Dry-process cement preheating decomposition system

A dry process cement and calcining furnace technology, applied in the field of cement production, can solve the problem of less processing capacity, and achieve the effects of preventing spillage and reducing the amount of harmful substances formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

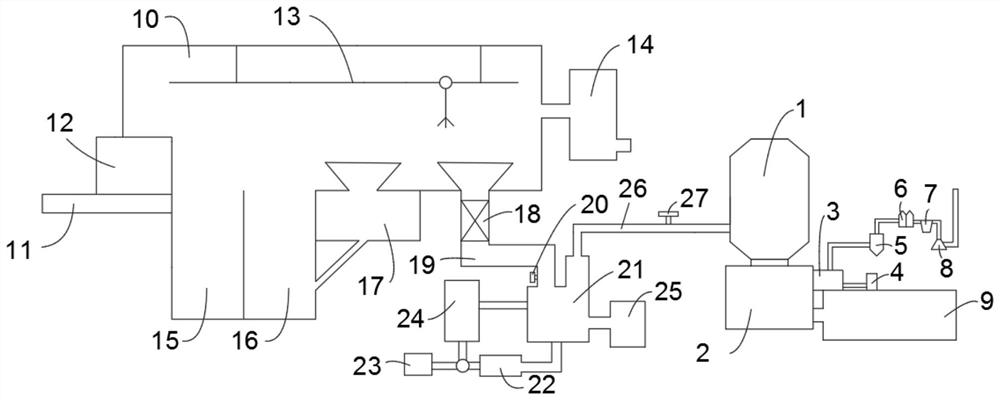

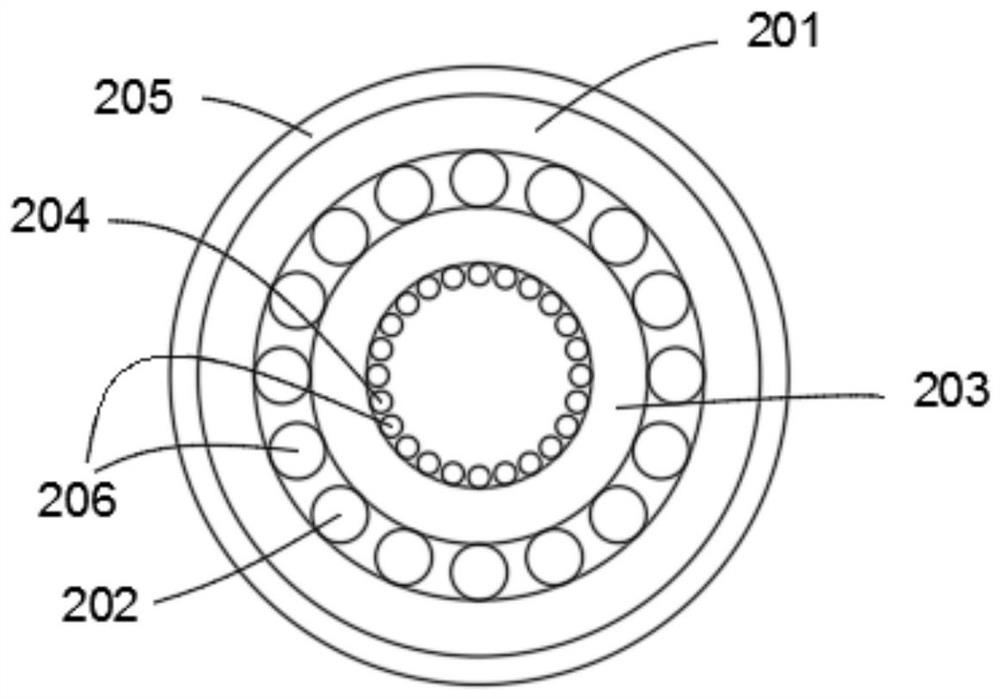

[0027] Examples, see attached Figure 1-2 , a dry-process cement preheating decomposition system provided by the present invention includes a decomposition furnace 1, a decomposing mechanism is provided on one side of the decomposition furnace 1, and a pulverized coal burner 2 is provided at the lower end of the decomposition furnace 1. One side of the pulverized coal burner 2 is provided with a dilution cooler 3, one side of the dilution cooler 3 is connected with a dilution blower 4, and the upper end of the dilution cooler 3 is connected with a cyclone separator 5, and the cyclone separator The upper end of device 5 is connected with dechlorination equipment 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com