A kind of technical method of repairing arc quartz crucible

The technology of a quartz crucible and a process method is applied in the direction of chemical instruments and methods, manufacturing tools, glass forming, etc., which can solve problems such as poor penetration and connection effects, hidden cracks falling off, and poor melting effects, so as to maintain heat transfer efficiency, Avoid safety hazards and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

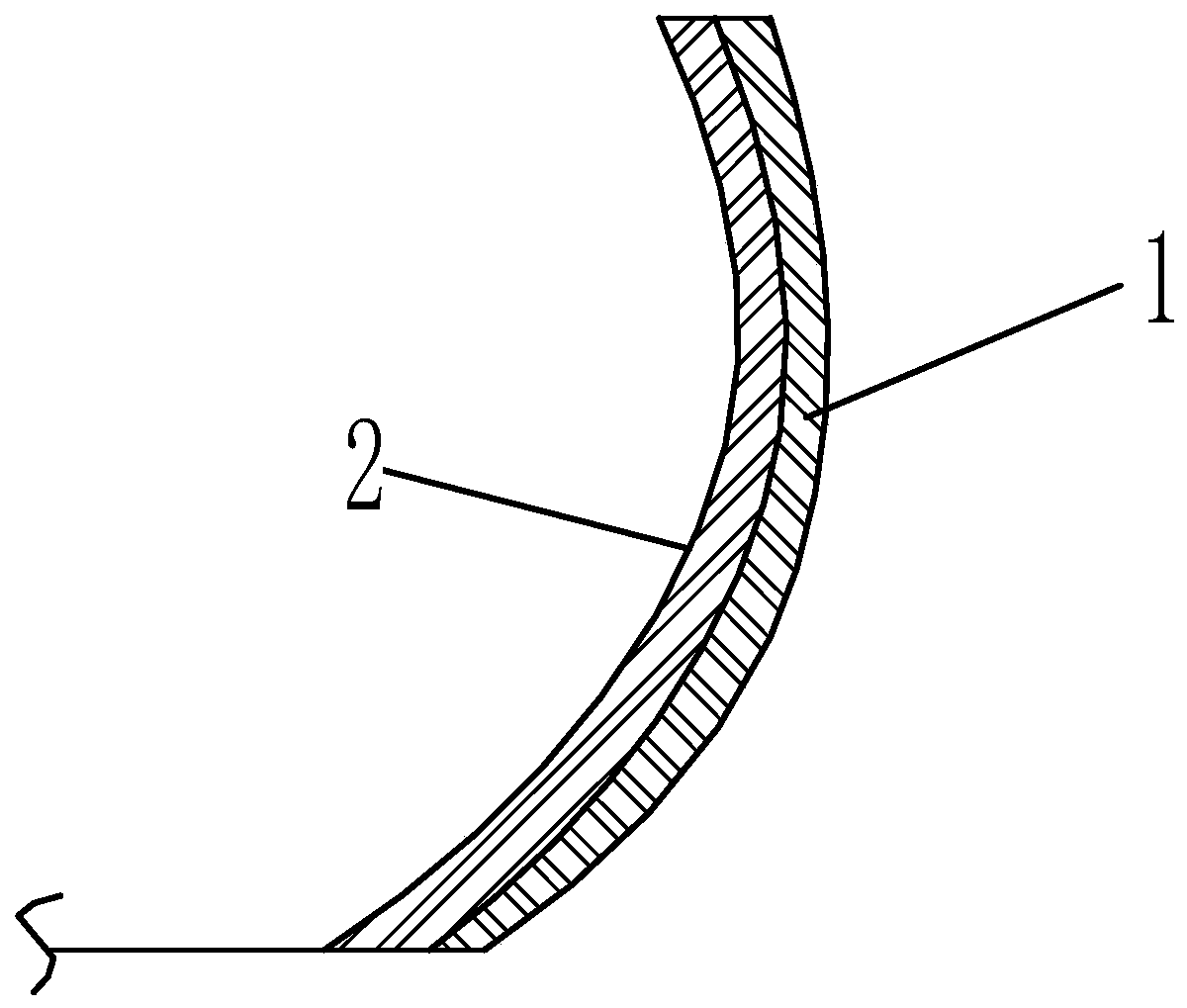

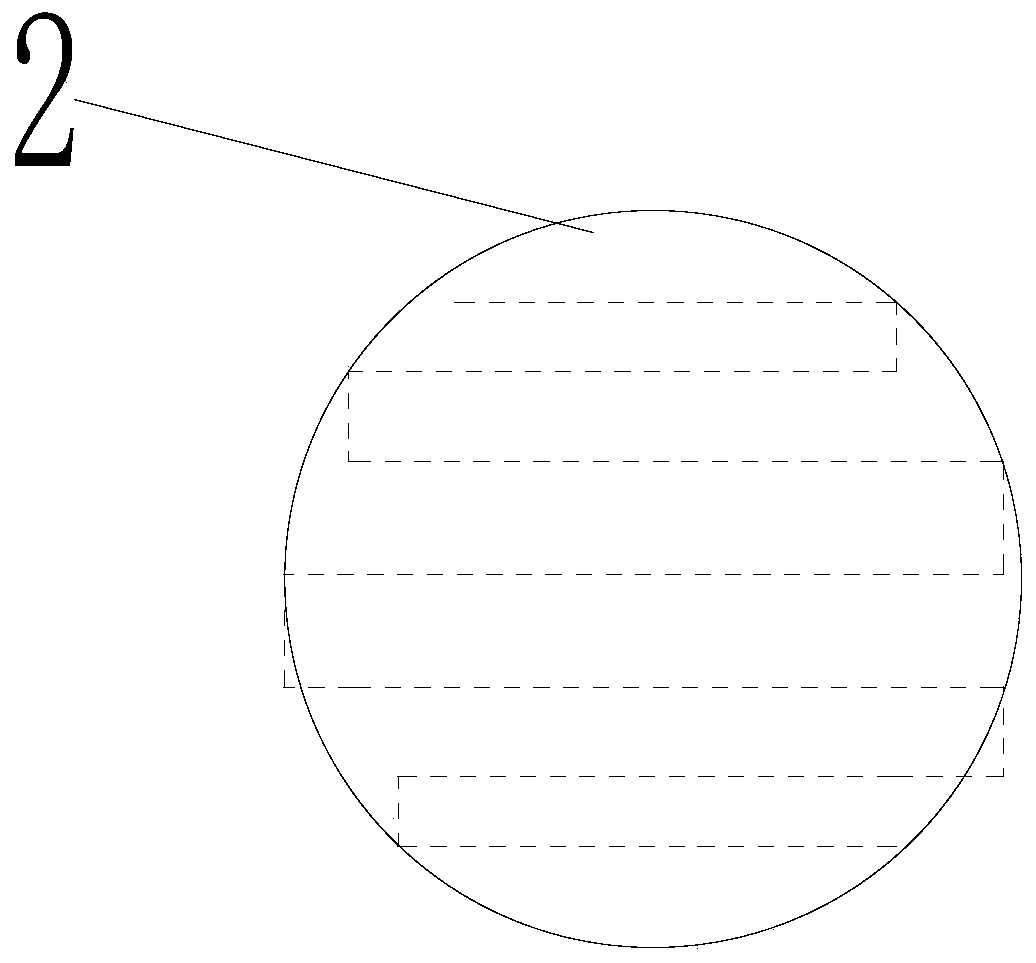

[0026] The following is attached Figure 1-2 To further explain the present invention in detail:

[0027] ①Prepare the crucible: transfer the graphite crucible and the quartz crucible with damaged points to the workbench. During and after the transfer, always keep the crucible open upward.

[0028] ②Grinding: Use a grinding head to polish the defective spots in the inner cavity of the quartz crucible from the inside to the outside, and stop grinding until the damaged spots disappear and form pits. The pits are round pits or square pits. Or conical pits.

[0029] ③Clean the crucible: clean the graphite crucible and the quartz crucible at the same time, and dry after cleaning. When cleaning the quartz, use pure water to remove the dust left by the grinding in the quartz crucible. Use absorbent cotton and pure water to clean the inner and outer walls of the quartz crucible several times. Scrub, the outer wall of the quartz crucible is washed with a brush and pure water several times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com