Pressure cooking utensil

A technology of cooking utensils and pressure, applied in the field of cooking utensils and pressure cooking utensils, can solve the problems of long cooking time, sticking to the pan, health problems, etc., and achieve the effect of shortening time, increasing pressure, and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

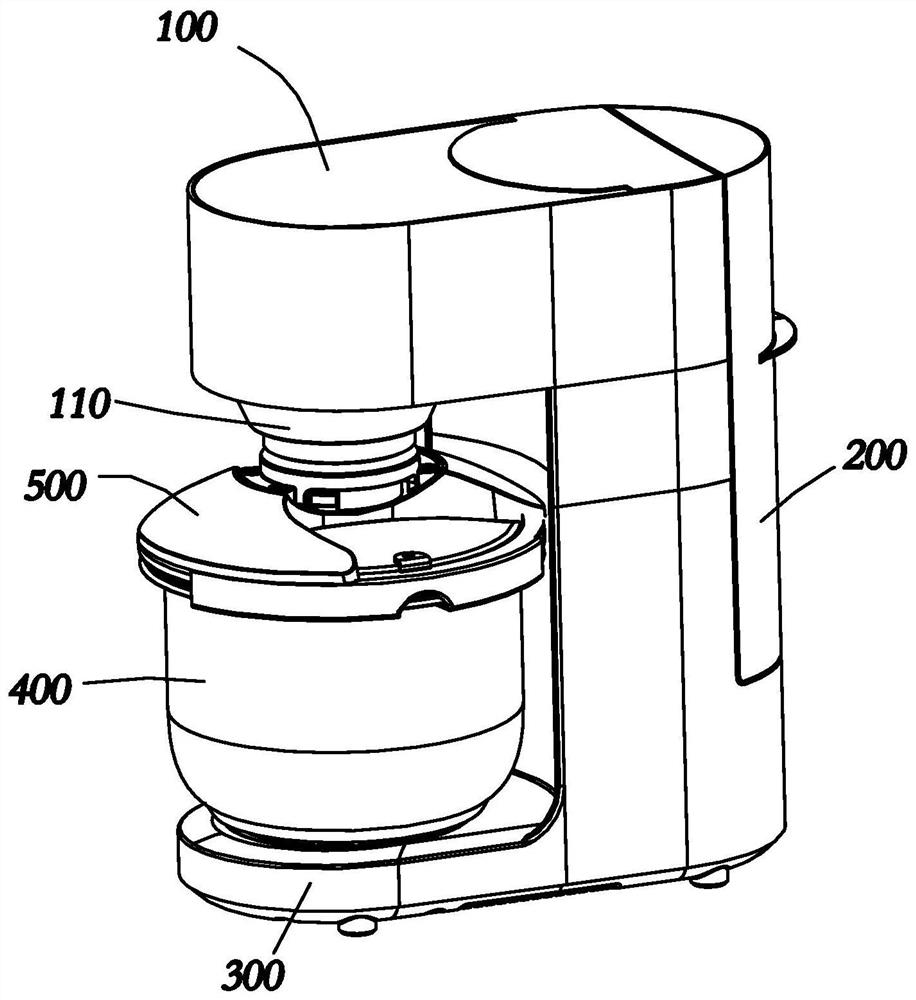

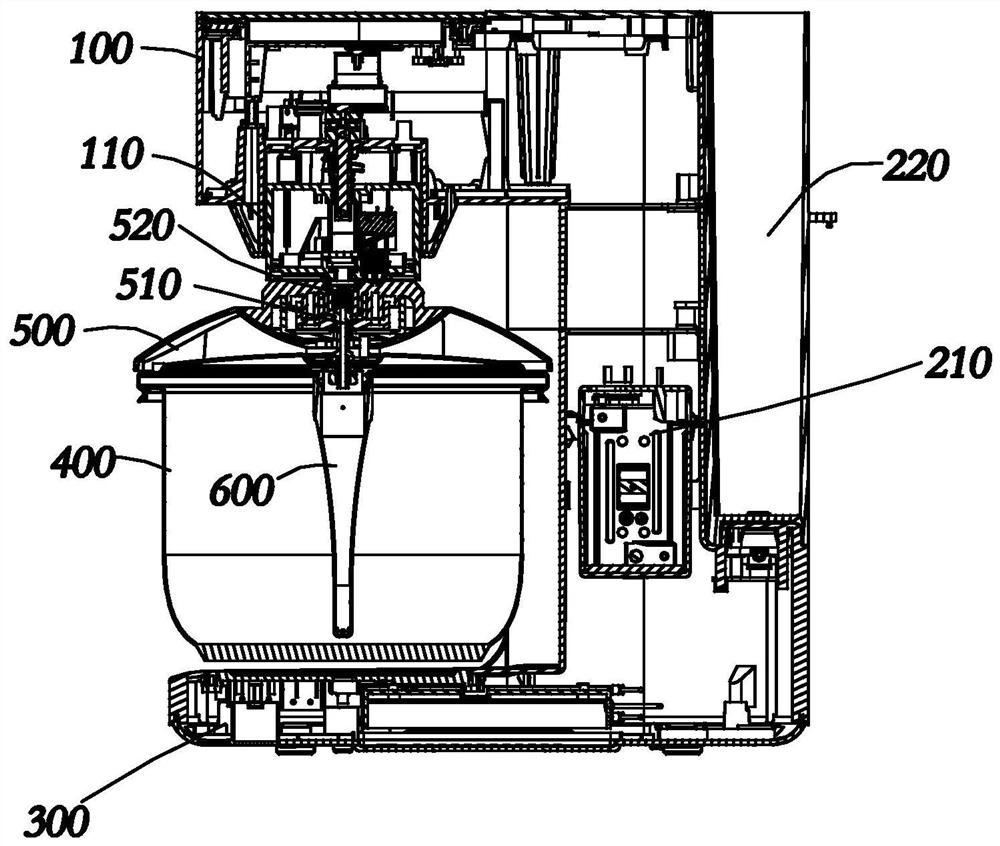

[0028] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 A first embodiment of the invention is shown.

[0029] In this embodiment, the pressure cooking appliance includes a body and a pot body 400, wherein the body is composed of a body 200 and a head 100 protruding from one side of the body 200 and a base 300 and a base 300, and the body 200 is provided with The steam generating device 210 generates high-temperature and high-pressure steam through the steam generating device 210 . There is a space between the machine head 100 and the base 300 to form an open space, and the pot body 400 is placed in the open space to facilitate the putting in and taking out of the pot body 400 . In the cooking preparation stage, the pot body 400 is placed on the base 300. The pot body 400 includes the pot body 400 body and the pot cover 500. The pot cover 500 is provided with an air intake channel 510 communicating with the cooking cavity of the pot body 400. The machine head 100 is pr...

