Curing and shaping equipment for PTC heating device

A heating device, curing molding technology, applied in the direction of ohmic resistance heating parts, electric heating devices, electrical components, etc., can solve the problems of high failure rate, large power consumption, poor consistency, etc., and achieve the effect of improving heating and curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

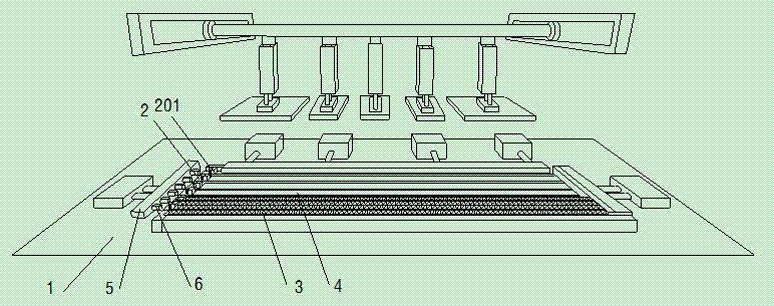

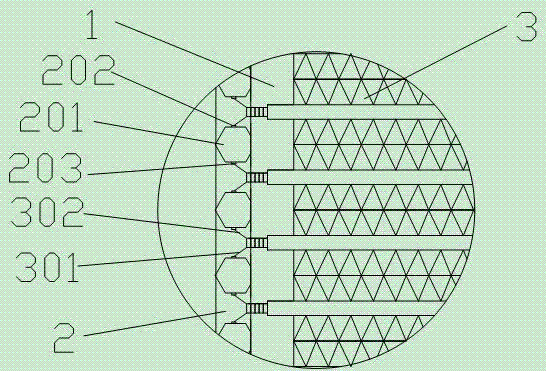

[0013] Such as Figure 1~2 The solidification molding equipment of a kind of PTC heating element shown, comprises console 1, and described console one end is fixed with circuit board 2, and described circuit board 2 is provided with several No. 1 fixing blocks 201 alternately, and No. 1 fixing blocks 201 The two sides are respectively provided with a positive electrode head 202 and a negative electrode head 203, and the PTC heating element 3 is arranged on the console 1, and the positive electrode sheet 301 and the negative electrode sheet 302 of the electrode lead-out end of the PTC heating element 3 are connected to the positive electrode head 202 and the negative electrode head respectively. 203 connection, there is a groove 4 corresponding to the PTC heating element 3 on the operating table 1, the width of the groove 4 is greater than or equal to the width of the heating element of the heating element, and the circuit board 2 side and the operating table 1 outside are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com