Patents

Literature

30results about How to "Change the heating method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

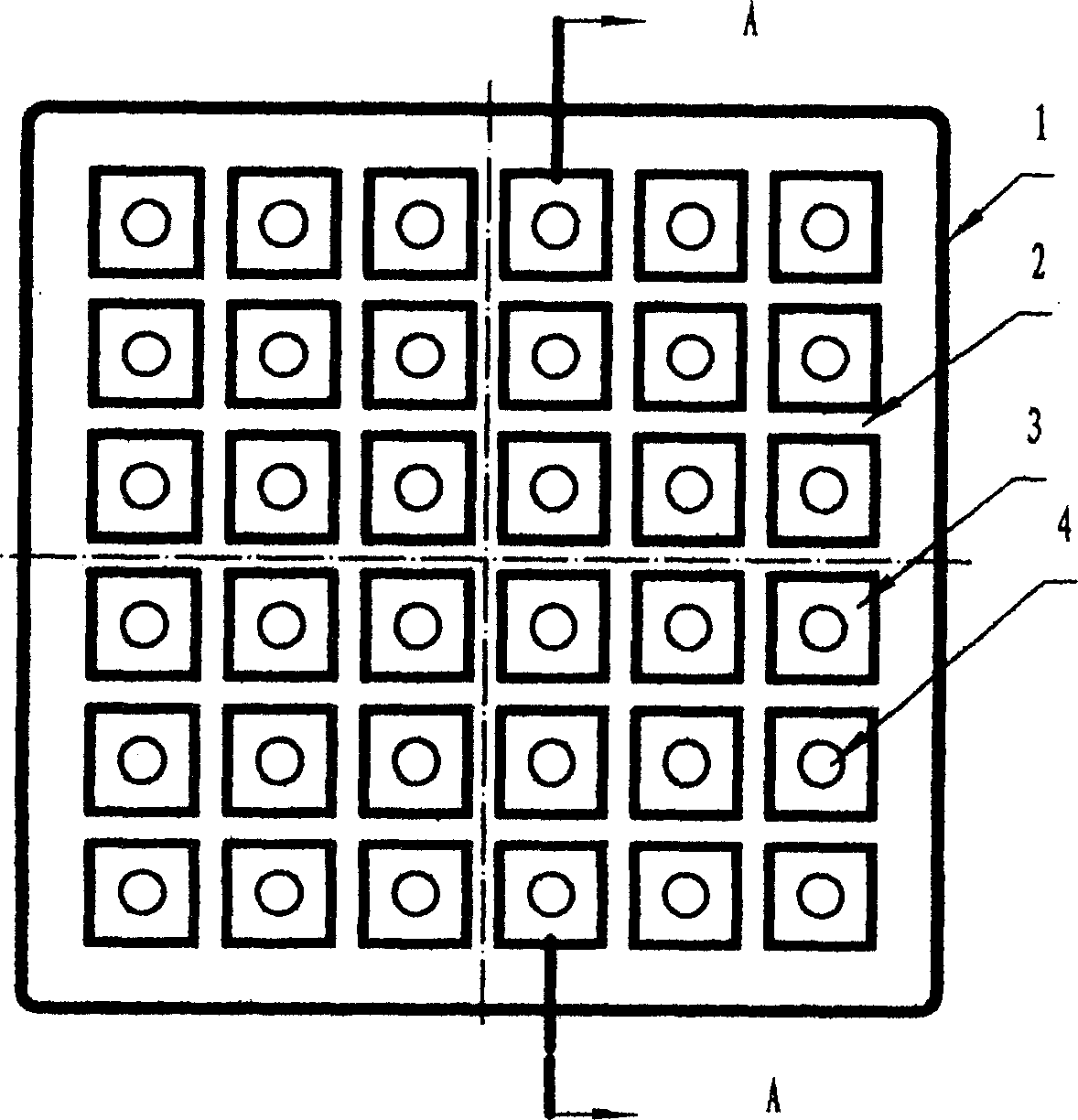

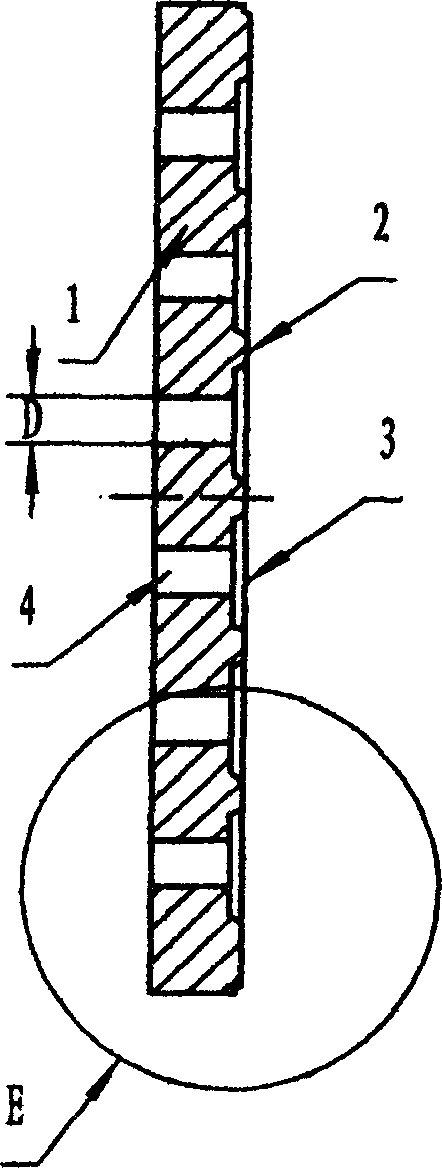

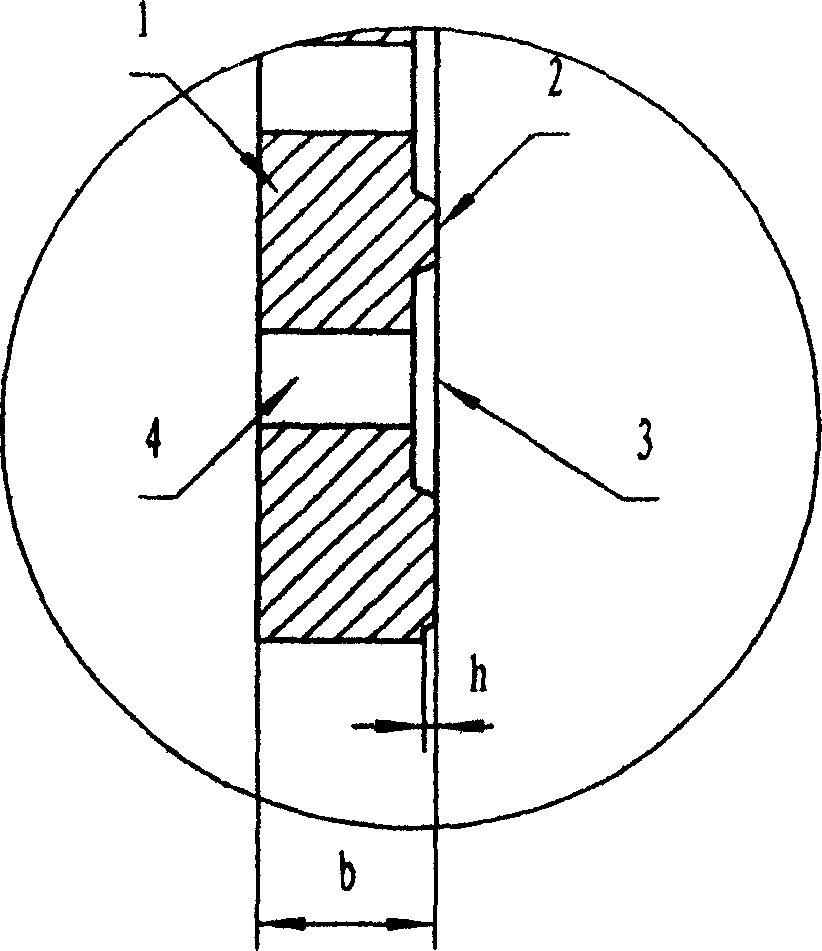

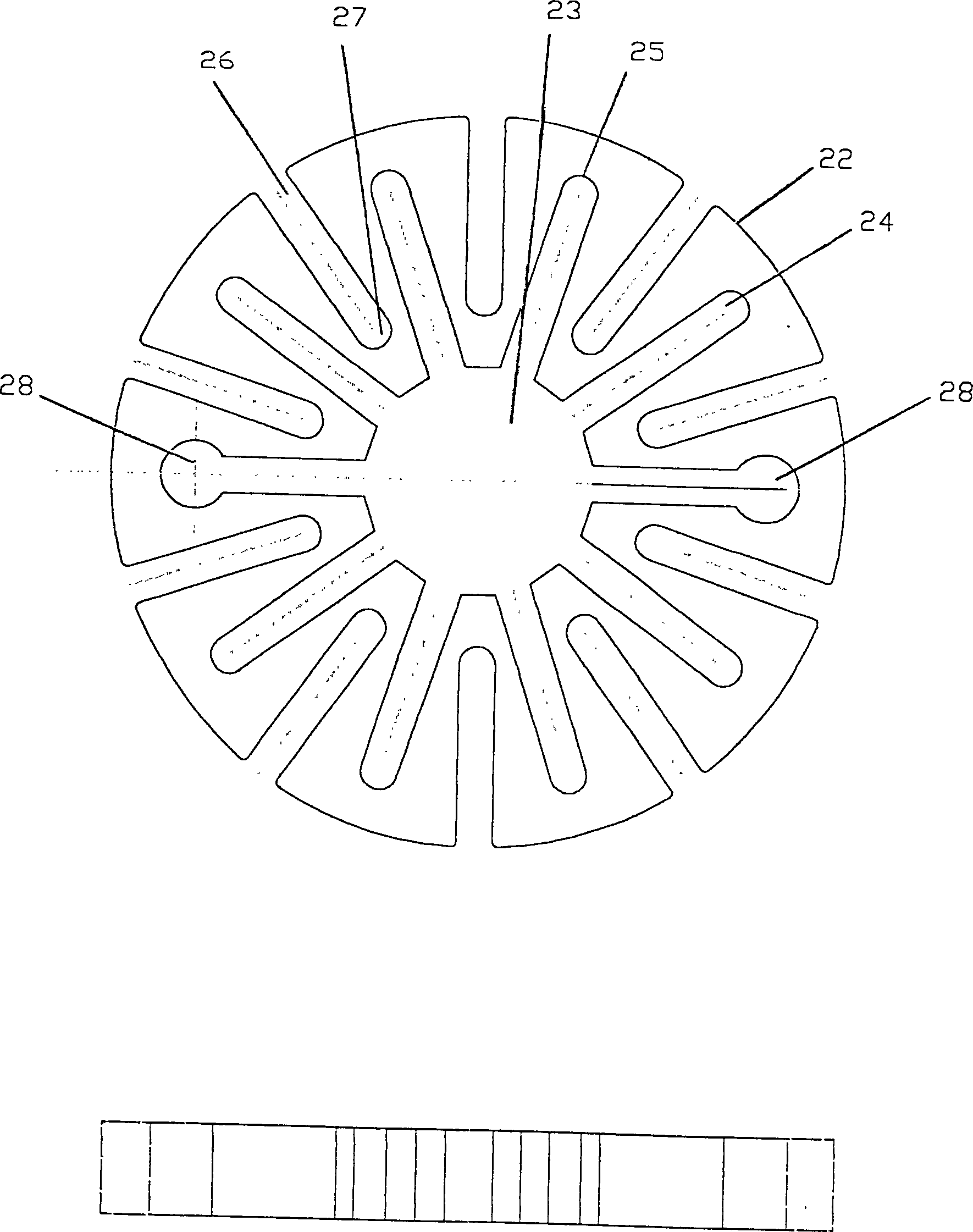

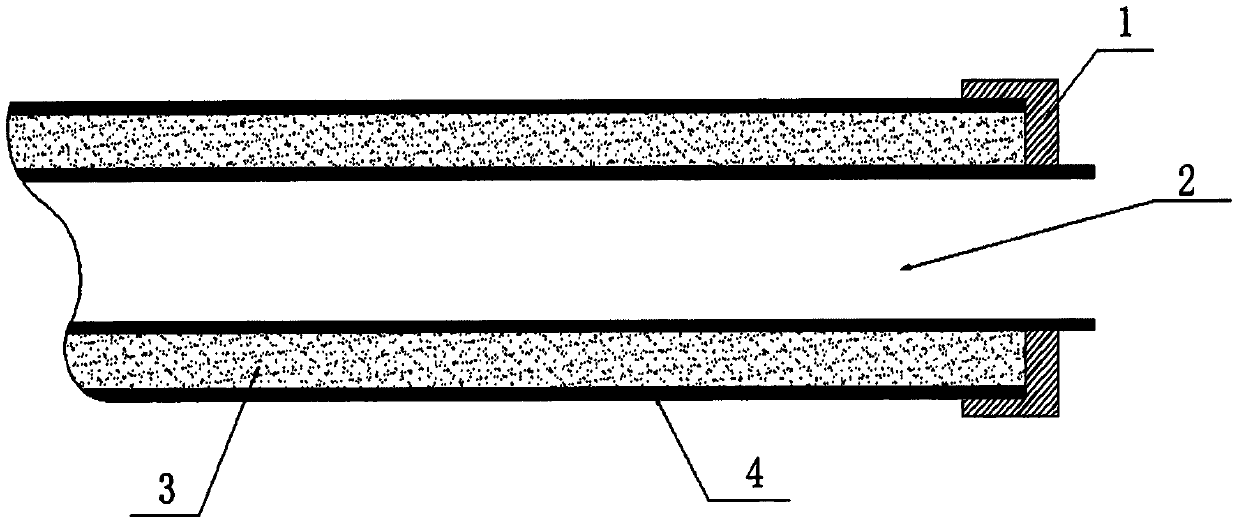

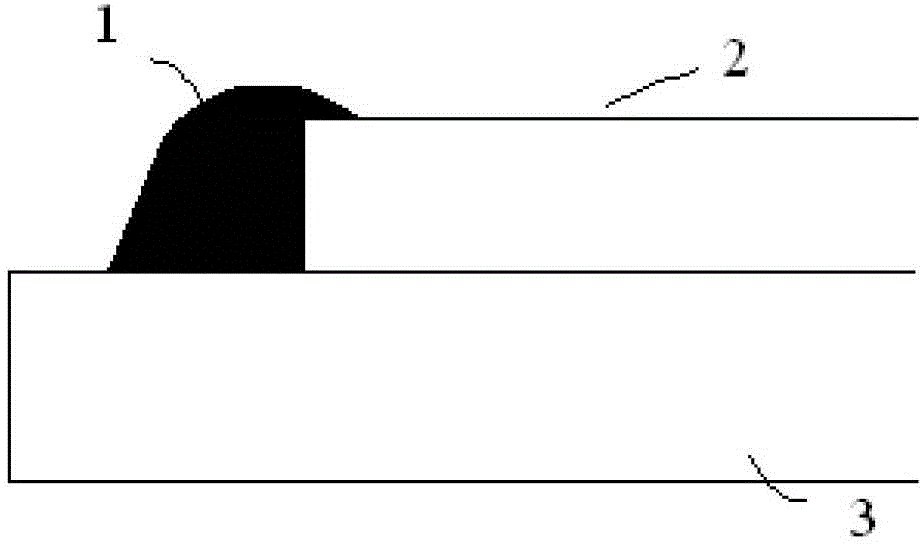

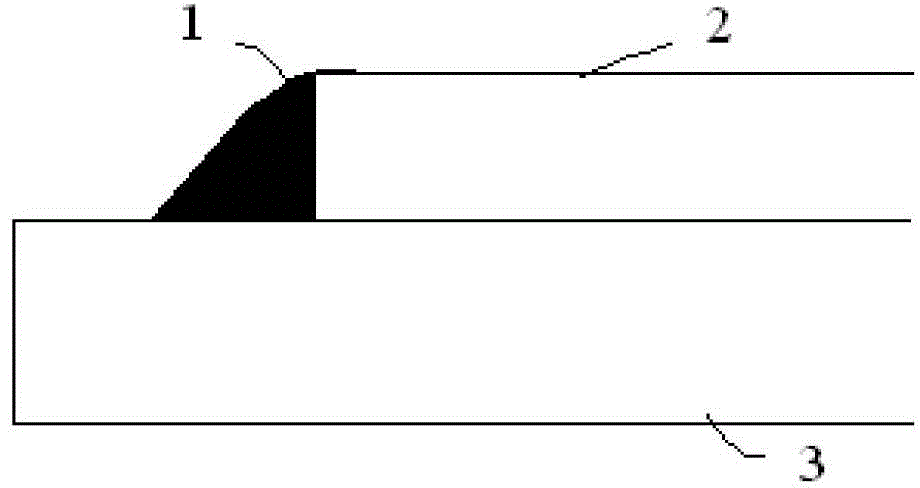

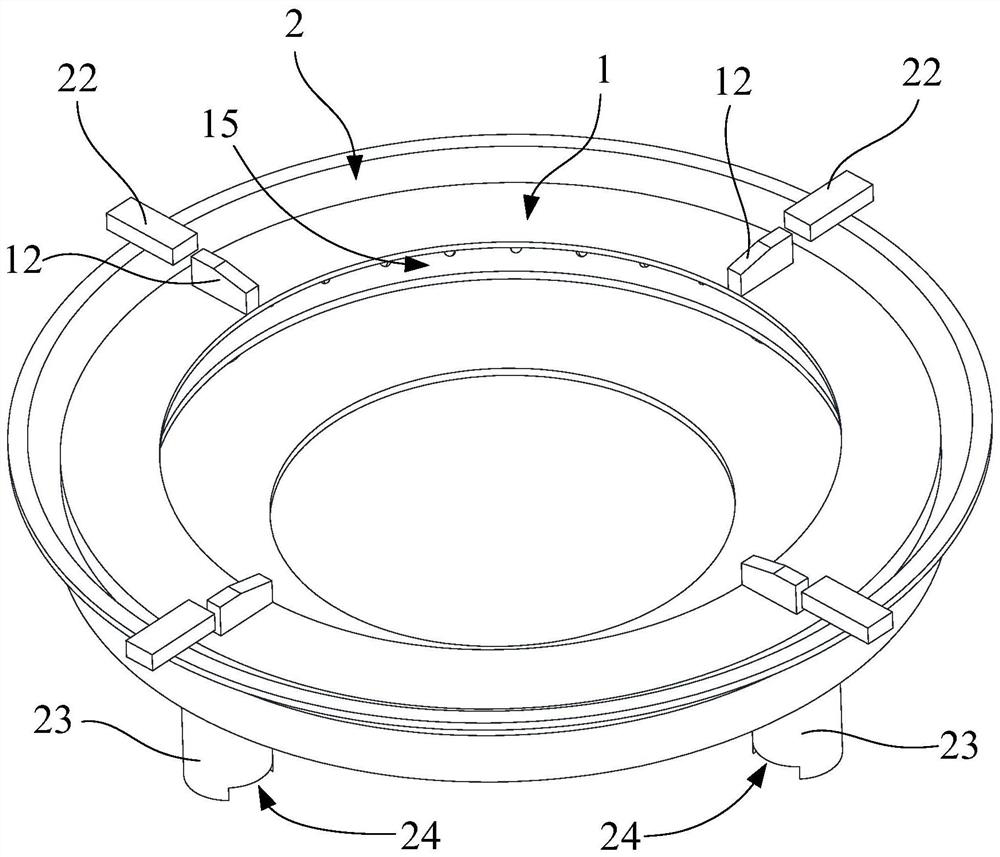

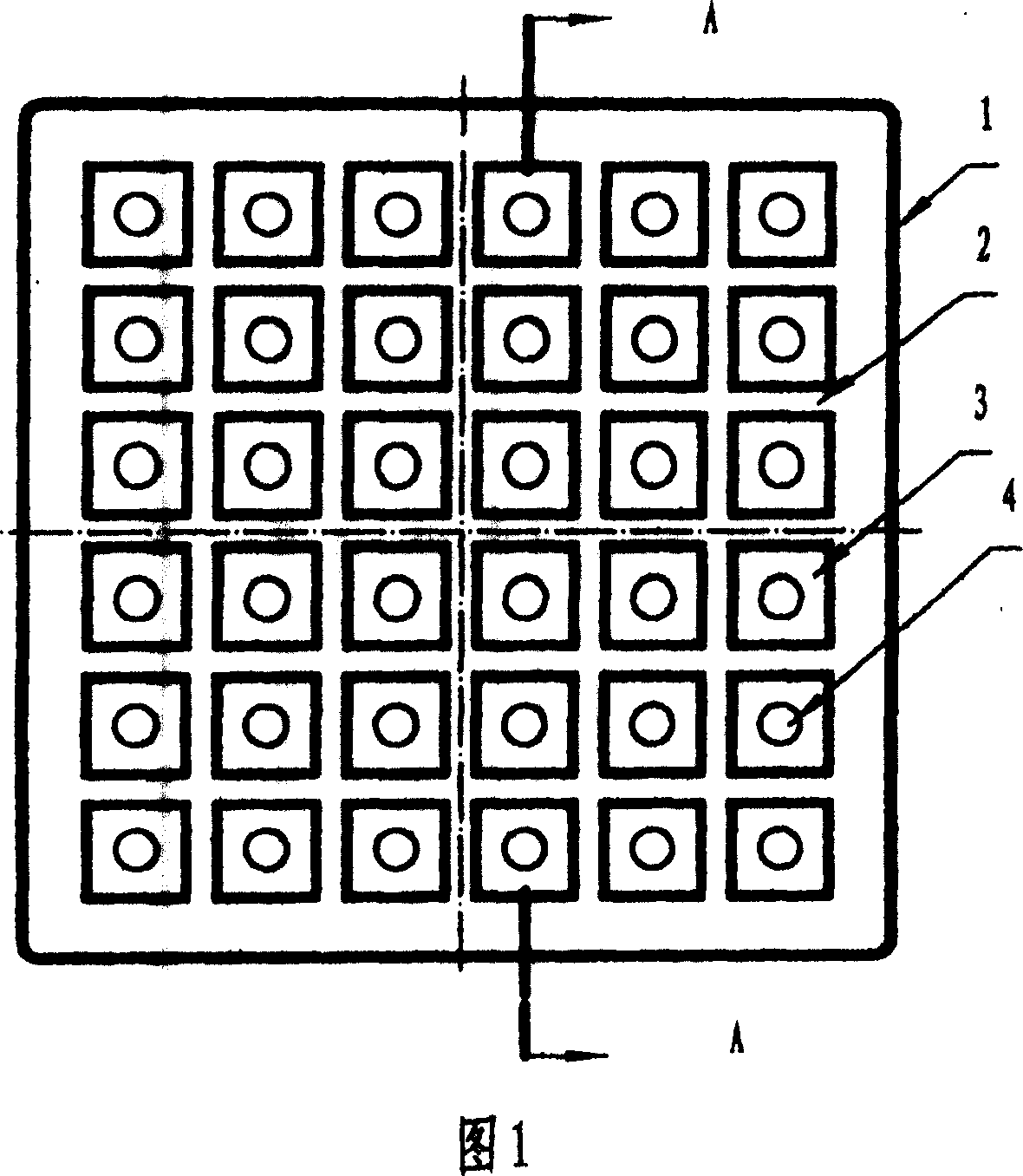

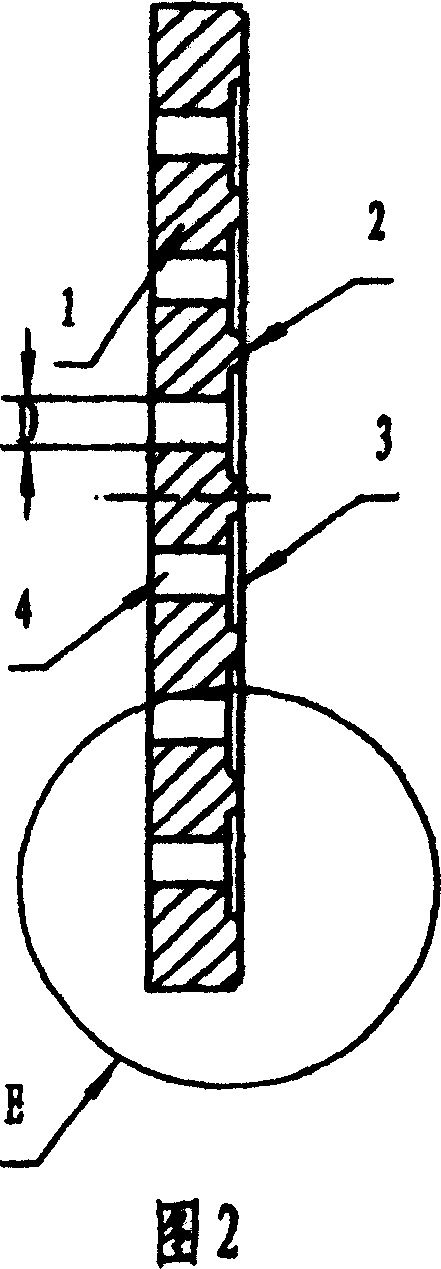

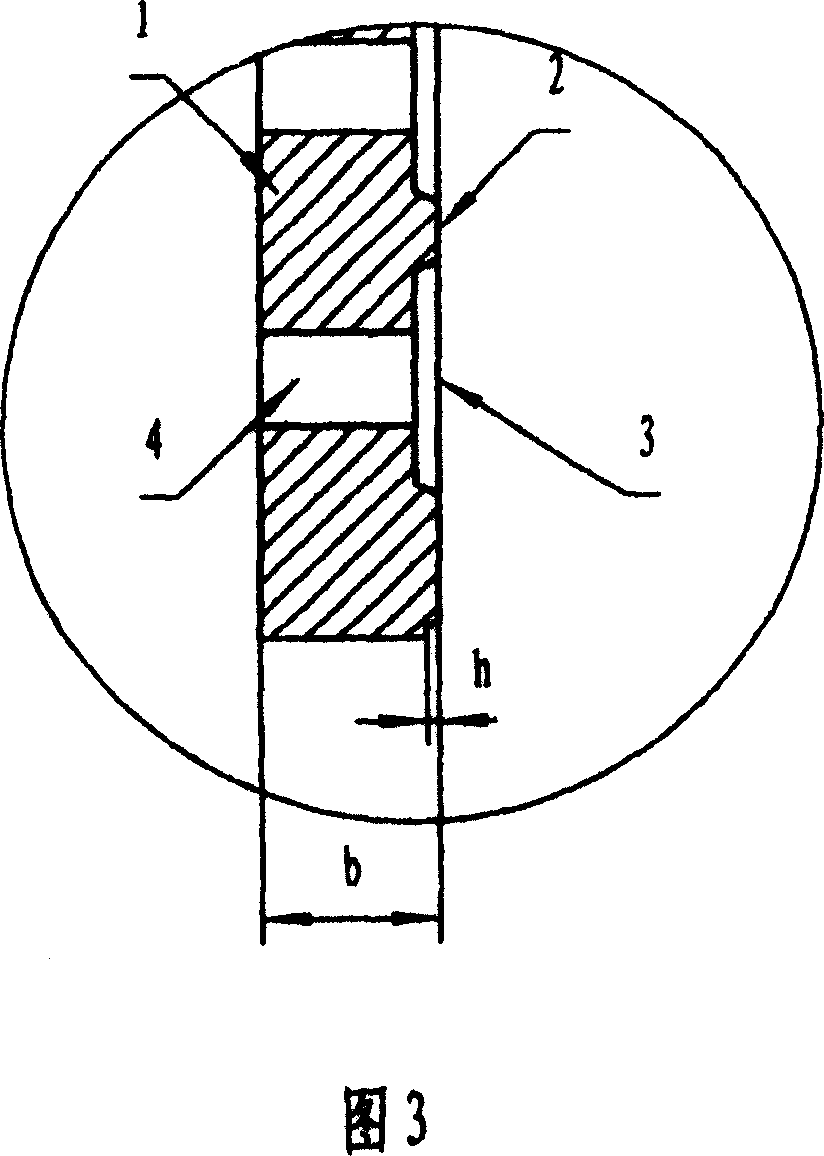

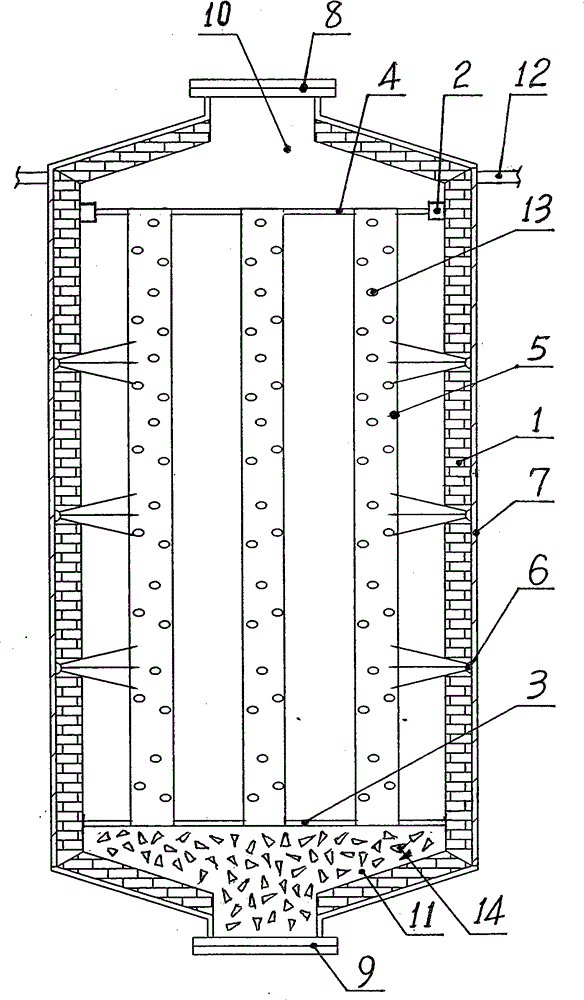

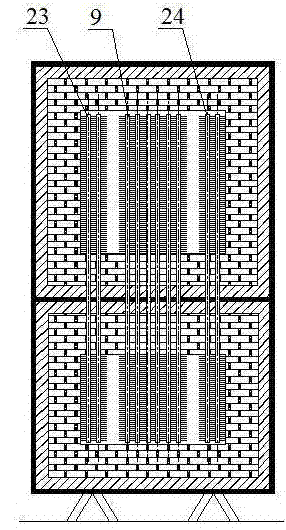

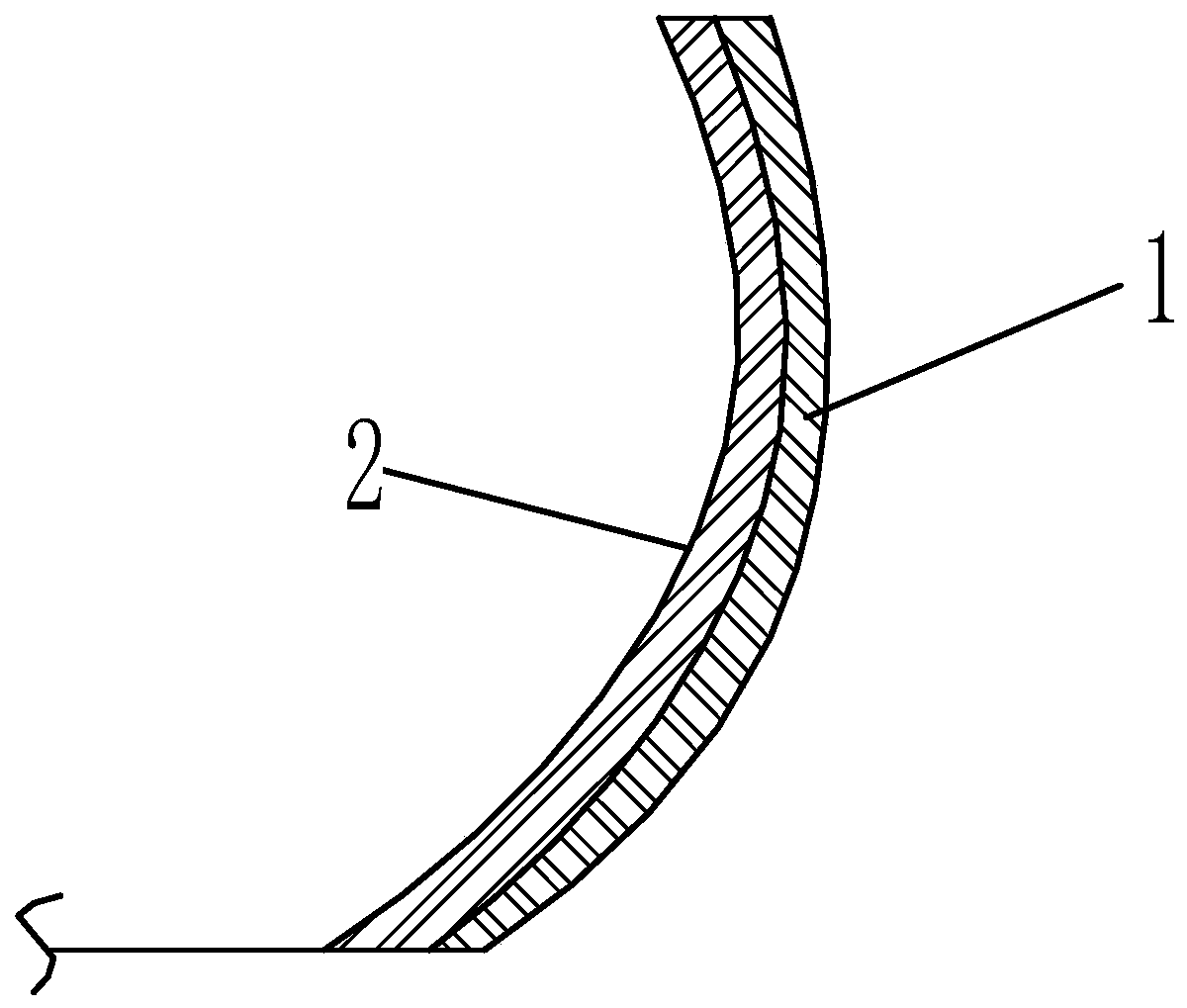

Energy-saving ceramic fire resistant bearing board

InactiveCN1724964AChange the heating methodChange the state of heatingCharge supportsBrickCombustion chamber

The invention is an energy-saving ceramic flame-resistant bearing firing plate, for solving the technical problem of making the glazed outside wall bricks fired by the same kiln have no obvious color difference but small deformation, thus improving the quality of finished products, and besides, for strengthening the intensity of bearing firing plate, reducing its breakage rate. For this, the invention fills ribs and blanks at the bottom of the bearing firing plate, where a through hole is equipped within each blank. The blanks and holes can be regularly shaped or irregularly shaped. The invention is mainly used in ceramic kiln to bear and transport the fired ceramic blanks in the course of firing and especially applied to the glazed outside wall blanks.

