Patents

Literature

66results about How to "Improve firing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Road silicate cement clinker and preparation method thereof

InactiveCN104496228AImprove flexural performanceImprove wear resistanceCement productionHigh fractureShrinkage rate

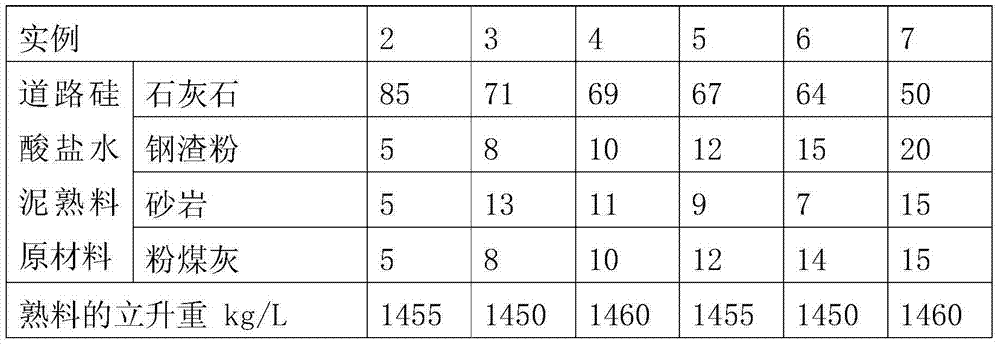

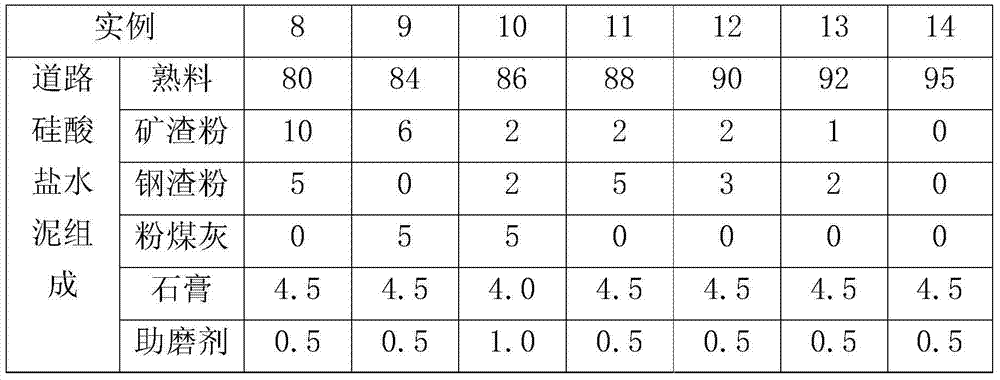

The invention relates to road silicate cement clinker and a preparation method thereof. The preparation method for the road silicate cement clinker comprises the following steps: grinding and roasting a cement raw material, wherein the cement raw material consists of the following substances in parts by weight: 50-85 parts of lime stones, 5-20 parts of steel slag powder, 5-15 parts of sandstones and 5-15 parts of coal ash. The preparation method can be used for recycling the steel slag, grinding the steel slag into powder after drying, and adopting the prepared steel slag powder as a cement production raw material to prepare road silicate cement clinker with low heat and high fracture resistance, so that the sintering quality of the clinker can be effectively improved after the steel slag powder is added. On the basis of meeting the technical requirements specified in the road silicate cement national standards, the road silicate cement clinker can be used for improving the fracture resistance and wear resistance of the cement, and lowering the hydration heat evolution and the dry shrinkage rate.

Owner:CHINA BUILDING MATERIALS ACAD

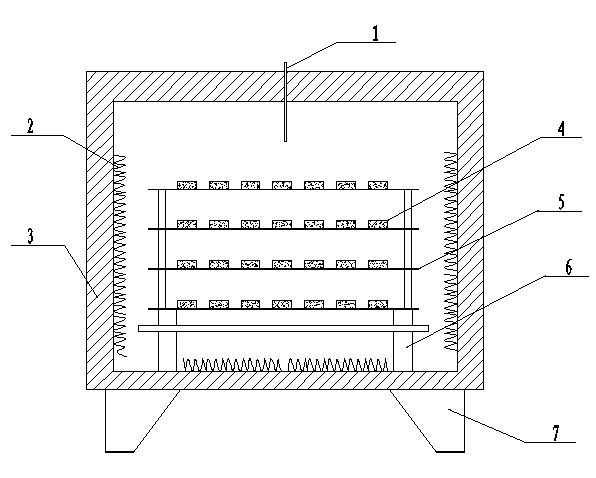

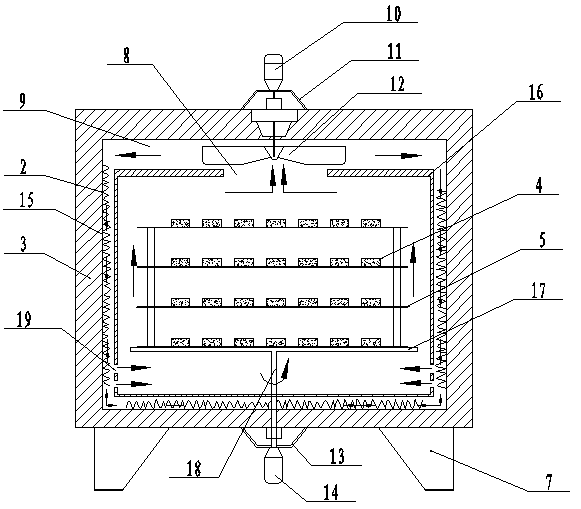

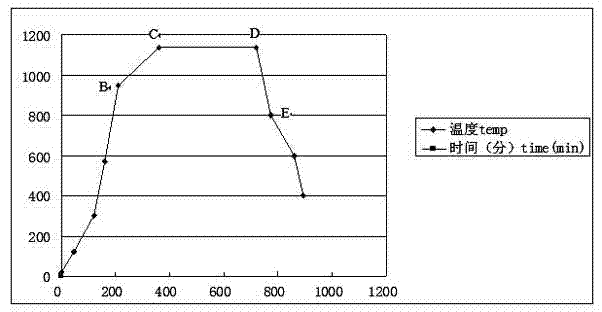

High temperature sintering resistance furnace

InactiveCN102798286AImprove uniformityGuaranteed uniformityLighting and heating apparatusInsulation layerEconomic benefits

A high temperature sintering resistance furnace comprises a hearth with an insulation layer, wherein the lower part of the hearth is supported by a base, kiln furniture is arranged in the hearth, and an in-furnace hot air circulation system and a rotating device for bearing a workpiece are arranged in the hearth. The uniformity of temperatures at different parts of the high temperature sintering resistance furnace is well guaranteed, particularly when a large batch of workpieces are loaded, the thermotechnical effect deviation in the traditional furnace is eliminated through force convection and kiln furniture rotation, and meanwhile, the sintering atmosphere in the furnace is effectively regulated and improved andthe sintering quality of the workpiece is improved; and the temperature uniformity is excellent, the furnace volume can be sufficiently used, the yield of single furnace can be substantially improved, the energy consumption of single product is reduced, and the economic benefit and the practical value are very high.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

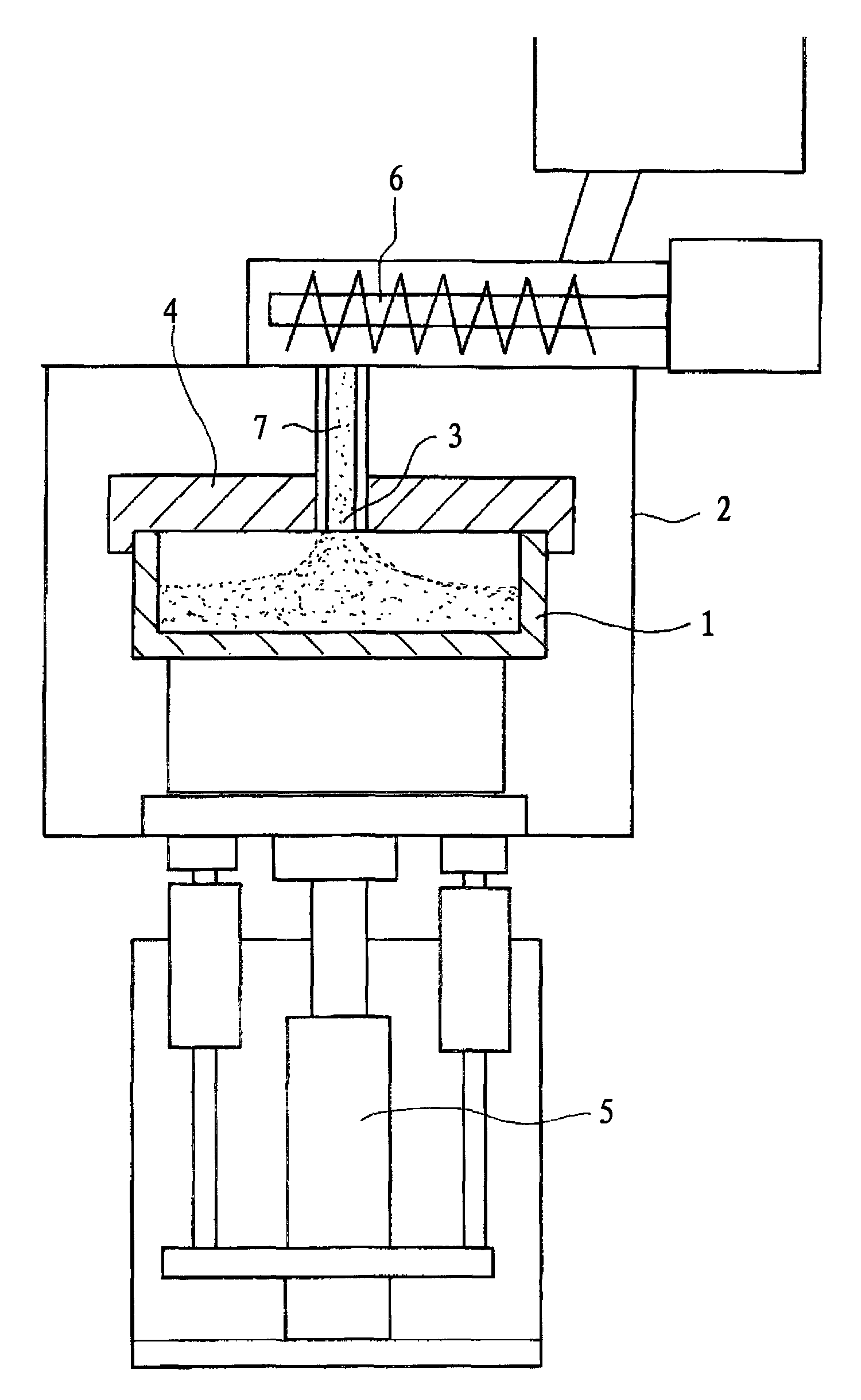

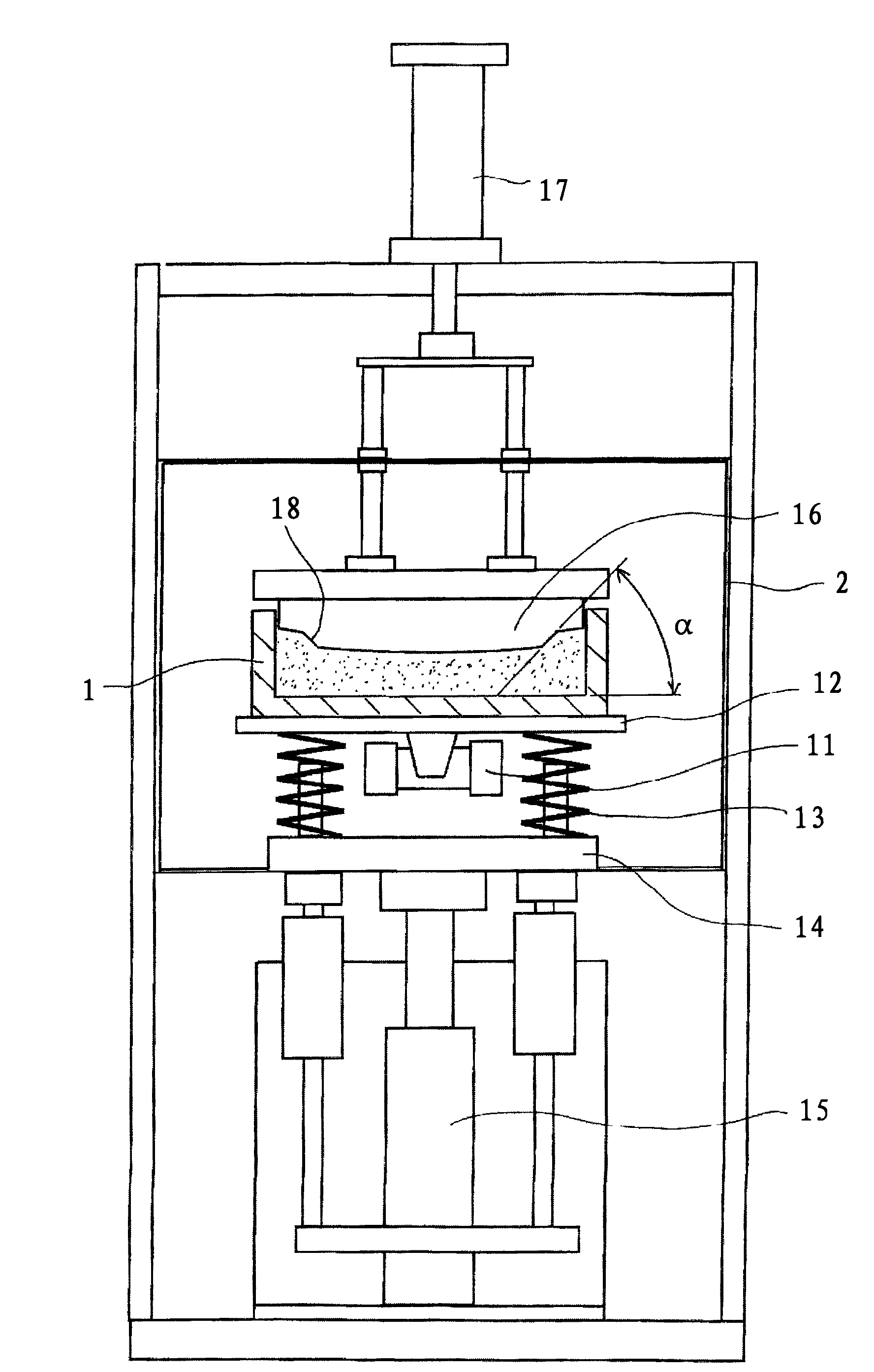

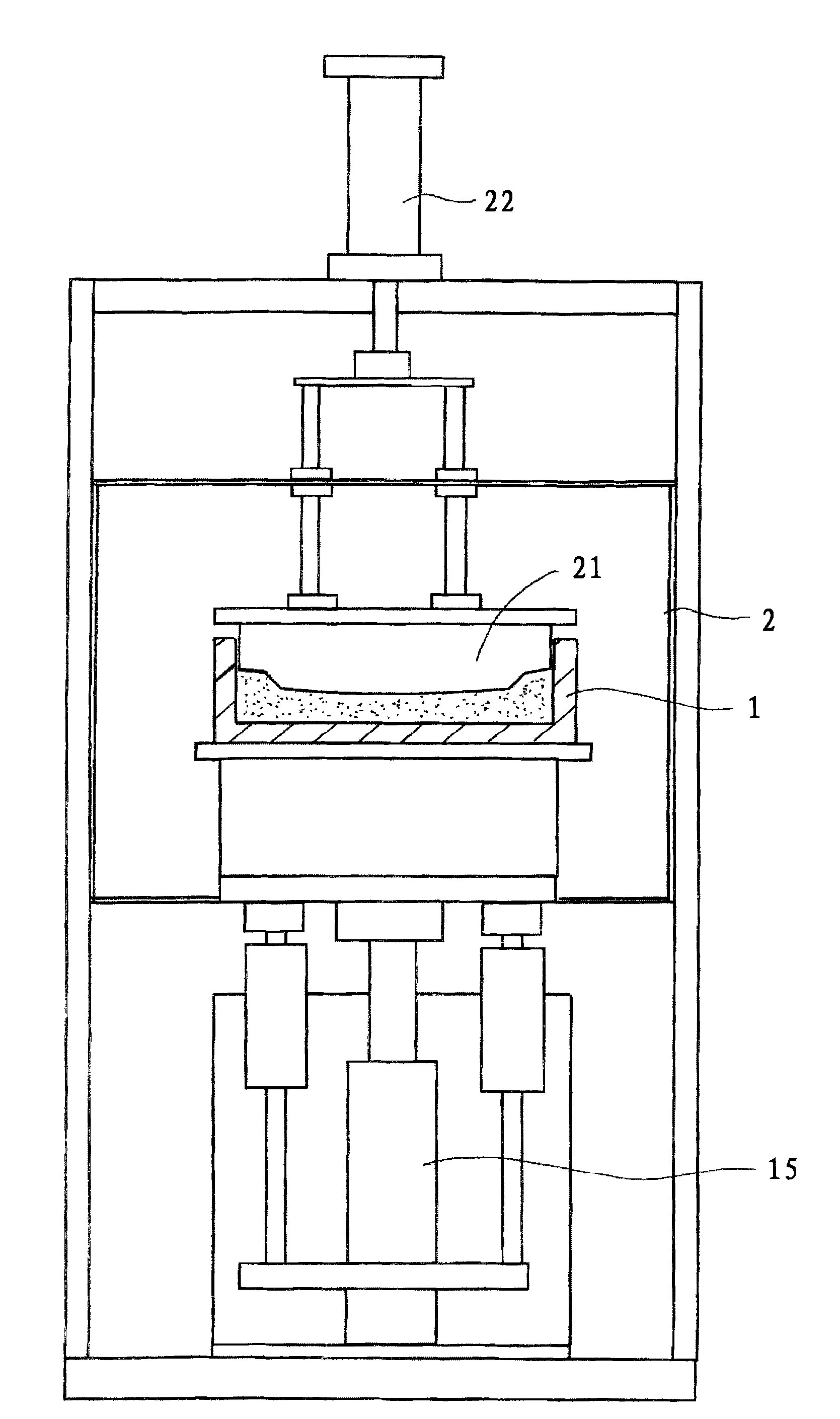

How to fill the inside of the sagger with powder

ActiveCN102275746AEasy transferWeight increaseElectrode manufacturing processesShaping press ramCooking & bakingMaterials science

PROBLEM TO BE SOLVED: To provide a method for packing powder which is in a dry state and made to have a surface shape formed by making the thickness of the central part of the powder thicker and the thickness of the peripheral part of the powder thinner in a sagger in a compacted state.SOLUTION: A prescribed amount of the dry powder is supplied into the sagger 1. While a first pressing plate 16 is brought down to a prescribed position to a powder surface, vibration is applied to the sagger 1, and the powder surface is formed in a shape in which the middle is hollowed according to the lower surface shape of the first pressing plate. Next, the formed powder surface is pressed down further by a second pressing plate 17 to compact the powder. In this way, the productivity of a burning process and the quality of baking can be improved.

