Intelligent optimization method for temperature control of ceramic kiln

A temperature control and intelligent optimization technology, applied in the field of control, can solve problems such as lack of scientificity and affect the quality of ceramic firing, and achieve the effect of improving the quality of ceramic firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

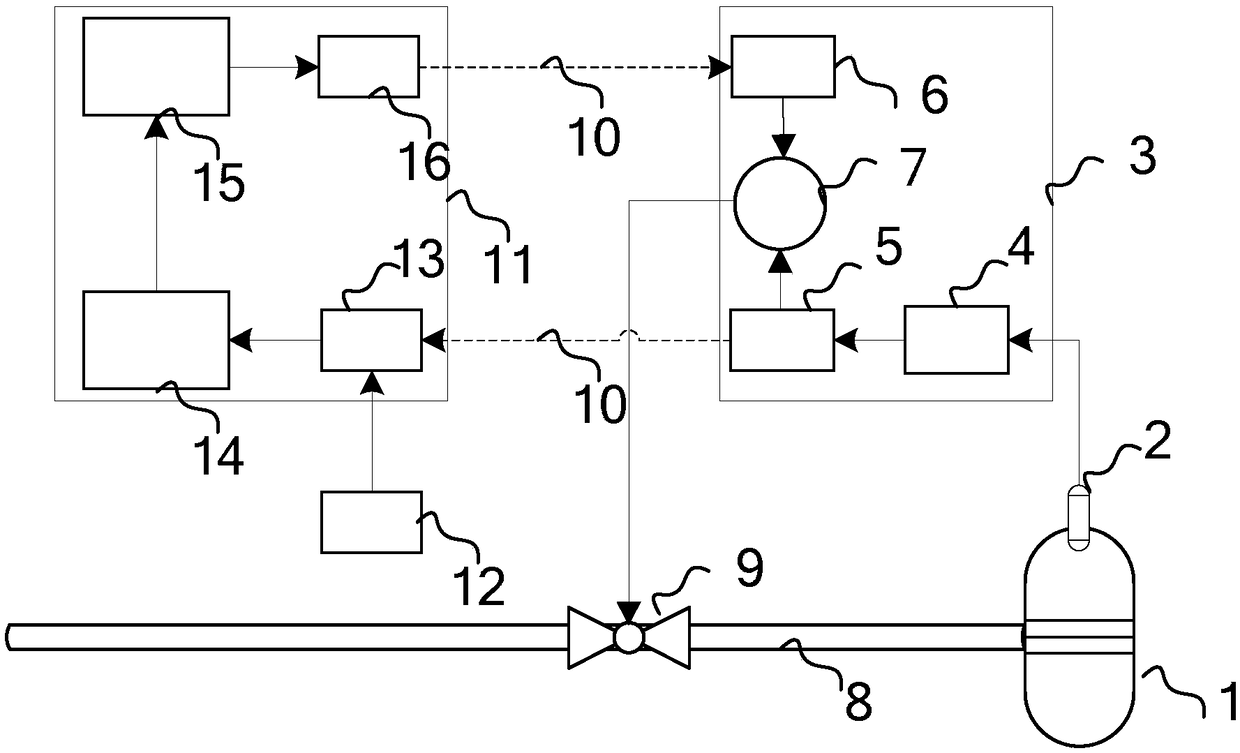

[0069] Such as figure 1 Shown is the structural composition of the ceramic kiln temperature control intelligent optimization system of the present invention. In the whole system, including: ceramic kiln 1, thermocouple temperature sensor 2, ceramic kiln controller 3, AD conversion module 4, actual furnace temperature curve module 5, set temperature control curve module 6, PID control Module 7, Gas Pipeline 8, Electric Proportional Valve 9, Wireless Communication 10, PC 11, Percentage Scoring Module for Current Ceramic Firing Results 12, Sample 13, Sample Library 14, Genetic Optimization Processing Module 15, Optimized Temperature Control Curve Module 16.

[0070] Among them, the thermocouple temperature sensor 2 measures the current analog temperature in the ceramic kiln 1 and transmits it to the AD conversion module 4 in the ceramic kiln controller 3 to obtain the digital value of the current furnace temperature.

[0071] In the primary firing process of the ceramic kiln, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com