Road silicate cement clinker and preparation method thereof

A technology of road portland and cement clinker, applied in the field of road portland cement preparation, cement clinker, road portland cement clinker, can solve the problems of complex steel slag composition, difficult cement raw meal, large fluctuation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

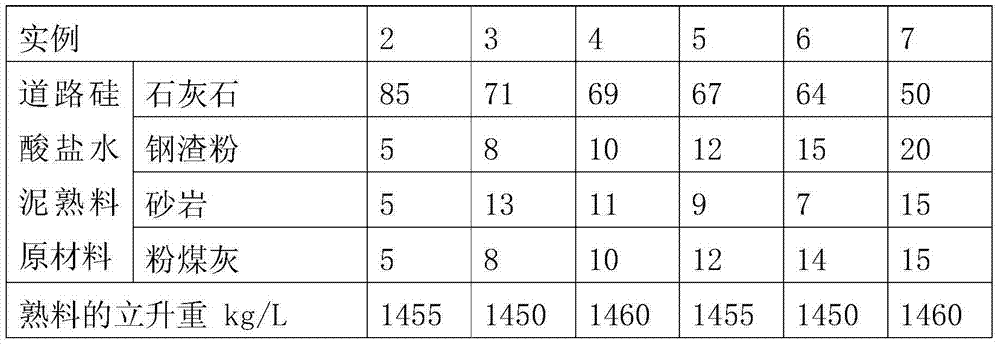

[0014] This implementation proposes a road Portland cement clinker prepared by using steel slag powder ingredients, which is used to prepare low-heat and high-flexibility road Portland cement. The cement clinker is made by grinding and calcining cement raw meal, and the cement raw meal is composed of the following materials in parts by weight: limestone: 50-85 parts; steel slag powder: 5-20 parts; sandstone : 5-15 parts; and fly ash: 5-15 parts. The percentages by weight of oxides in each component of the raw meal in the raw meal are: 60.0-74.0% for CaO, 60.0-74.0% for SiO 2 19.5-25.0%, Al 2 o 3 2.0-8.0%, Fe 3 o 4 4.5-7.0%. The clinker in this embodiment includes: tricalcium aluminate<5.0%, dicalcium silicate 15.0-40.0%, and tetracalcium aluminoferrite 16.0-20.0%.

Embodiment 2

[0016] This implementation proposes a preparation method of road Portland cement clinker prepared by using steel slag powder ingredients, which includes: 50-85 parts by weight of limestone, 5-20 parts by weight of steel slag powder, 5-15 parts by weight of sandstone, and powder The cement raw material composed of 5-15 parts by weight of coal ash is ground; then the raw material powder is calcined to obtain cement clinker. It effectively improves the firing quality of the clinker, and the vertical lift weight of the clinker is increased from 1300kg / L of general Portland cement clinker to 1450kg / L.

Embodiment 3

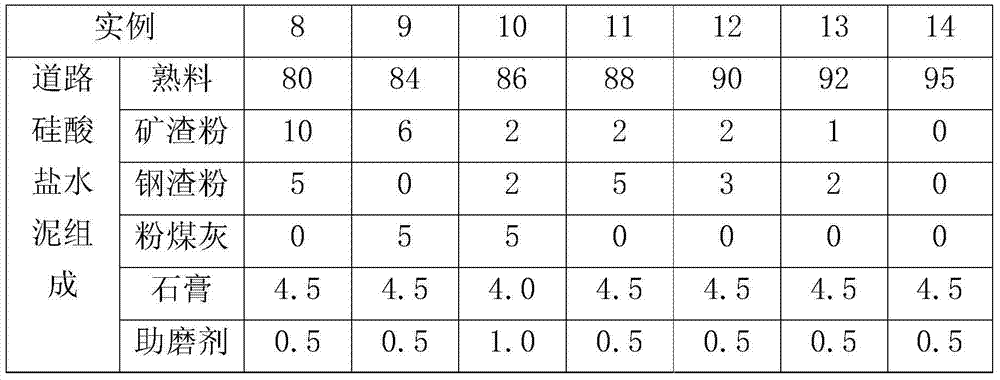

[0018] This implementation proposes low-heat and high-bending road Portland cement, which includes: cement clinker: 80-95%; slag powder: 0-10%; steel slag powder: 0-5%; pulverized coal Ash: 0-5%; Grinding aid: 0.5-1.0%; and Gypsum: 4.0-5.0%. The cement clinker is the cement clinker described in the examples prepared by the method described in Implementation 2. Wherein the gypsum is dihydrate gypsum, anhydrite or industrial by-product gypsum; the grinding aid is triethanolamine or talcum powder. The 28d flexural strength of the road portland cement described in this embodiment exceeds 9.0MPa; the 28d mortar wear is less than 2.5kg / m 2 ; The dry shrinkage rate of 28d mortar reaches 0.06%. The preparation method of the low-heat and high-bending road Portland cement described in this implementation is to mix the prepared low-heating and high-bending road Portland cement clinker with fly ash and (or) gypsum and ( Grinding aids) mixed together and ground together until the specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Heat of hydration | aaaaa | aaaaa |

| Heat of hydration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com