Owner:NGK INSULATORS LTD

Energy-saving ceramic fire resistant bearing board

InactiveCN1724964AChange the heating methodChange the state of heatingCharge supportsBrickCombustion chamber

The invention is an energy-saving ceramic flame-resistant bearing firing plate, for solving the technical problem of making the glazed outside wall bricks fired by the same kiln have no obvious color difference but small deformation, thus improving the quality of finished products, and besides, for strengthening the intensity of bearing firing plate, reducing its breakage rate. For this, the invention fills ribs and blanks at the bottom of the bearing firing plate, where a through hole is equipped within each blank. The blanks and holes can be regularly shaped or irregularly shaped. The invention is mainly used in ceramic kiln to bear and transport the fired ceramic blanks in the course of firing and especially applied to the glazed outside wall blanks.

Owner:康健伟

Method for preparing corundum abrasive by microwave sintering

InactiveCN107445595AReduce production energy consumptionLower sintering temperatureOther chemical processesMicrowave sinteringEnergy consumption

The invention discloses a method for preparing corundum abrasive by microwave sintering, and belongs to the technical field of abrasive preparation. The corundum abrasive comprises the following raw materials in percentage by weight: 95-98% of Al2O3, 0.5-2.5% of SiO2, 0.5-1% of MgO, 0.2-1% of TiO2, 0.2-1% of MnO2, and 0.1-1% of CuO. The method comprises the following steps: mixing the raw materials; molding; crushing; sieving; grading; performing rubber removing; transferring the rubber-removed blank particles into an SiC crucible; increasing the temperature to reach 1300-1500 DEG C at the rate of 10-20 DEG C per minute; then maintaining the temperature for 5-30min, and performing microwave sintering to obtain the corundum abrasive. With the adoption of the method, energy consumption of the corundum abrasive production can be greatly decreased; in addition, the blank particles are in contact with each other, so that the clearances among the particles are small, the temperature gradient of a sintered body can be reduced, the sintering time is greatly decreased, and as a result, the corundum abrasive sintering quality can be improved.

Owner:河南建筑材料研究设计院有限责任公司

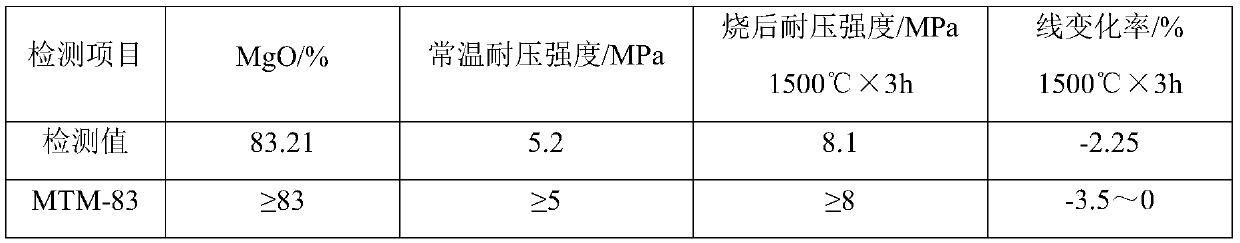

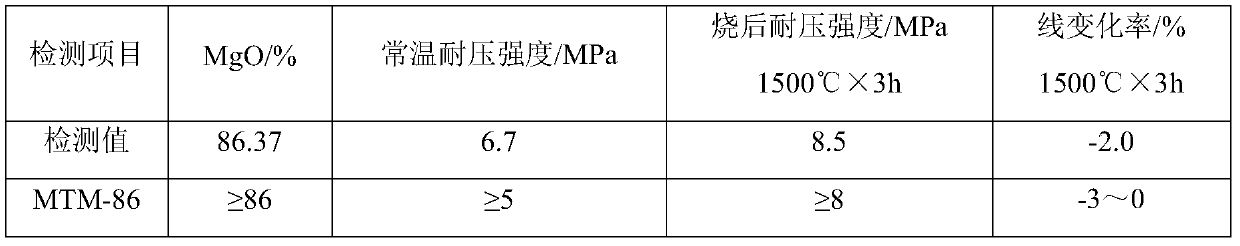

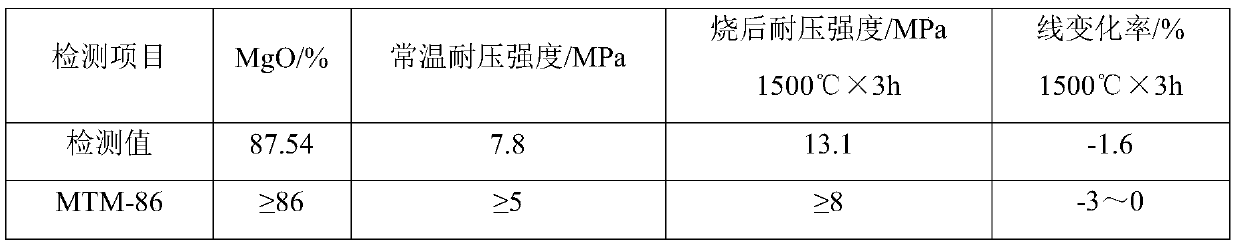

Tundish magnesia coating and preparation method thereof

The invention belongs to the technical field of refractory materials, and particularly relates to a tundish magnesia coating taking a post-burn regenerated magnesia carbon material as a main raw material and a preparation method thereof. The coating is characterized in that a waste magnesium carbon brick is dried, iron-removed and broken, sufficient burning is conducted at a high temperature, and after drawing, molten tumors and residues remaining on the surface of a reclaimed material are manually cleaned up; after breaking, the insufficiently burnt parts in the middle are manually picked out, the burning rate being 90% is achieved, re-breaking is conducted, and the post-burn regenerated magnesia carbon material with different particle sizes and the MgO content larger than 85 wt% is obtained, so that the tundish magnesia coating taking the post-burn regenerated magnesia carbon material as the main raw material is stable in performance, high in strength, good in demolding, excellent in construction performance and low in cost, and circulating utilization of waste refractory materials is achieved.

Owner:瑞泰马钢新材料科技有限公司

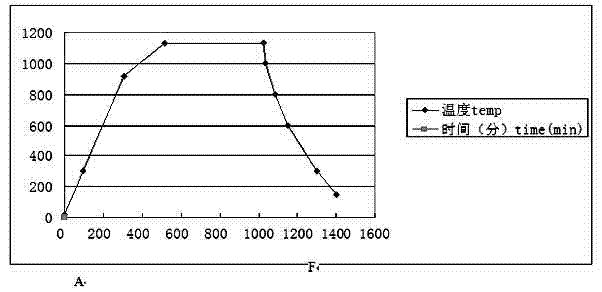

Control method for firing high-performance quartz ceramic

The invention provides a control method for firing high-performance quartz ceramic, which comprises the following steps: selecting high-purity (higher than 99.00%) quartz sand with reasonable grain size distribution, adding water, carrying out ball milling, homogenizing, adding the other two raw materials, carrying out secondary grain size distribution, stirring to injecting dynamic slurry into a mold, curing, and firing in a batch type kiln or progressive kiln through a six-step method, including low temperature stage, oxidative decomposition and crystal form transition stage, re-oxidative decomposition and firing stage, high temperature holding stage, cooling stage and recooling stage, thereby obtaining the high-performance quartz ceramic. The firing method provided by the invention saves the energy, promotes the development and utilization of high-performance quartz ceramic raw materials and natural gas, and effectively controls the firing temperature curve of the high-performance quartz ceramic; and the fired quartz ceramic has the advantages of uniform internal structure, excellent thermal shock stability and excellent rupture resistance. The operating process is stable, and implements low-carbon low-pollution emissions.

Owner:苏州先才新材料科技有限公司 +1

Isostatic pressing electrical porcelain blank formula with non-plasticity clay used as raw material

The invention provides an isostatic pressing electrical porcelain blank formula with non-plasticity clay used as raw material. The formula comprises the following components, by weight, 48%-55% of alumina, 18%-25% of feldspar flux, 15%-25% of calcined clay and 5%-15% of viscous agents. The formula takes chemically-synthesized viscous agents as viscous materials to replace plastic clay used in existing ingredients. Therefore, the non-plasticity clay can be used to replace scarce plastic clay raw materials. The cost of blank materials is reduced. The dependence of isostatic pressing electrical porcelain blanks on one-off resources is reduced.

Owner:CHINA XD ELECTRIC CO LTD

An archaized brick

The invention discloses an archaized brick and belongs to the technical field of ceramic bricks. A blank of the archaized brick is prepared from 21% by weight of bauxite, 7% by weight of magnesian soil, 6% by weight of bentonite, 11% by weight of a material named as a Chinese character 'Tingqiansha' by the inventor, 18% by weight of a material named as a Chinese character 'Tailisha' by the inventor, 12% by weight of a material named as a Chinese character 'Ruichangtu' by the inventor, 15% by weight of mica and 10% by weight of a material named as a Chinese character 'Hushatou' by the inventor. According to firing temperature of the archaized brick, surface temperature is 860-1015 DEG C and bottom temperature is 960-1010 DEG C in a front temperature zone, surface temperature is 1035-1128 DEG C and bottom temperature is 1025-1120 DEG C in a middle temperature zone, and surface temperature is 1125-1200 DEG C and bottom temperature is 1130-1205 DEG C in a high-temperature zone. By adjusting blank components and ratios of the archaized brick, archaized bricks with different specifications can be fired in a same kiln, thus avoiding building of a plurality of kilns and reducing investment. The archaized brick is advantaged by good color and lustre, high hardness, low water absorption, high wear resistance, and the like. Firing quality of the archaized brick is greatly improved.

Owner:湖北兴成建陶股份有限公司

Graphite heater furnace

The invention relates to a graphite heater furnace, in particular to a graphite heater furnace with multiple levels of graphite heating bodies of heating rods which are arranged in the horizontal direction inside a heating space part of a furnace body and capable of forming uniform temperature distribution on a burned object and improving the burning quality of the burned object. In order to realize the purpose, the graphite heater furnace comprises a housing, a furnace body which is arranged inside the housing and composted of an insulation body and graphite heating body which is arranged in a heating space part inside the furnace body and can produce heat, wherein the graphite heating bodies are horizontally arranged and distributed in multiple levels, the burned object is arranged on the heating rods in the heating space part inside the furnace body, and the outer periphery of the furnace body is provided with a cooling water trough.

Owner:喏莫里克株式会社 +1

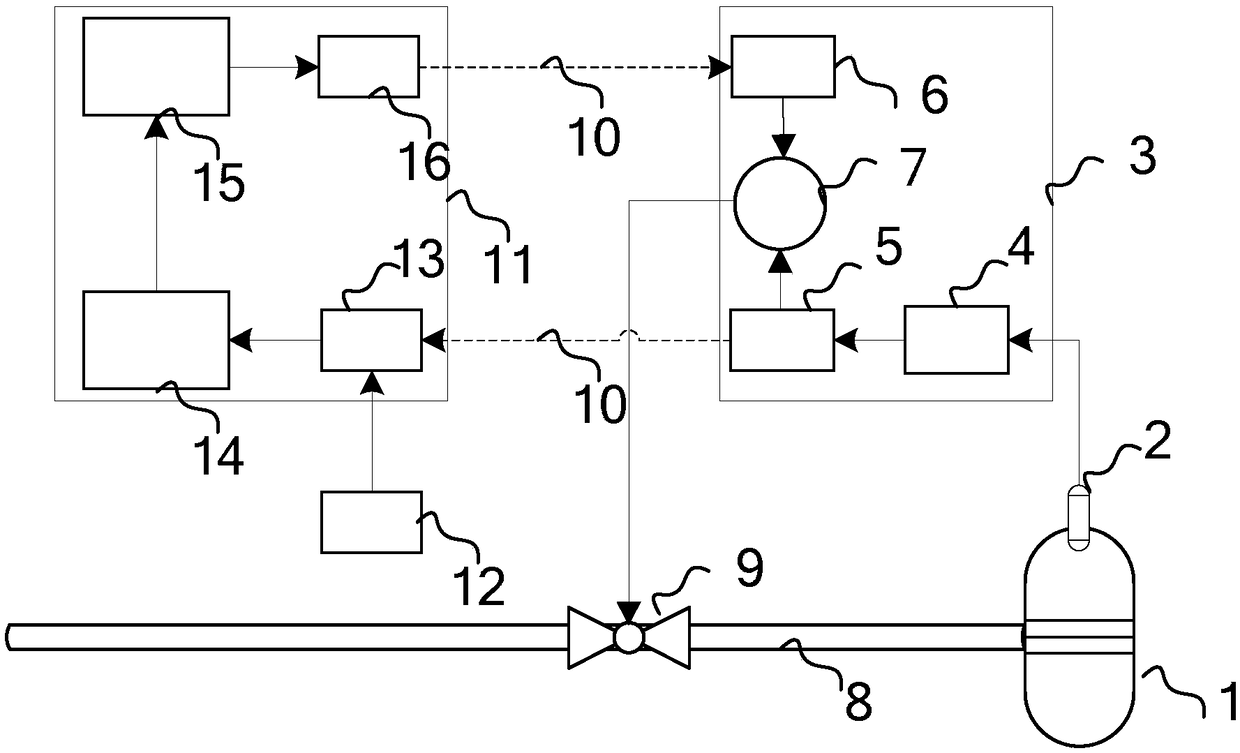

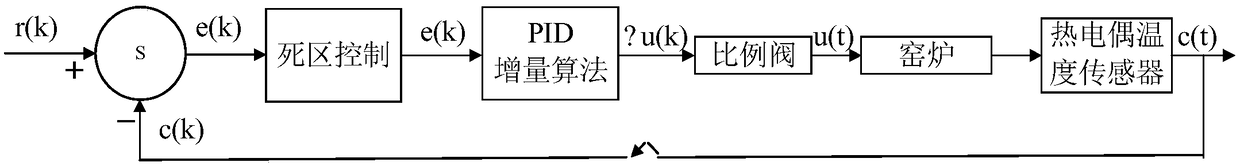

Intelligent optimization method for temperature control of ceramic kiln

InactiveCN108931144AImprove firing qualityControl devices for furnacesTemperature controlTemperature curve

The invention discloses an intelligent optimization method for temperature control of a ceramic kiln. The intelligent optimization method comprises the following specific steps that step (1), during each firing process, a kiln controller performs PID control on the kiln temperature according to the set kiln temperature control curve through a PID control module; step (2), after each completion offiring, the kiln controller transmits the actual temperature data in the kiln to a PC through wireless communication; step (3), the ceramic firing result is scored and evaluated by a firing technician, and the score is input into the PC and forms a sample with the actual temperature data; step (4), the PC optimizes the kiln temperature curve according to the samples through the genetic algorithm;and step (5), the optimized temperature control curve is transmitted by the PC through wireless communication to the kiln controller for control of the next ceramic firing process. The intelligent optimization method achieves the effect of improving the quality of ceramic firing by optimizing the kiln temperature control curve.

