared by adding 0.1% potassium nitrate in the solution 48%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com