Detachable type quick heating calcining furnace for SCR (Selective Catalytic Reduction) plate type catalyst production

A rapid heating and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, electric furnace heating, etc., can solve the problems of not meeting the production process requirements, product quality defects, etc., to reduce energy consumption, prolong service life, The effect of widely promoting the value of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

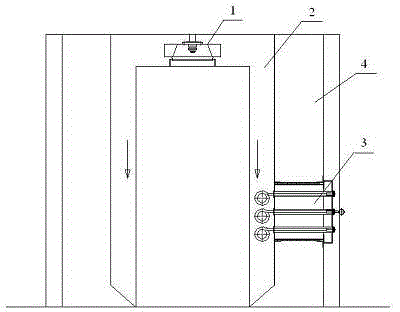

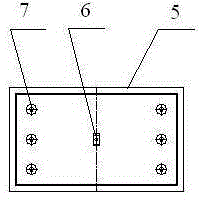

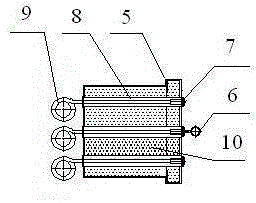

[0013] Such as figure 1 As shown, the detachable fast heating module 3 is installed in the installation hole reserved in the middle and lower part of the furnace wall 4 of the calciner, so that the electric heating tube 9 is in the circulation air duct 2 of the calciner, and the supplemented fresh air plays the role of the circulation fan 1 The bottom is sent from top to bottom and installed in the circulating air duct 2. The fresh cold air and the surface of the resistance wire sleeve made of nickel-chromium alloy material of the electric heating tube 9 are continuously heat-exchanged, so that the air can quickly heat up and meet the requirements of product production. Process requirements to ensure product firing quality. The detachable rapid heating calciner for the production of SCR plate catalyst is composed of a shell 5, a pull ring 6, a terminal post 7, a porcelain sleeve 8, an electric heating tube 9 and a heat insulating fiber 10, etc., and the shell 5 is a stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com