Push plate with holes and for electronic material roasting

An electronic material and push plate technology, applied in the field of kiln furniture, can solve the problems of reducing the use times of the push plate, high technical requirements for thermal shock resistance, and large volume of the push plate hole, so as to prolong the service life and facilitate the thermal shock resistance. The effect of good performance and firing quality

Inactive Publication Date: 2012-05-09

江苏三恒高技术窑具有限公司

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The domestic kilns for producing electronic materials are mainly high-temperature push plate kilns, and firing has high technical requirements on the thermal shock resistance of the push plate. A long time will affect the firing quality of the product; Chinese patent application 2004200232388 discloses "kiln furniture that resists rapid cooling and rapid heating", and a central hole is arranged in the middle of the shed plate, and a lining plate is arranged above the central hole, and several stainless steel lines are buried along the central hole. Silk ring, the area of the center hole accounts for 25-40% of the entire kiln furniture area

The push plate hole of this structure occupies a relatively large volume. Although it is conducive to uniform heat conduction, it affects the strength of the push plate and reduces the number of times of use of the push plate. In addition, several stainless steel wire rings buried along the center hole are not applicable. In a high temperature firing environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

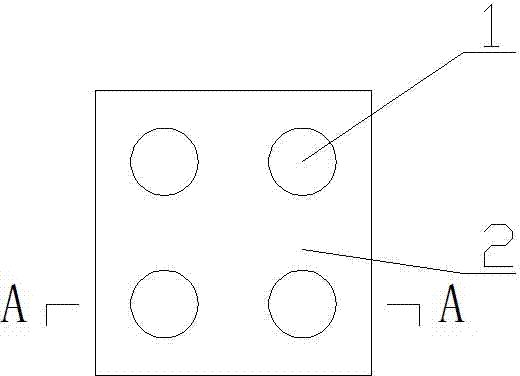

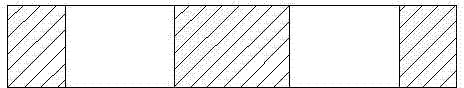

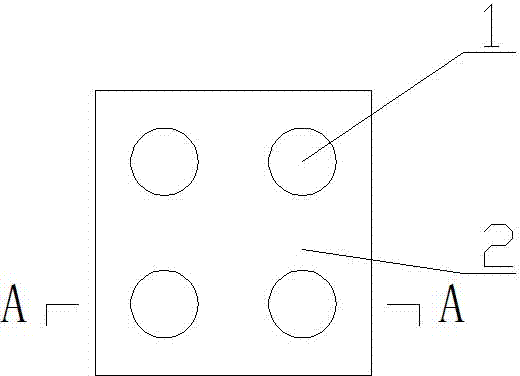

[0007] A push plate with holes for electronic material baking, comprising a rectangular body 1, 2-8 through holes 2 are opened in the central area of the rectangular body 1, and the area of the through holes 2 accounts for 10-20% of the total area of the push plate .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A push plate with holes and for electronic material roasting belongs to the technical field of kiln furniture and comprises a rectangular body. A plurality of through holes are arranged on the central area of the rectangular body, and the area of the through holes occupies 10% to 20% of the whole area of the push plate. Kiln atmosphere is ensured to be smooth by changing arrangement of the through holes of the push plate, products are evenly heated, good in roasting quality, capable of ensuring strength of the push plate not to be affected by the through holes, thermal shock resistance of the push plate is facilitated, and service life of the push plate is prolonged.

Description

technical field [0001] The invention belongs to the technical field of kiln furniture, in particular to a push plate with holes for electronic material roasting. Background technique [0002] The domestic kilns for producing electronic materials are mainly high-temperature push plate kilns, and firing has high technical requirements on the thermal shock resistance of the push plate. A long time will affect the firing quality of the product; Chinese patent application 2004200232388 discloses "kiln furniture that resists rapid cooling and rapid heating". A central hole is arranged in the middle of the shed plate, and a lining plate is arranged above the central hole, and several stainless steel lines are buried along the central hole. For silk rings, the area of the central hole accounts for 25-40% of the entire kiln furniture area. The push plate hole of this structure occupies a relatively large volume. Although it is conducive to uniform heat conduction, it affects the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27B9/30

Inventor 王立平

Owner 江苏三恒高技术窑具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com