Conductive silver adhesive and preparation method thereof

A technology of conductive silver glue and silver powder, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of short curing time, long curing time, high shrinkage rate, etc., and achieve good fluidity, high product quality, The effect of low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Component formula (parts by weight):

[0038] 52 parts of spherical silver powder, 15 parts of bisphenol A epoxy resin, 18 parts of cyclohexanone, 4 parts of dicyandiamide, 1 part of imidazole, 9 parts of moisture curing polyurethane and 1 part of polyethylene glycol ether.

[0039] making process:

[0040] After mixing the above-mentioned components, stirring and defoaming are performed until the components are uniformly dispersed to obtain the finished conductive silver glue.

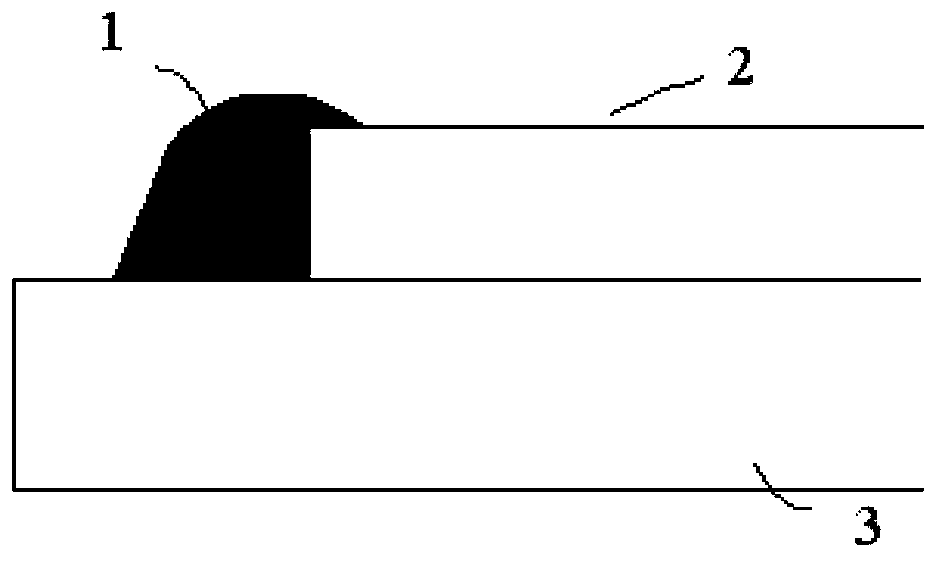

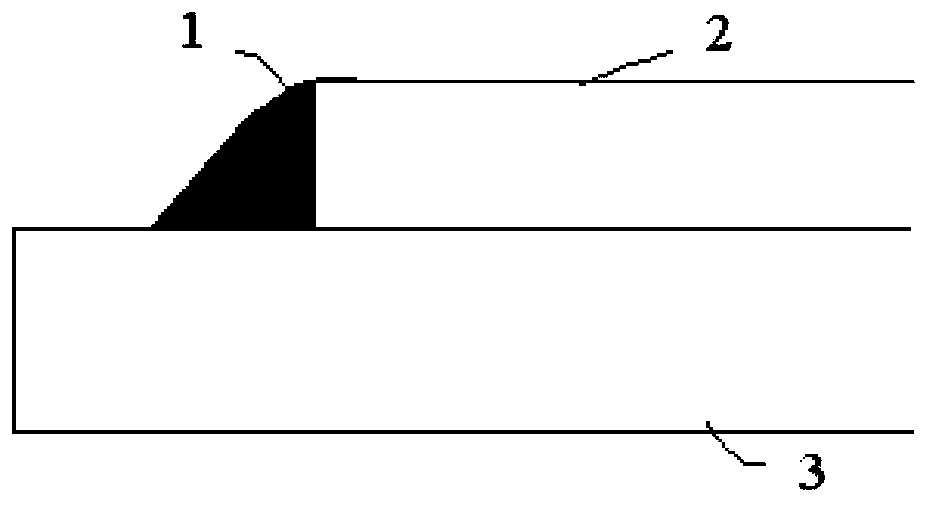

[0041] The curing temperature of the above-mentioned conductive silver glue is about 70°C, the curing time is about 15 minutes, the longitudinal shrinkage rate after curing is about 15%, the transverse shrinkage rate is less than 5%, and the resistivity is less than 1.2×10 -4 Ω·cm. Appearance after curing see Figure 5 .

Embodiment 2

[0043] Component formula (parts by weight):

[0044] 50 parts spherical silver powder, 10 parts bisphenol A epoxy resin, 4 parts aliphatic epoxy resin, 21 parts isopropyl alcohol, 4 parts adipic dihydrazide, 9 parts moisture curing polyurethane and 2 parts polyethylene glycol ether.

[0045] The preparation process is the same as in Example 1.

[0046] The curing temperature of the above-mentioned conductive silver glue is about 70°C, the curing time is about 16 minutes, the longitudinal shrinkage rate after curing is about 17%, the transverse shrinkage rate is less than 5%, and the resistivity is less than 1.2×10 -4 Ω·cm.

Embodiment 3

[0048] Component formula (parts by weight):

[0049] 56 parts of spherical silver powder, 10 parts of bisphenol A epoxy resin, 2 parts of aliphatic epoxy resin, 16 parts of acetone, 2 parts of adipic acid dihydrazide, 2 parts of dicyandiamide, 1 part of imidazole, 9.5 parts of moisture curing polyurethane and 1.5 parts polyethylene glycol ether.

[0050] The preparation process is the same as in Example 1.

[0051]The curing temperature of the above-mentioned conductive silver glue is about 70°C, the curing time is about 14 minutes, the longitudinal shrinkage rate after curing is about 14%, the transverse shrinkage rate is less than 5%, and the resistivity is less than 1.2×10 -4 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com