Owner:HANGZHOU DIANZI UNIV

Multifunctional ceramic firing kiln and manufacturing method of porcelain thereof

The invention discloses a multifunctional ceramic firing kiln and a manufacturing method of porcelain of the multifunctional ceramic firing kiln. The multifunctional ceramic firing kiln can fire pottery and the porcelain, the firing effect of the pottery and the porcelain is good, implementation is easy, and the firing effect is good. The multifunctional ceramic firing kiln comprises a kiln body. The kiln body is provided with an electric heating device and a fuel gas heating device at the same time. The electric heating device comprises an electric heating body, and the fuel gas heating device comprises a gas mixing device. The method includes the steps that in the heating firing process, when the temperature of a kiln chamber rises to a certain numerical value, a blank in the kiln chamber and / or kiln gas in the kiln chamber are / is fully oxidized, the kiln chamber is heated through furnace gas, certain carbon monoxide is generated in the kiln chamber through fuel gas combustion, reduction flames are generated, and the porcelain blank in the kiln chamber continues being heated and fired.

Owner:景德镇市英才科技有限公司

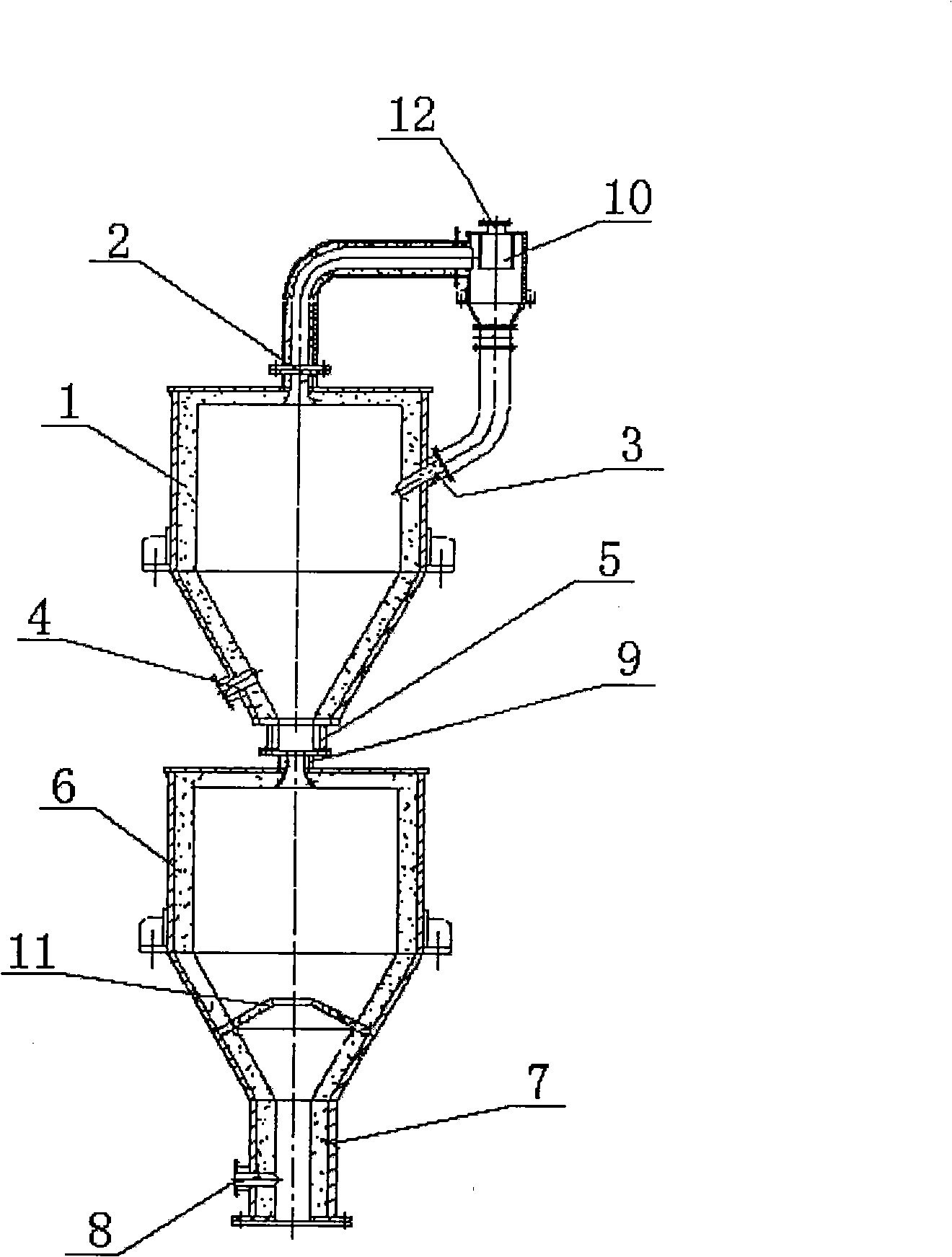

Method for drying and burning alkali-containing aluminosilicate slurry

ActiveCN101264911AObvious technical advantagesImprove heat transfer efficiencyChemical industryAluminium oxides/hydroxidesChemical reactionEngineering

The invention relates to a method of drying and burning alkaliferous aluminosilicate slurry, which is characterized in that the comprises two steps of atomizing drying and circular burning, the atomized slurry fogdrop is to contact with the vertically risen thermal current for drying, and then entering the firing furnace after circulation and growing; the slurry is continuously and circularly burnt in the furnace, the quality is preferably and the product is finished when the agglomerate material with higher specific gravity is out of the firing furnace. The method of the invention has the advantages that the slurry is fully atomized, the powdery material can fully contact with high temperature fume, and the heat exchange is promptly and completely with high heat transfer efficiency and low thermal loss. The sintering time of the powdery material in the furnace is short, the chemical reaction of material is fully, the unit volume productive capacity is higher with simple technological process and equipment, long performance period and low maintenance cost. The powdery material can realize closed feeding and closed discharge with slight dust pollution for environment.

Owner:中铝中州铝业有限公司

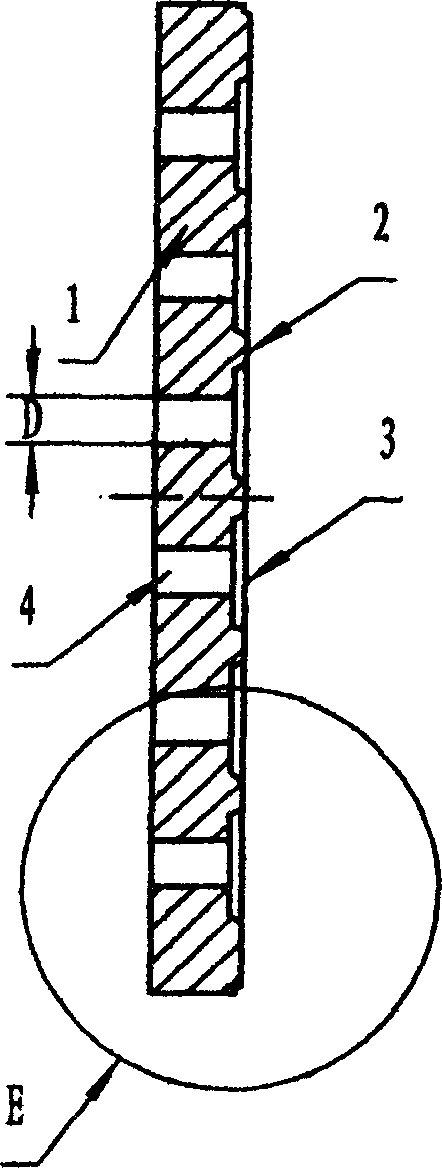

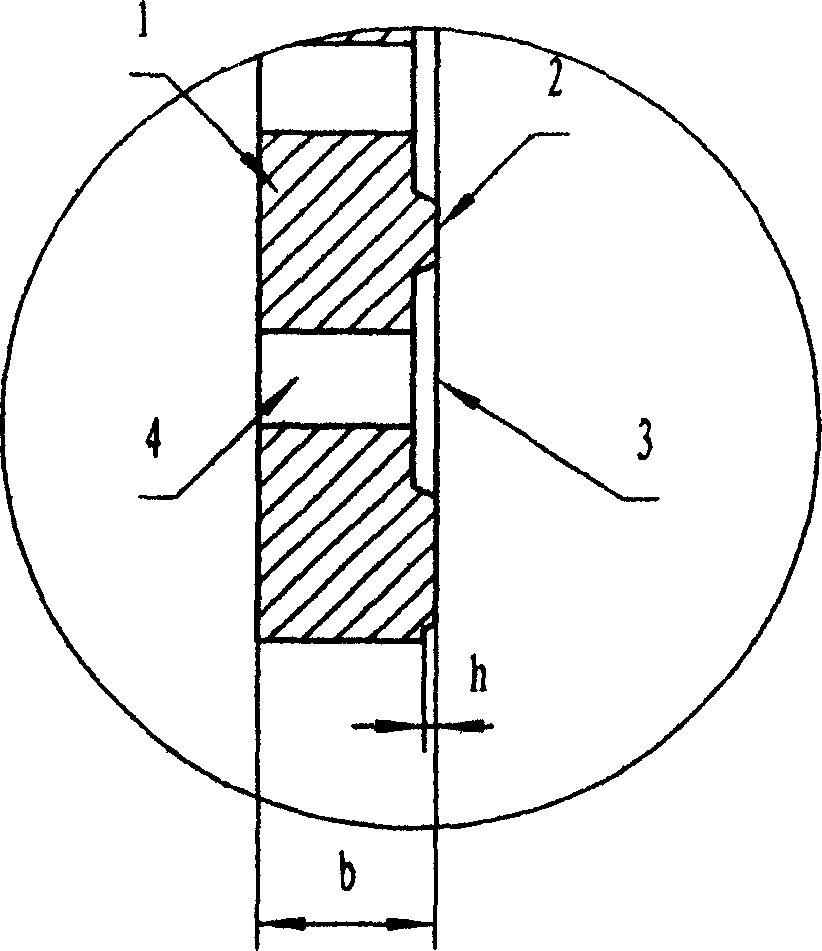

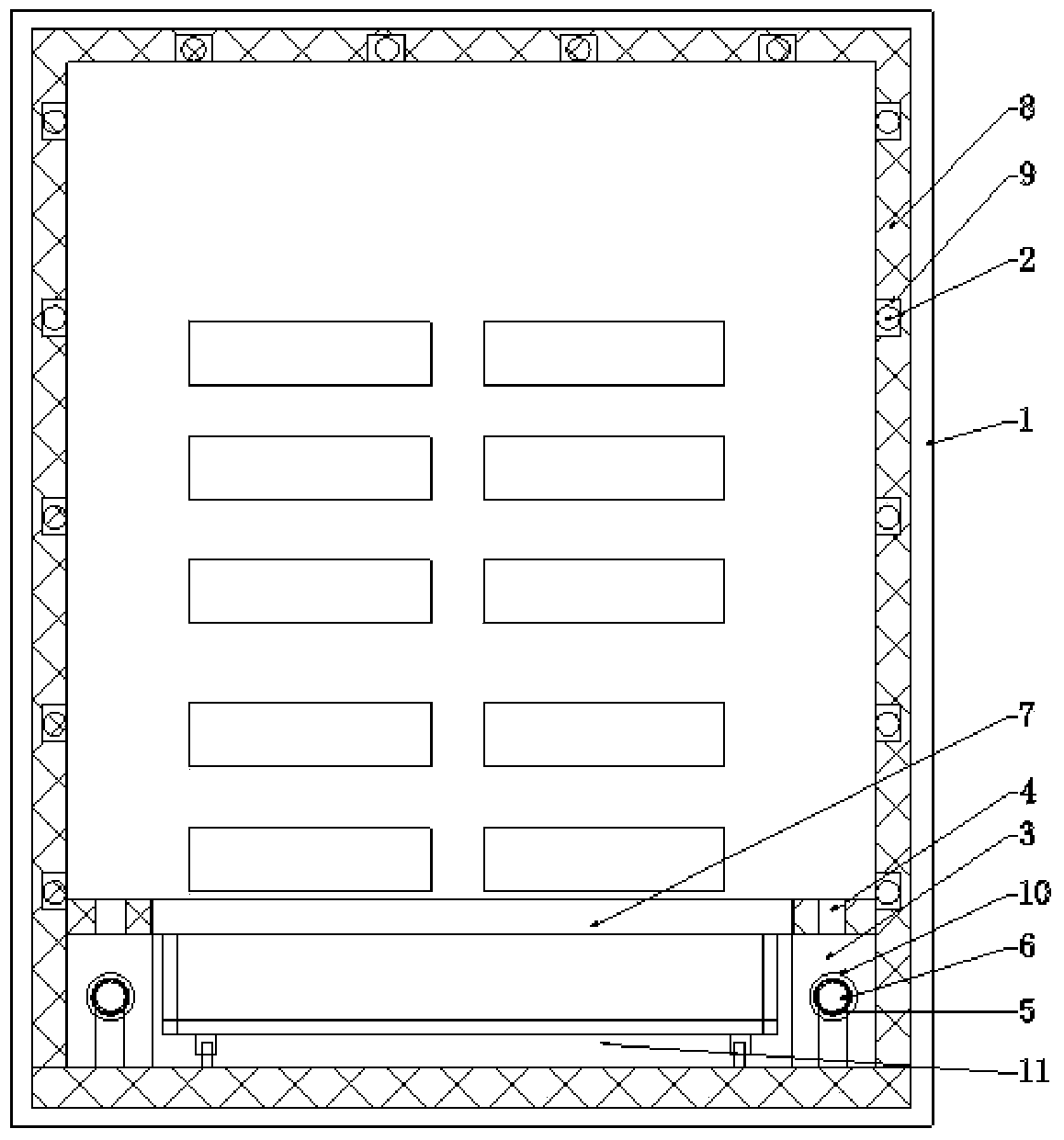

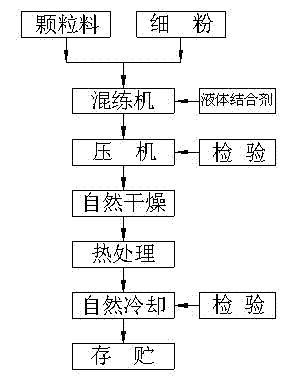

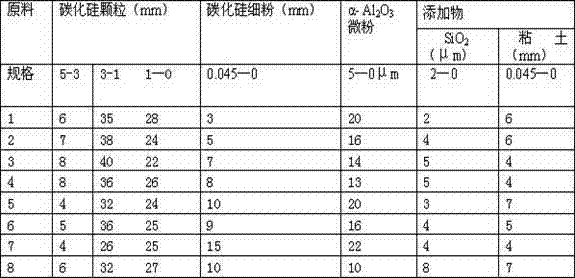

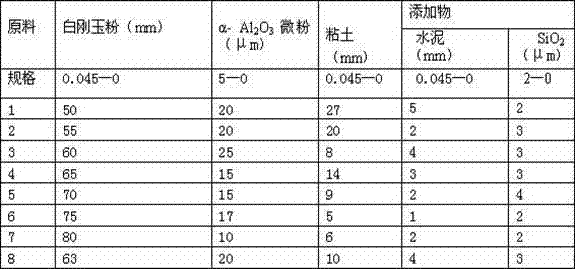

Sagger brick and masonry fire clay for firing sliding bricks by buried carbon

The present invention discloses a sagger brick and masonry fire clay for firing sliding bricks by buried carbon. The sagger brick for firing the sliding bricks by the buried carbon comprises, by weight percentage, 55-70 % of silicon carbide particles; 3-15 % of silicon carbide fine powder; 10-25 % of alpha-Al2O3 fine powder; and 5-15 % of additives which are the silicon-aluminum fine powder and micro powder. The masonry fire clay comprises, by weight percentage, 63-80 % of white corundum powder; 10-20 % of alpha-Al2O3 fine powder; 5-10 % of clay and 1-7 % of additives which are calcium-containing cement and silicon-containing fine powder with effects of promoting coagulation, reducing water and high temperature enhancing. The sagger brick and the masonry fire clay are simple in components, low in production cost, good in thermal conductivity, good in thermal shock resistance and good in high temperature strength. The masonry saggar can meet requirements of firing the sliding bricks by the buried carbon, sealed anti-oxidation, efficient heat transferring and structural stability, and also can significantly improve quality of the fired sliding bricks and qualified rate of anti-oxidation after firing.

Owner:瑞泰马钢新材料科技有限公司 +2

Formula of wet-method high-strength electrical porcelain blank

InactiveCN103693940AIncreased wet billet strengthImprove green body qualityClaywaresHigh intensitySolvent

The invention discloses a formula of a wet-method high-strength electrical porcelain blank. According to the formula, the high-strength electrical porcelain blank comprises the following components in percentage by weight: 35%-40% of alumina, 5%-10% of feldspar solvent, 30%-40% of kaolin and10%-20% of illite clay. As high plastic clays such as kaolin and illite clay are adopted in the formula, the wet blank strength of the formula is improved, the formability of the formula is enhanced, the process property of an electrical porcelain blank is excellent, the preparation cost is reduced, the formula can meet the production demands of an overall formed product which is higher than 3 meters, and the phenomenon such as falling caused by poor plasticity of the blank formula during fettling can be reduced.

