Glass pickle jar shaping mechanism

A forming mechanism and kimchi pot technology, which is applied in glass forming, glass re-forming, glass production, etc., can solve the problem that the product specifications and quality cannot be effectively guaranteed, the height is different, and the size and size of the mouth are not uniform. and other problems, to achieve the effect of convenient processing, labor saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

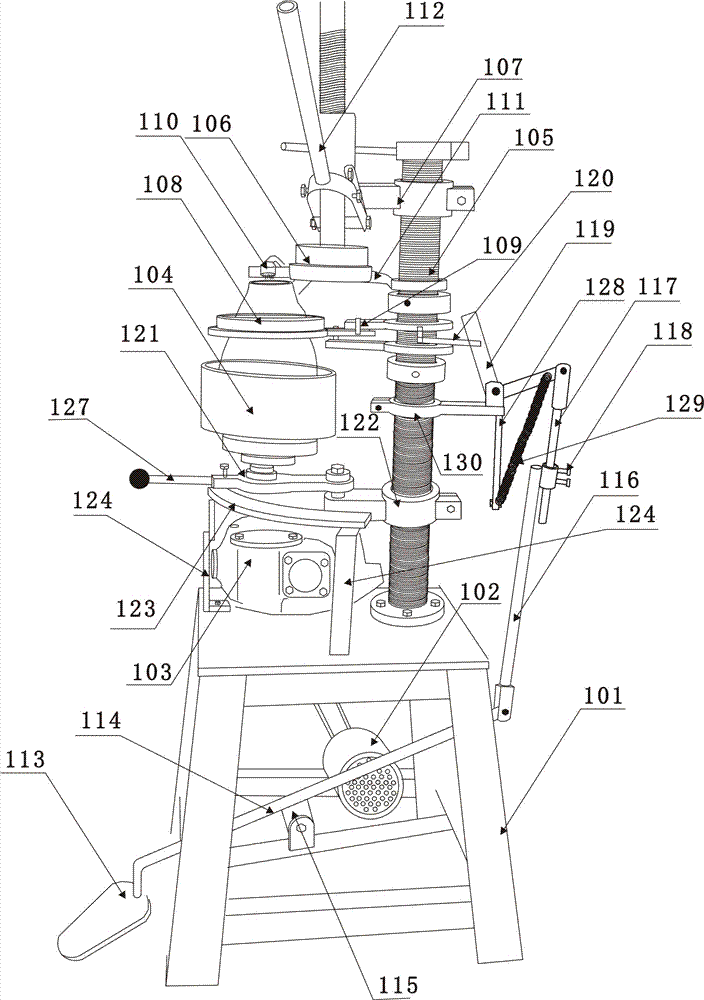

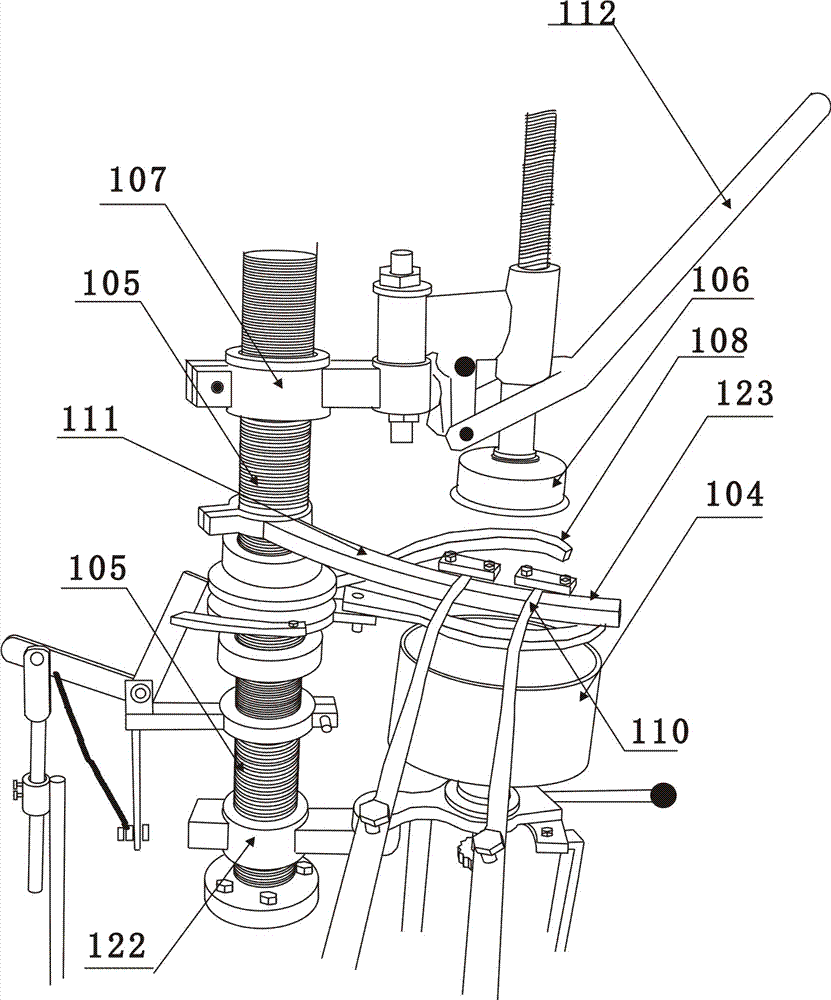

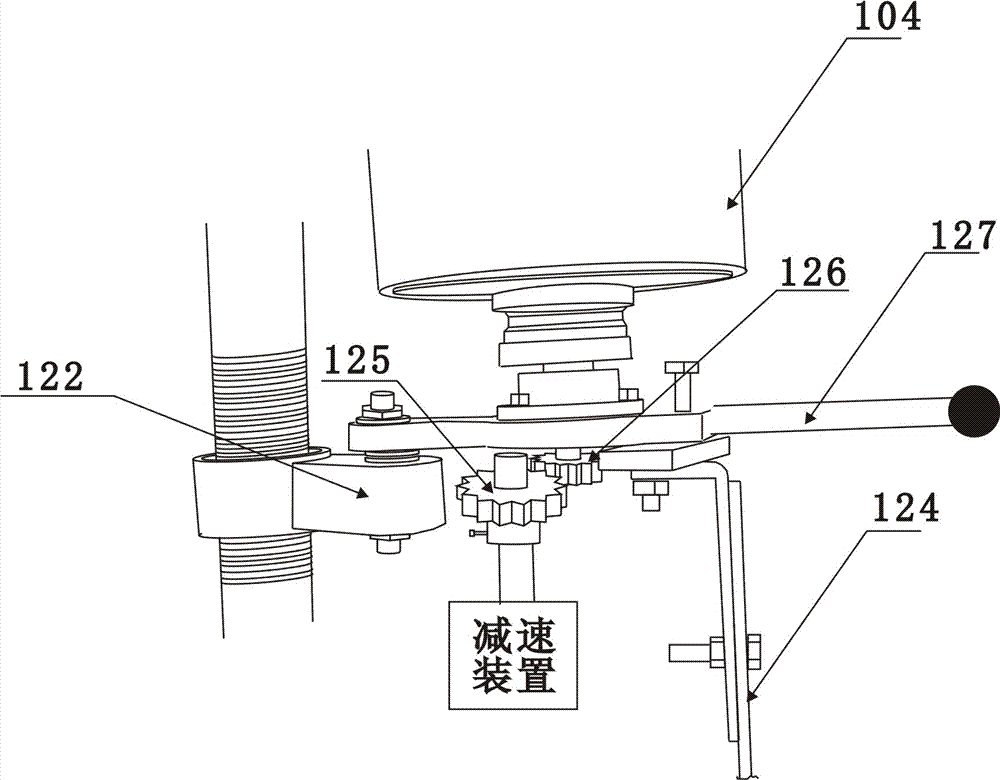

[0021] In order to overcome the deficiencies of the prior art, the present invention provides a glass kimchi jar forming mechanism to solve the shortcomings of manual blowing. The forming mechanism of the device is used to process the glass jar that has formed the initial shape into a finished product. Such as figure 1 As shown: the device includes a metal frame 101 and a motor 102, wherein a column 105 is fixed on the metal frame 101, and the column 105 can be fixed on the metal frame 101 by bolts. The motor 102 is connected with the deceleration device 103 , and the power is provided through the deceleration device 103 to make the tray 104 rotate.

[0022] It includes a deceleration device 103 installed on the metal frame 101 to cooperate with the motor 102, a tray 104 that can be rotated under the drive of the deceleration device 103, and an upper mold 106 on the water receiving tray. The upper mold 106 on the water receiving tray passes through the upper The mold support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com