Owner:康健伟

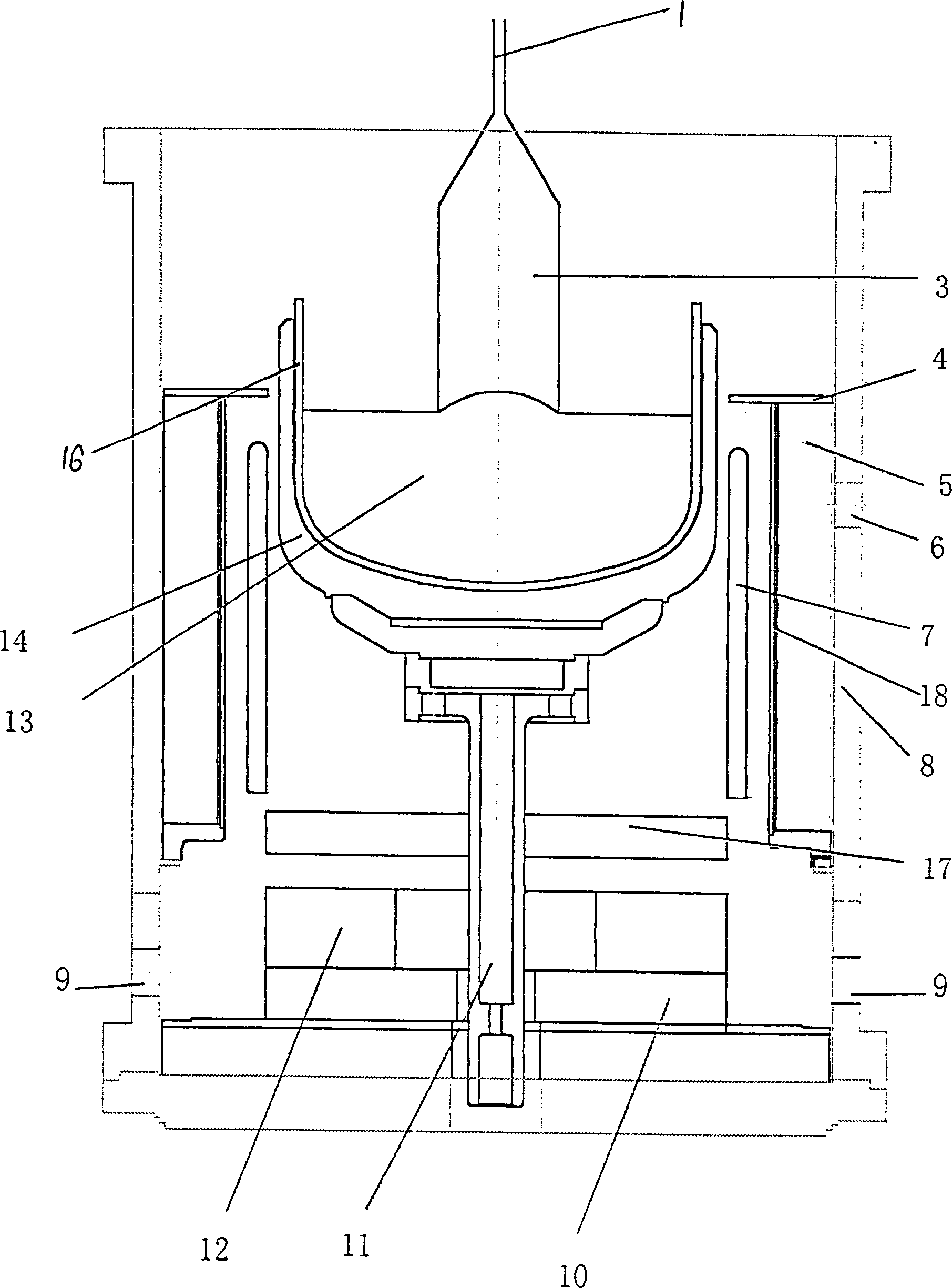

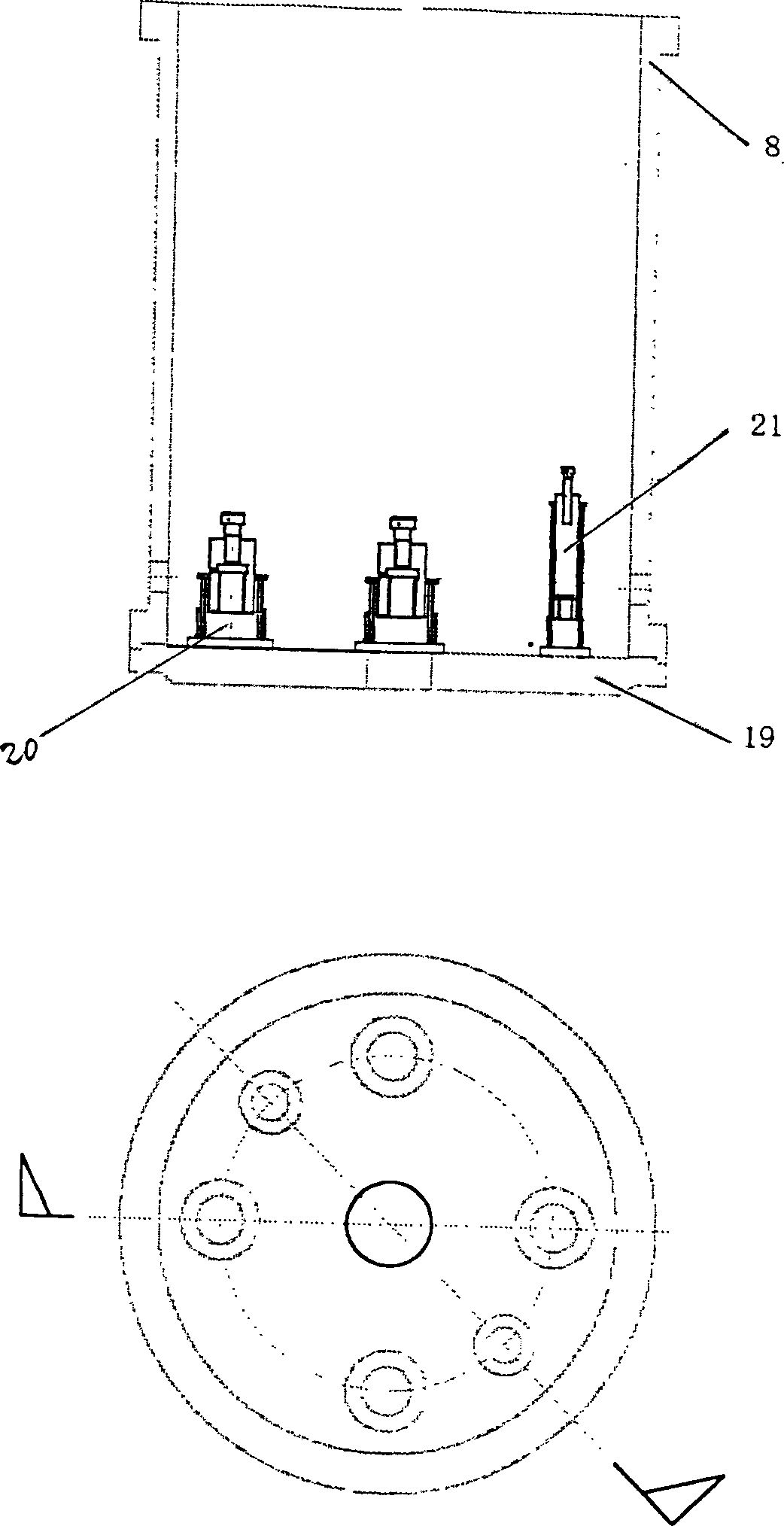

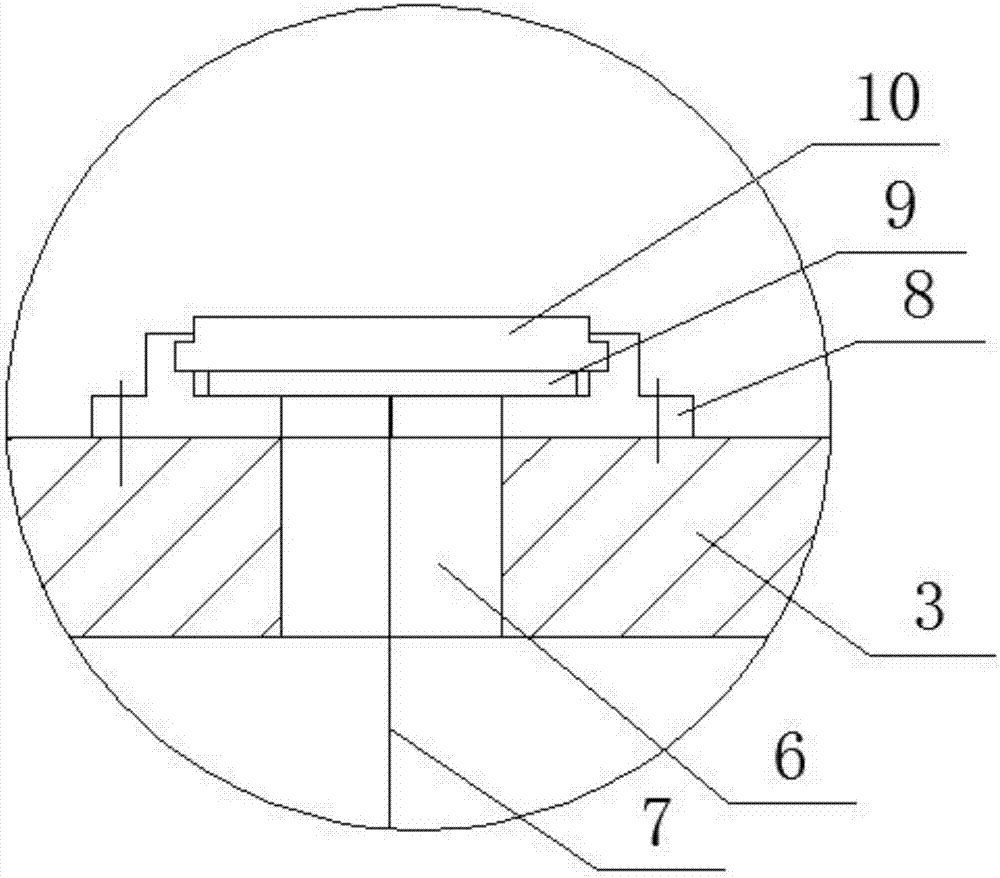

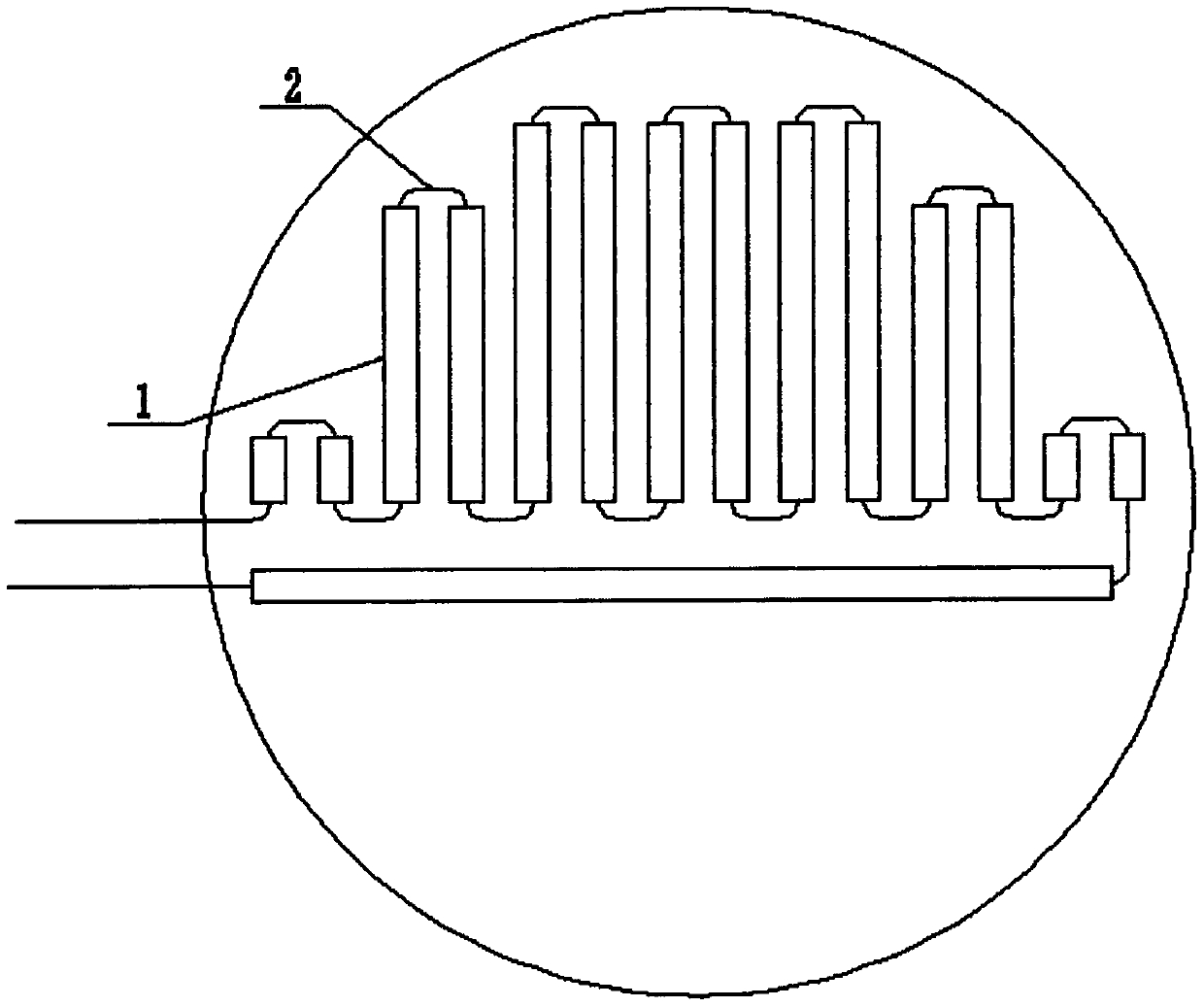

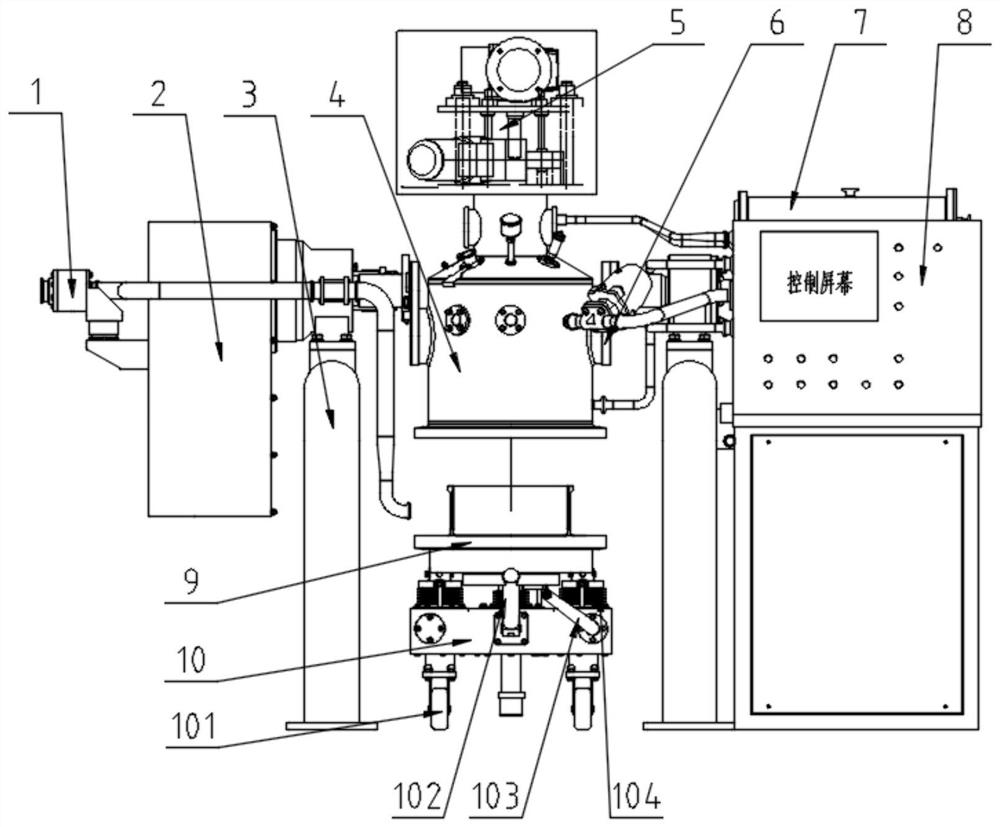

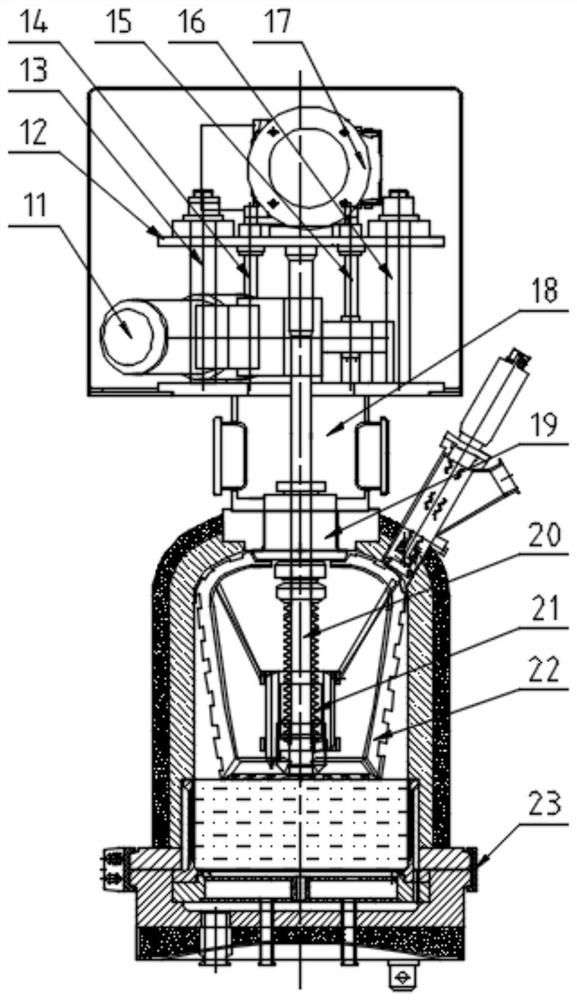

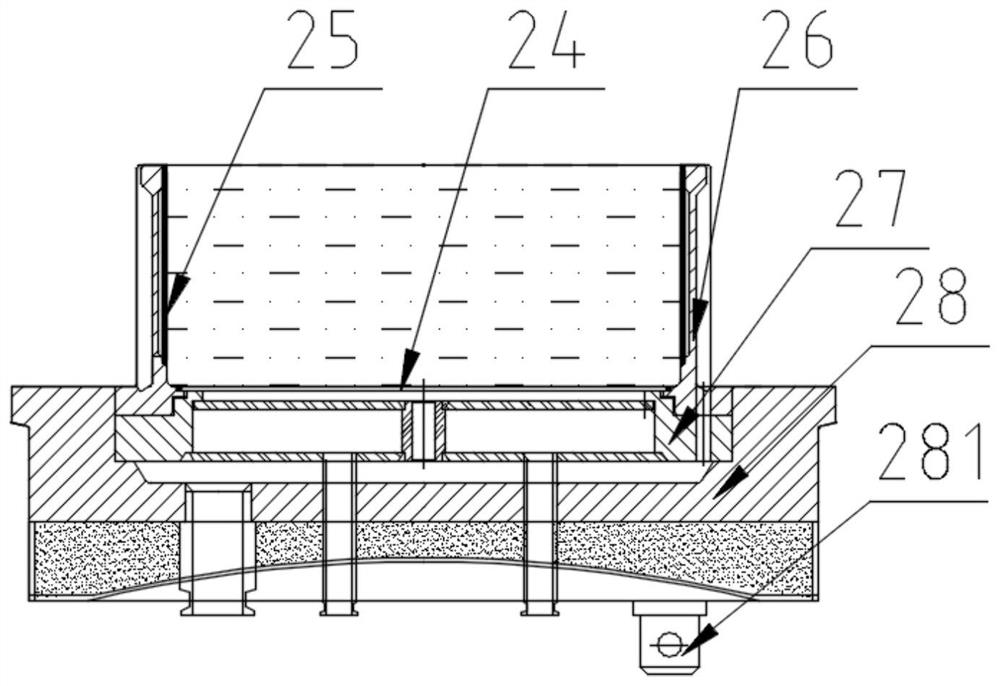

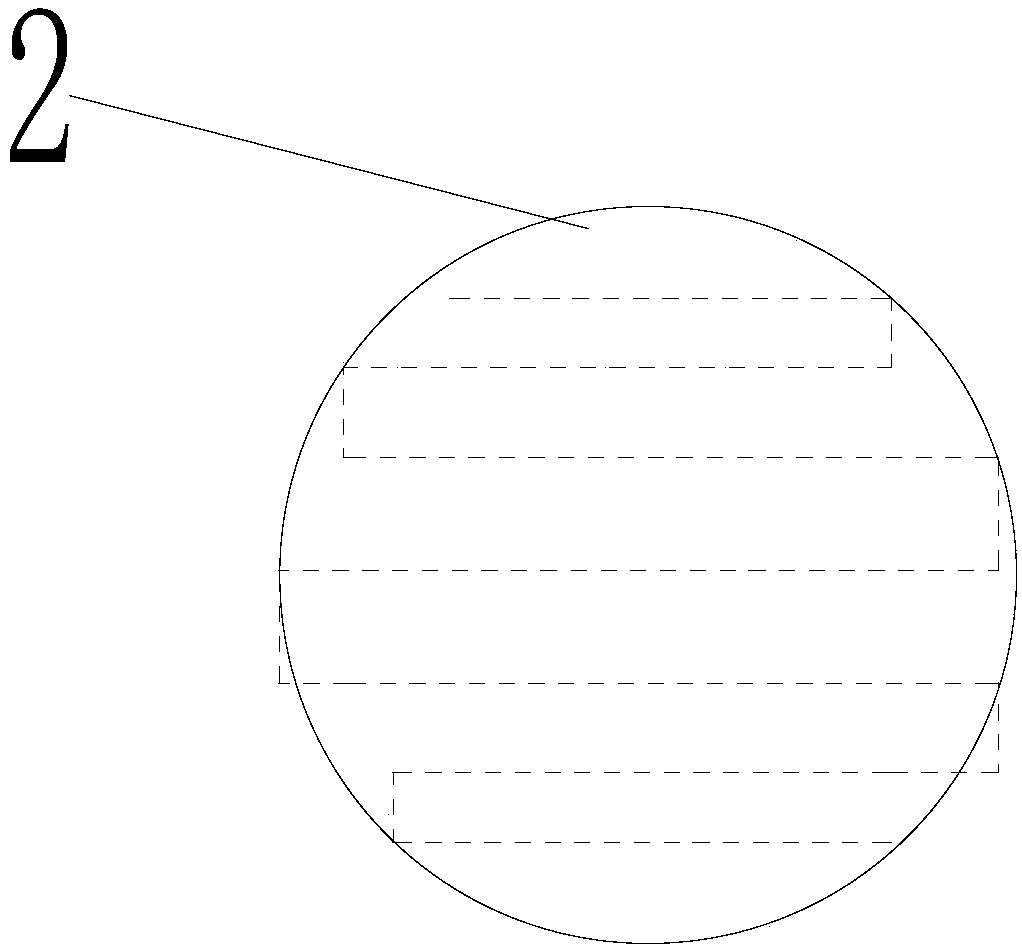

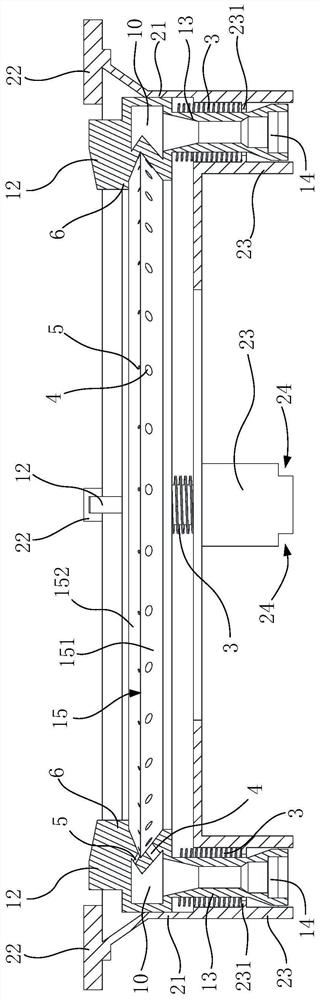

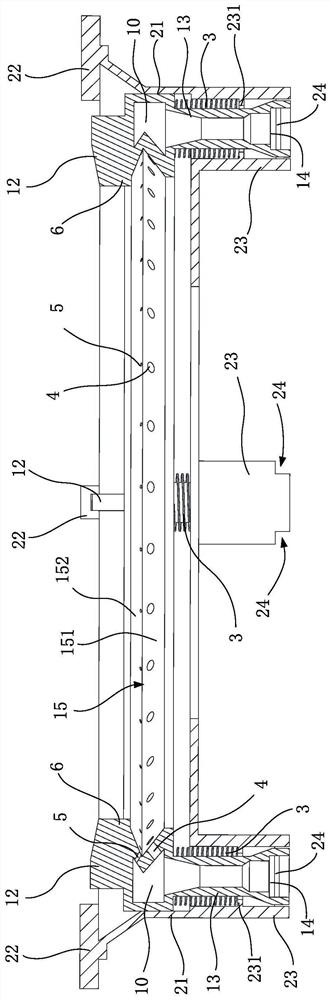

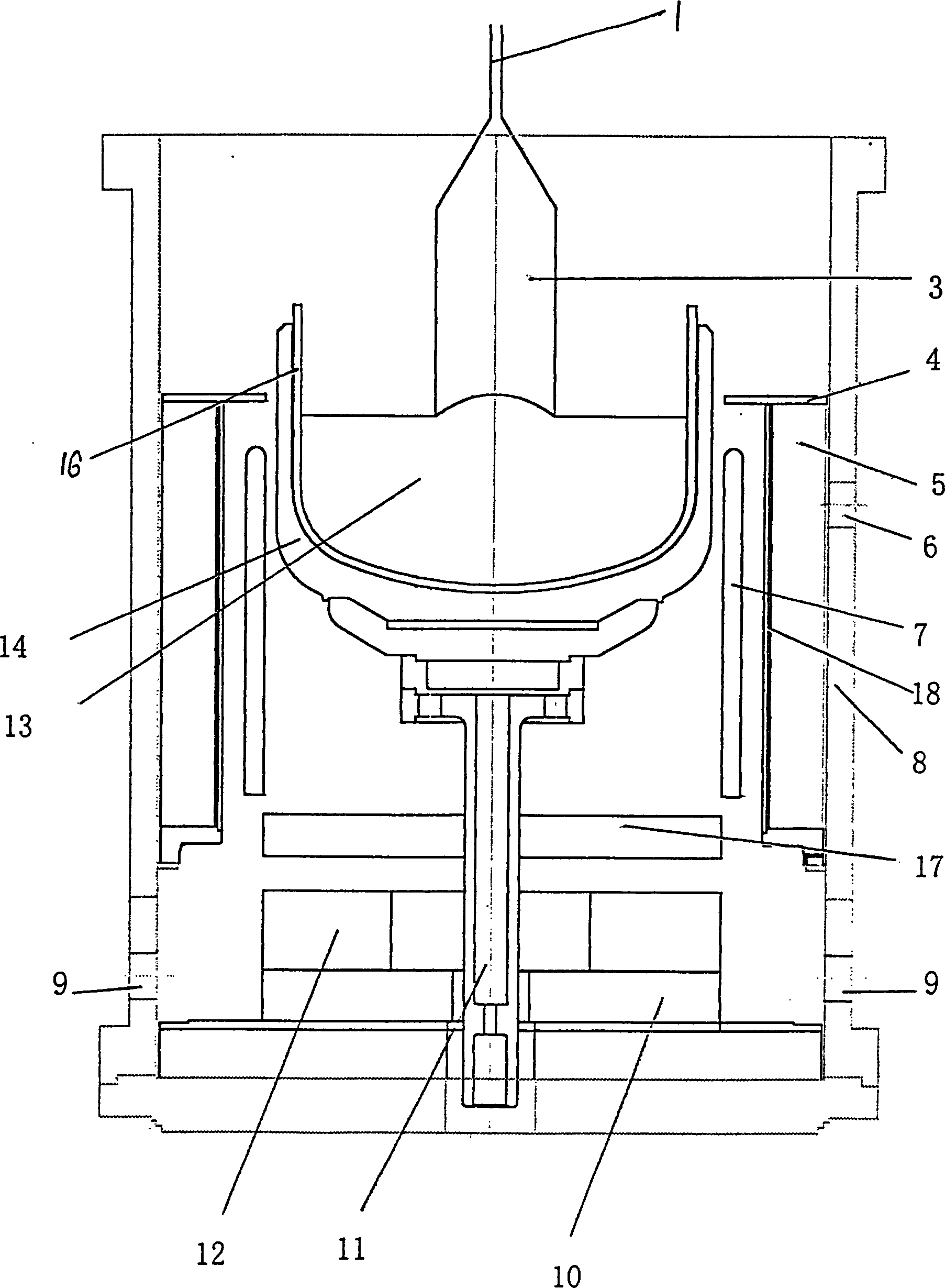

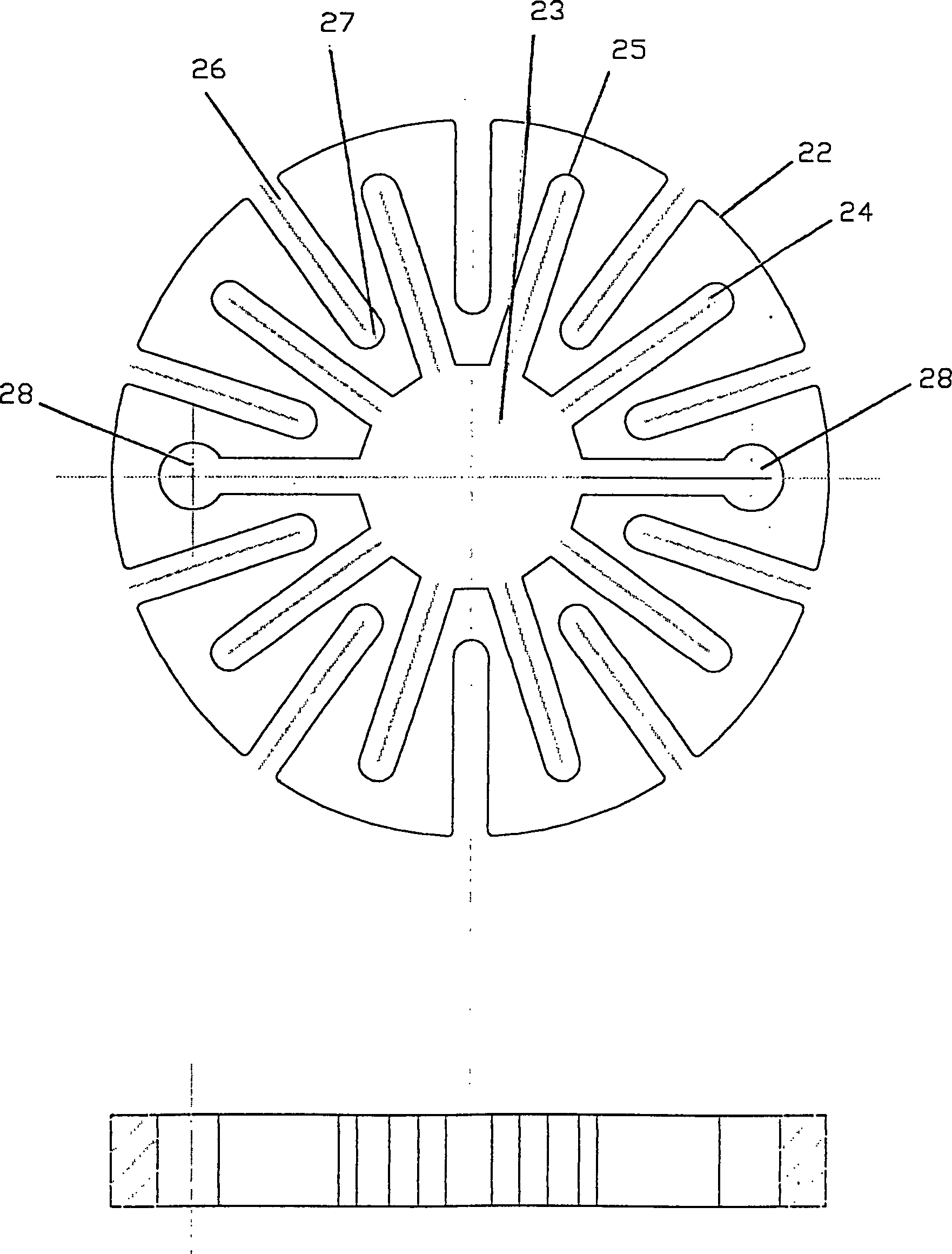

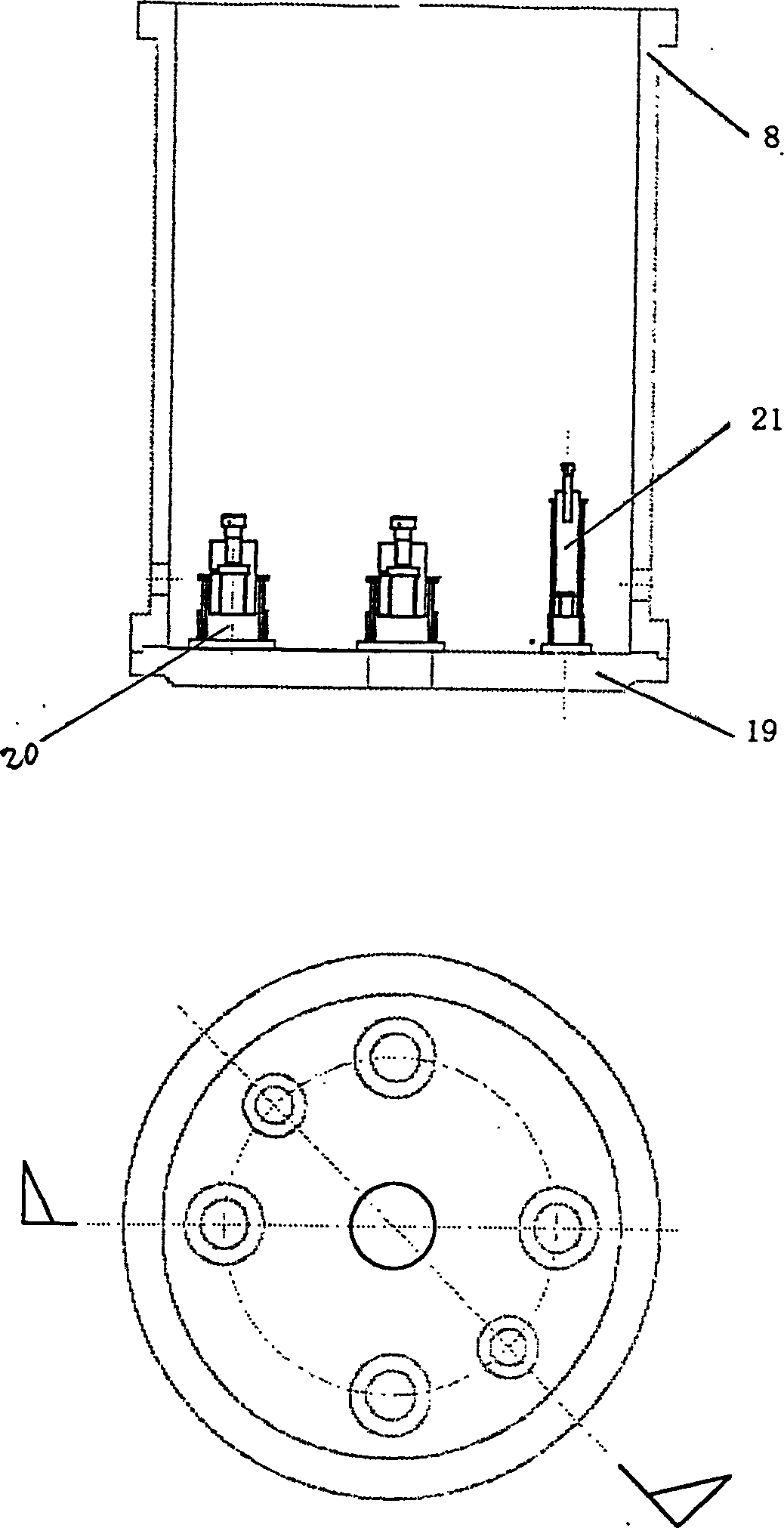

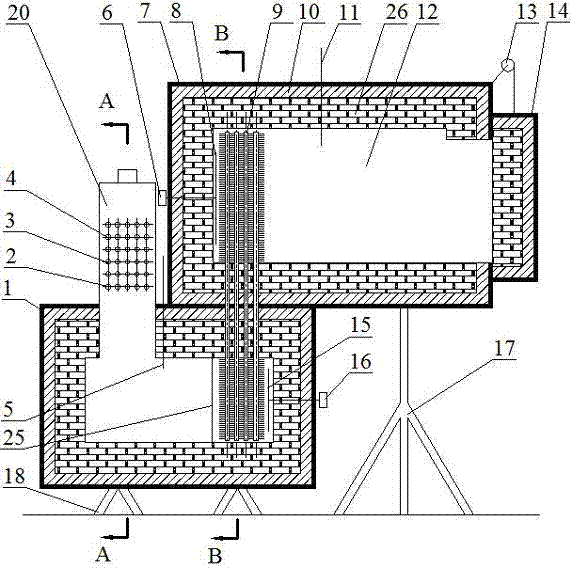

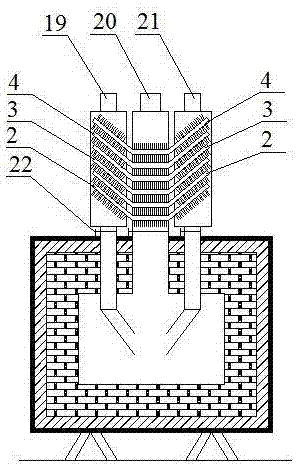

Method of speeding smelting of polycrystalline material and bottom heater for pulling monocrystal

InactiveCN1417388AIncrease temperatureChange the heating methodBy pulling from meltDc currentEngineering

The present invention relates to a method of speeding melting of polycrystalline raw material and the bottom heater for pulling monocrystal. The method comprises leading DC current to bottom heater while leading DC current to the main heater, so that the quartz crucible is heated from both lateral side and bottom. The bottom heater comprises one disc heating body and two electrodes. The present invention can short the melting time of polycrystalline material and save electric power, and thus increase the yield of monocrystal silicon or germanium.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

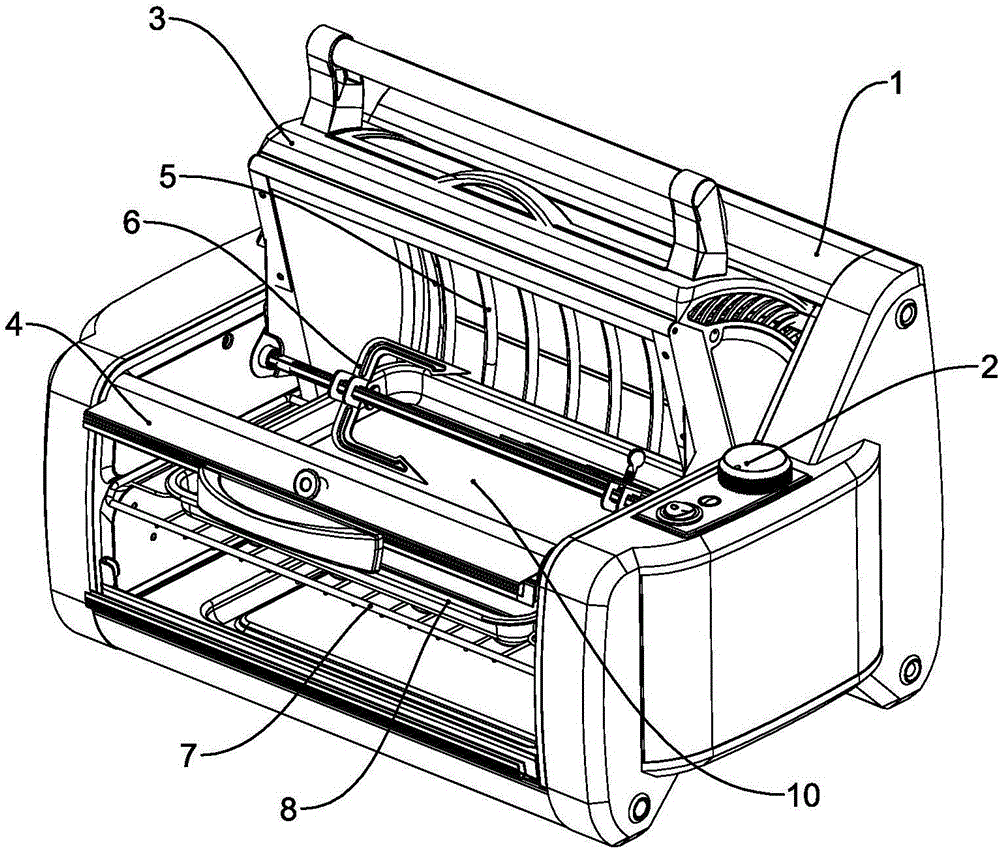

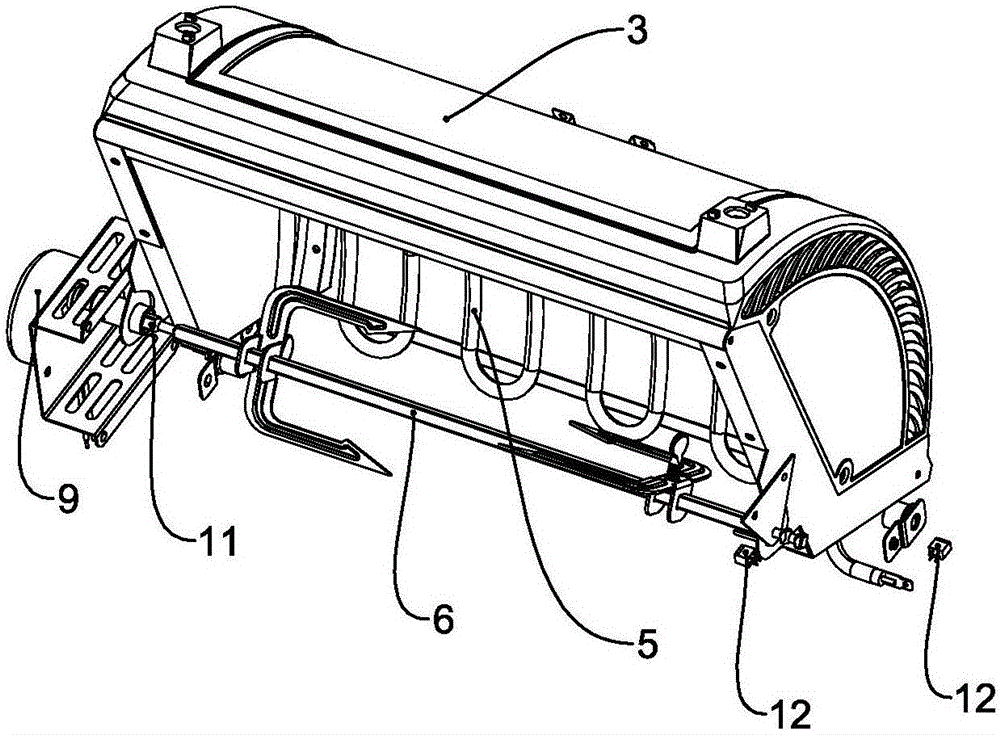

