Multifunctional ceramic firing kiln and manufacturing method of porcelain thereof

A multi-functional, ceramic technology, used in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of difficult automation of gas, high technical difficulty in manual operation, low heat utilization rate, etc., and achieves bright color and strong sense of hierarchy. , Improve the effect of firing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

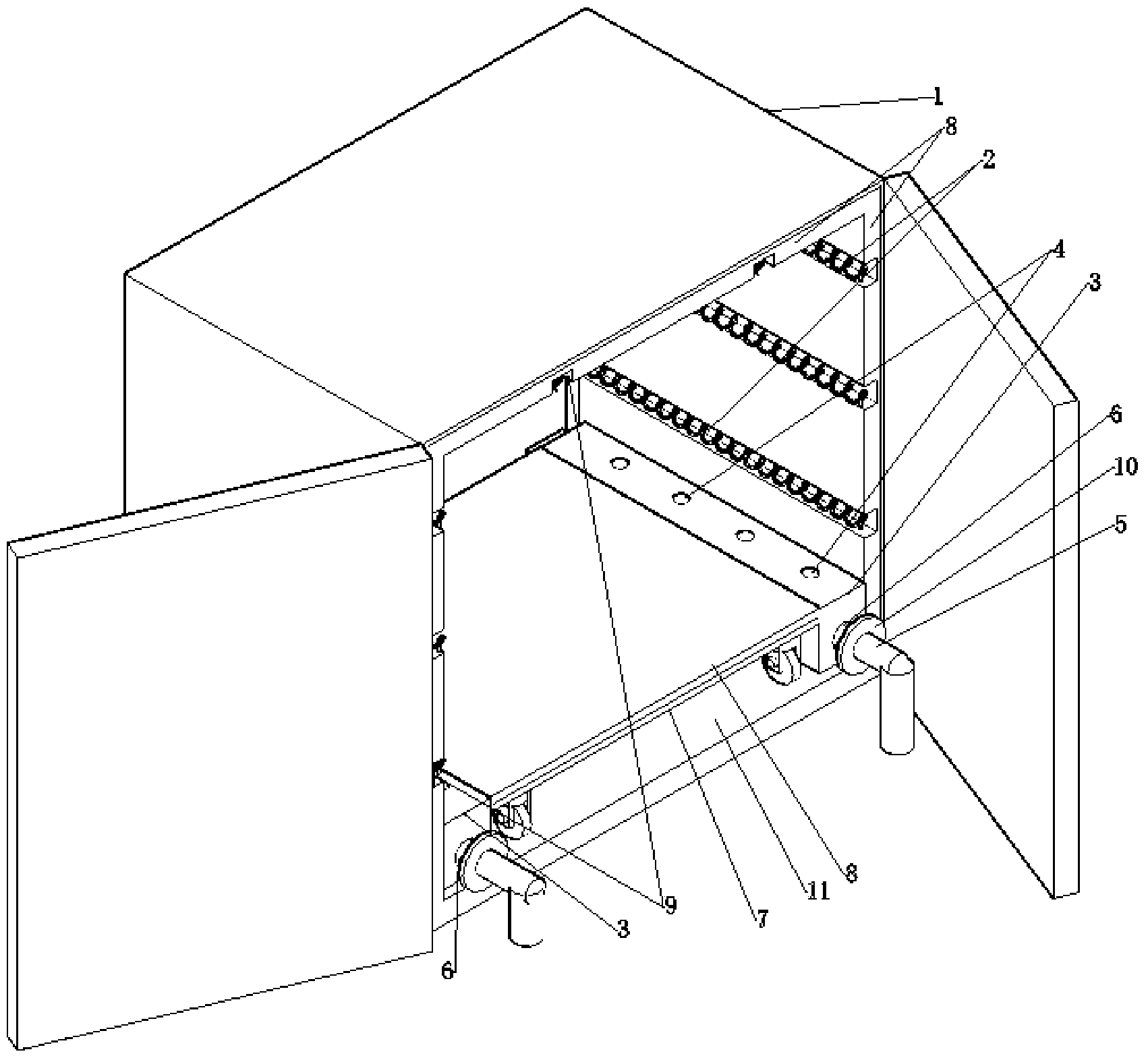

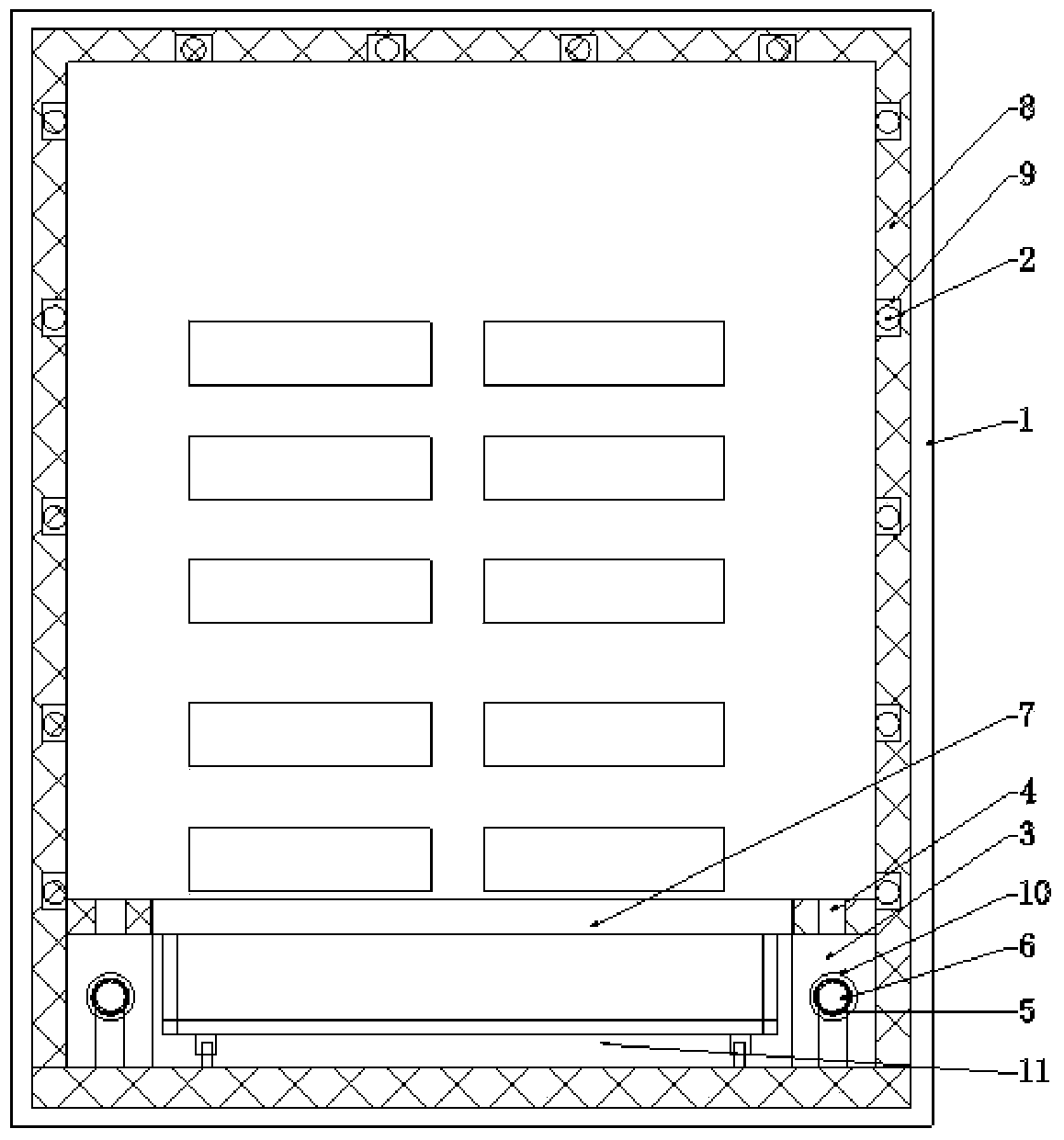

[0012] In order to further understand the technical solution of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings.

[0013] The embodiment of the multifunctional ceramic kiln of the present invention is such as figure 1 and 2 As shown, the furnace body 1 including the corresponding peripheral side walls and the top wall in the furnace chamber are respectively provided with integral heat-insulation lining boards 8, and the wall surfaces of the integral heat-insulation lining boards 8 on the left, right, rear and top of the furnace chamber Corresponding receiving grooves 9 are provided.

[0014] In the furnace cavity of the furnace body 1, an electric heating device and a gas heating device are provided at the same time. Heating body 2. The gas heating device includes gas mixing chambers 3 arranged on opposite sides of the bottom of the furnace cavity of the furnace body 1. On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com