Self-cleaning trigger connector system

a technology of trigger connectors and self-cleaning, which is applied in the field of self-cleaning firearm trigger stop mechanisms, can solve the problems of existing system lock-up and fail to function, serious injury or death, and reduce accuracy and precision when firing, so as to reduce accuracy, prevent over-manipulation, and increase the speed of firing a firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

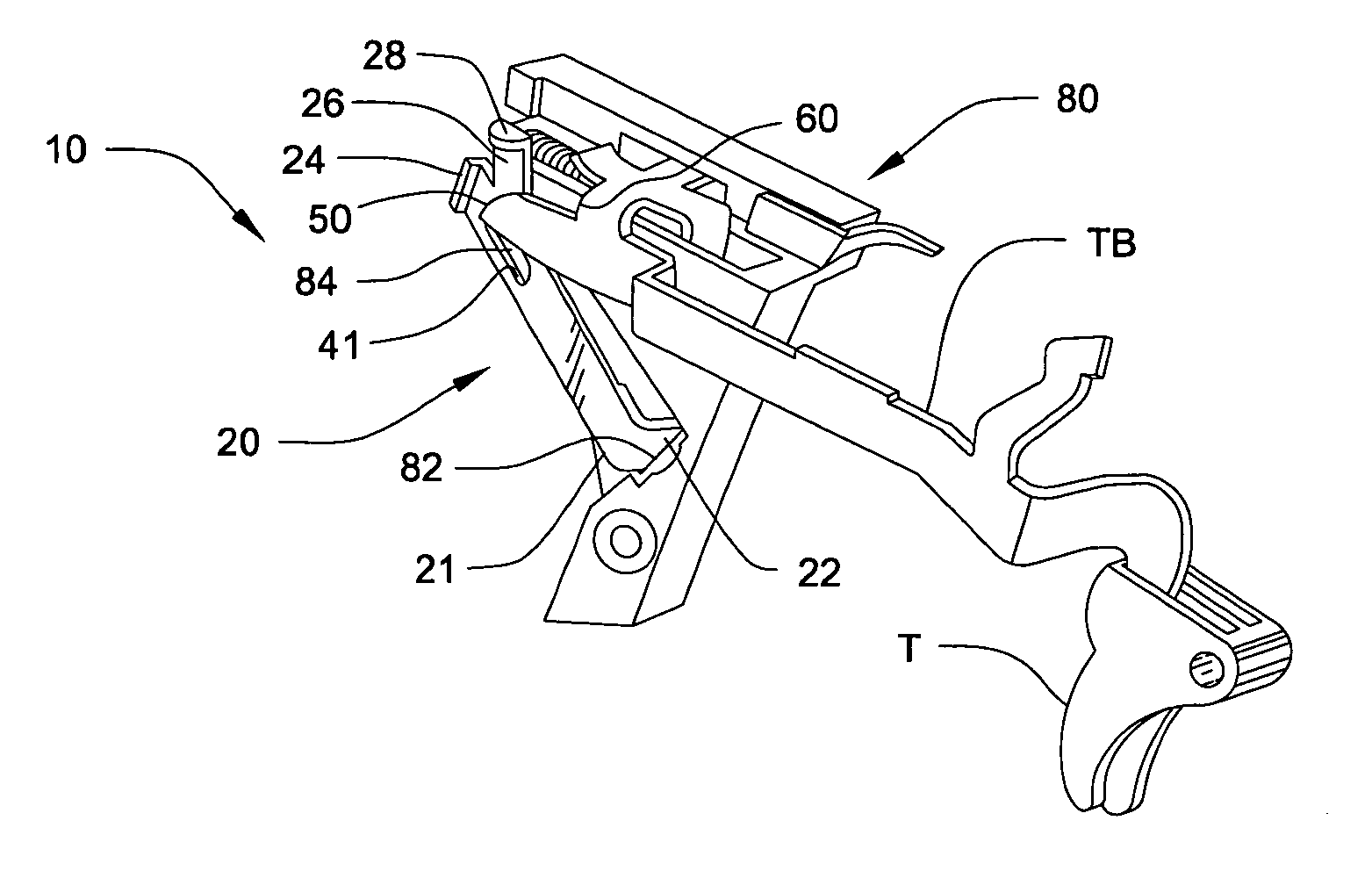

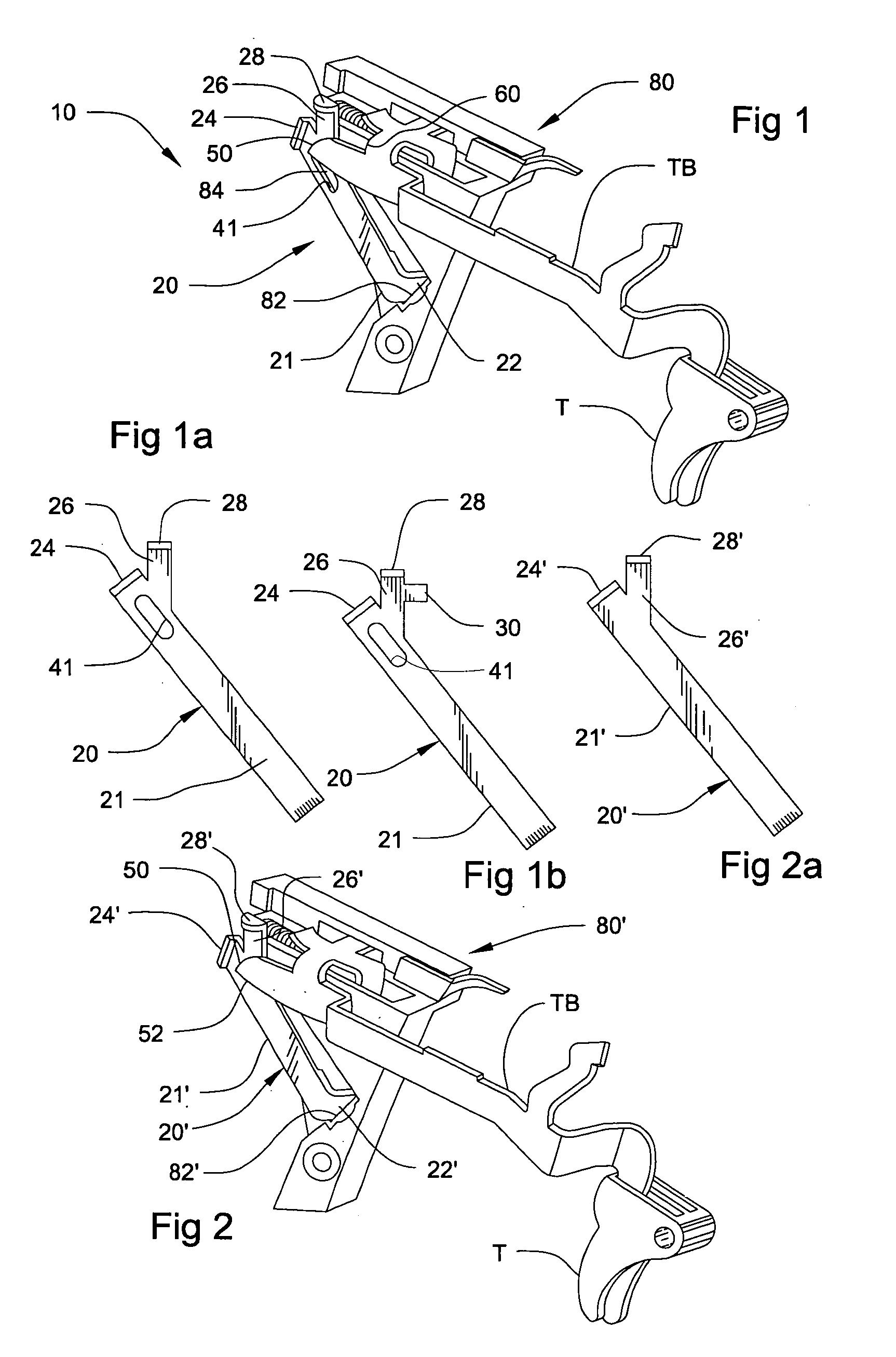

