Microcrystal glass combined plate material and its production technology

A glass-ceramic and vitrification technology, which is applied in the field of building decoration materials, can solve the problems of difficult to achieve the texture of natural stone, consume a lot of manpower and material resources, and have a long production cycle, and achieve low porosity, save mold consumption, and burn speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing:

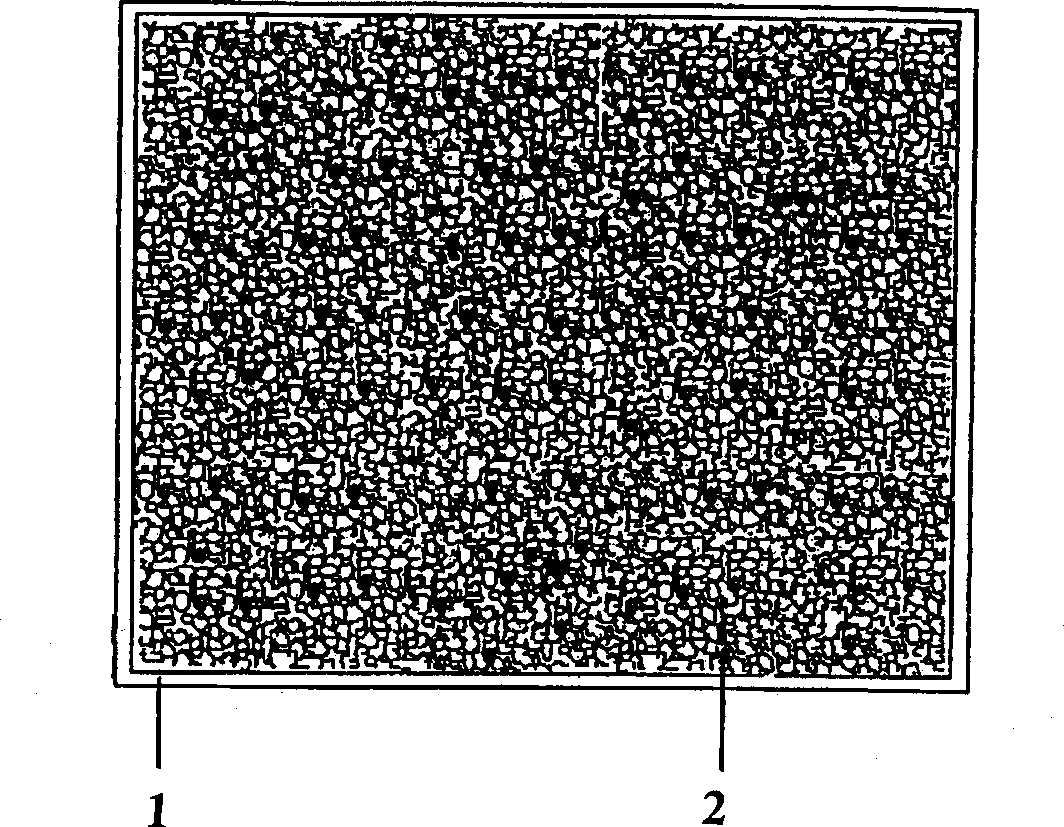

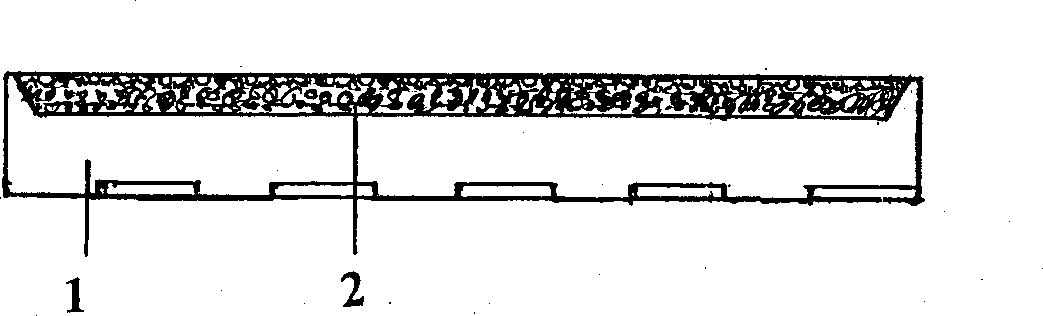

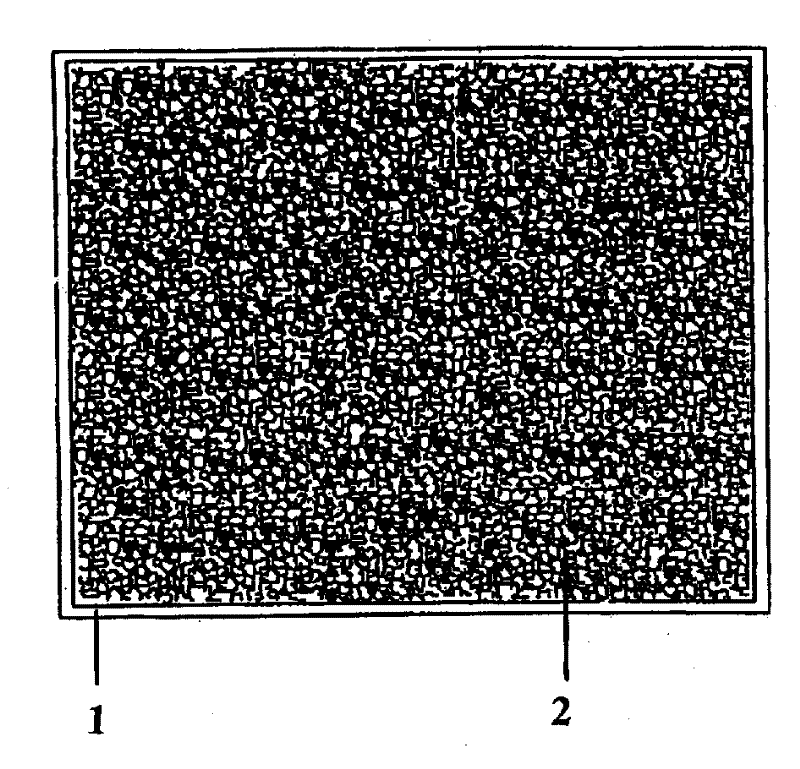

[0028] The structure of the embodiment of the ceramic-glass-ceramics composite plate of the present invention is as follows: figure 1 , figure 2 As shown, it includes a bottom layer 1 made of vitrified brick material combined from bottom to top, and a surface layer 2 made of glass-ceramic material.

[0029] The production process of the embodiment of the present invention composite plate:

[0030] 1. The chemical composition of the vitrified plate (weight%):

[0031] The vitrified plate is composed of clay, quartz, feldspar sand, talc and other components, and its content range is:

[0032] al 2 o 3 15%~22% (weight), SiO 2 67%~74% (weight),

[0033] K 2 O, Na 2 O 4%~10% (weight), CaO<1% (weight),

[0034] MgO2 o 3 <1%,

[0035] And adopt the following method to prepare:

[0036] (1) Clay, quartz and feldspar sand are made into mud by ball milling; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com