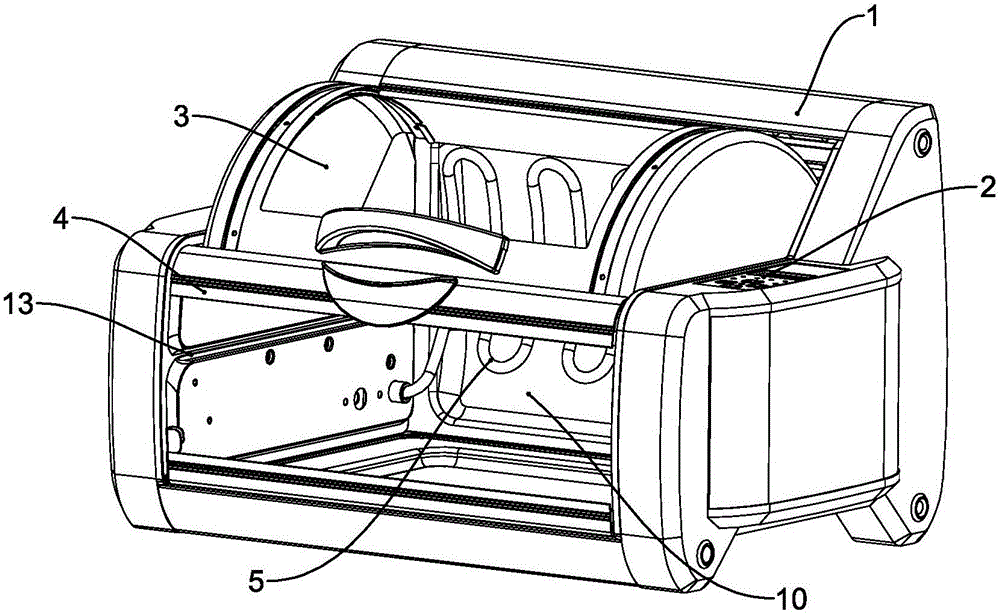

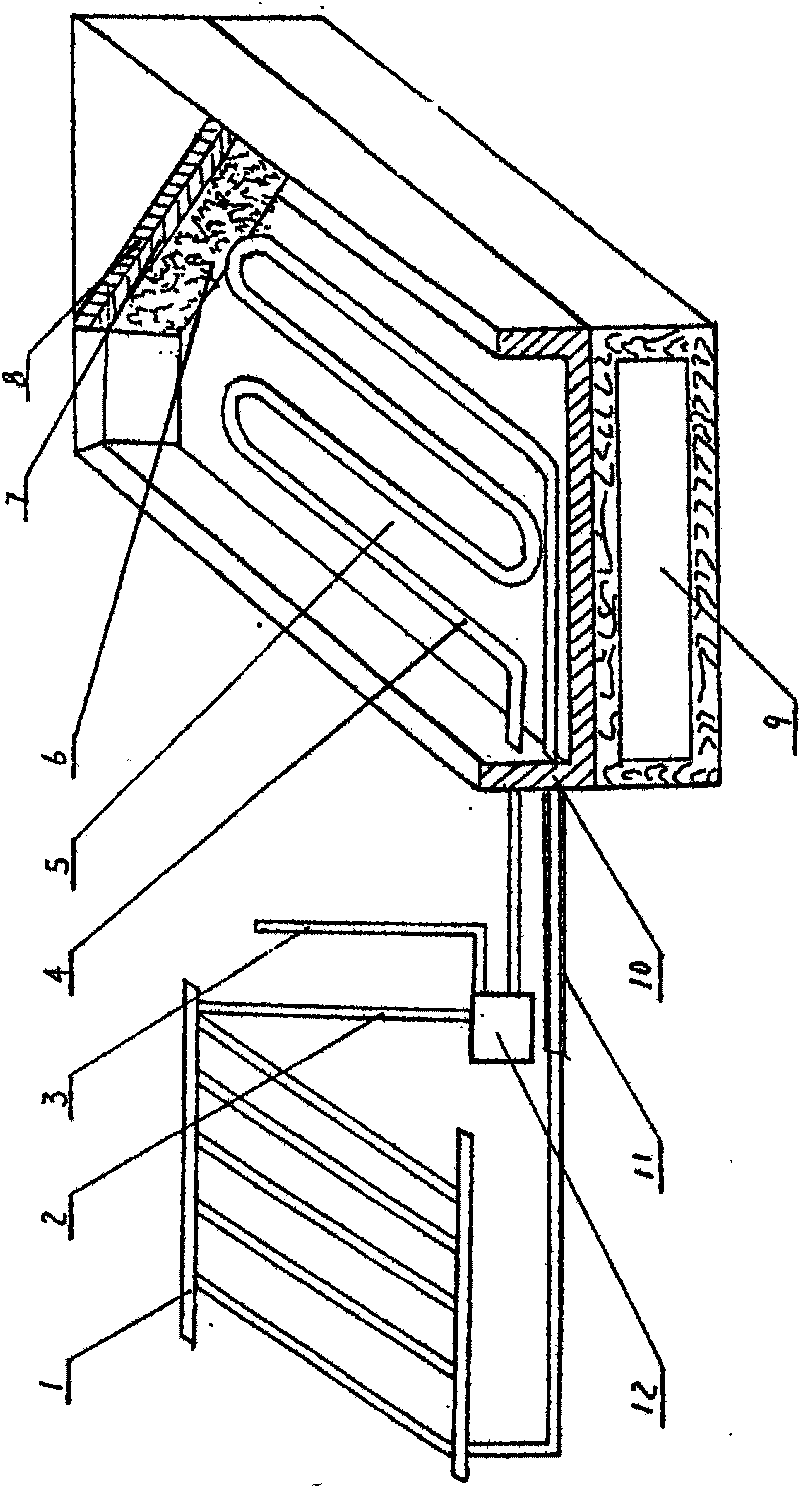

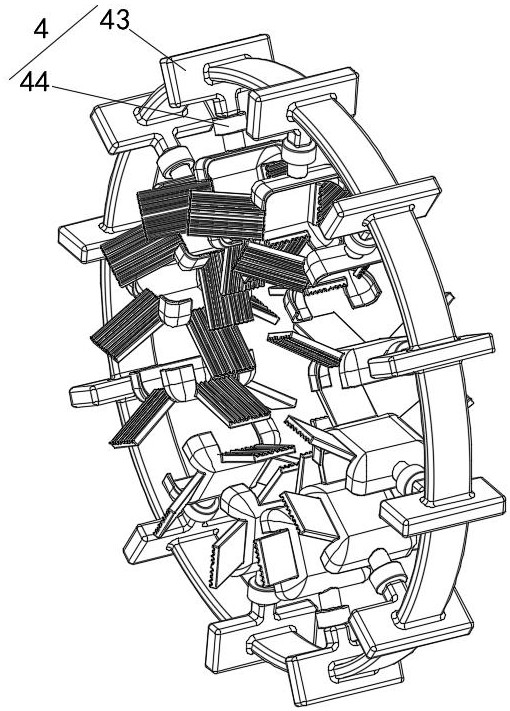

Multifunctional electric oven

PendingCN106821025AChange placementChange the heating methodRoasting apparatusRoasters/grillsElectric controlFood item

The invention discloses a multifunctional electric oven which is capable of changing a placement mode and a heating mode of foods, is high in heating efficiency and convenient to contract and expand, and is capable of saving energy and capable of carrying out different heating modes on multiple foods. The multifunctional electric oven comprises a box body assembly (1), an electric control assembly (2), an up-sliding door (3) and a side-opening door (4), wherein the electric control assembly (2) is located on the box body assembly (1); the up-sliding door (3) and the side-opening door (4) are located at the top and the front part of the box body assembly (1) separately; a closed heating cavity (10) is enclosed by the up-sliding door (3), the side-opening door (4) and the box body assembly (1) when the up-sliding door (3) and the side-opening door (4) are closed; a heating tube (5) is arranged in the heating cavity (1); the heating tube (5) can rotate in a horizontal state and a vertical state; and the up-sliding door (3) and the side-opening door (4) can be independently or commonly opened and closed to achieve different grilling function modes. The multifunctional electric oven can be widely applied to the field of food processing equipment.