Owner:CHINA XD ELECTRIC CO LTD

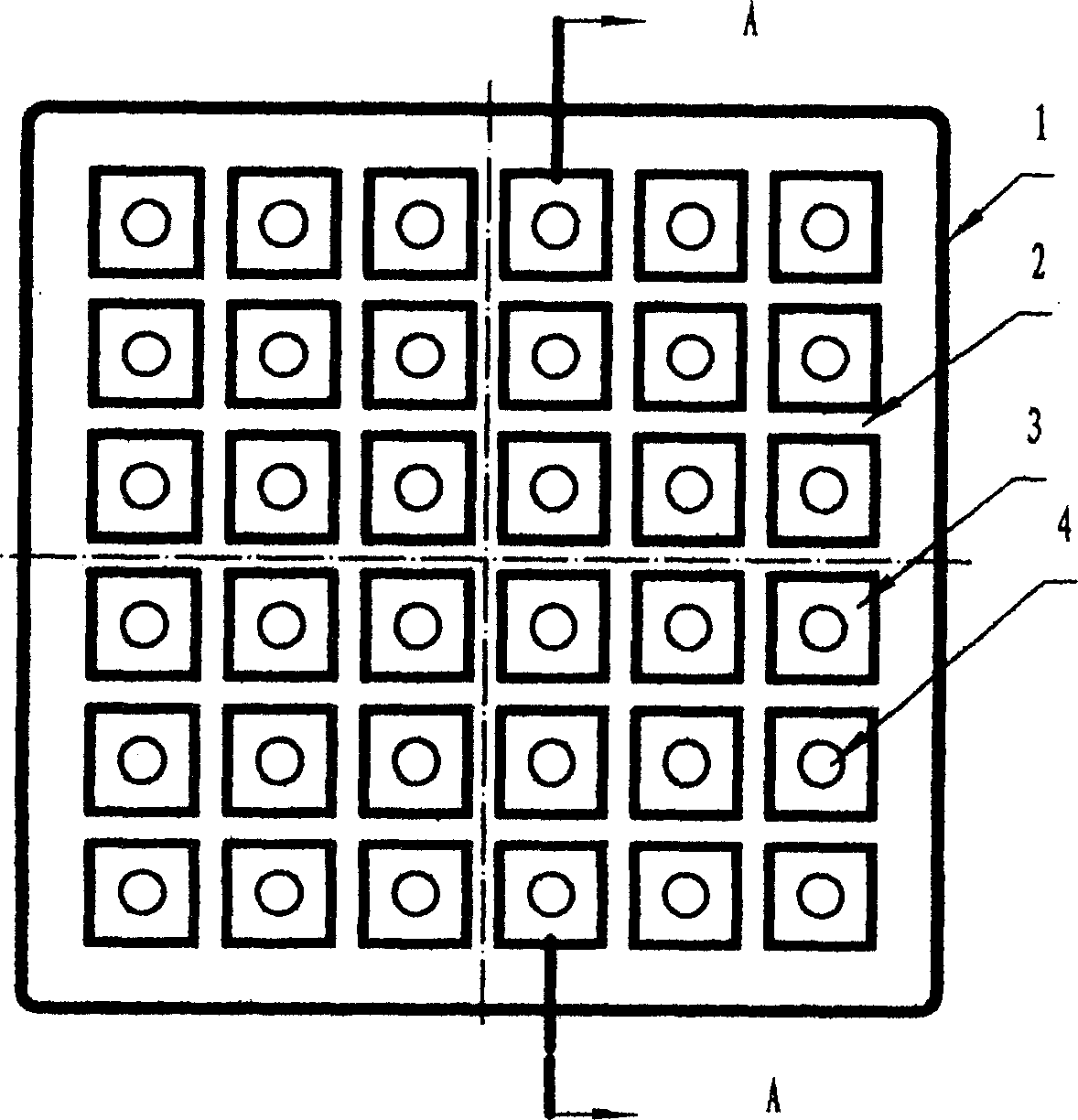

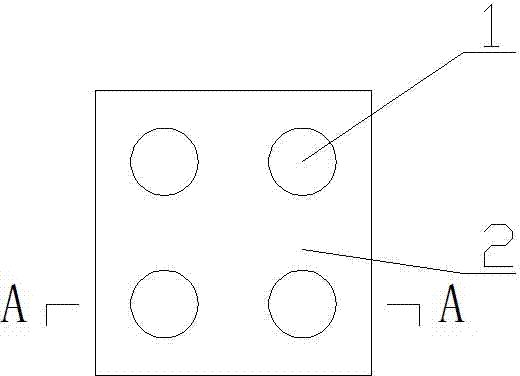

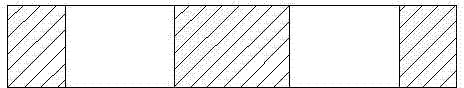

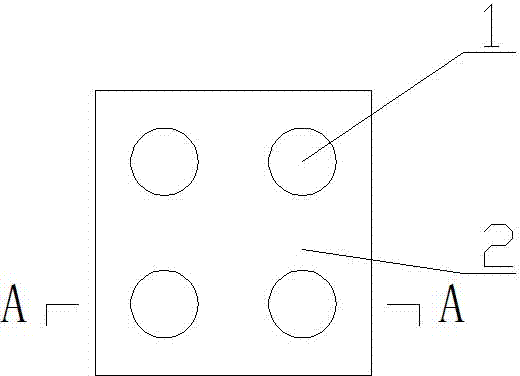

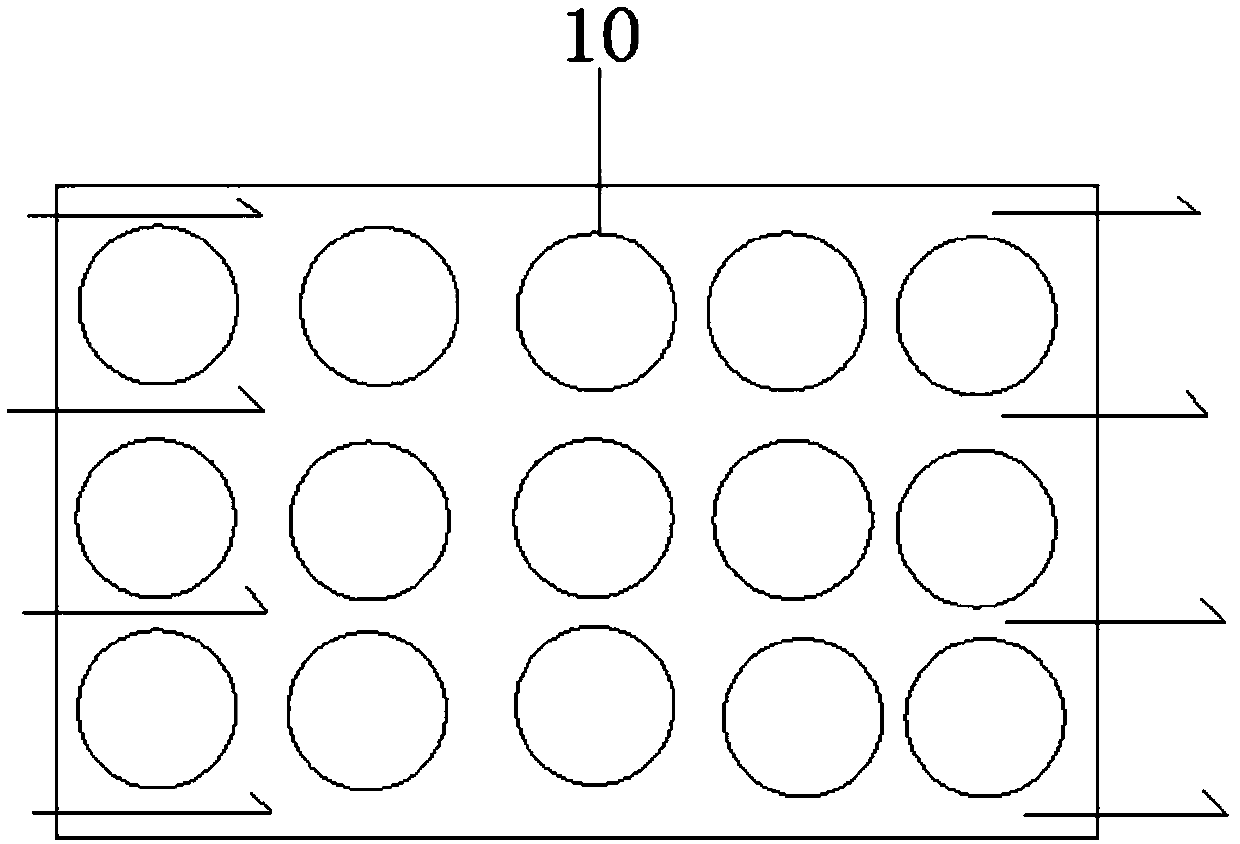

Push plate with holes and for electronic material roasting

InactiveCN102445074AImprove thermal shock resistanceEvenly heatedFurnace typesEngineeringMechanical engineering

A push plate with holes and for electronic material roasting belongs to the technical field of kiln furniture and comprises a rectangular body. A plurality of through holes are arranged on the central area of the rectangular body, and the area of the through holes occupies 10% to 20% of the whole area of the push plate. Kiln atmosphere is ensured to be smooth by changing arrangement of the through holes of the push plate, products are evenly heated, good in roasting quality, capable of ensuring strength of the push plate not to be affected by the through holes, thermal shock resistance of the push plate is facilitated, and service life of the push plate is prolonged.

Owner:江苏三恒高技术窑具有限公司

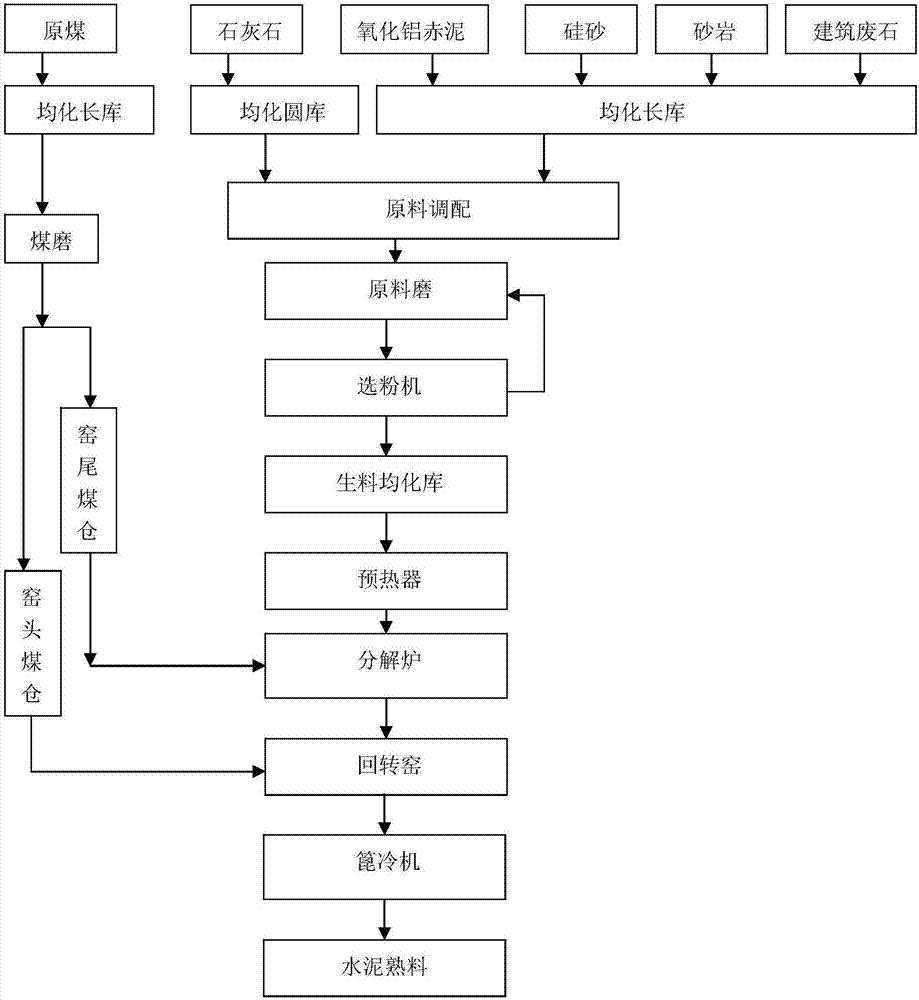

Cement clinker employing silica sand part instead of sandstone and preparation technology of cement clinker

ActiveCN107216055AAchieve control indicatorsImprove sintering qualityClinker productionRed mudToxic industrial waste

The invention relates to a cement clinker employing a silica sand part instead of sandstone. The cement clinker is prepared from the following raw materials in parts by weight: 87-90% of limestone, 2.7-3.0% of alumina red mud and 6-9% of silica sand, sandstone and construction waste rocks, wherein the mass ratio of the silica sand to the sandstone to the construction waste rocks is 1:3:1. A technology specifically comprises the following steps of carrying out burdening, homogenizing, grinding, powder selecting, preheating and decomposing, and finally carrying out high-temperature calcination and then cooling to obtain the cement clinker. By adopting the scheme of replacing the sandstone with the silica sand part to produce the cement clinker, the grindability of raw meal mill is improved; meanwhile, a lot of industrial waste silica sand and construction waste rocks are consumed, so that effective utilization of resources is achieved; the firing quality of the clinker is improved, the firing energy consumption of the clinker is further reduced and the production cost.

Owner:TIANJIN ZHENXING CEMENT

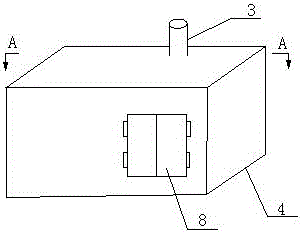

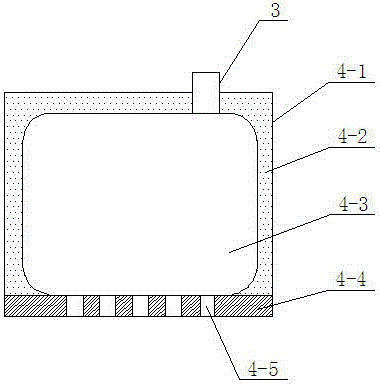

Novel firewood-coal-electricity integrated high-temperature equipment for ceramic firing

InactiveCN106197022AImprove firing qualityPrecise and controllable temperatureCharge manipulationFurnace typesElectricitySmoke

The invention provides a novel firewood-coal-electricity integrated high-temperature equipment for ceramic firing. The novel firewood-coal-electricity integrated high-temperature equipment for ceramic firing comprises an electric-control high-temperature furnace and a firewood-coal combustion furnace. The electric-control high-temperature furnace communicated with the firewood-coal combustion furnace through a smoke channel. The electric-control high-temperature furnace is located above the firewood-coal combustion furnace and used for providing the temperature required for ceramic firing. The firewood-coal combustion furnace is used for providing reductive gas required for ceramic firing. An ash pond is arranged below the firewood-coal combustion furnace. The novel firewood-coal-electricity integrated high-temperature equipment for ceramic firing has the beneficial effects that when the firewood-coal-electricity integrated high-temperature equipment is used for ceramic firing, a green body to be fired is placed in a hearth of the electric-control high-temperature furnace, a temperature source is provided by the electric-control high-temperature furnace, an atmosphere source (the reductive gas) is provided by the firewood-coal combustion furnace, the atmosphere source provided by the firewood-coal combustion furnace enters the hearth of the electric-control high-temperature furnace through the smoke channel and air holes, and the ceramic firing quality is greatly improved.

Owner:HENAN UNIVERSITY

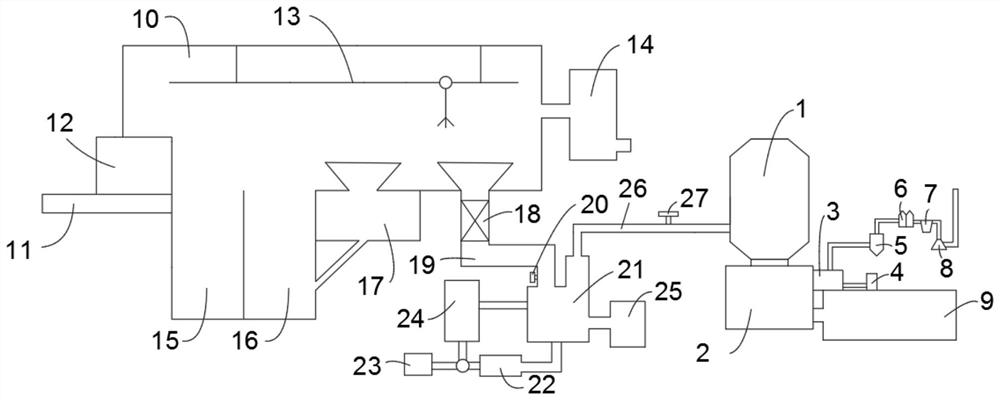

Dry-process cement preheating decomposition system

PendingCN113446608ADecompose thoroughlyReduce formationEmission preventionFurnace typesThermodynamicsProcess engineering

The invention discloses a dry-process cement preheating decomposition system. The dry-process cement preheating decomposition system comprises a decomposition furnace, wherein a decomposition assisting mechanism is arranged on one side of the decomposition furnace; a pulverized coal burner is arranged at the lower end of the decomposition furnace; a dilution cooler is arranged on one side of the pulverized coal burner; a dilution air blower is connected to one side of the dilution cooler; the upper end of the dilution cooler is connected with a cyclone separator; the upper end of the cyclone separator is connected with dechlorination equipment, one side of the dechlorination equipment is connected with a dust collector; one side of the dust collector is connected with an induced draft fan; and a rotary kiln is further arranged on one side of the pulverized coal burner. The system can be used for treating harmful gas (dioxin) in the household garbage incineration process in a dry-process cement preheating decomposition system.

