Microwave heating device for fast repairing asphalt pavement

A microwave heating device and asphalt pavement technology, applied in roads, roads, road repair and other directions, can solve the problems of long heating time, slow heat transfer, poor repair quality, etc., and achieve slow cooling speed, long constant temperature time, and no waste of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

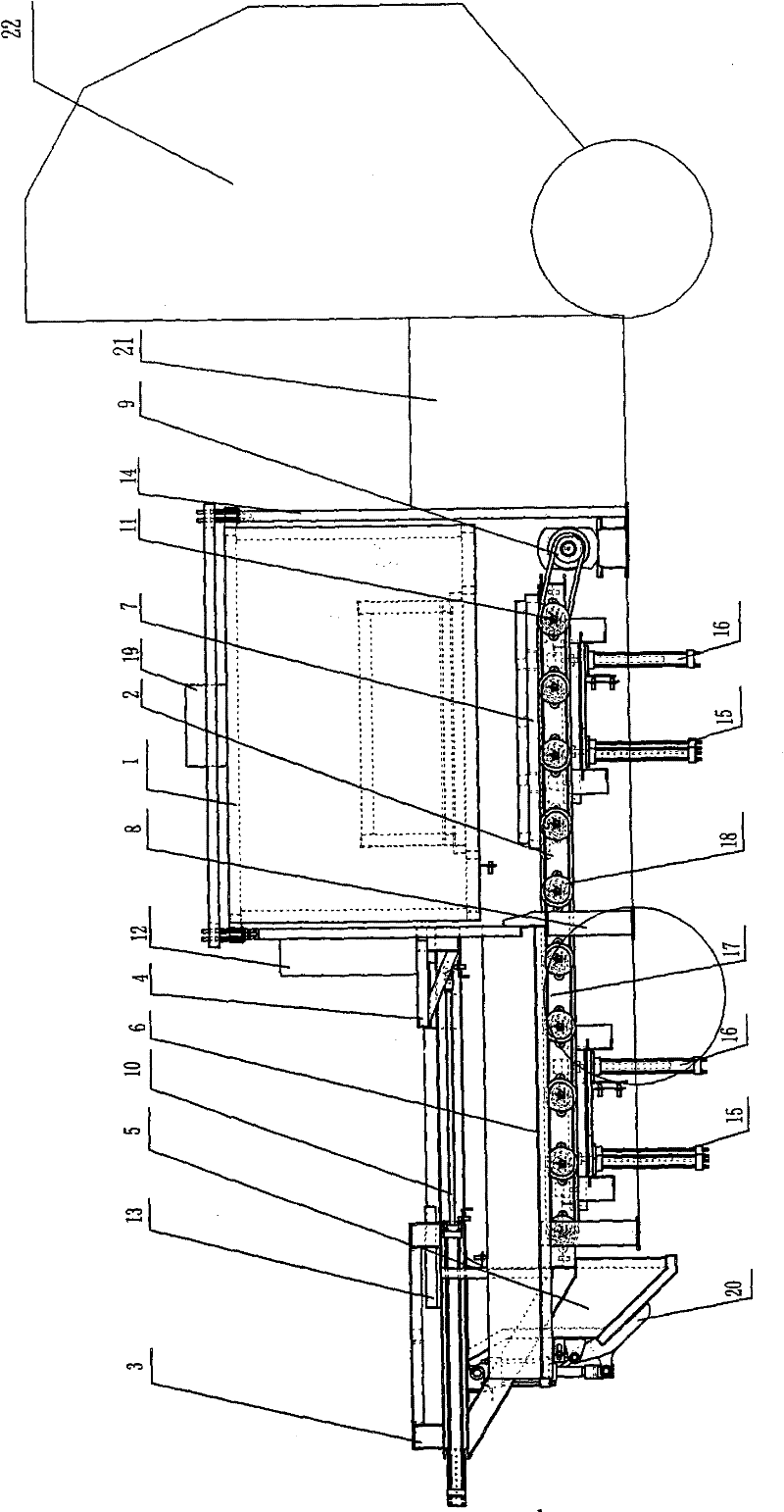

[0017] Accompanying drawing is embodiment of the present invention.

[0018] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0019] refer to figure 1 As shown, the microwave heating device for quickly repairing the asphalt pavement, the vehicle groove of the walking vehicle 22 is respectively equipped with a generator set 21, a microwave oven body assembly 1, a furnace body support 14, a motorized track 2, a tail support assembly 3, and a front platform device 4 , thermal insulation storage device 5, operating platform 6, lifting device 7, legs 8, motor and reducer 9, unloading device 10, synchronization device 11, control cabinet 12; the furnace body bracket 14 and the microwave oven body assembly 1 Connection, the inner cavity of the microwave oven body assembly 1 is equipped with microwave generators of different powers, the left side of the furnace body support 14 is connected to the front platform device 4, the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com