Embodiment 2

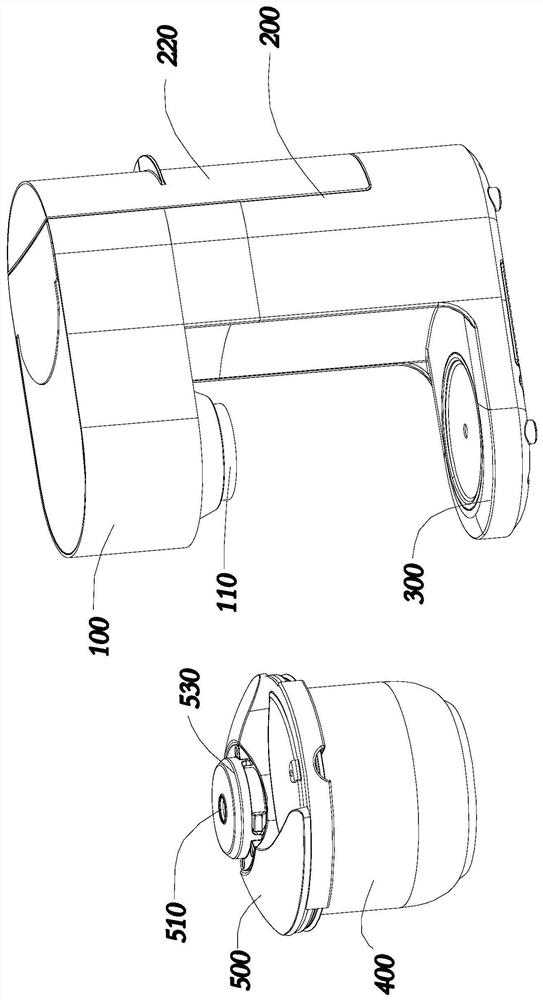

[0045] refer to Figure 4 , Figure 4 A second embodiment of the invention is shown. This embodiment is an improvement on the basis of Embodiment 1.

[0046] In this embodiment, the machine head 100 is reversibly arranged on the body 200, and the machine head 100 has a separate state from the pot body 400, and a docking state with the pot body 400. When the machine head 100 is separated from the pot body 400, the user can take off the pot body 400 from the base 300, or put the pot body 400 on the base 300; when the machine head 100 and the pot body 400 are in a docking state, the machine head The docking portion 110 on the pot cover 500 is connected to the intake channel 510 on the pot cover 500 . Compared with the solution in Embodiment 1, this embodiment uses the machine head 100 to turn over and dock with the pot body 400. When the pot body 400 is in the open state, the user can take out or put in the pot body 400 from the obliquely above, and take and place the pot body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com