Owner:SINOMA SUZHOU CONSTR

Dental furnace

ActiveUS20190167395A1Keep dryQuick and uniform firingFurnace componentsMuffle furnacesMetallurgyRadiation

A dental furnace for firing dental-ceramic compounds comprises a firing chamber for receiving ceramic elements to be fired. Further, a heating device for heating and firing the ceramic element is provided. The heating device comprises at least one heating element for producing IR radiation in the range of 0.8-5 μm.

Owner:VITA ZAHNFABRIK H RAUTER GMBH & CO KG

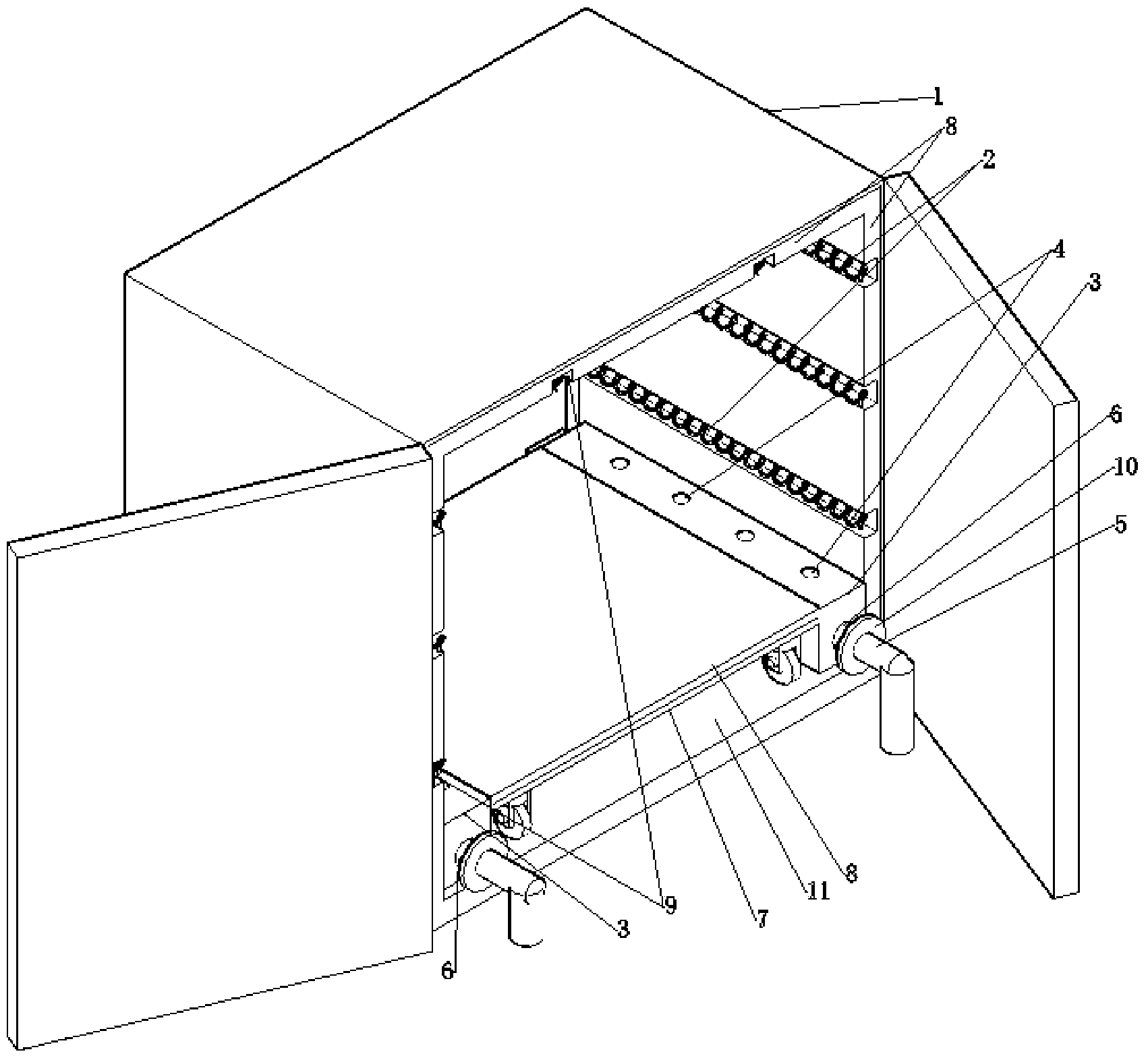

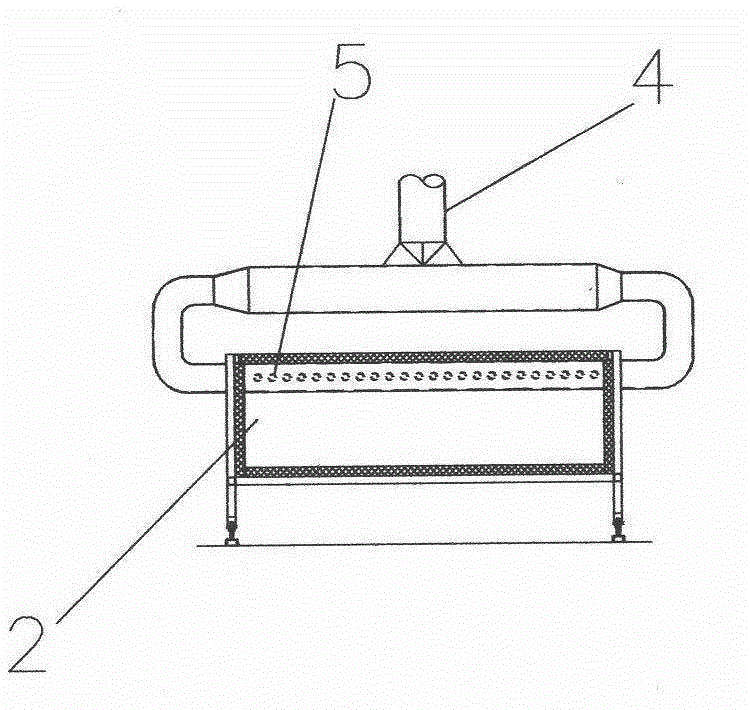

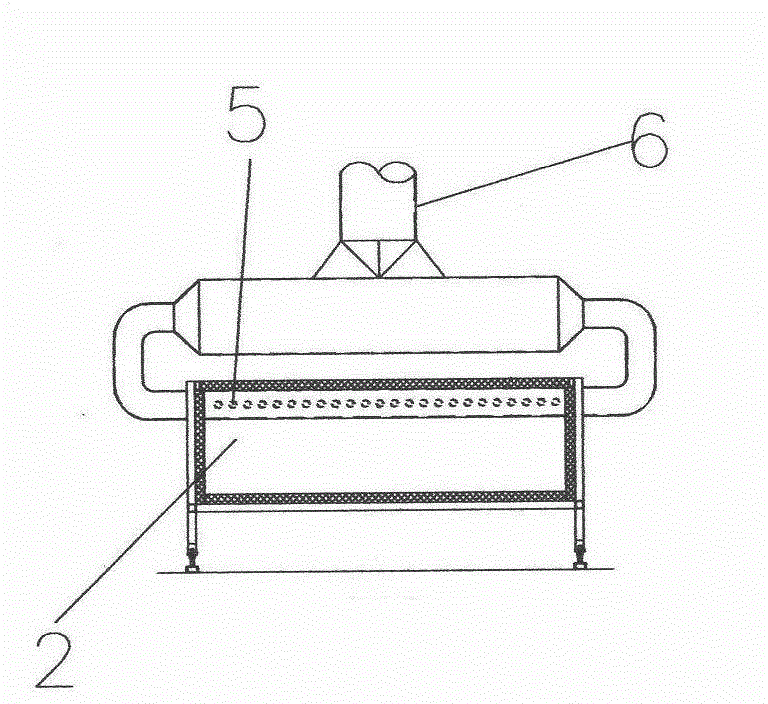

Energy-saving device capable of preheating coal gas on ceramic kiln

ActiveCN102748757ABurn fullyEliminate temperature differenceIndirect carbon-dioxide mitigationGaseous fuel burnerInlet manifoldKiln

The invention discloses an energy-saving device capable of preheating coal gas on a ceramic kiln. The ceramic kiln sequentially comprises a single-layer or multilayer drying area and a single-layer preheating area. A cold coal gas pipe which extends transversely is arranged above the single-layer or multilayer drying area and the single-layer preheating area. A gas inlet manifold for cold coal gas is arranged above drying boxes at the head of the single-layer or multilayer drying area and is perpendicularly connected with the cold coal gas pipe. The lower part of the gas inlet manifold transversely enters the internal top of a drying box at the head of the single-layer drying area, or transverse branches of the gas inlet manifold enter internal tops of drying boxes at the head of each layer of the multilayer drying area. A plurality of coal gas preheating pipes are perpendicularly arranged at all sections of the gas inlet manifold in each initial drying box. A primary output pipe for preheated coal gas is arranged above drying boxes at the tail of the single-layer or multilayer drying area. A secondary output pipe for the preheated coal gas is arranged above a drying box at one position of the preheating area and is perpendicularly connected with an output manifold. The lower part of the secondary output pipe is connected with the preheating pipes which enter the preheating box at the position. By adopting the structure, a good energy-saving effect can be realized and the sintering quality of ceramic products can be effectively improved.