Owner:ZHUHAI FEILONG ELECTRIC APPLIANCE CO LTD

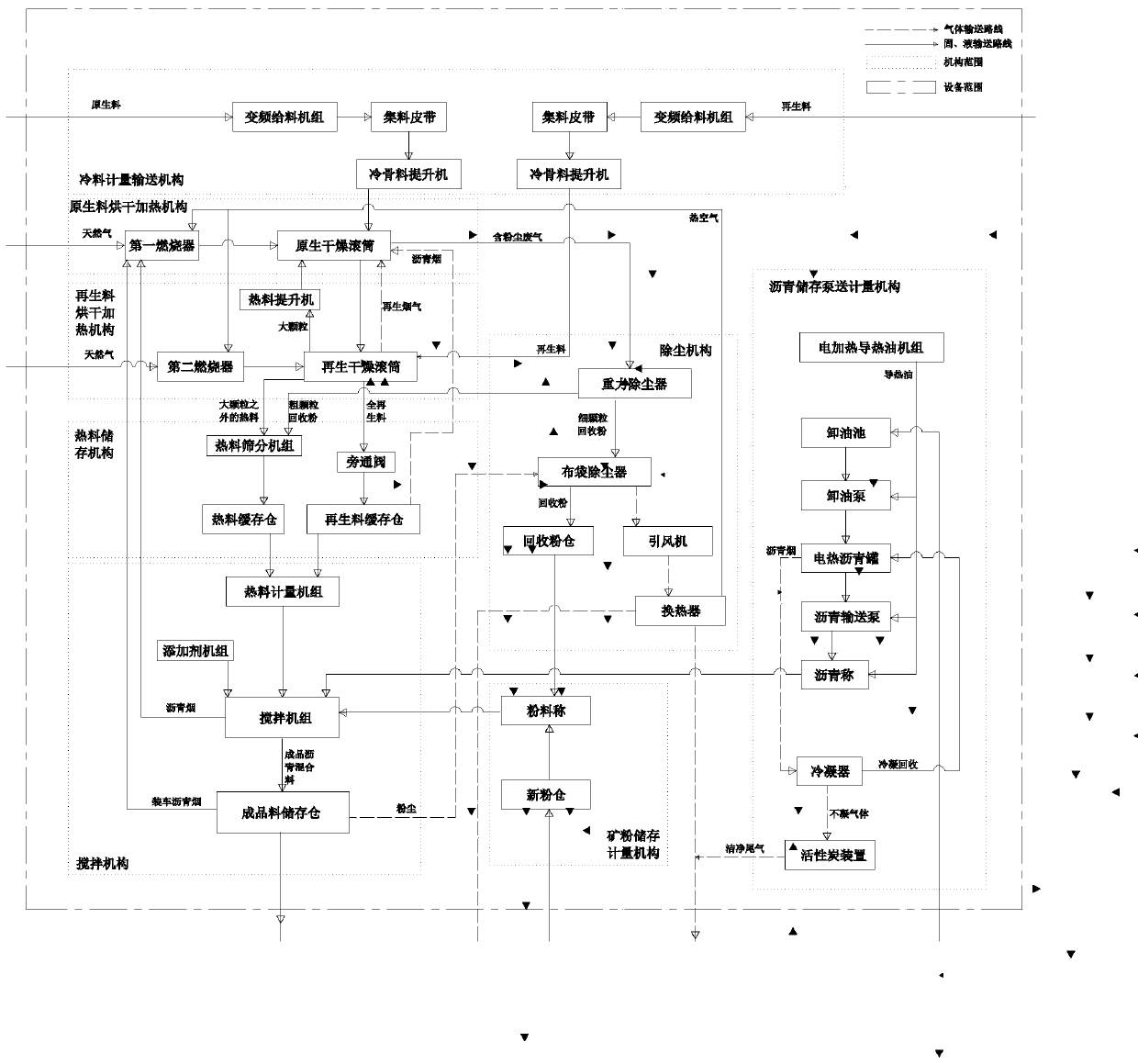

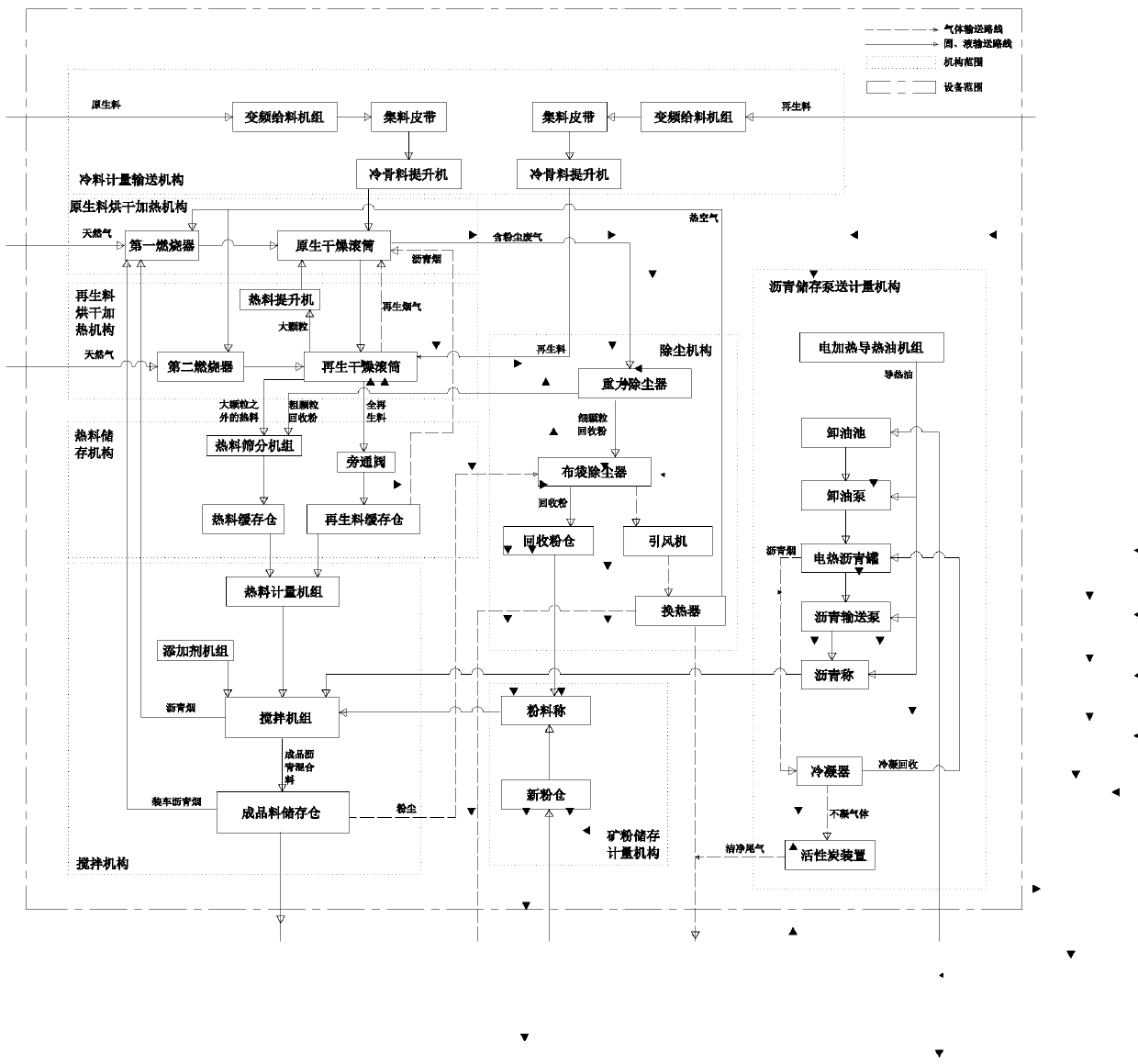

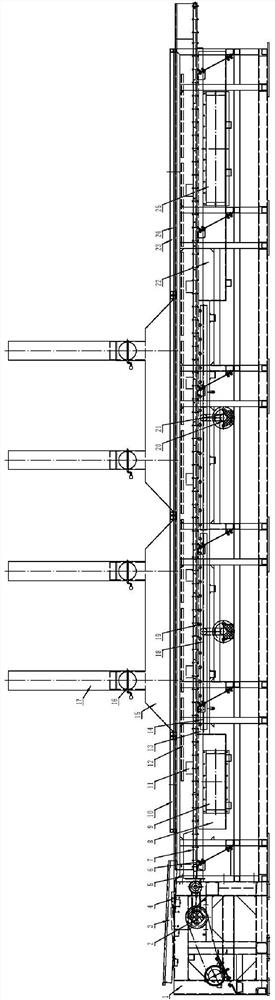

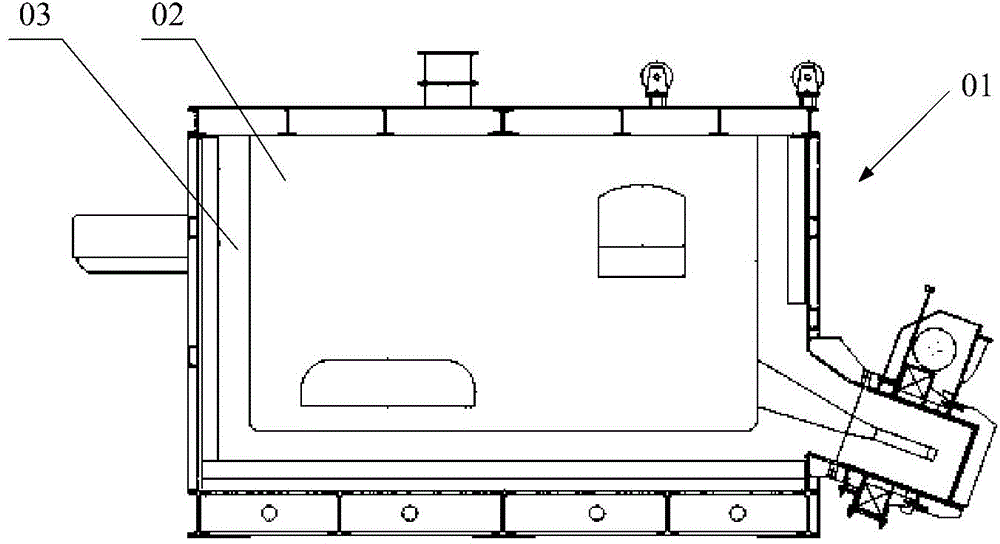

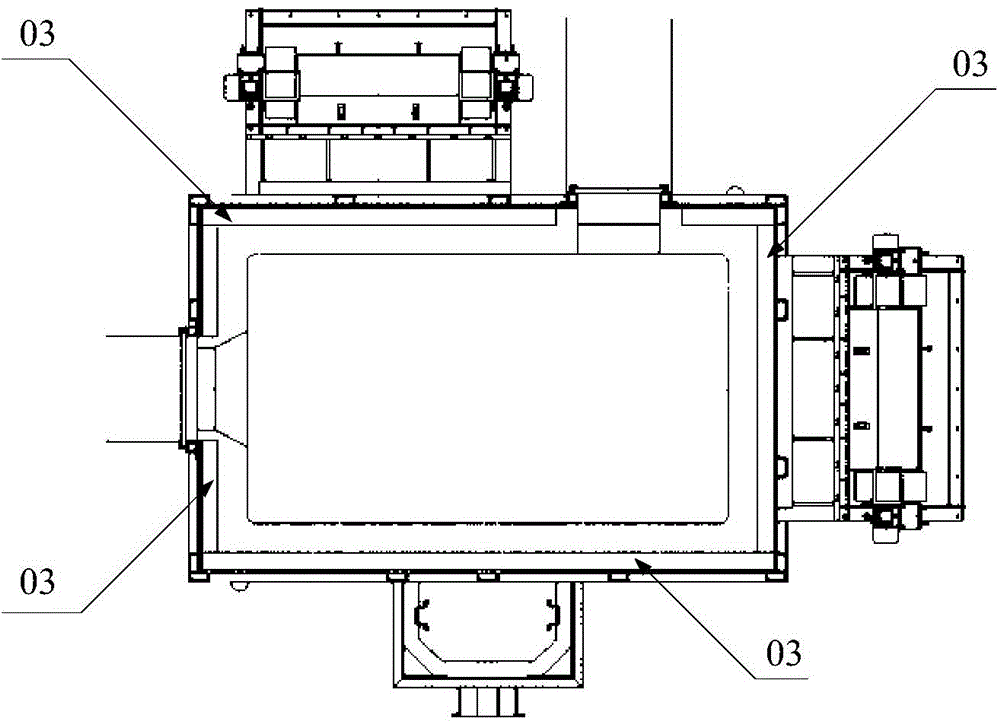

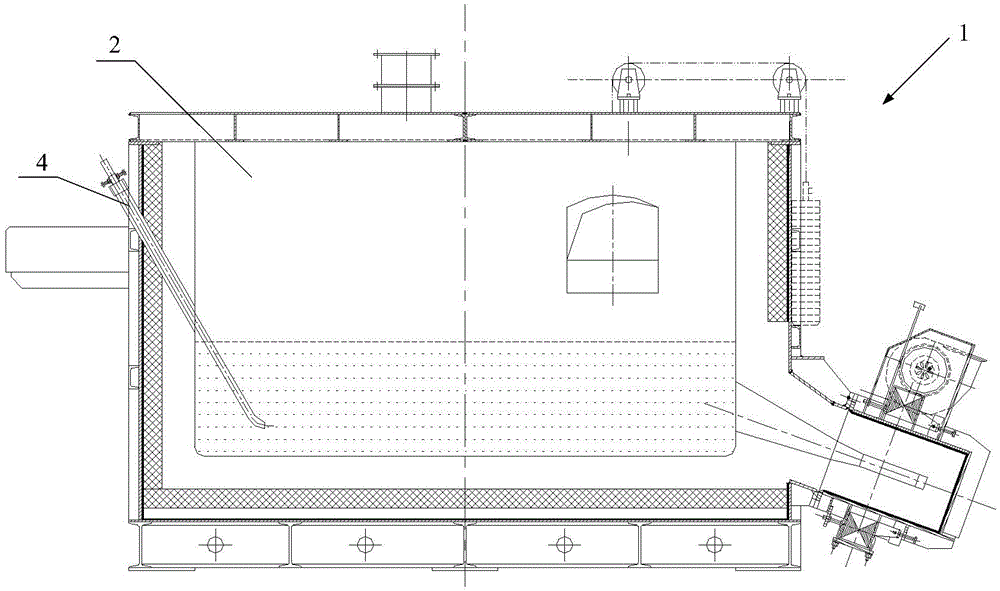

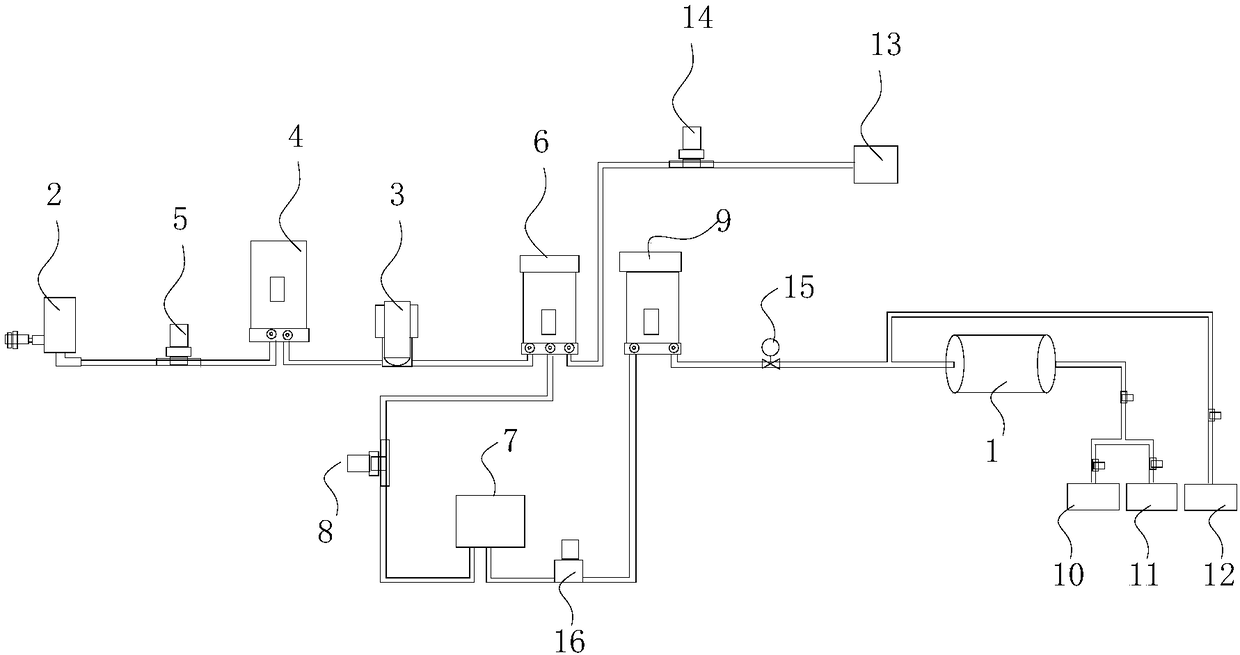

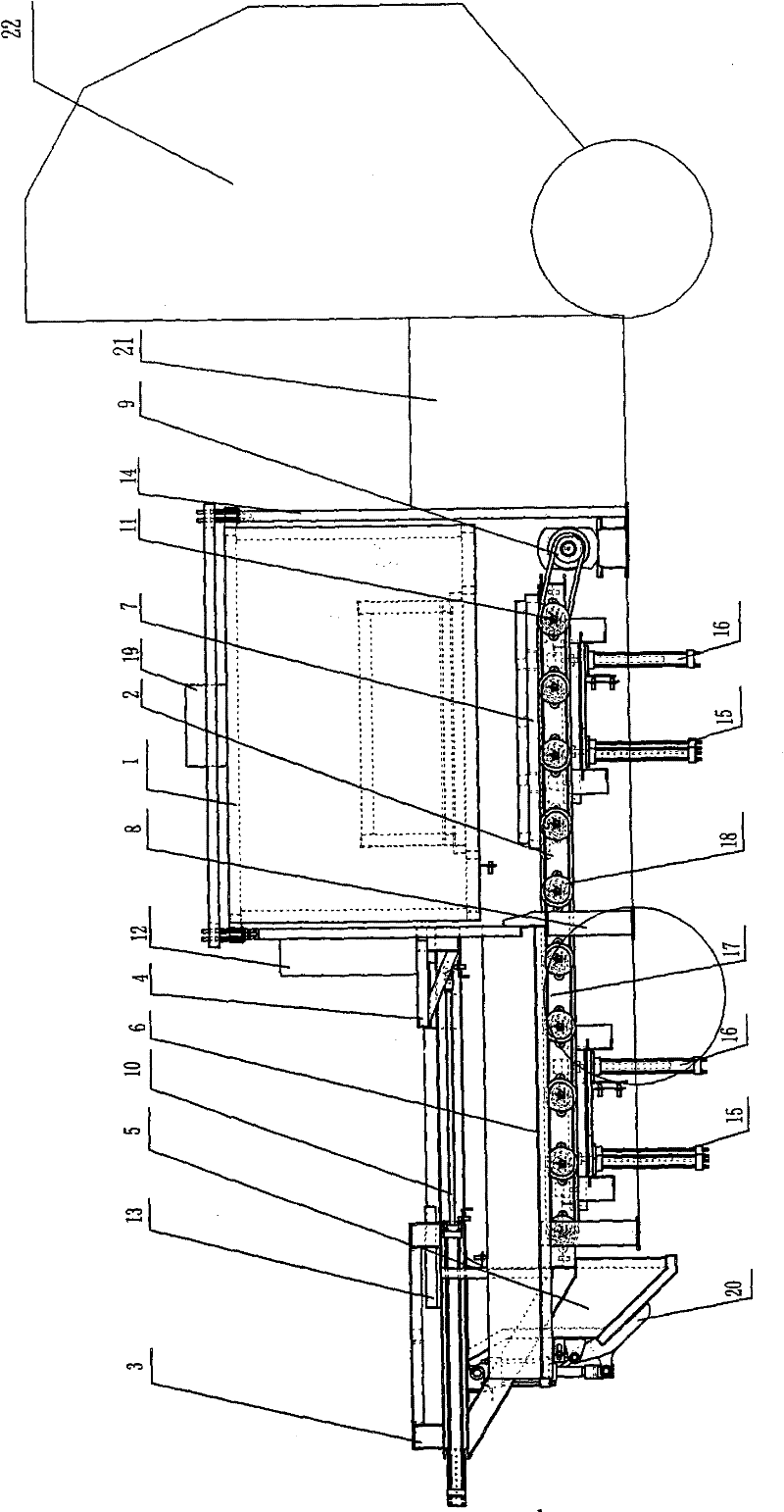

Environment-friendly and energy-saving type fully-recycled asphalt mixture stirring equipment

InactiveCN109706821AReduce asphalt smoke concentrationReduced asphalt smoke concentrationRoads maintainenceProcess engineeringAsphalt

The invention discloses environment-friendly and energy-saving type fully-recycled asphalt mixture stirring equipment, which belongs to the field of asphalt mixture stirring equipment and comprises acold material metering and conveying mechanism, an asphalt storage pumping and metering mechanism, a raw material drying mechanism, a regenerated material drying mechanism, a dust removal mechanism, amineral powder storage metering mechanism, a hot material storage mechanism and a stirring mechanism; and the cold material metering and conveying mechanism comprises a raw material metering and conveying assembly and a regenerated material metering and conveying assembly. According to the invention, the regenerated material heating mode is changed; the asphalt smoke concentration of the regenerated material is reduced; asphalt flue gas generated during full-regeneration of the mixture is reduced from the source, the service life of a cloth bag in a bag-type dust collector is prolonged, the maintenance strength of equipment is reduced, the influence of water vapor flue gas on the equipment, combustion and environment is reduced, and the equipment is designed in an environment-friendly manner and is compatible with a production conventional proportion, namely, the regenerated asphalt mixture with the regenerated material additive proportion of 10-60% and the 100% raw asphalt mixture with no regenerated material.

Owner:江苏人杰筑路机械科技有限公司

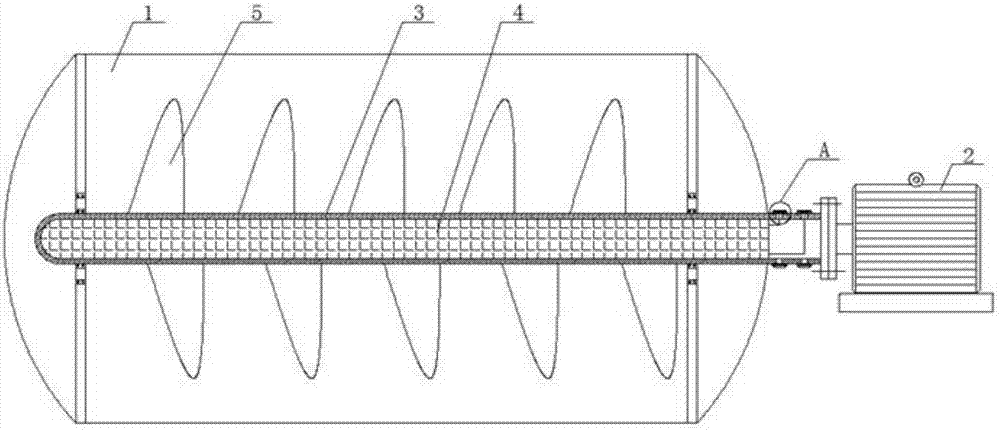

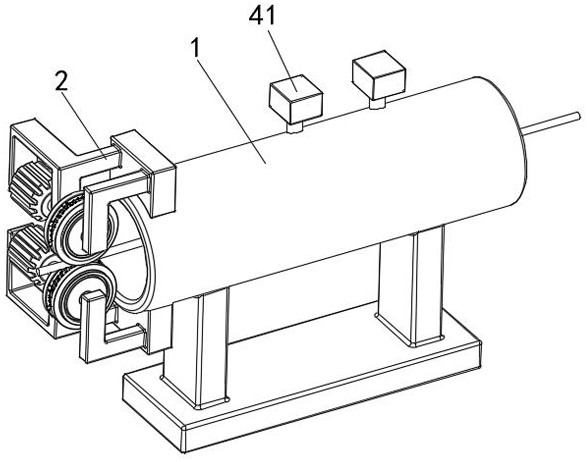

High-efficiency asphalt tank

InactiveCN107964851AChange the heating methodImprove heating efficiencyRoads maintainenceElectricityBiochemical engineering

The invention belongs to the technical field of asphalt tanks, and discloses a high-efficiency asphalt tank, which is used to solve the problem of low heating efficiency in the existing asphalt tanks. The present invention comprises a tank body, a drive motor is arranged outside the tank body, the drive motor is connected with a stirring shaft, the stirring shaft extends into the tank body and is connected with a stirring blade, the stirring shaft is a hollow shaft, the An electric heating wire is arranged in the hollow shaft, the stirring blade is a hollow blade, and an electric heating wire layer electrically connected with the electric heating wire in the hollow shaft is arranged in the hollow blade.