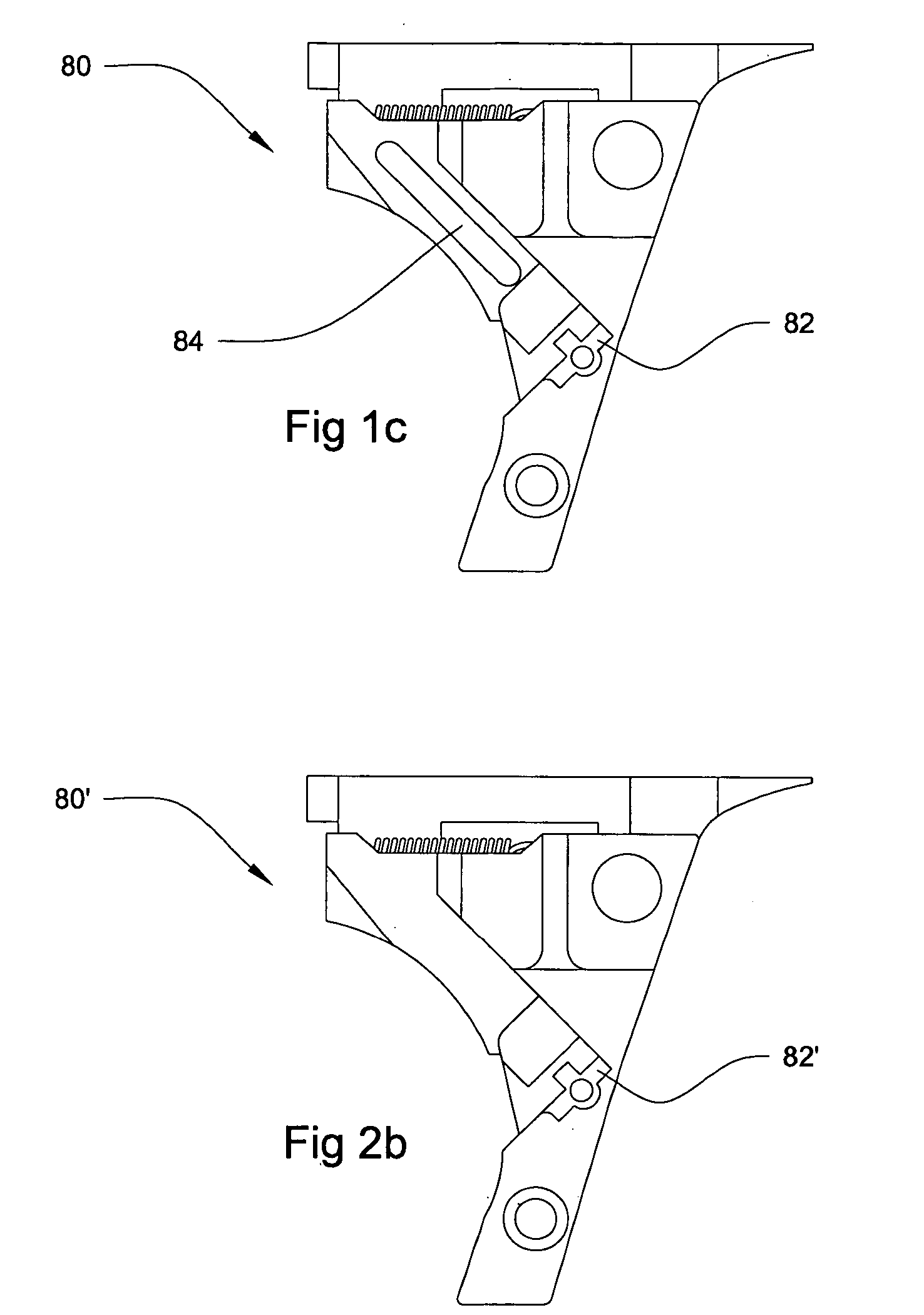

[0037] Referring now to the drawings, where the present invention is generally referred to with numeral 10, it can be observed that it basically includes self-cleaning trigger connector 20, bent at predetermined locations to permit its mechanical transactions to effectuate a self-cleaning trigger connector mechanism, and trigger mechanism housing 80. Instant invention 10 is made out of a durable and lightweight material as stainless steel, alloy metal, or other material having similar characteristics. In the preferred embodiment, self-cleaning trigger connector 20 is manufactured as a single metallic piece and has a general consistent thickness throughout of approximately 0.65 mm to 1.25 mm, so as to cooperatively interact with the general trigger mechanism of semiautomatic firearms that have an enclosed striker assembly. Such a firearm may be “GLOCK”, without limitation to this specific brand.

[0038] As seen in FIG. 1, self-cleaning trigger connector 20 and trigger mechanism housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com