Owner:梁嘉承

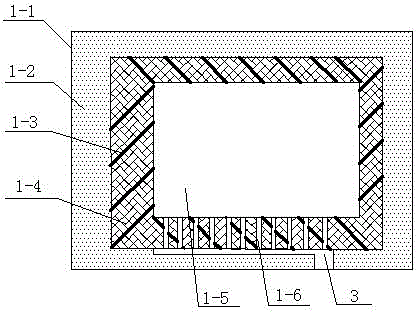

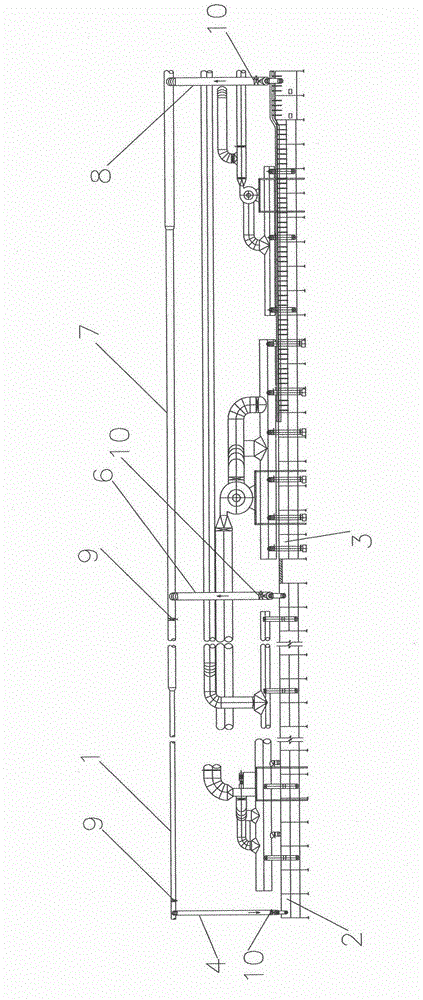

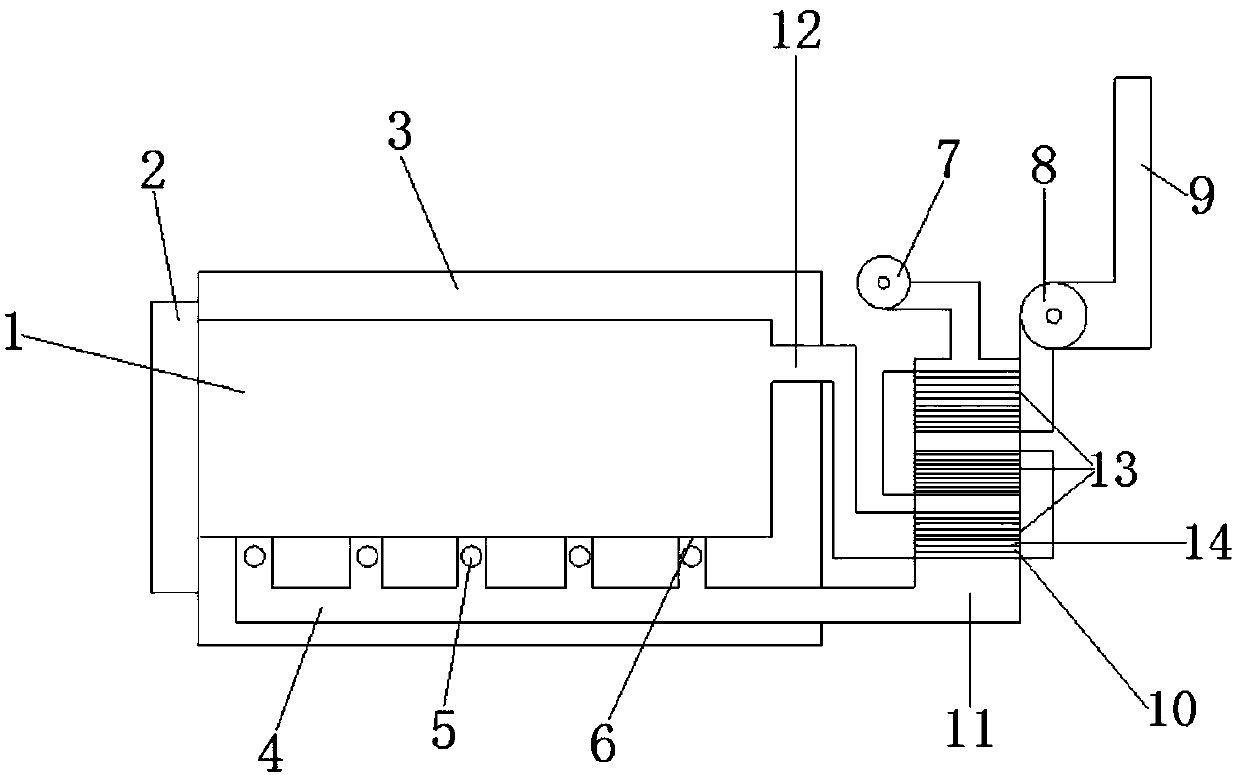

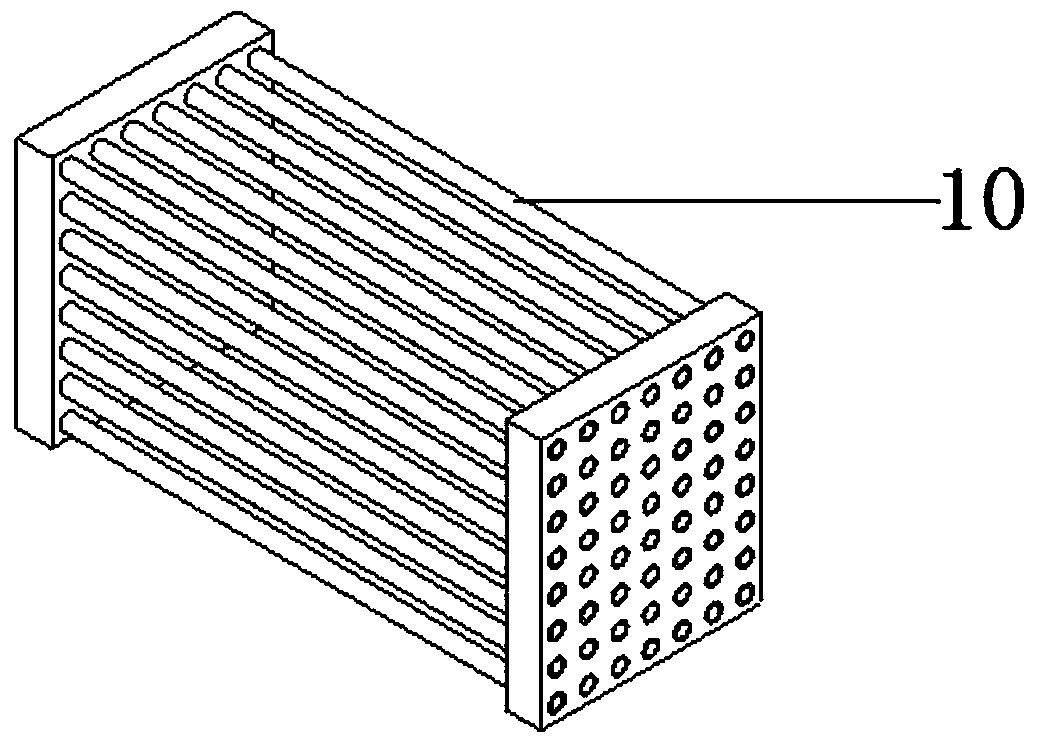

Heat exchange chamber-type energy saving shuttle kiln

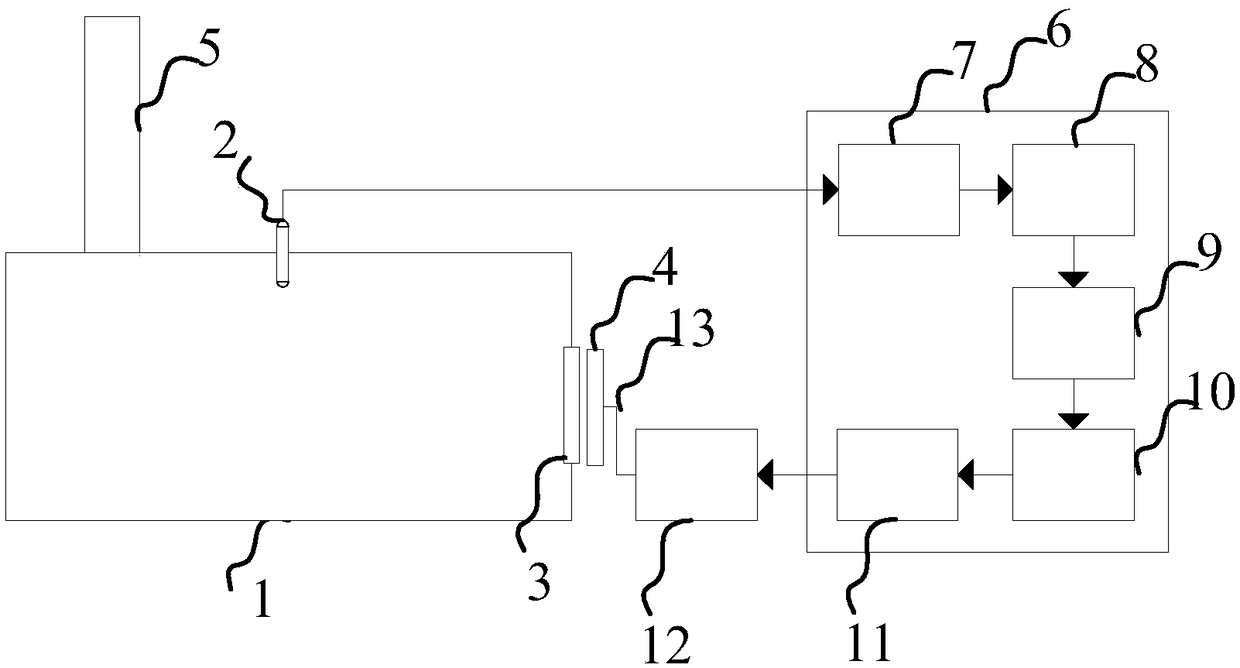

InactiveCN107764072ASolve the problem of a large amount of waste heat dischargeReduce the impactFurnace typesWaste heat treatmentTemperature differenceEngineering

The invention discloses a heat exchange chamber-type energy saving shuttle kiln, comprising a kiln body 1; a furnace wall 3 is arranged on the periphery of the kiln body 1, a kiln door 2 is arranged on one side surface of the kiln body, an air exchange opening 12 is arranged opposite to the kiln door 2, the air exchange opening 12 is connected to a heat exchange chamber 11, the heat exchange chamber-type energy saving shuttle kiln is characterized in that heat exchange ceramic tubes 10 are arranged in the heat exchange chamber 11, the top of the heat exchange chamber 11 is provided with a blower 7, the side surface of the heat exchange chamber 11 is provided with a draught fan 8 connected to a chimney 9, the bottom of the kiln body 1 is provided with a burning opening 6, the burning opening 6 is connected to a gas supply pipeline by a fuel gas pipeline 5, and the bottom of the kiln body 1 is provided with a combustion air pipeline 4. The heat exchange chamber-type energy saving shuttlekiln solves the problem of massive discharge of waste heat of the chimney, when the kiln is burnt to 1600 DEG C, the temperature of the chimney is reduced to the temperature smaller than 140 DEG C from the original temperature larger than 1000 DEG C, preheating discharge is obviously reduced, environmental influence and energy waste are reduced, fuel gas is saved by about 30%, and the energy saving and emission reduction are realized truly. A temperature difference in the kiln is reduced to improve the product sintering quality, and the rate of finished products is as high as 99%.

Owner:宜兴市海科耐火材料制品有限公司

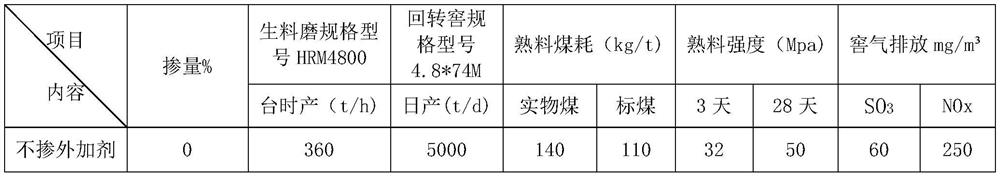

Admixture for dry-process cement kiln clinker production

The invention discloses an admixture for dry-process cement kiln clinker production, and belongs to the technical field of building material admixtures. The admixture disclosed by the invention is prepared from the following raw materials in parts by weight: 3-10% of rare earth, 20-40% of fluorite, 3-10% of nano metal powder, 30-60% of gypsum, 5-10% of modified steel slag powder and 1-5% of glycerol. The rare elements are hybridized and doped in clinker combustion, so that the eutectic point can be reduced, and the effects of destroying the crystal structure and improving the activity of the clinker are achieved. Fluorite and gypsum are added to achieve a mineralization effect, and metal nano powder is doped to catalyze clinker combustion, so that the firing speed is increased. The nano metal powder and the modified steel slag are matched with each other, so that efficient combustion of the clinker is jointly realized. The additive disclosed by the invention is 0.6-1% in doping amount,can remarkably improve the yield of a raw mill, improve the strength of clinker, fix sulfur and denitrate, comprehensively reduce the cost and realize efficient reutilization of waste resources, andhas wide economic benefits and social benefits.

