Admixture for dry-process cement kiln clinker production

A dry-process cement and admixture technology, applied in the field of building material admixtures, can solve the problems of low steel slag utilization, environmental impact, imperfections, etc., and achieve the effects of saving coal consumption, increasing production, and accelerating firing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

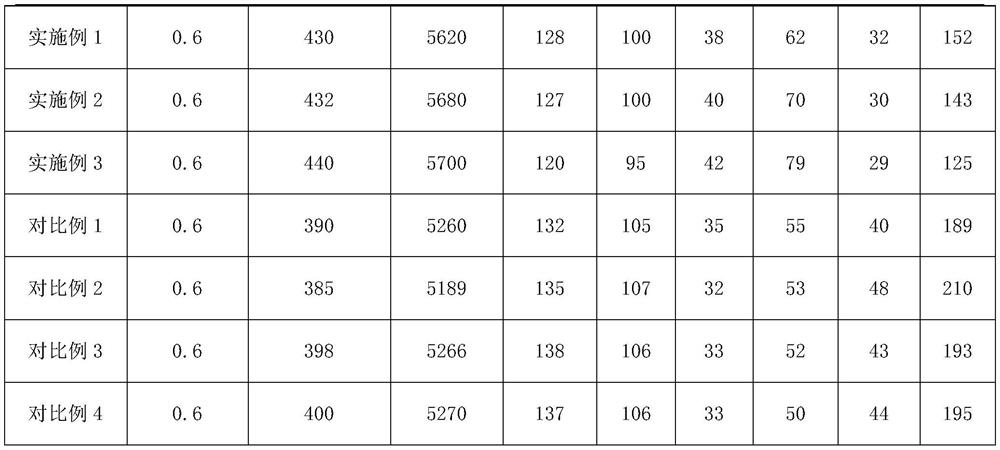

Embodiment 1

[0027] An admixture for the production of clinker in a dry cement pit is composed of the following raw materials in parts by weight: 3% of rare earth, 40% of fluorite, 3% of nanometer metal powder, 48% of gypsum, 5% of modified steel slag powder, Glycerin 1%.

[0028] The water content of the rare earth is less than 2%.

[0029] Nano metal powder is nano titanium dioxide powder.

[0030] Modified steel slag powder is prepared by the following method:

[0031] 1) After cleaning the steel slag, dry it, grind it to obtain steel slag powder, add montmorillonite powder and starch, add water and stir evenly to obtain a mixed slurry, the amount of water added is twice the mass of the steel slag powder;

[0032] 2) Adding step (1) sodium sulfate solution with 0.1% mass of the mixed slurry and polyethylene glycol with 0.3% mass of the mixed slurry, mix evenly, and ball mill in a planetary ball mill for modification;

[0033] 3) After fully drying the modified slurry, press it into t...

Embodiment 2

[0037] An admixture for the production of clinker in a dry cement pit is composed of the following raw materials in parts by weight: 7% of rare earth, 30% of fluorite, 7% of nanometer metal powder, 45% of gypsum, 8% of modified steel slag powder, Glycerin 3%.

[0038] The water content of the rare earth is less than 2%.

[0039] Nano metal powder is nano titanium dioxide powder.

[0040] Modified steel slag powder is prepared by the following method:

[0041] 1) After cleaning the steel slag, dry it, grind it to obtain steel slag powder, add montmorillonite powder and starch, add water and stir evenly to obtain a mixed slurry, the amount of water added is twice the mass of the steel slag powder;

[0042] 2) Adding step (1) sodium sulfate solution with 0.3% mass of the mixed slurry and polyethylene glycol with 0.5% mass of the mixed slurry, mix evenly, and ball mill in a planetary ball mill for modification;

[0043] 3) After fully drying the modified slurry, press it into t...

Embodiment 3

[0047] An admixture for the production of clinker in a dry cement pit is composed of the following raw materials in parts by weight: 10% of rare earth, 20% of fluorite, 10% of nanometer metal powder, 50% of gypsum, 10% of modified steel slag powder, Glycerin 5%.

[0048] The water content of the rare earth is less than 2%.

[0049] Nano metal powder is nano titanium dioxide powder.

[0050] Modified steel slag powder is prepared by the following method:

[0051] 1) After cleaning the steel slag, dry it, grind it to obtain steel slag powder, add montmorillonite powder and starch, add water and stir evenly to obtain a mixed slurry, the amount of water added is twice the mass of the steel slag powder;

[0052] 2) Adding step (1) sodium sulfate solution with 0.5% mass of the mixed slurry and polyethylene glycol with 0.8% mass of the mixed slurry, mix evenly, and modify by ball milling in a planetary ball mill;

[0053]3) After fully drying the modified slurry, press it into tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com