Owner:CHENGDU KECHUANGCHENG TECH

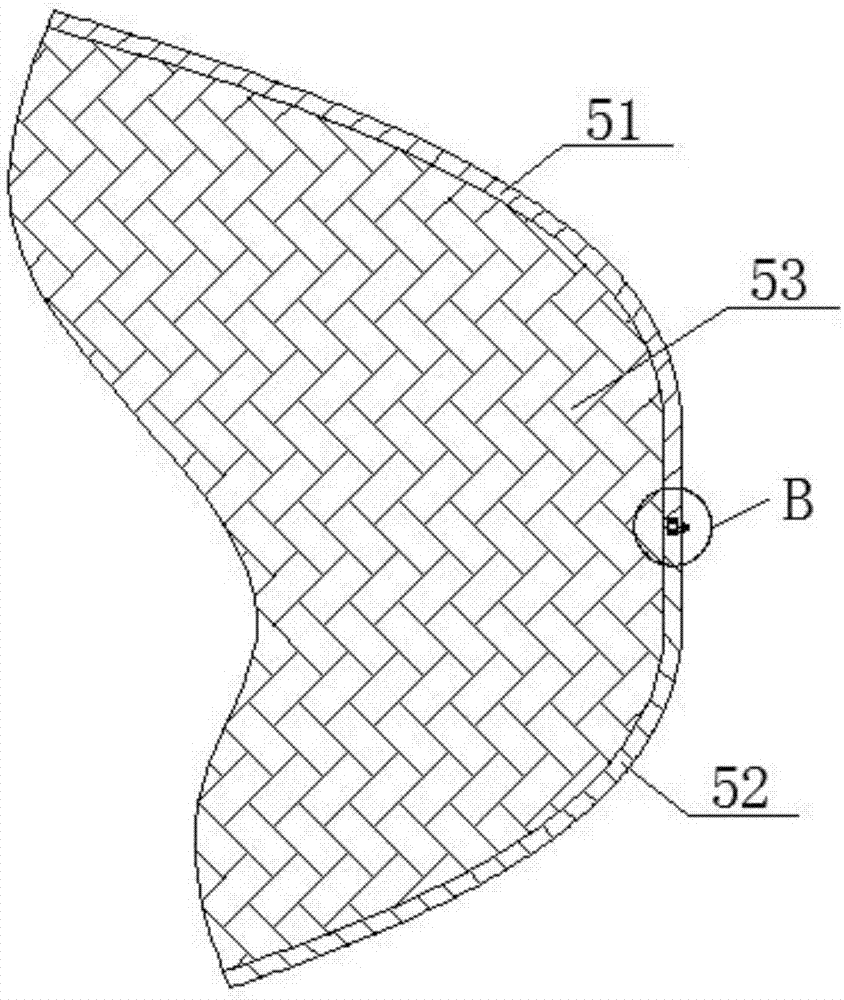

Magnesium smelting technique by microwave heating

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

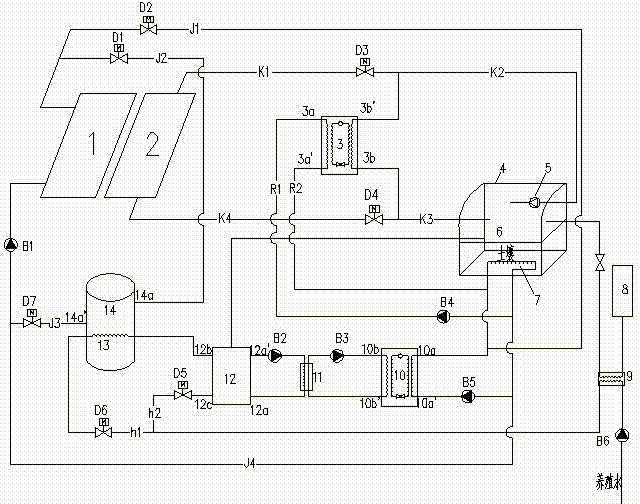

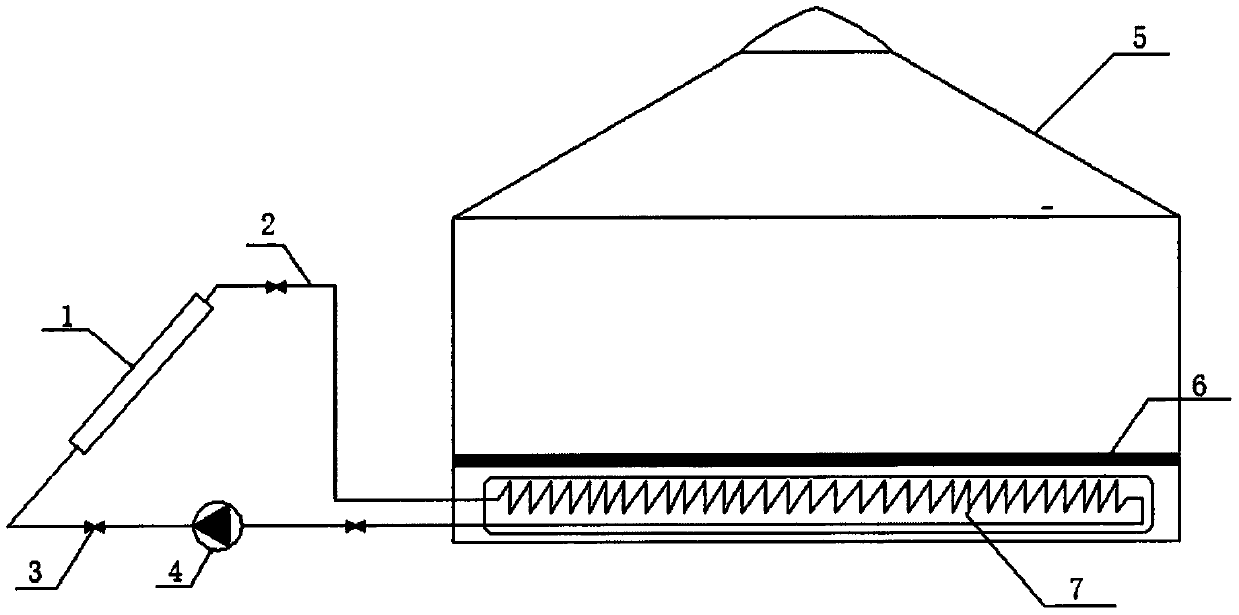

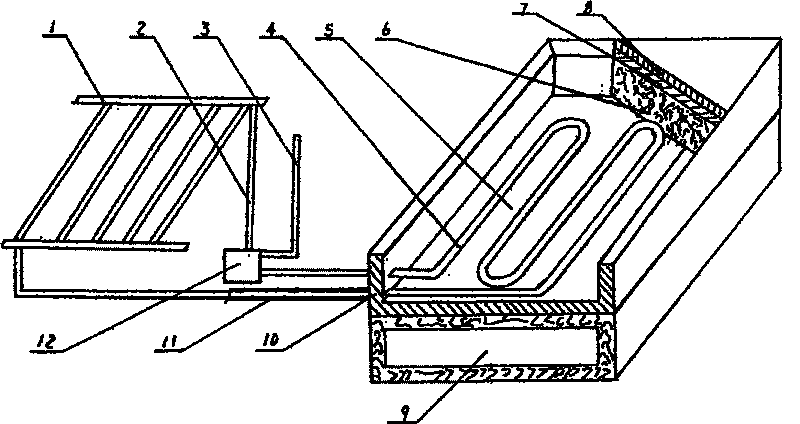

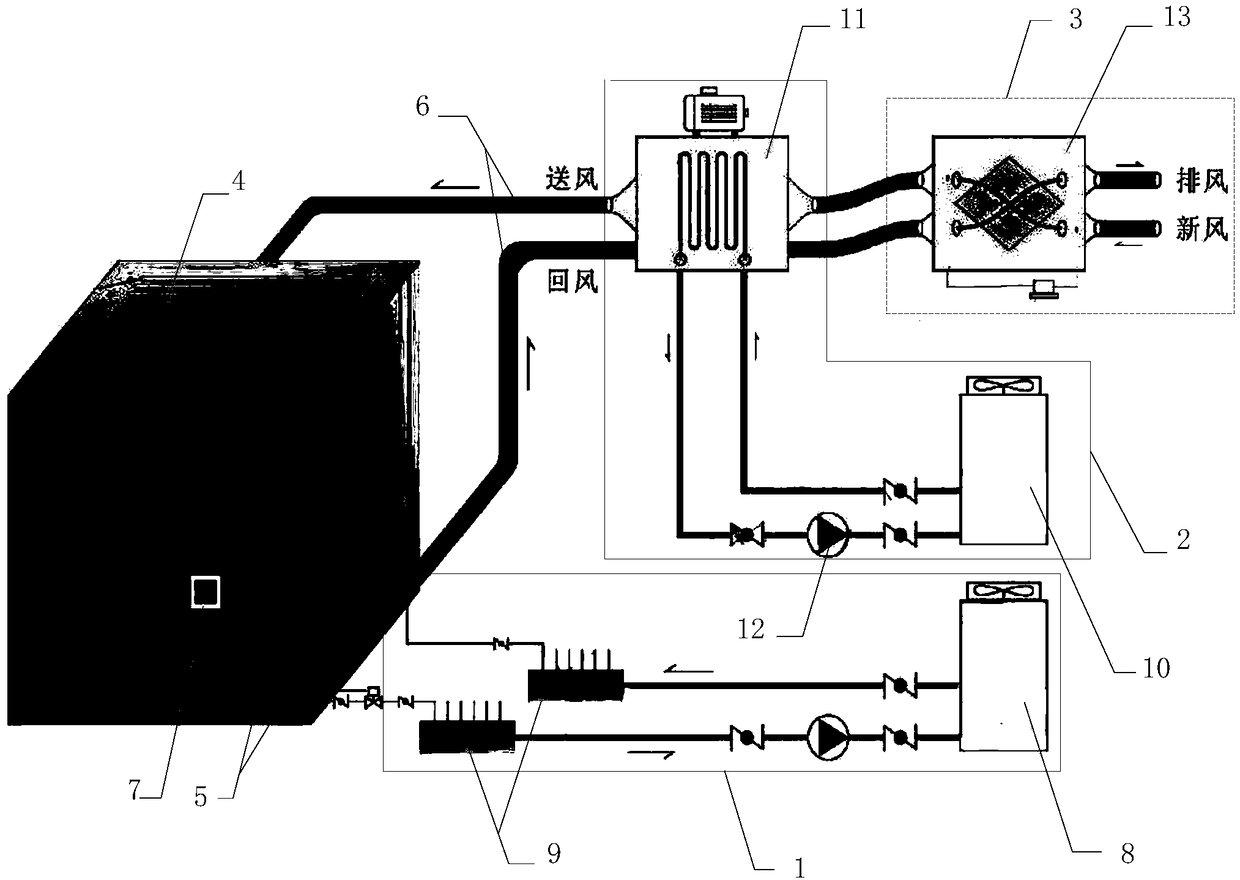

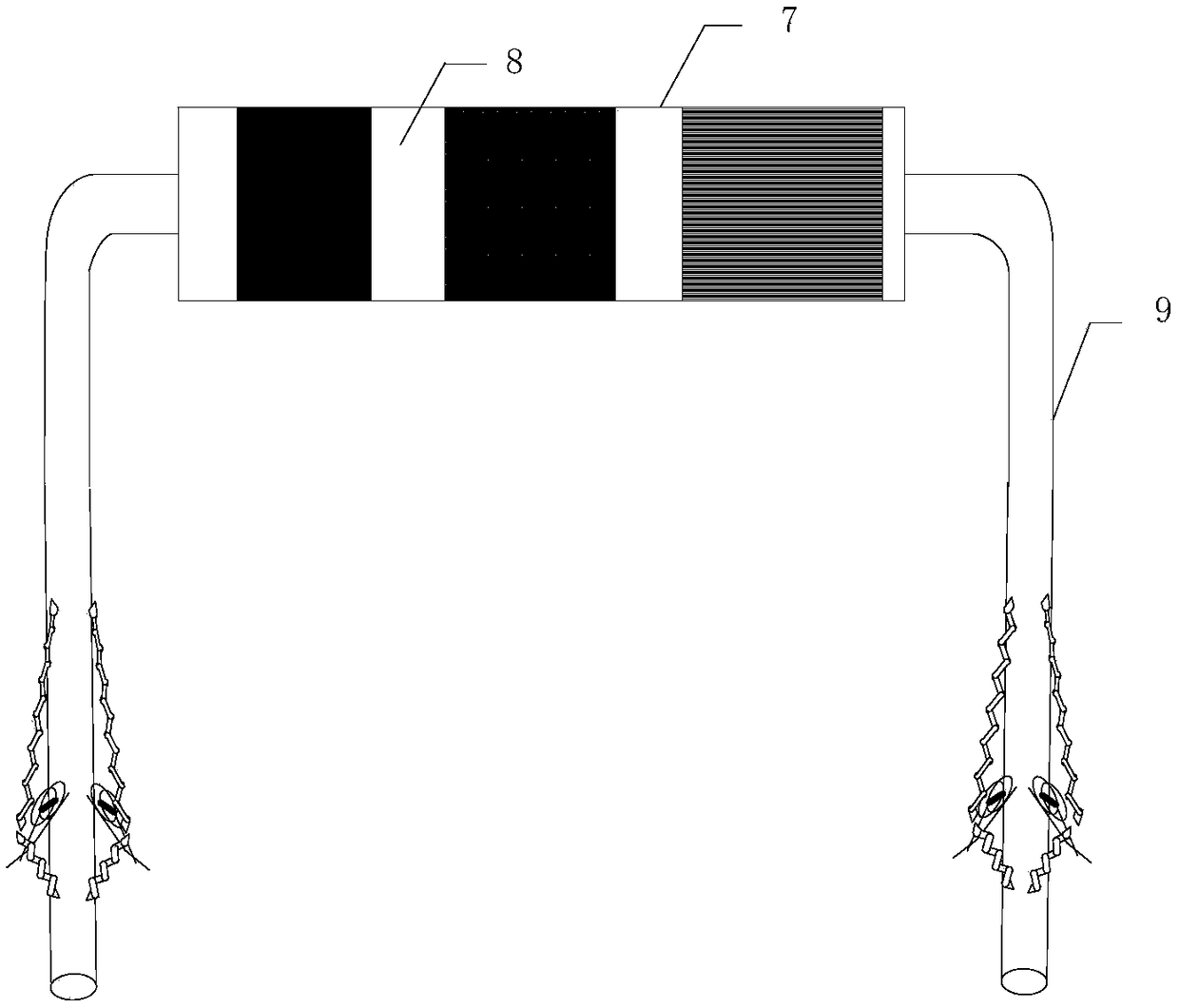

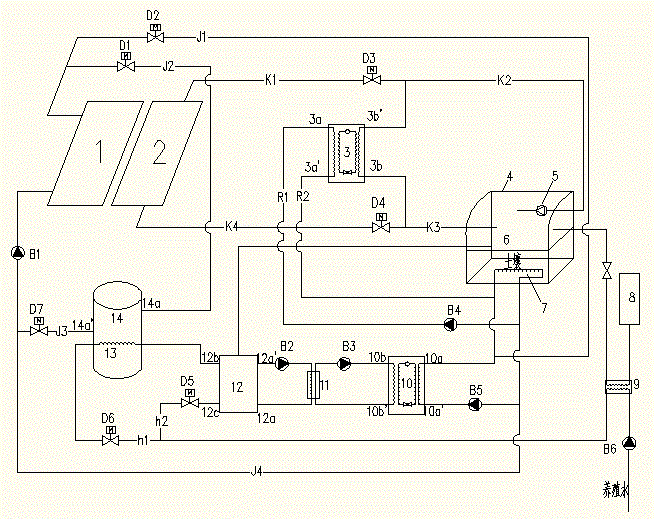

Greenhouse breeding water and air parallelly heated solar energy-heat pump united heat supply system

InactiveCN104764213AReduce intermediate linksSmaller specific heatFluid heatersSolar heat devicesHeat transfer efficiencyHeating system

The invention discloses a greenhouse breeding water and air parallelly heated solar energy-heat pump united heat supply system which comprises a solar water heating system, a soil heat storage and release system and a controller and further comprises a solar energy-heat pump air direct heating system and a new breeding water heating system. The solar energy-heat pump air direct heating system comprises a solar air heat collector group, a first heat pump and a fan. The new breeding water heating system consists of two portions, wherein the first portion comprises a sixth water pump, a waste heat exchanger, a sixth magnetic valve, a breeding water heat exchanger, a fifth magnetic valve, a breeding water preparation pond and a breeding pond. The soil heat storage and release system comprises a solar hot water heat collector group and a soil storage and release device. The greenhouse breeding water and air parallelly heated solar energy-heat pump united heat supply system changes an air and new breeding water heating mode in a breeding room, can decrease heat exchange middle links and is higher in heat transfer efficiency and better in energy-saving effect.

Owner:ZHEJIANG UNIV

Conductive silver adhesive and preparation method thereof

ActiveCN103396744AImprove heat curing efficiencySimple processNon-macromolecular adhesive additivesMacromolecular adhesive additivesLiquid-crystal displayAdhesive

The invention relates to a conductive silver adhesive including a silver powder, wherein the silver powder is a spherical silver powder. The invention also relates to a preparation method of the conductive silver adhesive. The conductive silver adhesive provided by the invention adopts the spherical silver powder, wherein a micro stacking of the spherical silver powder is a three-dimensional communication type; the conductive silver adhesive has good fluidity, high heating efficiency, and low shrinkage rate after curing; and prepared IPS type and FFS type liquid crystal display products have high quality. The conductive silver adhesive is also added with an accelerant and a catalyst and thus can change a heating mode, so that the conductive silver adhesive has higher heating curing efficiency and more uniform heating curing, obviously shortens the curing time, and improves the productivity. The preparation method of the conductive silver adhesive has simple preparation process, and is suitable for industrialized application.

Owner:BOE TECH GRP CO LTD +1

Phase change constant temperature system of Kazakh yurts in Xinjiang region

PendingCN109539370AImprove comfortEmission reductionSolar heating energySolar heat storageState of artCombustion

The invention discloses a phase change constant temperature system of Kazakh yurts in the Xinjiang region. The phase change constant temperature system comprises a solar heat collecting device, a circulating pump, a throttling valve, a phase change heat storage and supplying device and connected pipelines; and the phase change heat storage and supplying device is mainly of a sleeve structure, a circulating working medium flows in the inner circle pipe pass, and an outer circle shell pass is filled with a phase change material. Compared with the prior art, the phase change constant temperaturesystem has the advantages that a traditional yurt heat supplying mode is changed, nighttime furnace combustion harm is reduced, environment pollution and combustion exhaust emission are lowered, the dwelling environment of herdsmen is improved, and the comfort degree of the yurts is increased; rich solar resources of the Xinjiang region are utilized, and by combining with the phase change material, the purposes of energy conservation and emission reduction are achieved; and the phase change constant temperature system is simple in structure, convenient to dismount and mount and suitable for the Kazakh yurts which are set up in search of water and grass in pastoral areas.

Owner:代元军

Solar health bed

InactiveCN101711631AChange the heating methodNo pollution in the processSofasCouchesAluminium foilDisease

The invention relates to a solar health bed. The bed is characterized in that the bottom of the solar health bed is a bed seat, a vacuum insulation box is arranged above the bed seat, the inside of the vacuum insulation box is provided with an aluminium foil heat-reflecting layer, a stainless steel radiator is arranged above the aluminium foil heat-reflecting layer, a heat accumulation filling layer is arranged in the vacuum insulation box, a thermal insulating layer and an infrared physiotherapy pad are arranged above the heat accumulation filling layer, one end of the radiator is connected with a solar collector through a heat conducting pipe, is also connected with an emergency additional heater through the heat conducting pipe and is connected with the other end of the radiator to form a loop, the emergency additional heater is connected with a pressure exhaust pipe, and a sheathing tube is arranged outside the heat conducting pipe. The solar health bed of the invention changes the traditional heating mode of the berth and adopts solar energy as energy for natural heating, thus not causing environmental pollution; and the infrared physiotherapy pad are arranged so that the bed of the invention has physiotherapy and health care functions for human body and has a certain curative effect on rheumatism, arthritis, chronic bronchitis and other diseases.

Owner:张继文

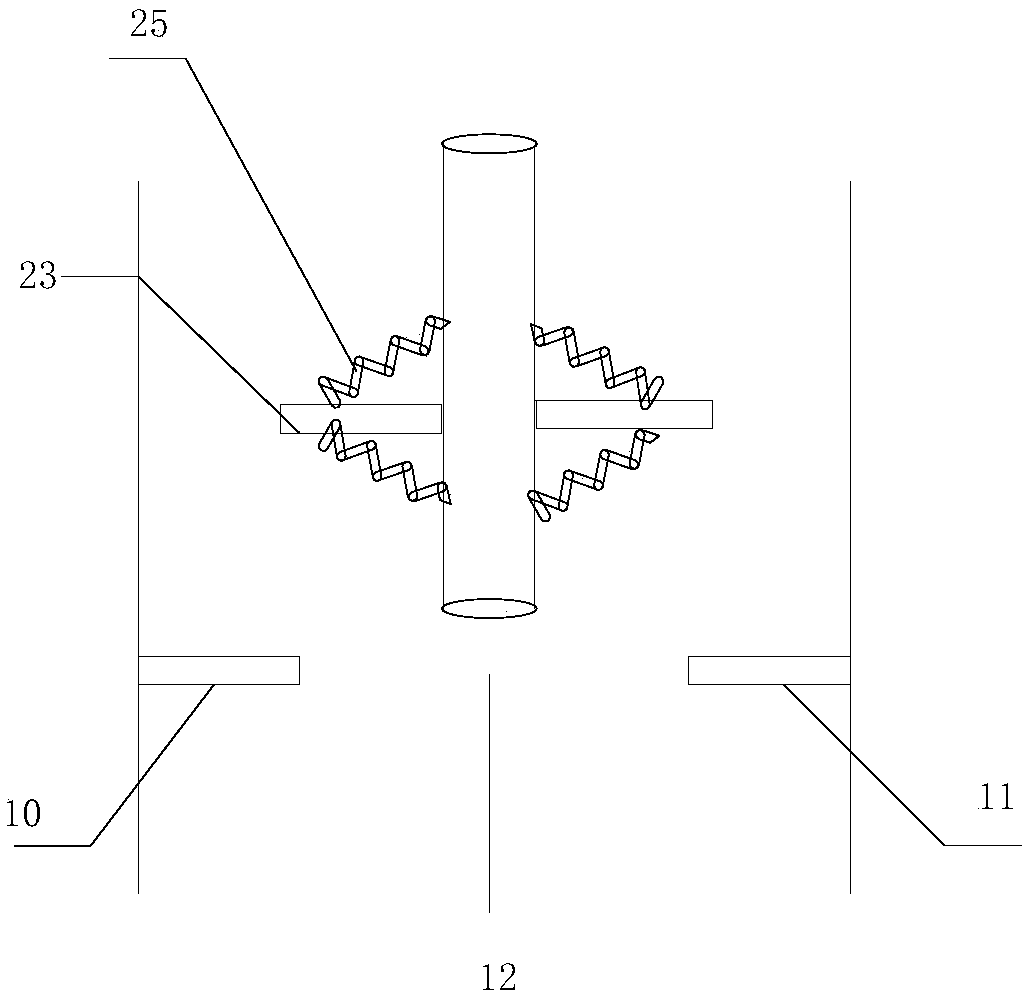

Capillary tube radiation control system

PendingCN108507092AChange the heating methodShorten the timeMechanical apparatusLighting and heating apparatusEngineeringFresh air

The invention discloses a capillary tube radiation control system which comprises a main control unit, a refrigeration / heating unit, a dehumidification unit, a fresh air exchange unit and multiple mutually independent capillary tube grids; wherein the refrigeration / heating unit, the dehumidification unit and the fresh air exchange unit are in communication connection with the main control unit; the capillary tube grids are arranged at preset positions in a building respectively; the refrigeration / heating unit is communicated with the capillary tube grids through first pipelines respectively; and the dehumidification unit and the fresh air exchange unit are communicated with the interior of the building through second pipelines respectively to form a fresh air heat exchange treatment systemwith intact circulation in a solid space of the building. The capillary tube radiation control system provided by the invention is improved in intelligent control effect and has more excellent use effect.

Owner:绵阳纽伦科技有限公司

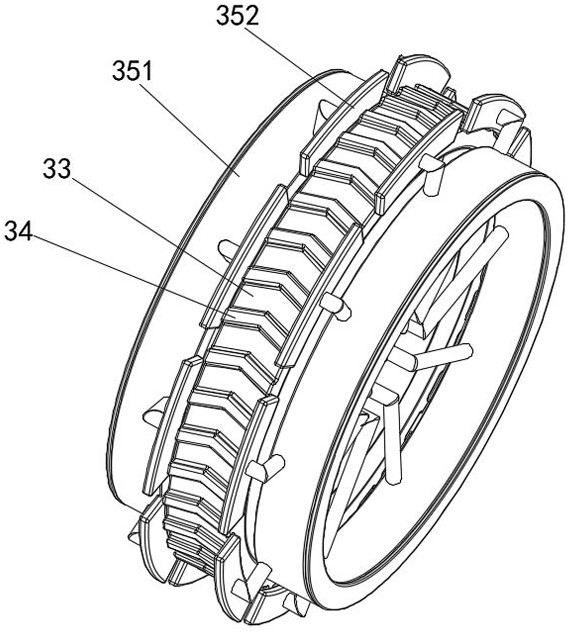

Inclined filtering, washing and drying machine

PendingCN113599886ALarge filter areaImprove heating efficiencyStationary filtering element filtersProcess engineeringMother liquor

The invention discloses an inclined filtering, washing and drying machine which comprises a charging cylinder, the charging cylinder is connected with an inclined system, the inclined system is connected with a rotary rear cover plate on an auxiliary process cylinder, a front cover plate of the auxiliary process cylinder is provided with process pipeline connectors, and the rotary rear cover plate is provided with a process rotary connector. The process rotary connector is connected with each pipe orifice on the charging cylinder through a hard pipe, the bottom of the charging cylinder is communicated with a filtering assembly, and the bottom of the filtering assembly is connected with a mother liquor rotary connector through a hard pipe pipeline; the rotary center of a rotary rear cover plate, the rotary center of the mother liquor rotary connector and the rotary center of the charging cylinder are positioned on the same axis; a lifting trolley for lifting and transferring the filtering assembly is arranged under the charging cylinder; and a stirring shaft and a stirring paddle connected with the outer side of the stirring shaft are arranged at the center position in the charging cylinder, and a rotary lifting assembly is arranged at the top of the charging cylinder. The invention provides a more efficient dynamic filtering, washing and drying machine, and the efficiency and operability of the whole machine are comprehensively improved.