Owner:临沂德艺科技发展有限公司

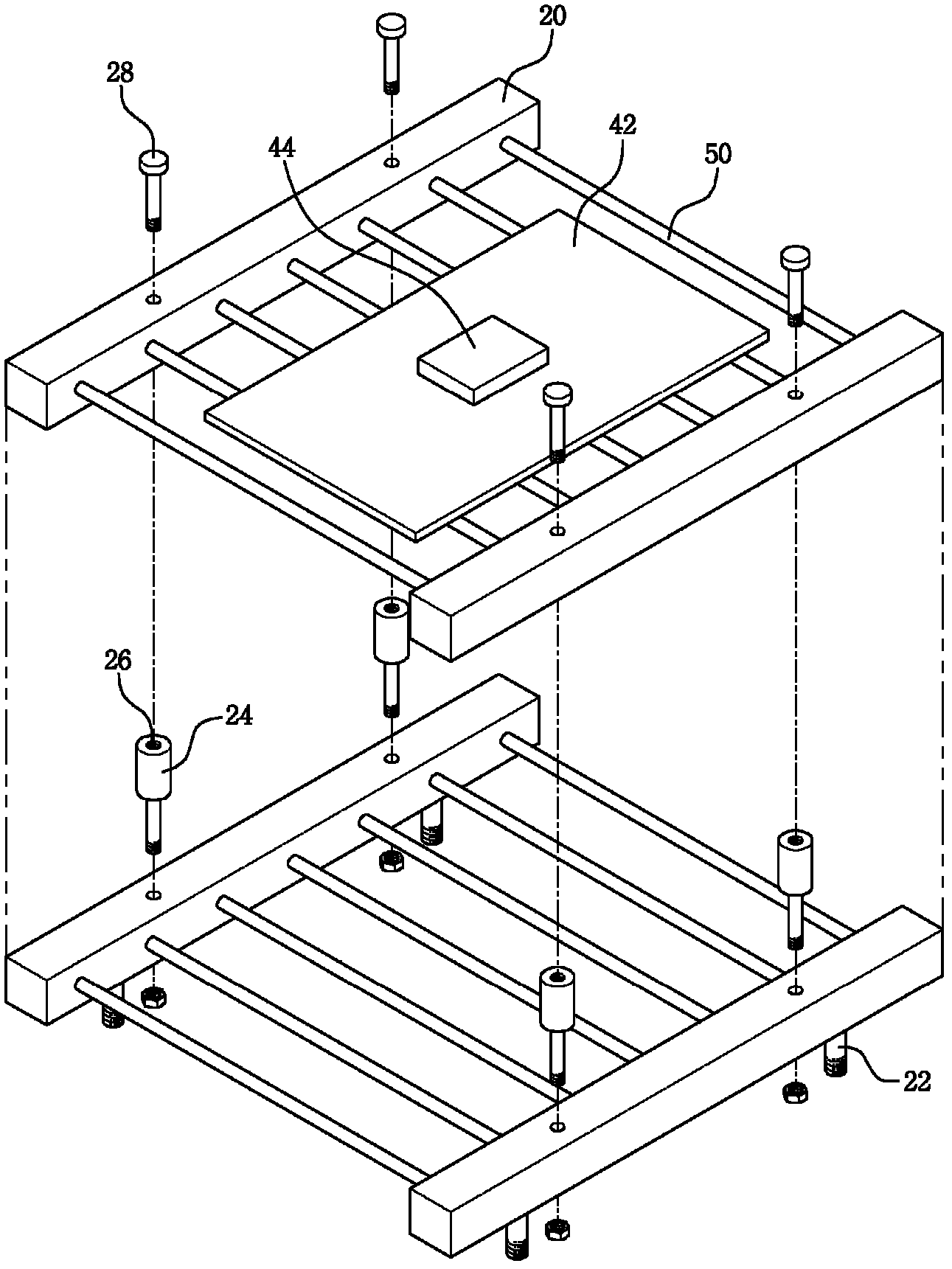

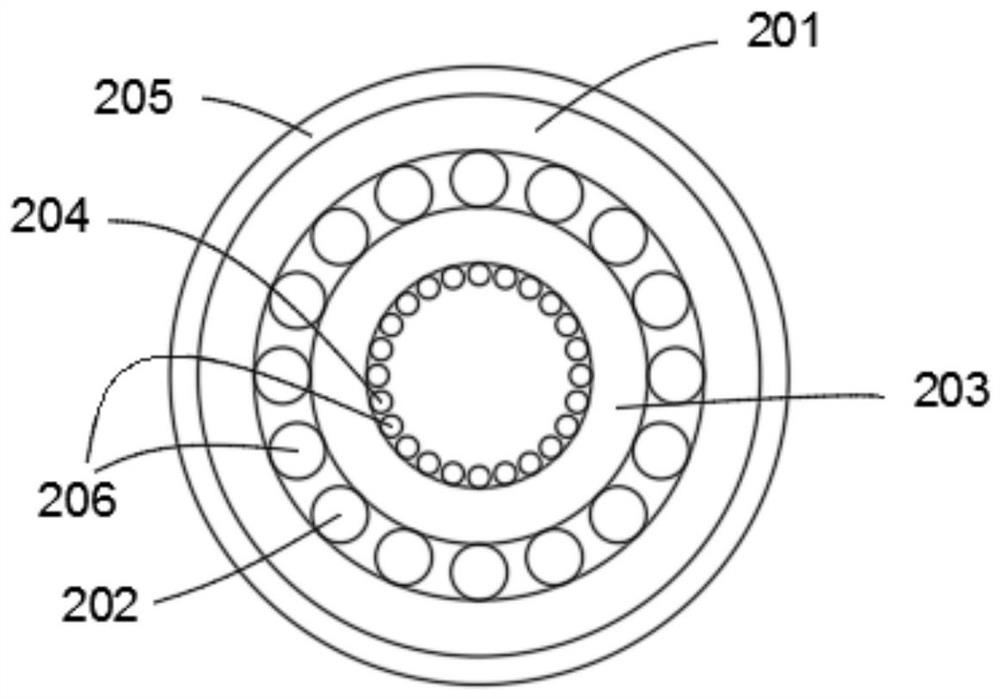

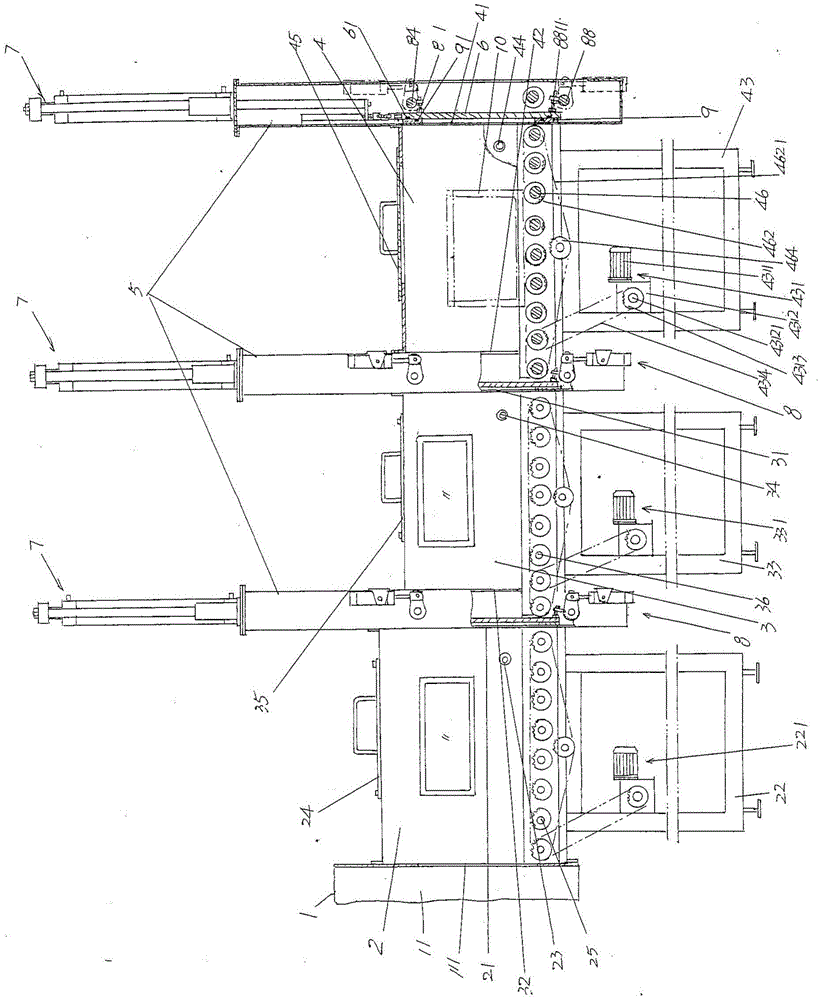

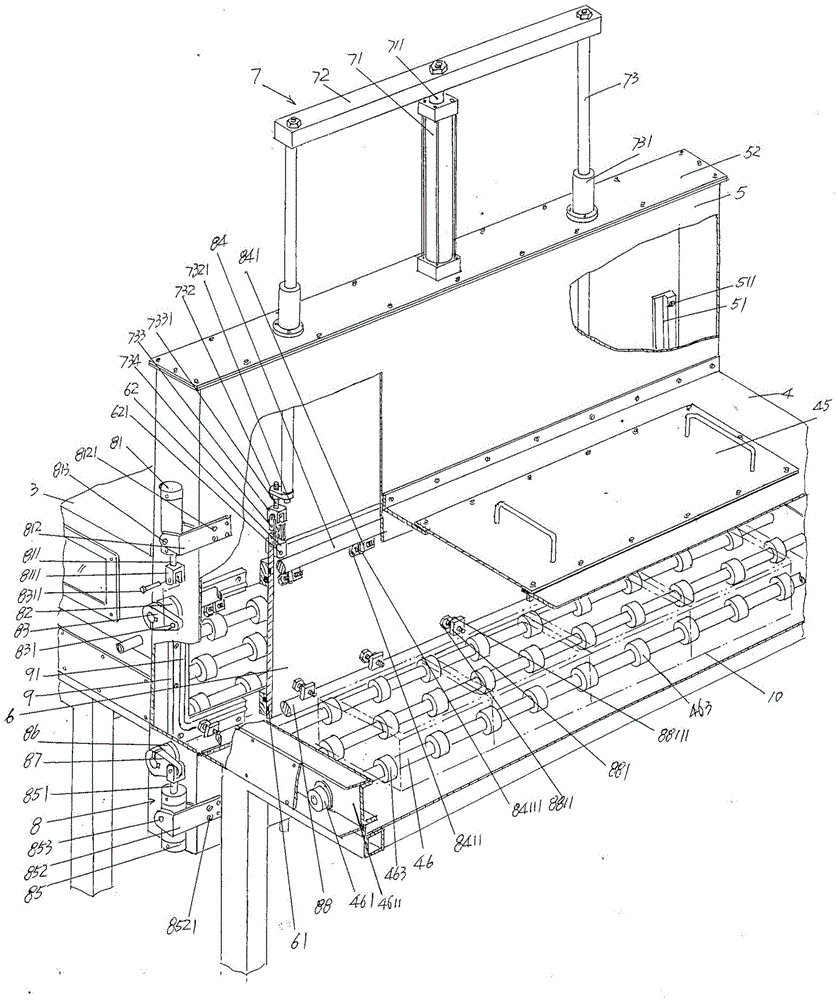

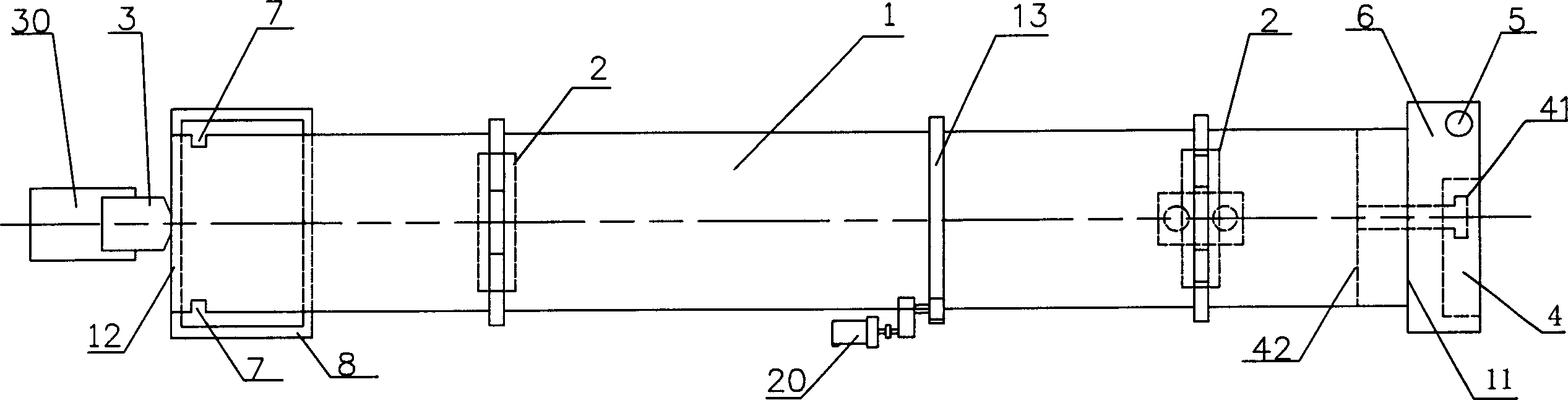

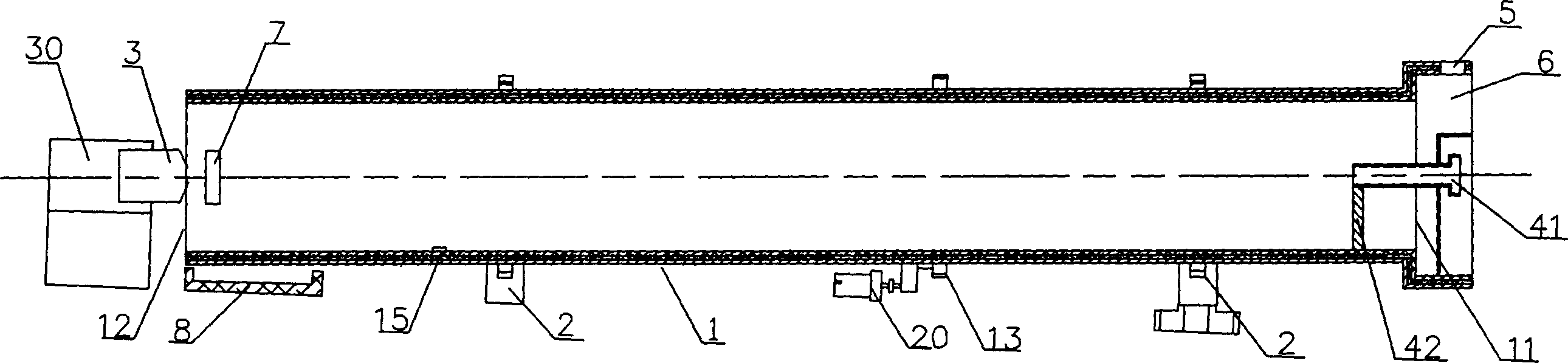

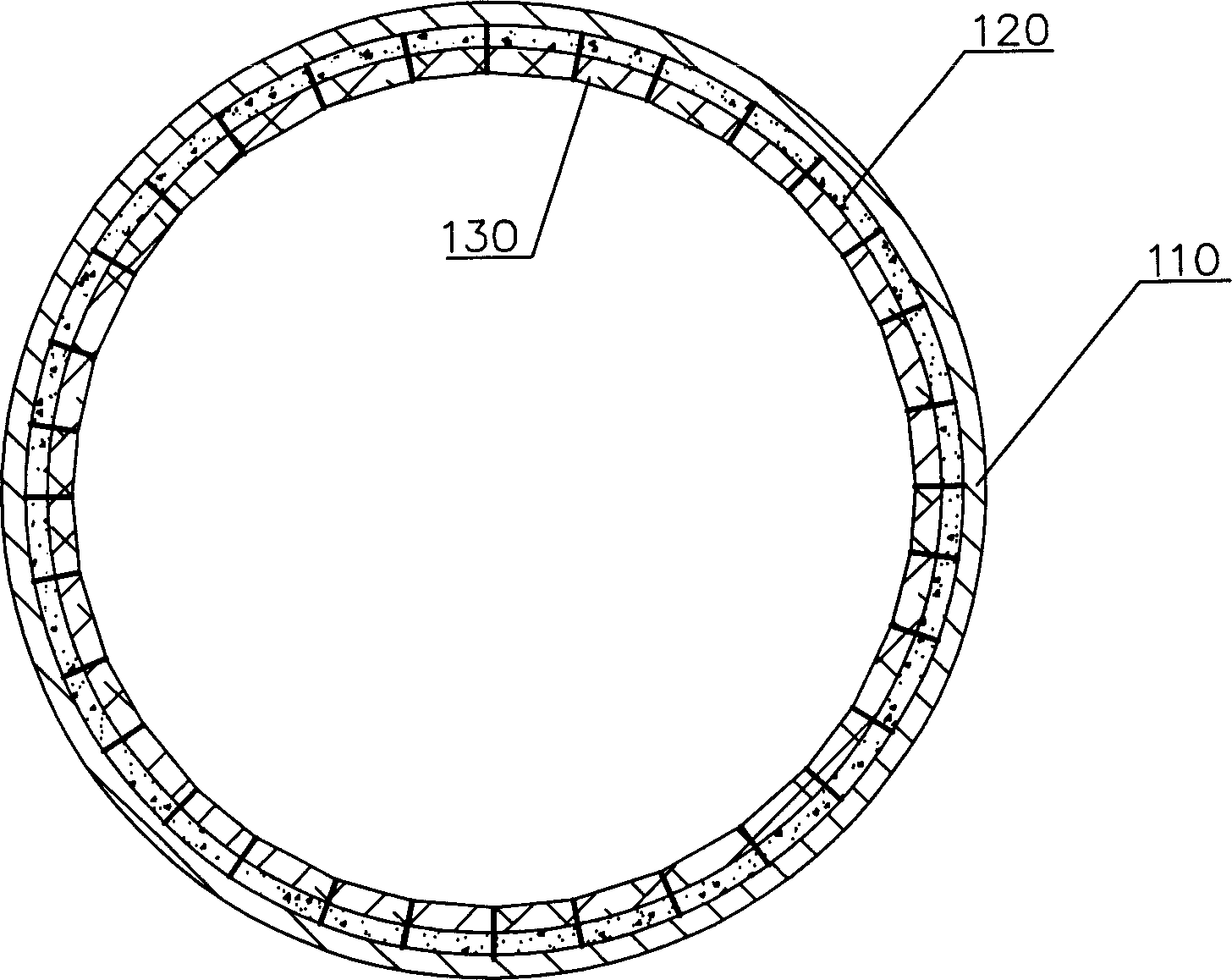

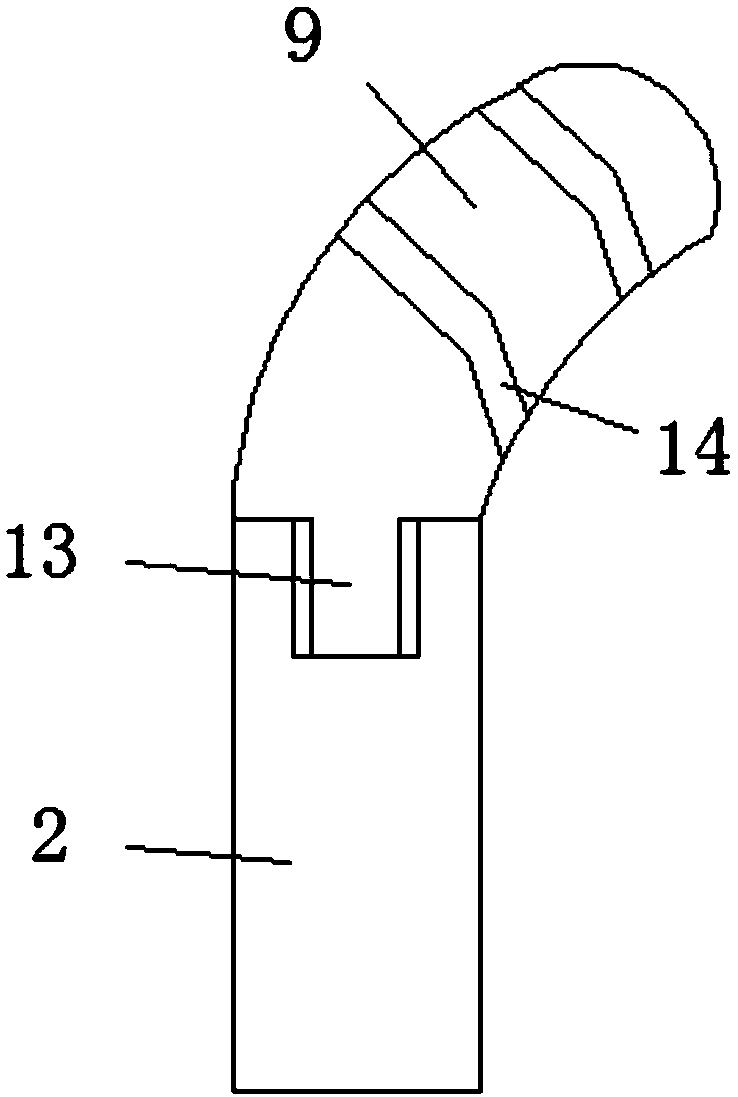

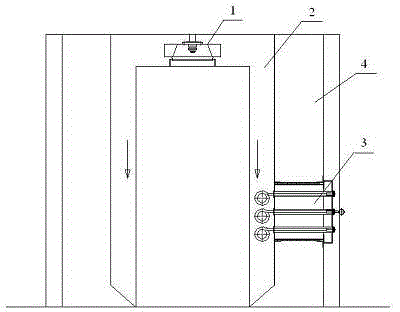

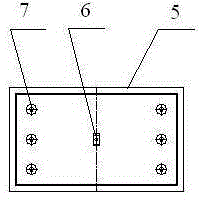

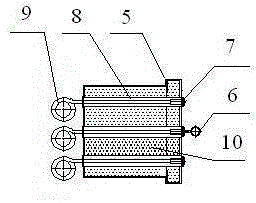

Replacement chamber sealing apparatus for electronic material firing furnace

InactiveCN105546993AShielding gas ensuresImprove firing qualityFurnace componentsElectronic materialsEngineering

The invention relates to a replacement chamber sealing apparatus for an electronic material firing furnace, and belongs to the technical field of an electronic kiln. The electronic material firing furnace comprises a furnace body, an inlet gas chamber box body, a left replacement chamber and a right replacement chamber; the inlet gas chamber box body is connected with the furnace body and is communicated with a hearth; the left replacement chamber is formed corresponding to a position of a cavity port of the inlet gas chamber box body and is communicated with the inlet gas chamber box body; the right replacement chamber is formed corresponding to a position of a left replacement chamber inlet of the left replacement chamber and is communicated with the left replacement chamber; the replacement chamber sealing apparatus comprises a replacement chamber door box; a replacement chamber lifting mechanism is arranged in the replacement chamber door box; and the replacement chamber sealing apparatus is characterized by further comprising a replacement chamber door external force application mechanism which is arranged at the front side or the rear side of the replacement chamber door box and is matched with one side of a replacement chamber door, which is back to a doorframe sealing ring. The replacement chamber sealing apparatus has a good sealing effect, ensures a vacuumizing effect, saves protection gas filled into the inlet gas chamber box body and the left and right replacement chambers and ensures atmosphere balance, and firing quality of an electronic material is improved.

Owner:SUZHOU HUIKE EQUIP CO LTD

Rotary kiln and method for producing calcining color frit using rotary kiln

InactiveCN1554605ASimple structureLess investment in infrastructureGlass furnace apparatusRotary drum furnacesFritEngineering

The present invention discloses a rotary kiln and method for producing calcined color frit therewith. The rotary kiln includes inclined lined cylinder with material feeding port in the head, drive system, flue with chimney, temperature metering unit inside the cylinder, heat source in the tail and discharge port in the tail. During production, the mixed raw material is fed to the inner hearth and rolled from head to tail while the cylinder is rotated and the high temperature gas flows from tail to head, so that the material is preheated and high temperature calcined to become color frit, which is discharged from the tail and cooled. The present invention has high yield and low cost.

Owner:贺建彪 +1

Preparation method for shrink grain glaze ceramic and product thereof

The invention discloses a preparation method for a shrink grain glaze ceramic and a product thereof. The shrink grain glaze ceramic comprises a ceramic biscuit and shrink grain glaze. The shrink grainglaze is prepared from the following raw materials in parts by weight: 30-50 parts of wollastonite, 30-40 parts of calcium carbonate heavy, 20-30 parts of kaolin, 4-8 parts of titanium dioxide, 2-4 parts of zirconium silicate, 1.5-2.5 parts of copper oxide, 1.5-2.5 parts of ferric oxide, 0.5-1.5 parts of manganese oxide and the balance purified water. The product has the components such as zirconium silicate, copper oxide, ferric oxide and manganese oxide, so that the chemical stability of the shrink grain glaze is better, performance such as swelling property, boiling humidity are more excellent, and the mechanical strength, thermal stability and dielectric strength of the shrink grain glaze ceramic are improved, so that the anti-fouling ability of the shrink grain glaze ceramic is relatively good, and the shrink grain glaze ceramic is convenient to clean. Sintered by a staged heating mode, the probability of pores in the glaze is relatively low, and the firing quality of the shrinkgrain glaze ceramic is improved. The product is mild in glaze color, unlikely to crack, green and environmentally friendly and suitable for being popularized.

