Energy-saving ceramic fire resistant bearing board

A firing plate and refractory technology, applied to lighting and heating equipment, furnace components, furnaces, etc., to achieve the effects of shortening the firing cycle, good strength, and changing the heating state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

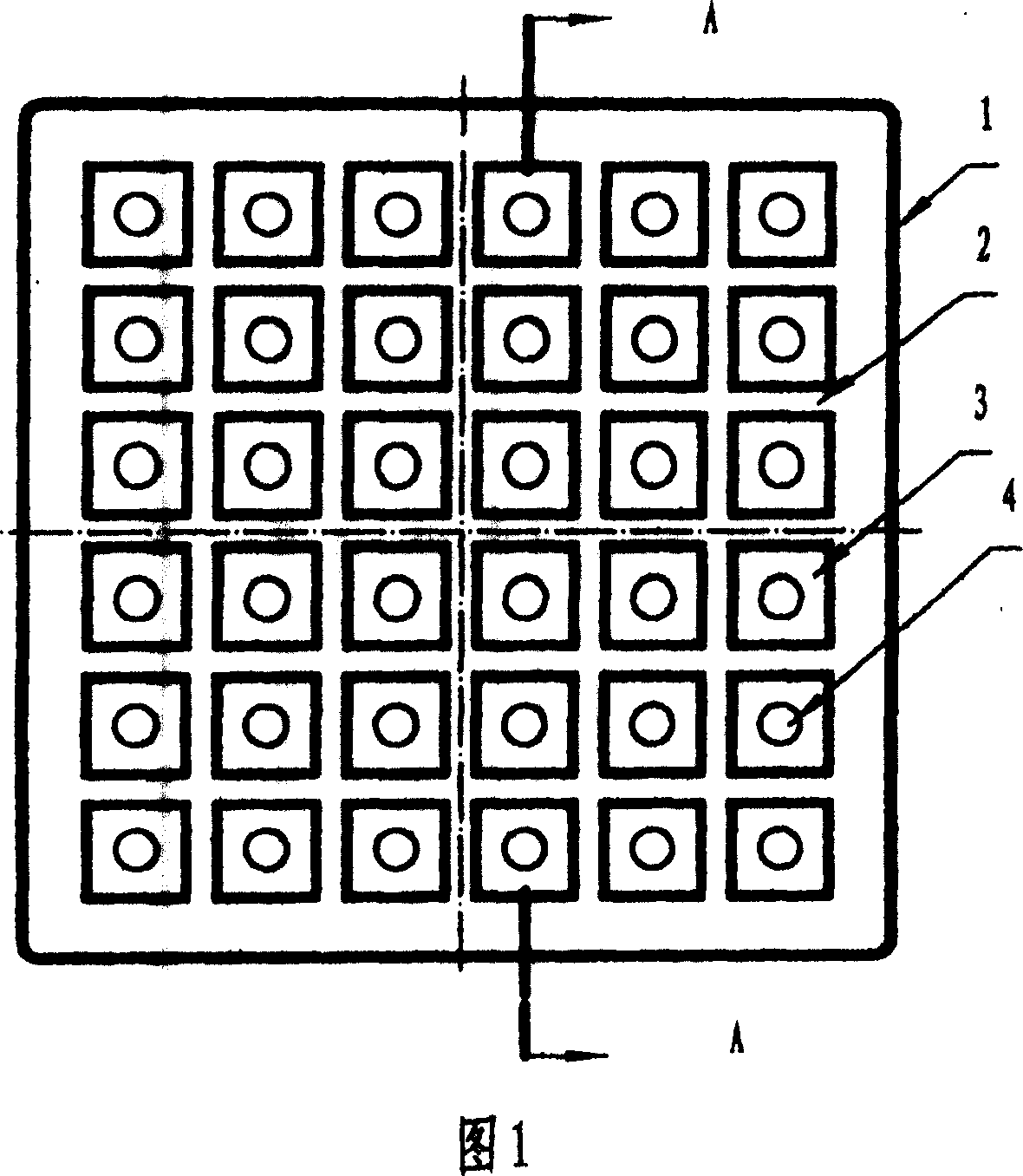

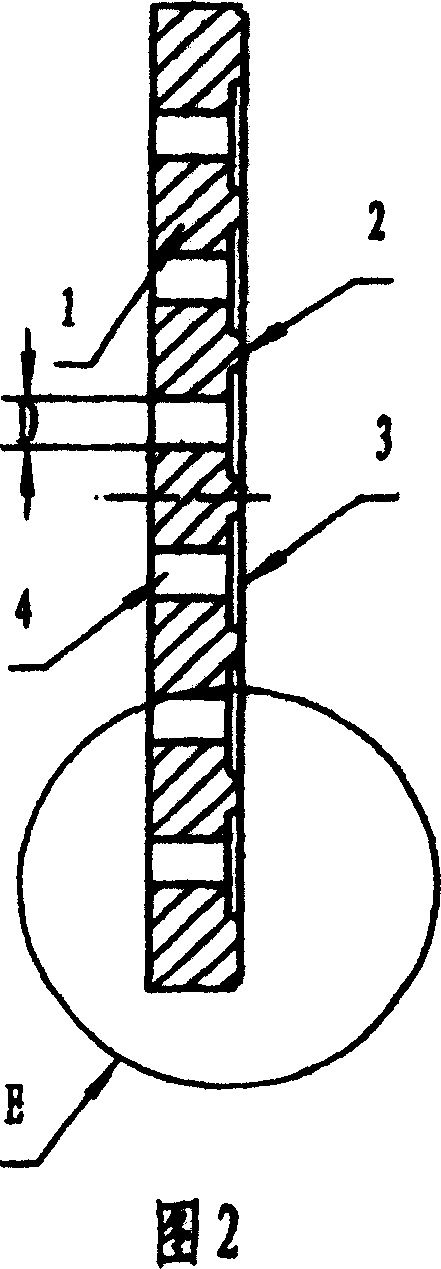

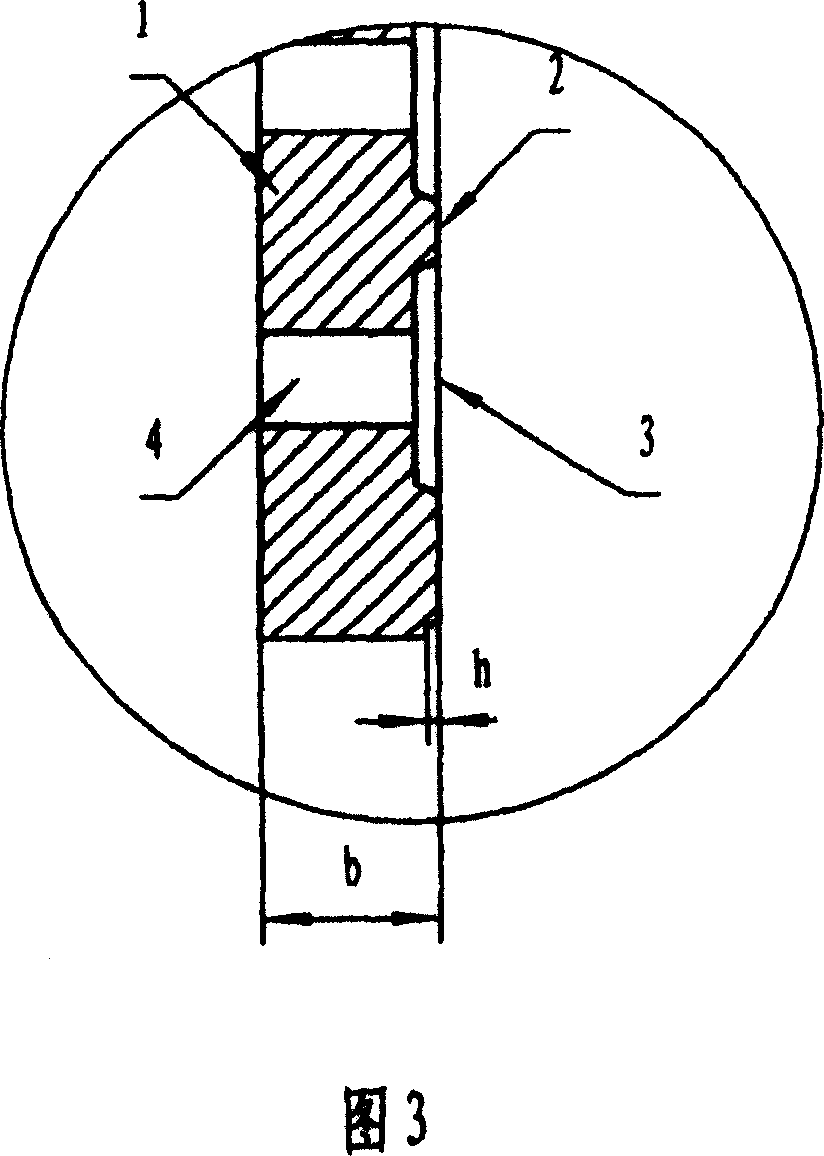

[0020] Referring to Fig. 1, Fig. 2 and Fig. 3, the face of an energy-saving ceramic refractory setter plate 1 is a flat plane, and its bottom plane is covered with ribs 2 vertically and horizontally arranged vertically and horizontally, forming a group of continuous square spaces 3 , a round through hole 4 is arranged in each space 3 . The specification of the setter plate in this example is: 460×460×10mm (length×width×thickness), the specification of each space 3 is 40×40mm, the thickness of the setter plate is b=10mm, and the height of each rib 2 is h=2.5mm , the ratio of rib 2 height h to setter 1 thickness b h b = 2.5 10 = 0.25 . The diameter D of the circular hole 4=10mm.

[0021] The space 3 at the bottom of the ceramic refractory setter plate can be made into regularly arranged squares, rectangles, rhombuses, triangles, polygons, circles, plum blossom...

Embodiment 2

[0023] Referring to Fig. 4, Fig. 5, and Fig. 6, the face of the ceramic refractory setter 5 of the present embodiment is a flat plane, and the bottom plane is covered with ribs 6 arranged vertically, horizontally and obliquely, and each space 7 is provided with A circular through hole 8 is arranged. The specification of the setter plate in this example is: 460×460×13mm (length×width×thickness), the rib 6 height h=2mm, the ratio of the rib 6 height h to the setter plate 5 thickness b h b = 2 13 = 0.15 . The diameter D of the circular through hole 8=12mm.

Embodiment 3

[0025] Referring to Fig. 7, Fig. 8, and Fig. 9, the face of the ceramic refractory setter 9 of the present embodiment is a flat plane, and the bottom plane is stamped with pentagonal spaces 11 arranged regularly, and in each space 11 All are provided with a round through hole 12, and ribs 10 are formed between each space. The specification of the setter plate in this example is: 460×460×8mm (length×width×thickness), the rib 10 height h=4mm, the ratio of the rib 10 height h to the setter plate 9 thickness b h b = 4 8 = 0.5 . The diameter D of the circular through hole 12 is 8 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com