Owner:SHANGHAI RUIPAI MACHINERY

Single-layer steam hot air fixation machine

PendingCN113925097AFast implementationChange the heating methodPre-extraction tea treatmentHot blastTea leaf

The invention discloses a single-layer steam hot air fixation machine. The single-layer steam hot air fixation machine consists of a machine head, a speed-adjustable eccentric transmission device, a feeding disc, a rack, a spring piece combination unit, a vibration groove combination unit, a withering box body, a front cover, a steam box body, a jet flow pipe combination unit, a gas-collecting hood combination unit, a dehumidification box body and rear covers. After improvement, a material uniformizing device is arranged in the feeding disc, and forward air nozzles are arranged on two sides of the withering box body; the jet flow pipe combination unit is arranged in the steam box body, and the jet flow pipe combination unit forms a passage through two rows of jet flow main pipes, four steam inlet pipe combination units, a plurality of jet flow pipes and the like; a heat preservation layer is arranged outside the steam inlet pipe combination units; rear air inlet nozzles are arranged on two sides of the dehumidifying box body; and each rear cover is provided with a stainless steel mesh. The whole structure and shape are improved, a traditional heating mode is also changed, and the purpose of quickly performing fixation on tea leaves is achieved.

Owner:SICHUAN DENGYAO MACHINERY EQUIP

A kind of conductive silver glue and preparation method thereof

ActiveCN103396744BImprove heat curing efficiencySimple processNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilver pasteConductive paste

A conductive silver paste comprises silver powder. The silver powder is spherical silver powder. Also disclosed is a method for preparing the conductive paste. The conductive silver paste has higher and more uniform heating-curing efficiency, the curing time is obviously shortened, and the production capacity is improved.

Owner:BOE TECH GRP CO LTD +1

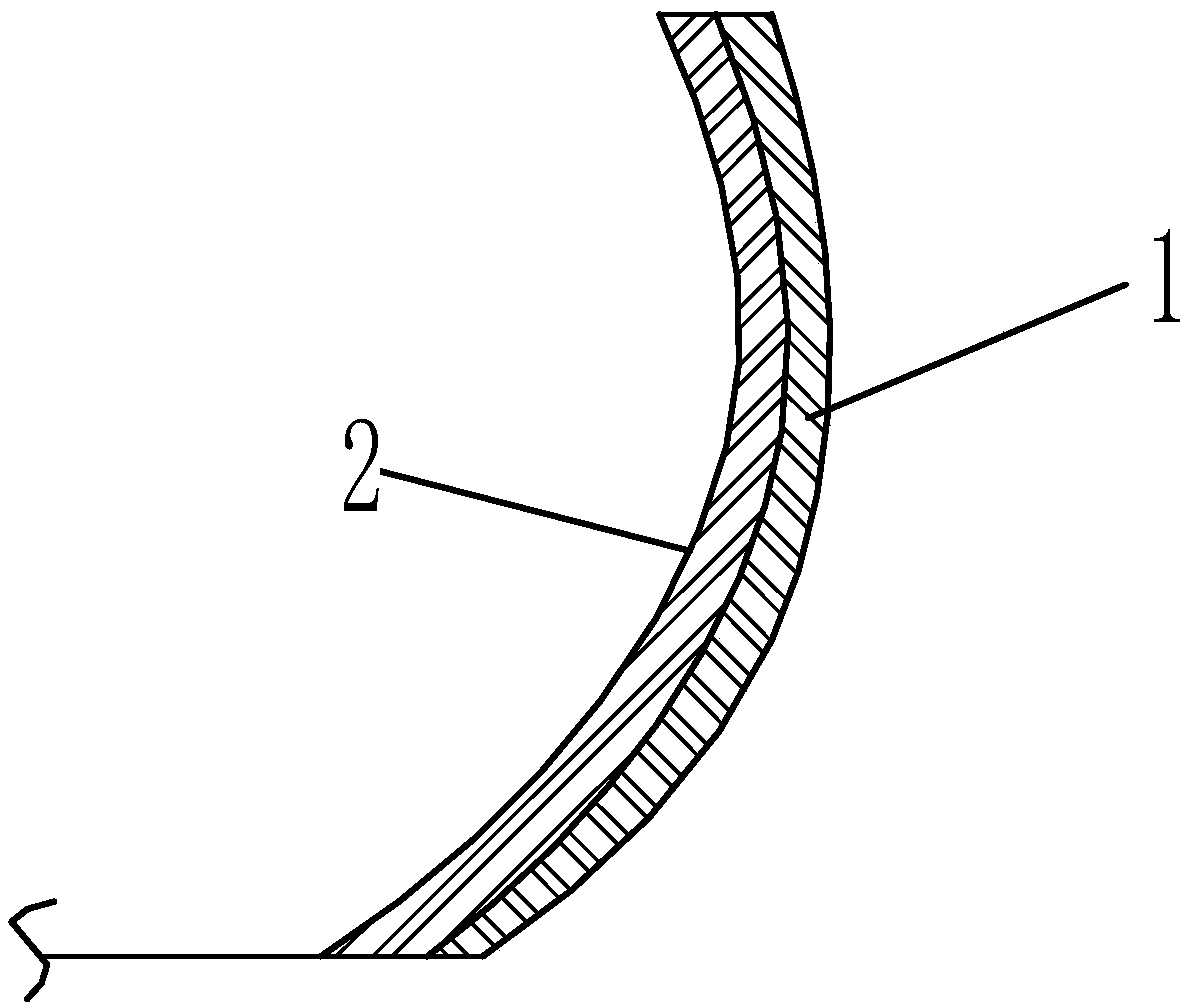

Process method for repairing arc quartz crucible

ActiveCN107739146AAvoid crackingChange the heating methodBy pulling from meltGlass shaping apparatusTemperature differenceEngineering

The invention discloses a novel process method for repairing an arc quartz crucible. The method comprises the following steps of 1, transferring a crucible; 2, performing grinding; 3, cleaning the crucible; 4, performing crucible local inside and outside preheating; 5, repairing concave pits; 6, performing post treatment. During the preheating, the inside and outside temperature difference type preheating is used; during the concave pit repairing, the used bending process is a multilayer filling process; the connection performance is good.

Owner:曲靖晶澳光伏科技有限公司

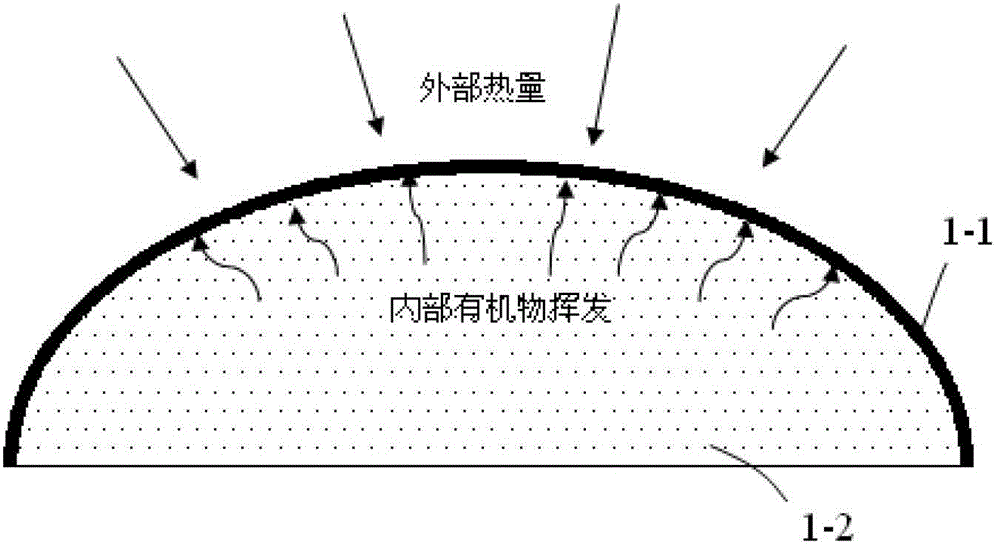

Slipper or sole material foaming technology and in-mold foaming device

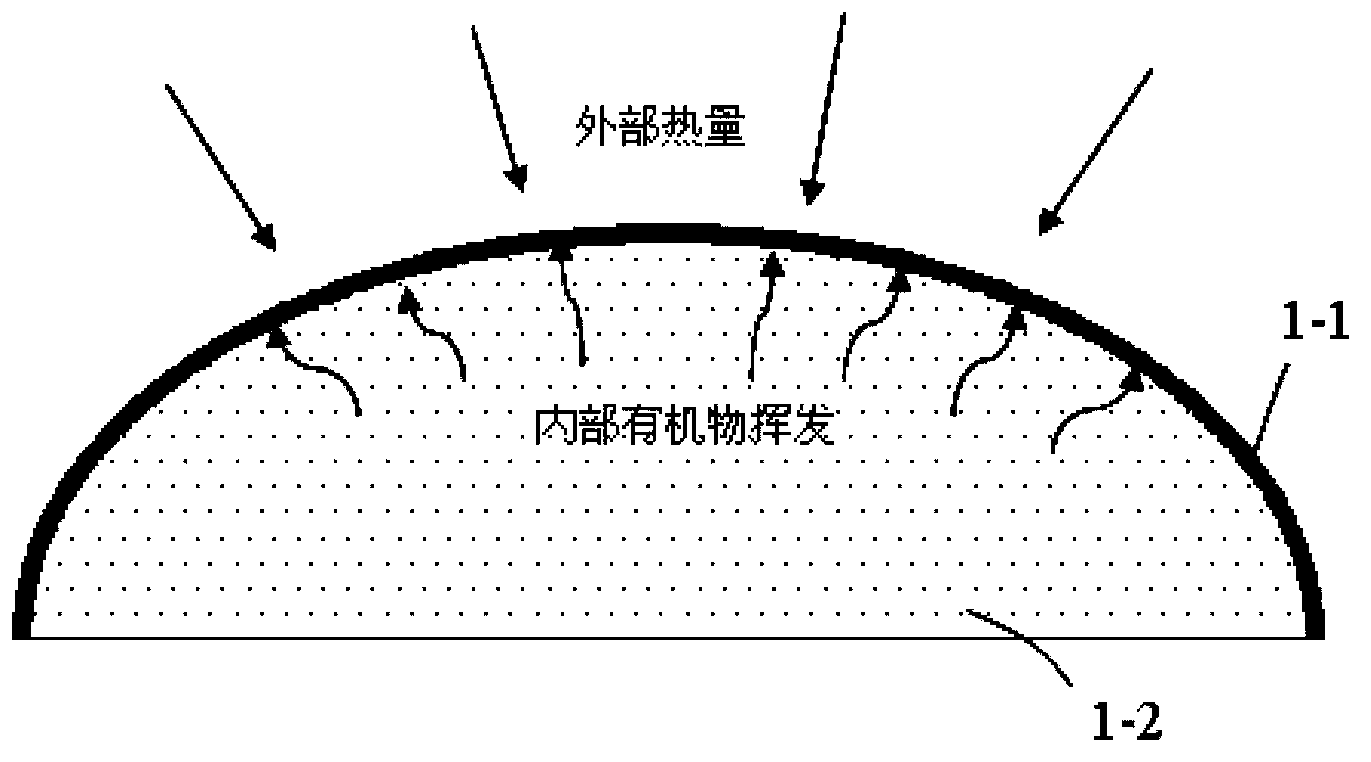

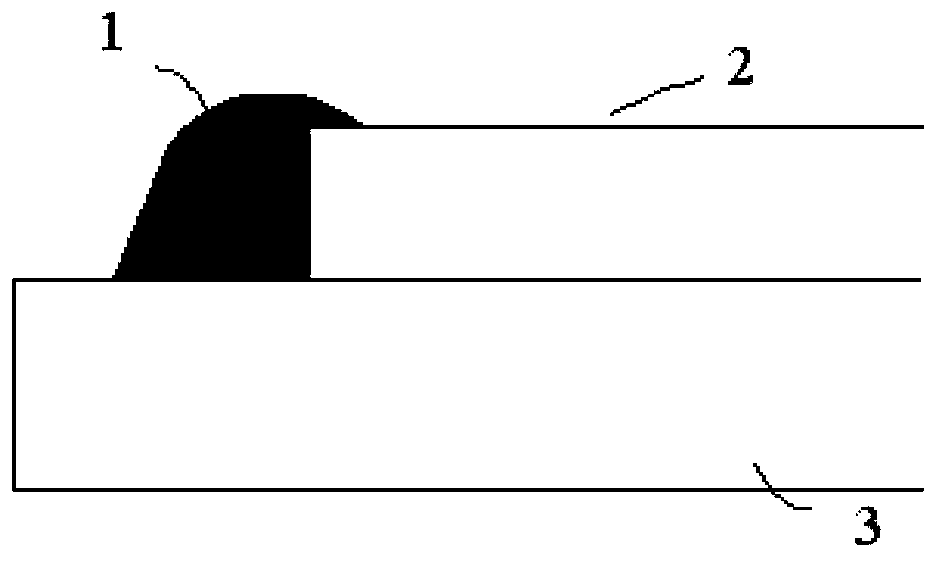

InactiveCN109624182AModerate cavity wall thicknessChange heat transferDomestic articlesMicrowaveVulcanization

The invention relates to the field of slipper or sole foaming technologies, and discloses a slipper or sole material foaming technology. The slipper or sole material foaming technology comprises the following steps that step (1), a cold blank is placed into a mold capable of being subjected to microwave penetrating; step (2), a mold cavity of the mold is vacuumized or the mold is placed in a vacuum environment; step (3), the cold blank is subjected to microwave heating to 170-180 DEG C under the vacuum condition; and step (4), after the step (3), the cold blank is kept at the constant temperature of 170-180 DEG C through microwaves under the vacuum condition, and the cold blank is subjected to vulcanization foaming. The mold is a ceramic mold. The invention further discloses an in-mold foaming device for the foaming technology. By utilizing the characteristic that the ceramic mold can be subjected to microwave penetrating, the cold blank in the ceramic mold can reach the foaming temperature instantly in a unified mode, the cold blank is heated evenly through microwave heating, thus the foaming vulcanization time of whole foaming materials is greatly shortened, accordingly, the foaming vulcanization time is shortened, and the production efficiency is improved.

Owner:泉州诚宇鞋业有限公司

stove burner

ActiveCN110566953BAvoid enteringImprove anti-blocking performanceStoves/ranges topsGaseous fuel burnerEngineeringMechanical engineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Energy-saving ceramic fire resistant bearing board

InactiveCN100351596CChange the heating methodChange the state of heatingCharge supportsCharge manipulationBrickCombustion chamber

The invention is an energy-saving ceramic flame-resistant bearing firing plate, for solving the technical problem of making the glazed outside wall bricks fired by the same kiln have no obvious color difference but small deformation, thus improving the quality of finished products, and besides, for strengthening the intensity of bearing firing plate, reducing its breakage rate. For this, the invention fills ribs and blanks at the bottom of the bearing firing plate, where a through hole is equipped within each blank. The blanks and holes can be regularly shaped or irregularly shaped. The invention is mainly used in ceramic kiln to bear and transport the fired ceramic blanks in the course of firing and especially applied to the glazed outside wall blanks.

Owner:康健伟

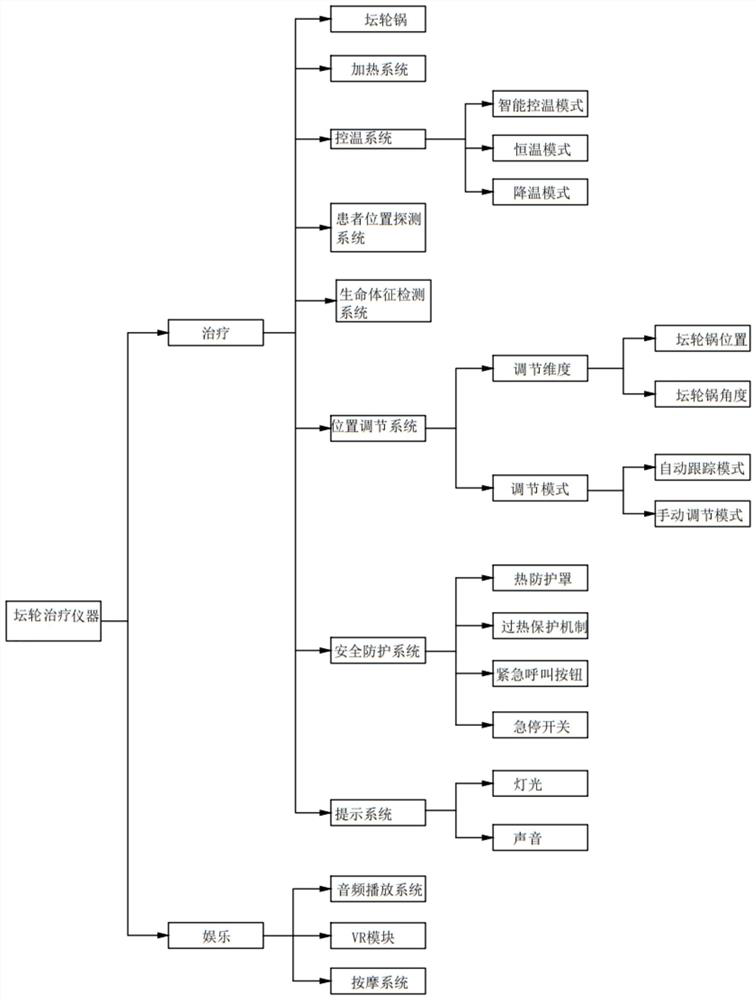

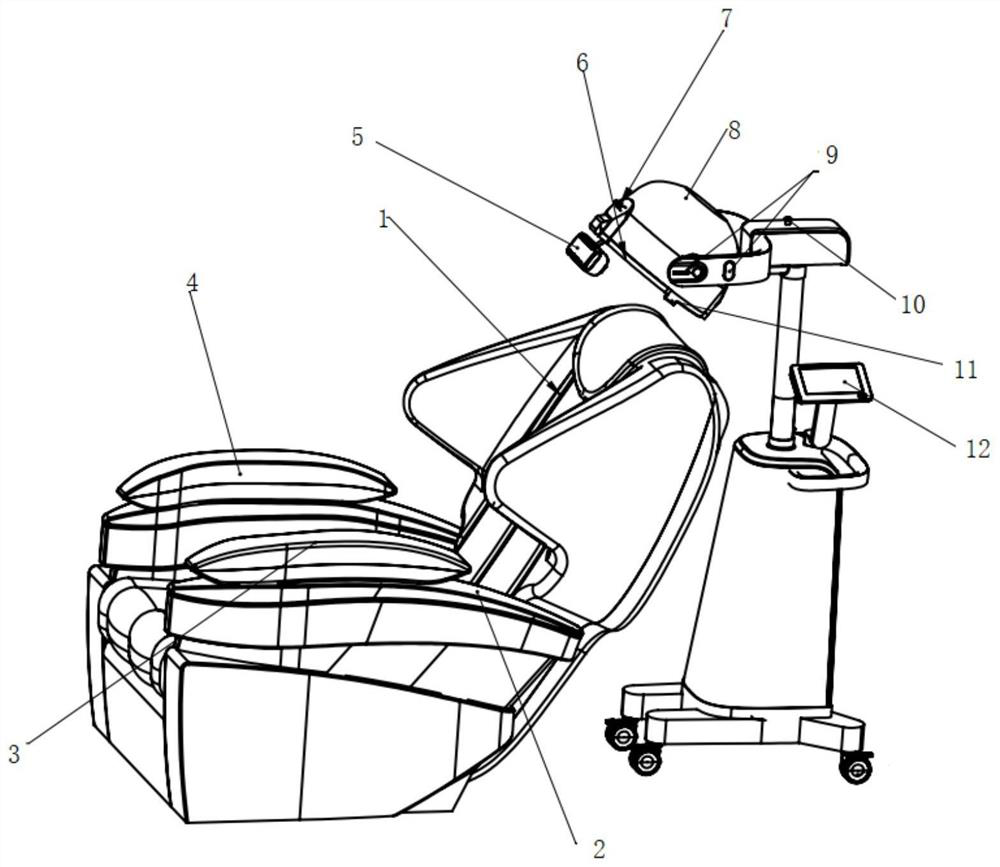

Jar wheel treatment system

PendingCN114795108AChange the heating methodChange controlPhysical therapies and activitiesChiropractic devicesTherapeutic effectTreatment system

The invention provides a jar wheel treatment system which comprises a hardware part and a software part, the hardware part comprises a medicine powder preparation system and a jar wheel treatment instrument, and the jar wheel treatment instrument has a treatment function and an entertainment function. The treatment function comprises a jar wheel pot, a heating system, a temperature control system, a patient position detection system, a vital sign detection system, a position adjustment system, a safety protection system and a prompt system, and the entertainment function comprises an audio playing system, a VR module and a massage system. The software part comprises an outpatient service system, a patient information identification and reading system, a jar wheel equipment central control system and a big data processing system. The heating mode and the control mode of the jar wheel pot are changed, quantification and precision of jar wheel treatment are achieved, the jar wheel treatment means can be popularized outwards in the future, the treatment effect and the patient experience can be greatly improved, and data support is provided for the treatment effect of the patient.

Owner:上海宏勃生物科技发展有限公司 +1

Bottom heater for pulling monocrystal

InactiveCN1200147CIncrease temperatureChange the heating methodBy pulling from meltDc currentEngineering

The present invention relates to a method of speeding melting of polycrystalline raw material and the bottom heater for pulling monocrystal. The method comprises leading DC current to bottom heater while leading DC current to the main heater, so that the quartz crucible is heated from both lateral side and bottom. The bottom heater comprises one disc heating body and two electrodes. The present invention can short the melting time of polycrystalline material and save electric power, and thus increase the yield of monocrystal silicon or germanium.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

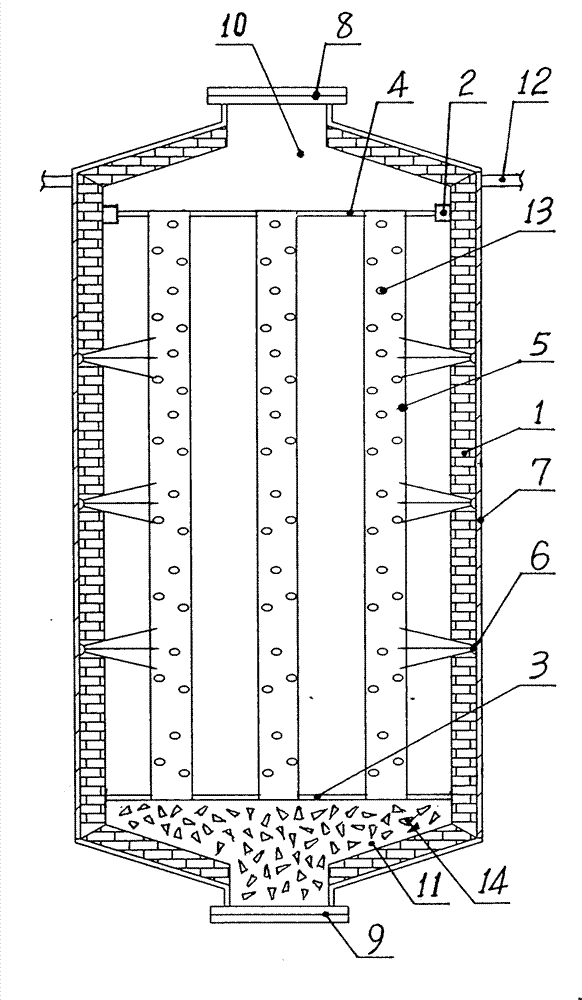

Method and device for stirring zinc liquid and protecting smelting through inert gas

InactiveCN104654784AAchieve the purpose of stirringChange the heating methodMaintainance of heating chambersCrucible furnacesMagnificationProduct gas

The invention discloses a device for stirring zinc liquid and protecting smelting through inert gas. The device comprises a furnace body, wherein a furnace hearth is formed in the furnace body; a furnace wall is arranged on the inner wall of the furnace body; the device also comprises a gas through pipe which is connected to the furnace hearth; a gas inlet of the gas through pipe is externally connected with an inert gas source; a gas outlet of the gas through pipe is arranged at the bottom of the furnace hearth; a gas discharging hole is formed in the top of the furnace body. Through the adoption of the device for stirring zinc liquid and protecting smelting through inert gas, the inert gas is used for stirring metal zinc liquid in the furnace, thereby accelerating the heat conduction; meanwhile, the inert gas quickly expands under the heating action of the high-temperature metal zinc liquid, thereby exerting a certain magnification effect on the convection of the zinc liquid; the heat exchange is accelerated; the heat efficiency is improved; the inert gas is introduced from the bottom and floats up to the surface of the zinc liquid to form an inert gas protection layer, thereby exerting a good anti-oxidation effect. The invention also discloses a method for stirring zinc liquid and protecting smelting through inert gas.