Owner:福建省德化县顺兴达陶瓷工艺有限公司

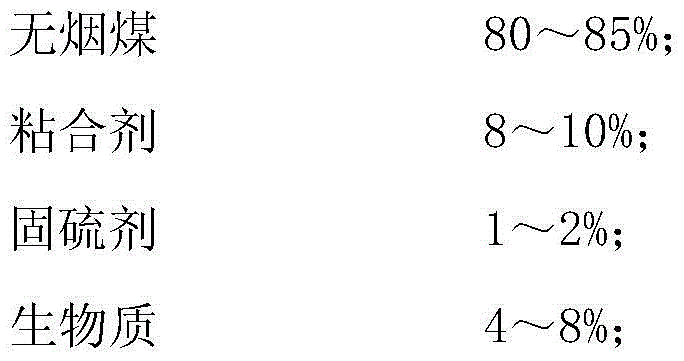

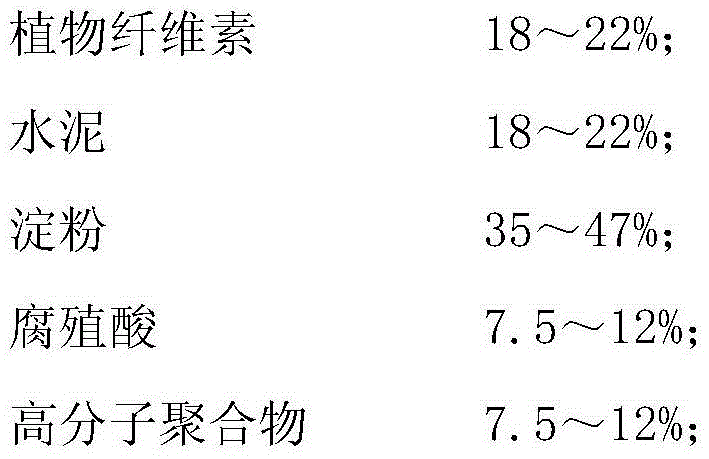

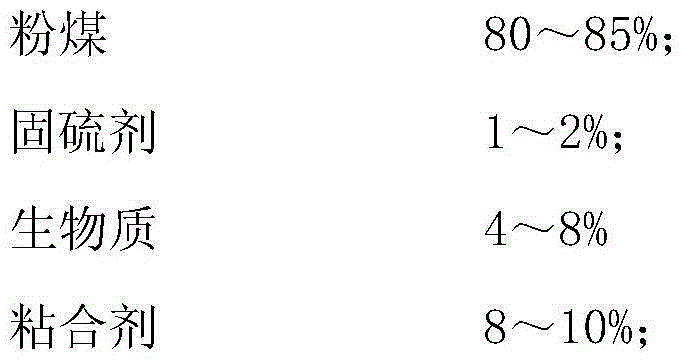

A kind of briquette for vertical industrial kiln and its preparation method

The invention discloses briquette coal for a vertical industrial kiln and a preparation method thereof, and belongs to the technical field of solid fuel. The briquette coal is characterized by comprising the following raw materials by mass percent: 80-85% of anthracite, 8-10% of adhesive, 1-2% of sulphur-fixing agent and 4-8% of biomass, wherein the calorific value of the anthracite is greater than or equal to 6100 kilocalorie / ton, the ash content is smaller than or equal to 6%, and sulphur is smaller than or equal to 0.4%. The adhesive comprises the following raw materials by mass percent: 18-22% of plant cellulose, 18-22% of cement, 35-47% of starch, 7.5-12% of humic acid and 7.5-12% of high-molecular polymer. According to the briquette coal, coal can be saved by 10-27%, the soot emission is reduced by 50-60%, the emission of sulfur dioxide can be reduced by 35-50%. The adopted adhesive is high in strength, and large in calorific value, and is not broken in the kiln, and the distribution uniformity is improved, the combustion temperature is even, the sintering quality of the product is improved, and the adhesive is nontoxic and tasteless.

Owner:单台阶

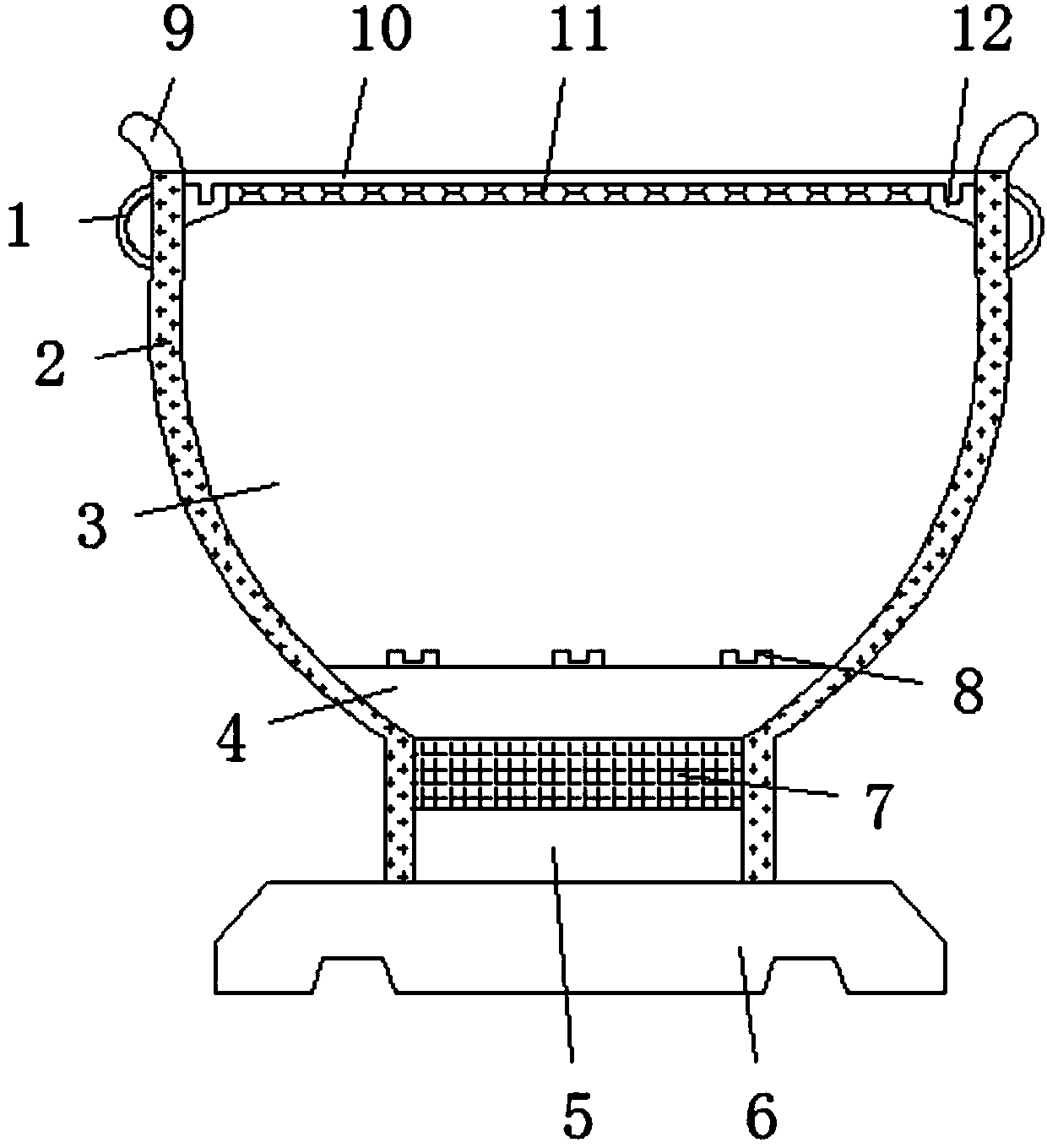

Sagger for ceramic production

InactiveCN107782158AGuaranteed uniformityDiversity guaranteedCharge supportsSurface layerScrew thread

The invention discloses a sagger for ceramic production, which comprises a brake bowl body, a refractory layer is arranged on the outside of the brake bowl body, a hanging ring is arranged on the outside of the refractory layer, and the refractory layer is threaded through a threaded column and a deflector plate. connected, and a through hole is opened inside the deflector, a backing plate is provided at the bottom of the brake bowl body, a hollow layer is opened on the upper surface of the backing plate, a storage plate is provided at the bottom end of the brake bowl body, and the storage plate The upper surface is provided with a positioning block, the bottom of the backing plate is provided with a base, the inner and outer walls of the brake bowl body are provided with a clamping block, and the top of the clamping block is provided with a cover plate, and the inner surface of the cover plate is provided with an adsorption plate . In the present invention, the overall structure design of the gate bowl is simple and reasonable, and the arc-shaped structure ensures the stability of flame flow, improves the quality of ceramic firing, and has strong practicability.

Owner:CHENGDU JUNSHUO RUIZHI INFORMATION TECH CO LTD

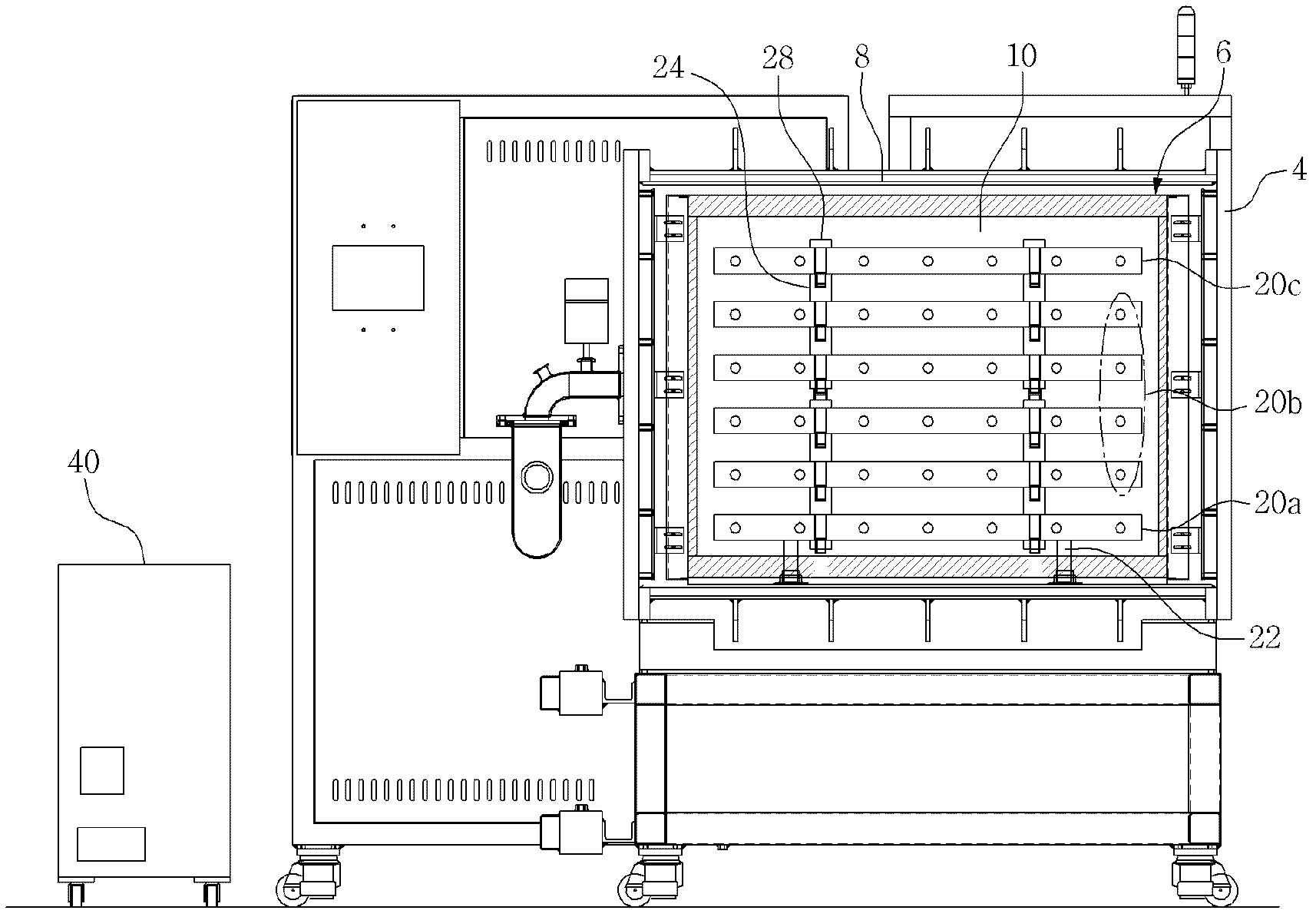

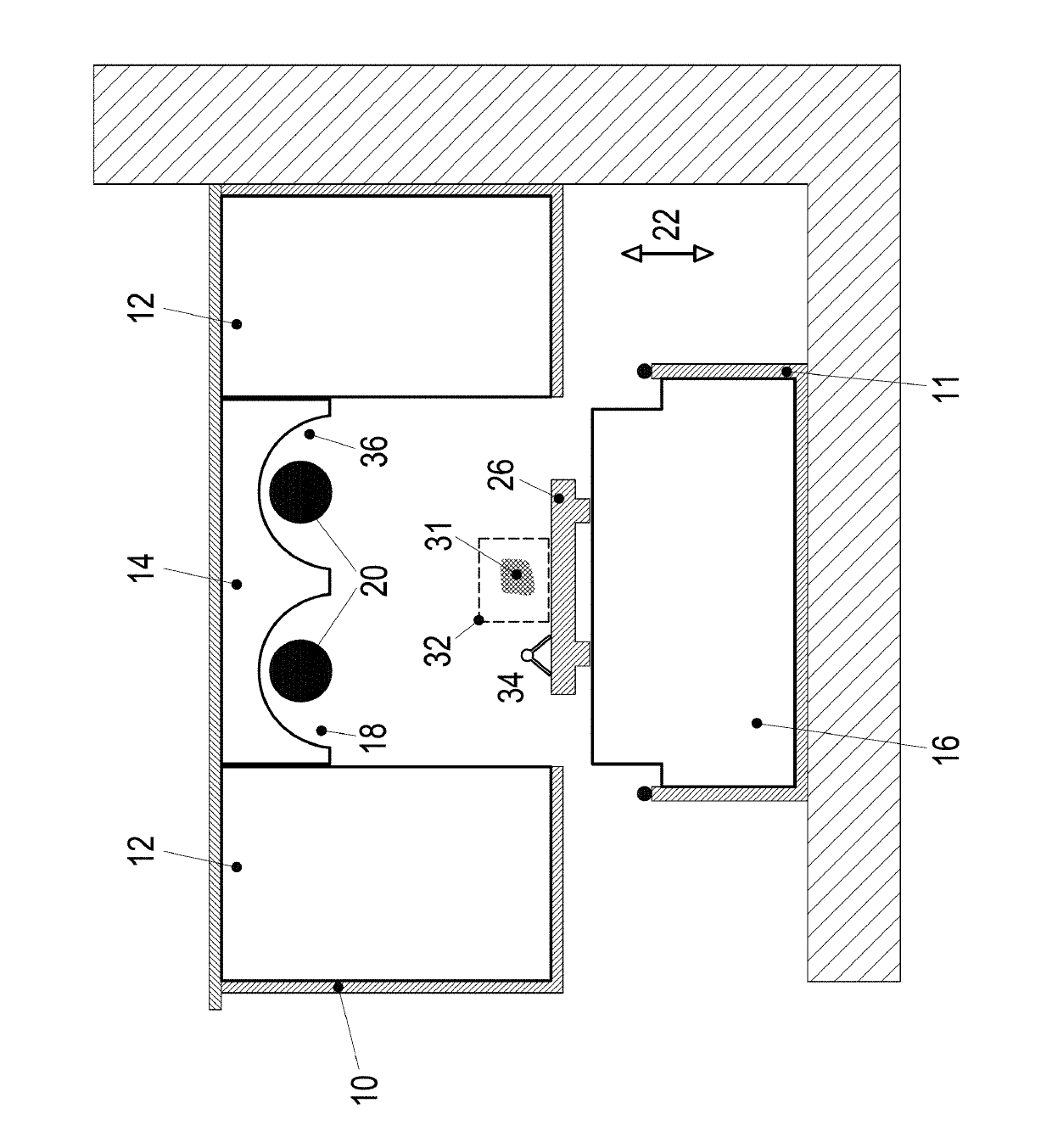

Detachable type quick heating calcining furnace for SCR (Selective Catalytic Reduction) plate type catalyst production

InactiveCN104567371AImprove heating efficiencyExtended service lifeCatalyst activation/preparationFurnace typesEngineeringSteel plates

The invention discloses a detachable type quick heating calcining furnace for SCR (Selective Catalytic Reduction) plate type catalyst production, and aims to solve the problem that the calcining quality of a product is affected by a fact that supplemented fresh air cannot be heated in time in the prior art. The detachable type quick heating calcining furnace is characterized in that a heating module (3) consists of a shell (5), a pull ring (6), wiring posts (7), ceramic sleeves (8), electrothermal pipes (9) and heat isolation fibers (10), wherein the shell (5) is a cuboid welded by a stainless steel plate and is filled with the heat isolation fibers (10); lead wires at the two ends of each of the three electrothermal pipes (9) respectively penetrate through the three ceramic sleeves (8) of the heat isolation fiber layers; the heating module (3) is arranged in a mounting hole reserved in the middle lower part of a furnace wall (4), so that the electrothermal pipes (9) are positioned in a circulating air duct (2). The detachable type quick heating calcining furnace has the advantages of scientific combination, simplicity in manufacturing, convenience in mounting, quickness in heating and the like and has wide popularization and application value.

Owner:湖北华夏窑炉工业(集团)有限公司

Method for automatically adjusting air door of ceramic kiln

InactiveCN108931145AImprove firing qualityRealize automatic adjustmentCharge composition/stateCharge treatment typeSignal amplificationPower flow

The invention discloses a method for automatically adjusting an air door of a ceramic kiln. The method comprises the following steps that firstly, a collected temperature value is converted into a current value through a thermocouple temperature sensor, the current value is input into a kiln controller, an AD conversion module in the controller converts a current analog signal into a digital signal, an actual temperature in the kiln is obtained through checking a thermometer, a temperature rising stage, a heat preservation stage and a cooling stage of ceramic firing are judged, and an instruction for adjusting an opening degree of the air door is sent out; according to the instruction, switching value is output by a one-way switching value output circuit of a switching value output module,then signal amplification is carried out through a circuit driving module, the amplified signal is transmitted to an electric push rod through a relay switch, high-low electrical levels of the outputswitching value determine whether the electric push rod ascends or descends, output time of the high-low electrical levels of the output switching value determines a distance of ascending or descending the electric push rod, therefore the opening degree of the air door of the ceramic kiln is adjusted, and finally, the oxidation atmosphere in the ceramic kiln is adjusted. According to the method,the stability of the ceramic firing quality is improved, and the labor intensity of firing workers is reduced.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com