A kind of briquette for vertical industrial kiln and its preparation method

An industrial and kiln technology, which is applied in the field of briquette coal for vertical industrial kilns and its preparation, can solve the problems of over-burning products, large smoke and dust emissions, and uneven calcination, so as to improve the uniformity of cloth distribution and meet the requirements of high-heat Value demand, improve the effect of cloth uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Prepare briquette according to the following steps:

[0039] (1) Prepared pulverized coal: pulverize anthracite into powder with a particle size of 80 mesh or more, and then dry it to moisture content ≤ 3%;

[0040] (2) Prepare sulfur-fixing agent: take 78 mass parts of lime and 22 mass parts of periclase, pulverize into powder with a particle size of 80 mesh, to obtain 100 mass parts of sulfur-fixing agent;

[0041] (3) Prepare biomass powder: shear the biomass and crush it into a powder of 50 mesh;

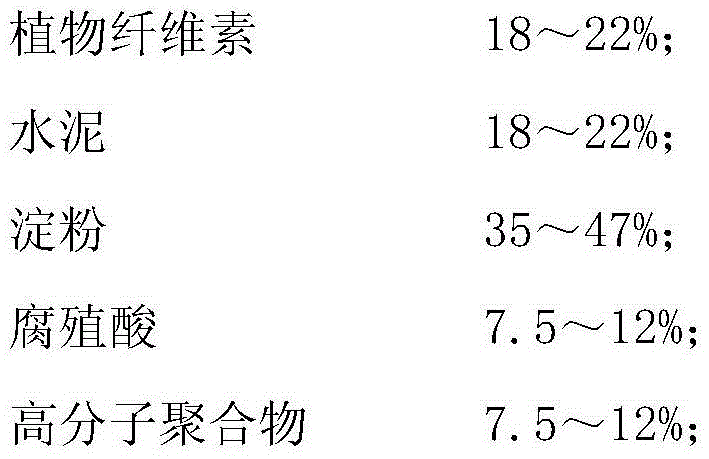

[0042] (4) Prepare the adhesive: take 18 parts by mass of vegetable cellulose, 18 parts by mass of cement, 40 parts by mass of starch, 12 parts by mass of humic acid and 12 parts by mass of high molecular polymer, and mix and blend them. In the form of a slurry, a 100-mass-point adhesive is obtained;

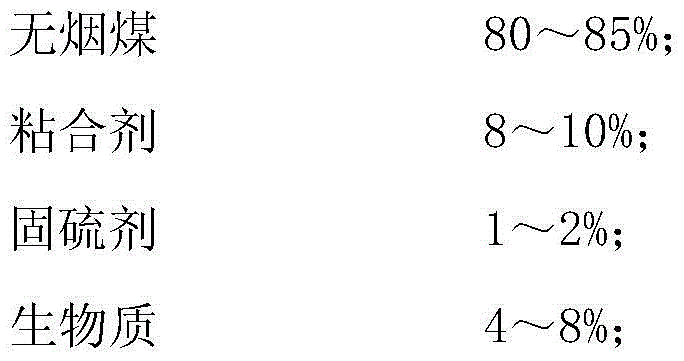

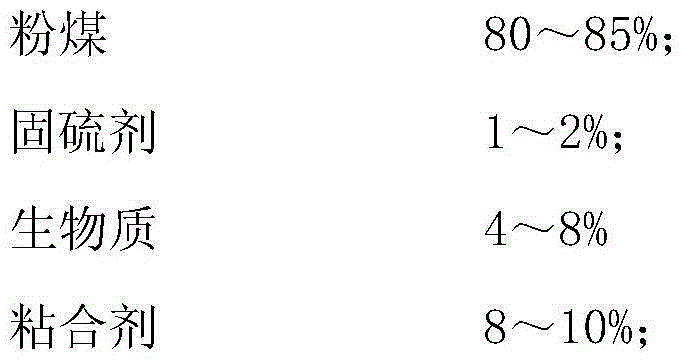

[0043] (5) Compression molding: take the raw materials prepared in steps (1) to (4) and their respective mass percentages: 80% pulverized coal, 2% sulfur-fixing agent, 8% biomass, a...

Embodiment 2

[0046] The difference between this embodiment and the first embodiment lies in the following steps:

[0047] (2) Preparation of sulfur-fixing agent: Take 83 mass parts of lime and 17 mass parts of periclase, pulverize into powder with a particle size of 150 mesh, to obtain 100 mass parts of sulfur-fixing agent;

[0048] (3) Preparation of biomass powder: the biomass is sheared and crushed into 150 mesh powder;

[0049] (4) Prepare the adhesive: take 19 mass parts of vegetable cellulose, 19 mass parts of cement, 47 mass parts of starch, 7.5 mass parts of humic acid and 7.5 mass parts of high molecular polymer, and mix and blend them. In a slurry state, a 100-mass-point adhesive was prepared.

Embodiment 3

[0051] The difference between this embodiment and the first embodiment lies in the following steps:

[0052] (2) Preparation of sulfur-fixing agent: taking 80 mass parts of lime and 20 mass parts of periclase, crushed into powder with a particle size of 150 mesh, to obtain 100 mass parts of sulfur-fixing agent;

[0053] (3) Preparation of biomass powder: the biomass is sheared and crushed into 150 mesh powder;

[0054] (4) Prepare the adhesive: take 22 parts by mass of vegetable cellulose, 22 parts by mass of cement, 35 parts by mass of starch, 10.5 parts by mass of humic acid, and 10.5 parts by mass of high molecular polymer, and mix and blend. In a slurry state, a 100-mass-point adhesive was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com