Spraying device for photovoltaic welding strip

A technology of spraying device and photovoltaic welding strip, applied in spraying device, device for coating liquid on the surface, coating, etc., can solve the problems of non-compliance with quality requirements, high scrap rate, uneven heating, etc. Excellent, reduce the scrap rate, and solve the effect of scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

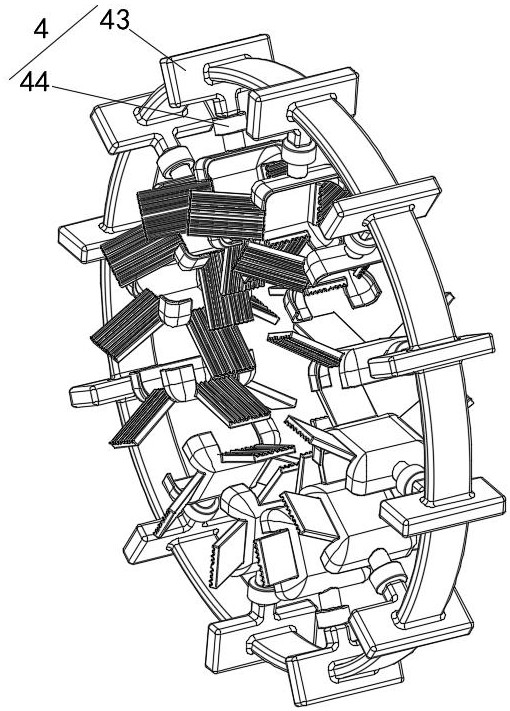

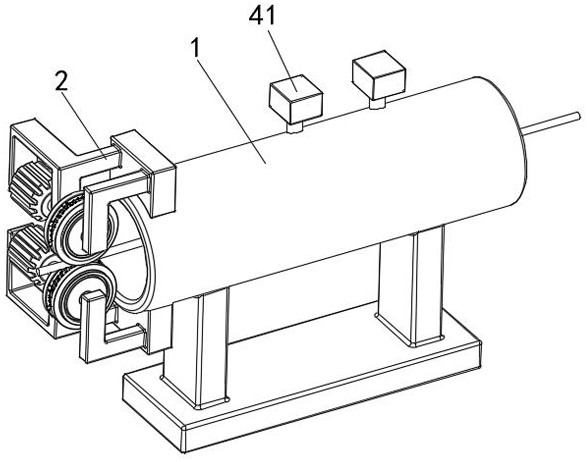

[0042] see Figure 1-8 , a spraying device for photovoltaic welding tape, including a protective shell 1, a fixing block 2, a transportation device 3, a spraying device 4 and a base, the lower side of the protective shell 1 is fixedly connected with the base, and the left part of the protective shell 1 The upper and lower sides are fixedly connected with a fixed block 2, the inner side of the fixed block 2 is fixedly installed with a transport device 3, and the inside of the protective shell 1 is fixedly installed with a spray device 4;

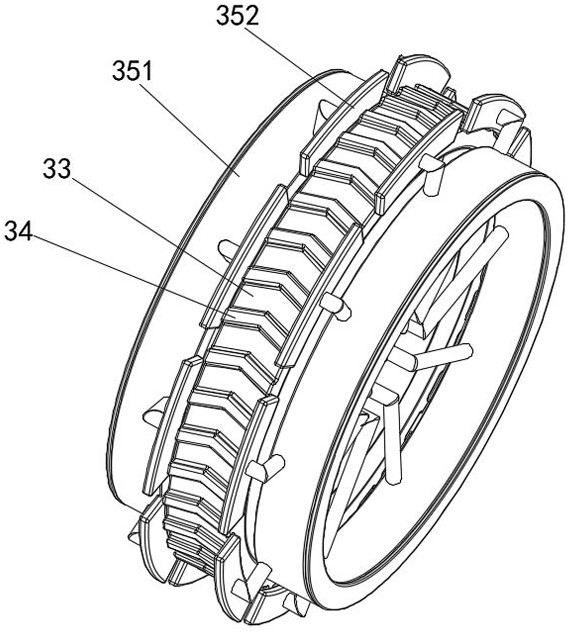

[0043] The transportation device 3 includes a first motor 31, a rotating shaft, a feeding roller 32, a rubber ring 33, a tire groove 34 and a preheating device 35. The inner front side of the fixing block 2 is fixedly connected with the first motor 31, and the rear of the first motor 31 A rotating shaft is rotatably connected to the side, a feeding roller 32 is fixedly connected to the rear side of the rotating shaft, and a rubber ring 33 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com