Owner:ZHUZHOU FLASHLIGHT IND FURNACE

Energy conservation water purification system

InactiveCN108328791AReduce consumptionMeet the needs of useTreatment involving filtrationMultistage water/sewage treatmentUltrafiltrationWater storage tank

The invention belongs to the technical field of household appliance and relates to an energy conservation water purification system. The system comprises a water purifier, a water storage device, a solar energy heat insulation container and a draining water temperature adjusting device. The water outlet of the water purifier is connected with the water storage device and the solar energy heat insulation container, the draining water temperature adjusting device is connected with the solar energy heat insulation container; the water purifier comprises a front filter element, a pressurized pump,an ultrafiltration film filter element, a first electromagnetic valve and a high pressure filter element; the water storage device comprises a water storage tank, a second electromagnetic valve and apostposition filter element, the water inlet of the water storage tank is connected with the high pressure filter element through the second electromagnetic valve, the water outlet of the water storage tank is connected with the water inlet of the postposition filter element, the water outlet of the postposition filter element is connected with the water inlet of the solar energy heat insulationcontainer; the outlet water temperature adjusting device comprises a heater, an instant heater and a refrigerator. The energy conservation water purification system has better filter effect.

Owner:广西河池未来之星环保科技有限公司

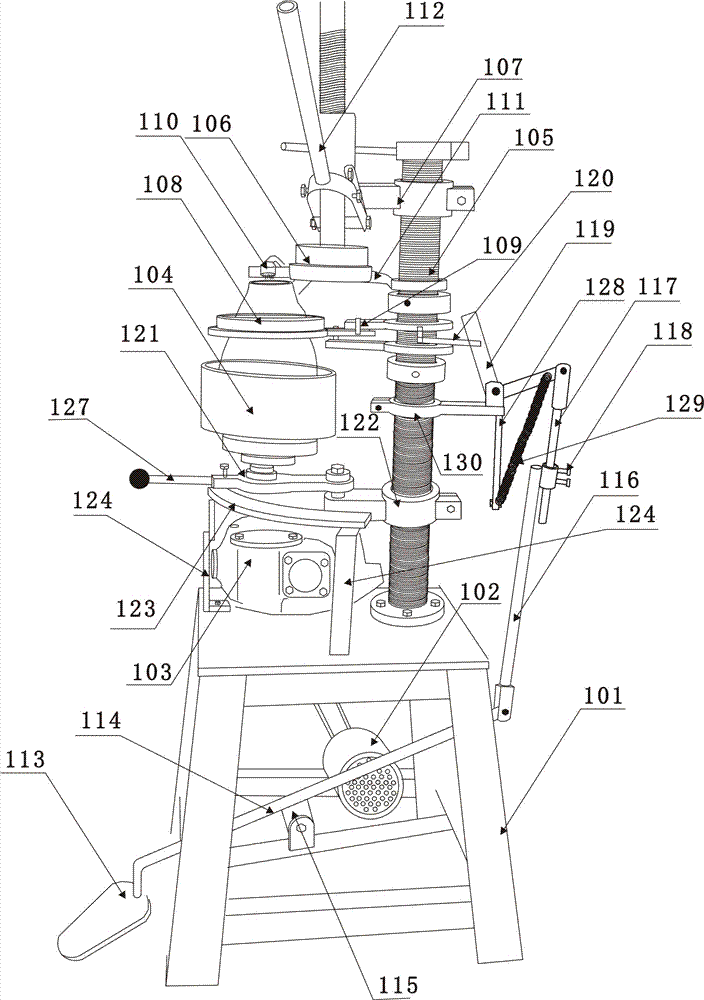

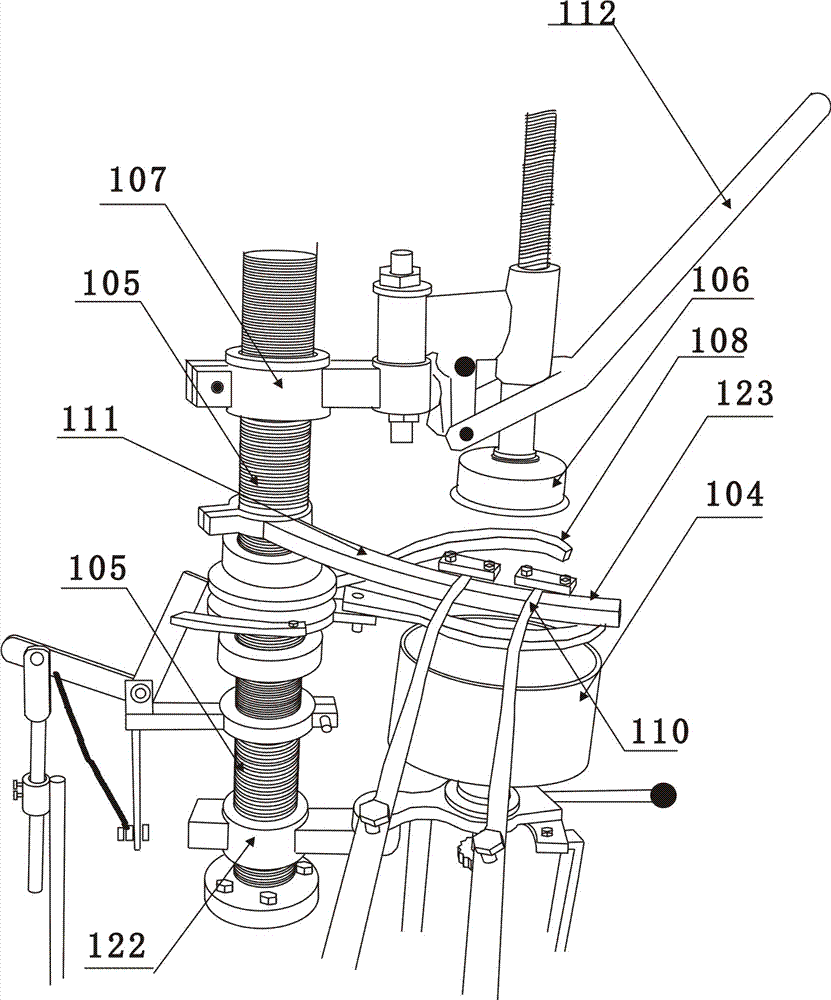

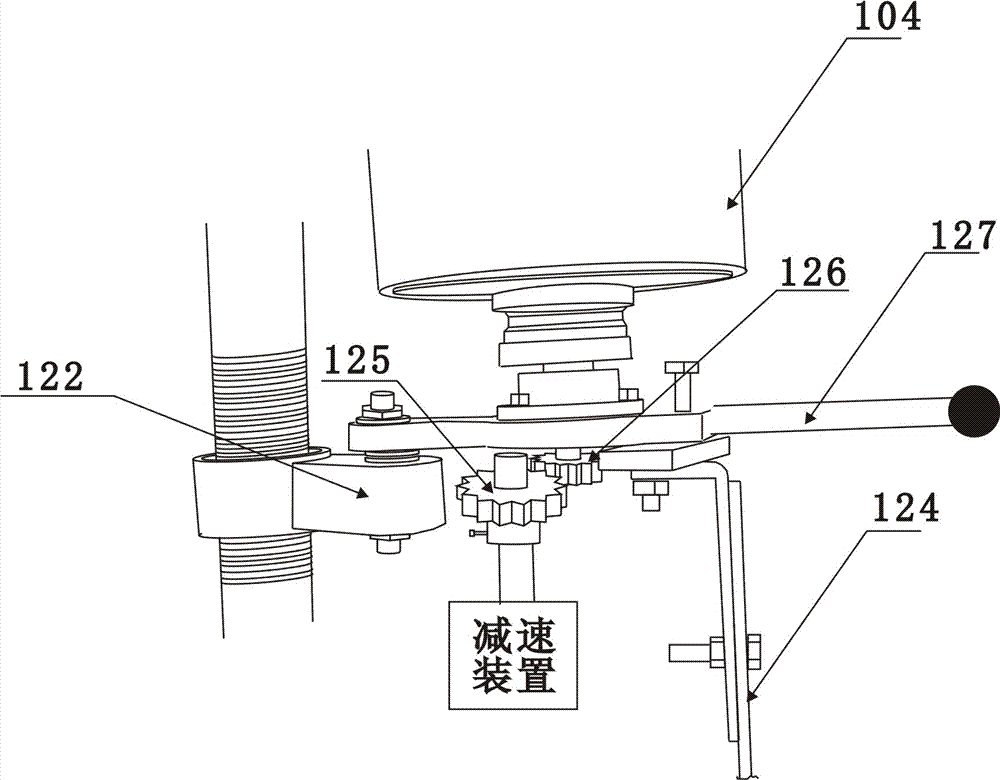

Glass pickle jar shaping mechanism

InactiveCN102408186BImprove yieldChange the heating methodGlass reforming apparatusGlass productionWater holdingEngineering

The invention discloses a glass pickle jar shaping mechanism which is characterized by comprising a metal frame, a motor, a speed reducing device, a tray, a water holding plate upper mold, a water holding plate lower mold and a heating gun, wherein an upright post is fixed on the metal frame; the speed reducing device is installed on the metal frame and is matched with the motor for working; the tray can be driven to rotate by the speed reducing device; the water holding plate upper mold is arranged at the upper end of the upright post through an upper mold support; the water holding plate lower mold is composed of two parts, each part is connected with a lower mold support, and the lower mold supports are arranged on the upright post; and the heating gun is used for heating and softeningglass. According to the glass pickle jar shaping mechanism, the defects that the specification quality of a product produced by traditional artificial blowing can not be effectively guaranteed, especially the sizes of the port parts are not uniform, and the phenomenon of different heights always appears are overcome; and the glass pickle jar shaping mechanism has the advantages of high product qualified rate and convenience in operation.

Owner:熊杰

Solar-heat pump combined heating system for parallel heating of water and air in greenhouse

InactiveCN104764213BSmaller specific heatIncrease profitFluid heatersSolar heat devicesSolar water heating systemEngineering

The invention discloses a greenhouse breeding water and air parallelly heated solar energy-heat pump united heat supply system which comprises a solar water heating system, a soil heat storage and release system and a controller and further comprises a solar energy-heat pump air direct heating system and a new breeding water heating system. The solar energy-heat pump air direct heating system comprises a solar air heat collector group, a first heat pump and a fan. The new breeding water heating system consists of two portions, wherein the first portion comprises a sixth water pump, a waste heat exchanger, a sixth magnetic valve, a breeding water heat exchanger, a fifth magnetic valve, a breeding water preparation pond and a breeding pond. The soil heat storage and release system comprises a solar hot water heat collector group and a soil storage and release device. The greenhouse breeding water and air parallelly heated solar energy-heat pump united heat supply system changes an air and new breeding water heating mode in a breeding room, can decrease heat exchange middle links and is higher in heat transfer efficiency and better in energy-saving effect.

Owner:ZHEJIANG UNIV

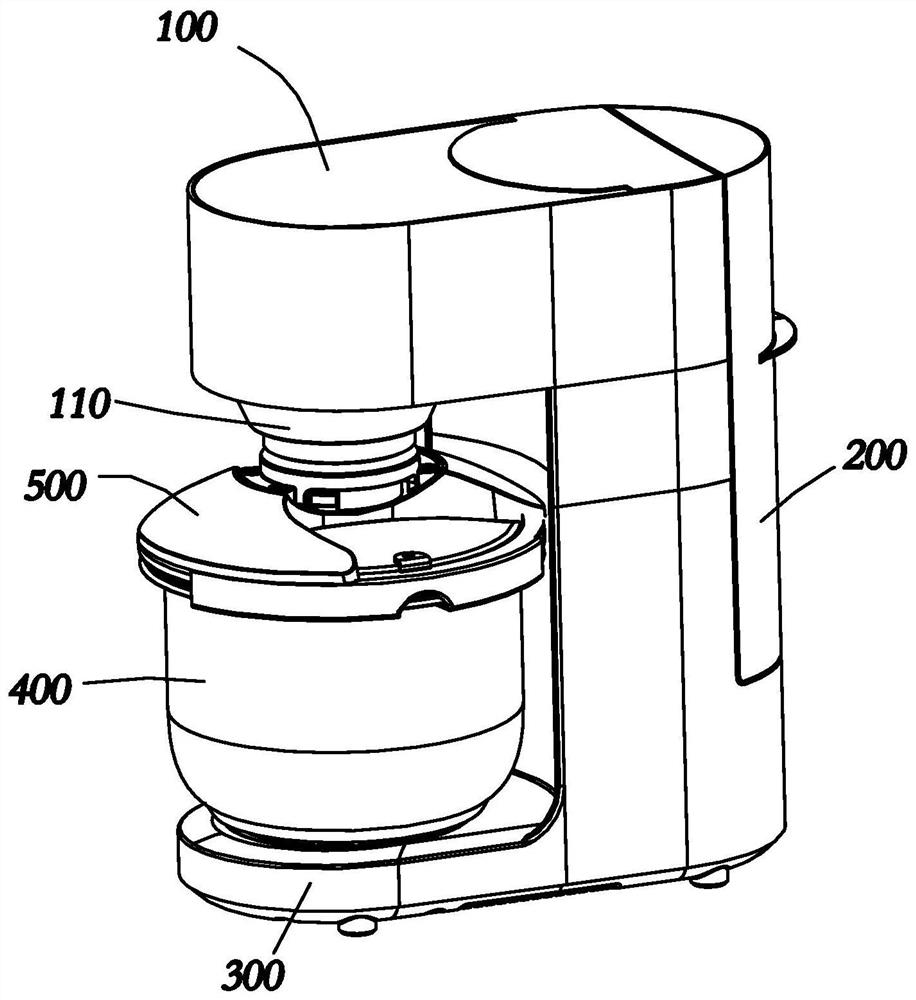

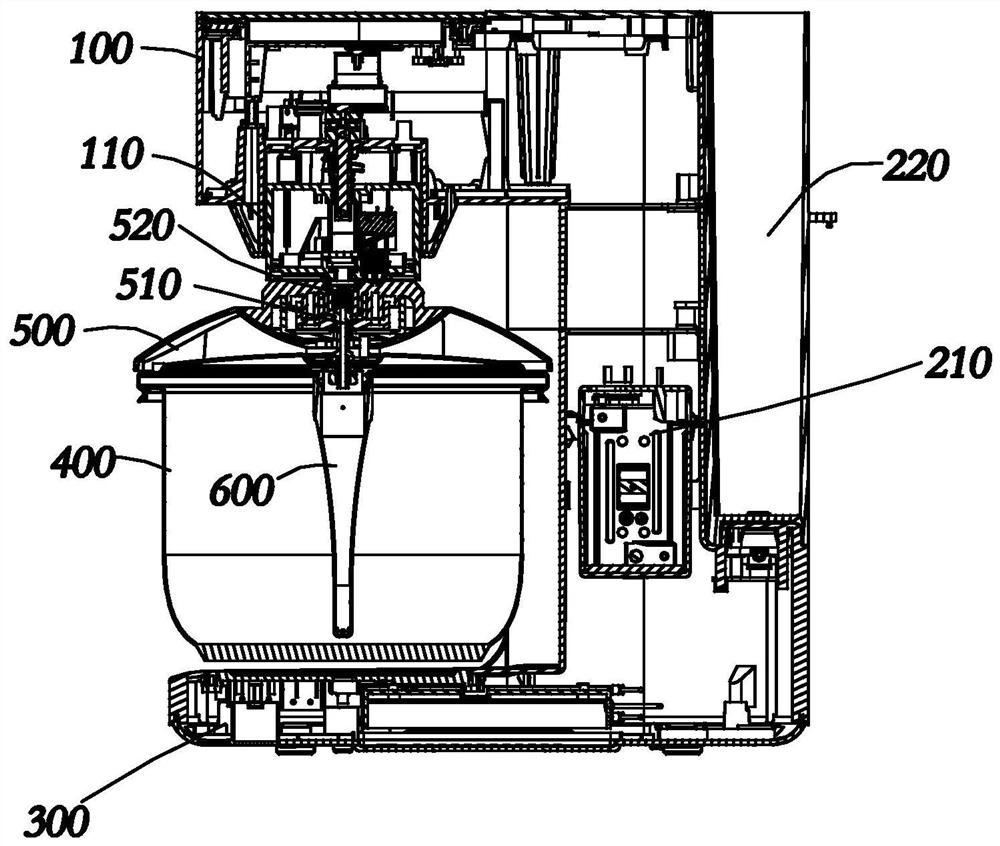

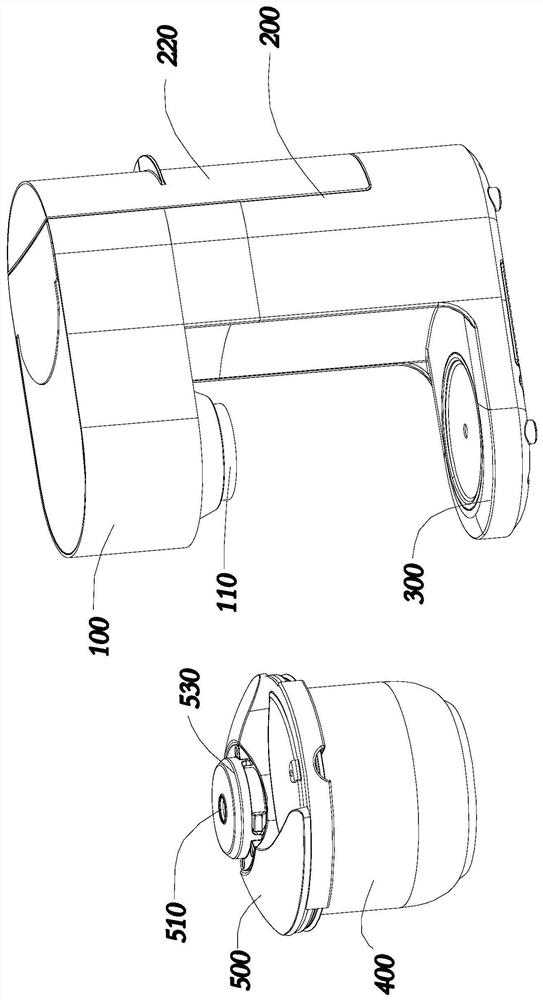

Pressure cooking utensil

PendingCN112826314AIncrease pressureShorten the timeSteam cooking vesselsPressure-cookersThermodynamicsProcess engineering

The pressure cooking utensil comprises a machine body and a pot body, a steam generation device is arranged in the machine body, the pot body comprises a pot body and a pot cover, the pot cover and the pot body are buckled to form a cooking cavity, a steam guide pipe communicated with the steam generation device is arranged on the pot cover, and the steam guide pipe is communicated with the steam generation device. the steam guide pipe is provided with a steam hole for spraying steam, the steam guide pipe extends into the pressure cooking cavity to spray steam so as to quickly increase the pressure in the cooking cavity, and food materials are stirred and heated under the pressure state. According to the pressure cooking utensil, high-temperature and high-pressure steam is rapidly generated through the steam generation device in the machine body, the high-temperature and high-pressure steam is directly introduced into the cooking cavity through the steam guide pipe to achieve rapid pressurizing and heating, and the problems that an existing pressure cooking utensil is long in pressurizing time, and food materials stick to a pot are solved.

Owner:JOYOUNG CO LTD

Microwave Heating Magnesium Smelting Technology

InactiveCN103882247BExploitation of New Technology for Magnesium SmeltingImprovement of Magnesium Refining TechnologyMicrowaveNew energy

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

Spraying device for photovoltaic welding strip

The invention discloses a spraying device for a photovoltaic welding strip. The device comprises a protective shell, a fixing block, a conveying device, a spraying device body and a base, wherein the conveying device comprises a first motor, a rotating shaft, a feeding roller, a rubber ring, a tire groove and a preheating device, the first motor is connected to the front side of the interior of the fixing block, the rotating shaft is rotationally connected to the rear side of the first motor, the feeding roller is connected to the rear side of the rotating shaft, the rubber ring is fixedly installed on the axial outer side of the feeding roller, and the preheating device is installed in the feeding roller. According to the spraying device for the photovoltaic welding strip, through the cooperation effect between the rubber ring and the tire groove, the photovoltaic welding strip is driven to be input inwards through the static friction force between the rubber ring and the photovoltaic welding strip, the purpose of automatic input is achieved, meanwhile, the rubber ring is made of rubber and has elasticity, and therefore, the effect that the shape of the photovoltaic welding strip cannot be changed due to clamping force is achieved, and the problem that the photovoltaic welding strip is scrapped due to external force factors is solved.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

Heat-controllable tubular gas heat treatment furnace

ActiveCN103526003BChange the heating methodReduce energy consumptionFurnace typesIndirect heat exchangersStraight tubeEvaporation

A heat-controllable tubular gas heat treatment furnace is characterized in that the heat-controllable tubular gas heat treatment furnace comprises a gas furnace (1) and a heat treatment furnace (12), one end of the heat treatment furnace (12) is supported on the gas furnace (1), the other end of the heat treatment furnace (12) is supported on a support (17), a condensation end at the upper ends of gravity assisted heat tubes is positioned in the heat treatment furnace (12) to heat the hearth of the heat treatment furnace (12), and an evaporation end at the lower end of a straight tube type gravity assisted heat tube traverses through the furnace walls of the heat treatment furnace (12) and the gas furnace (1), is positioned in the gas furnace (1) and is used for absorbing heat generated by the gas furnace (1); and the gas furnace (1) and the heat treatment furnace (12) are respectively connected with a ventilation unit for realizing the uniformity of the respective internal temperature. The heat-controllable tubular gas heat treatment furnace has the advantages of simple structure, flexible heat supply mode, utilization of all waste heats, energy saving, environmental protection and simple making process, and can be widely applied in the current industrial production.

Owner:NANTONG HITECH PRECISION MATERIAL CO LTD

A kind of technical method of repairing arc quartz crucible

ActiveCN107739146BAvoid crackingChange the heating methodBy pulling from meltGlass shaping apparatusIndustrial engineeringQuartz crucible

The invention discloses a novel process method for repairing an arc quartz crucible. The method comprises the following steps of 1, transferring a crucible; 2, performing grinding; 3, cleaning the crucible; 4, performing crucible local inside and outside preheating; 5, repairing concave pits; 6, performing post treatment. During the preheating, the inside and outside temperature difference type preheating is used; during the concave pit repairing, the used bending process is a multilayer filling process; the connection performance is good.

Owner:曲靖晶澳光伏科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com