Bottom heater for pulling monocrystal

A heating element and single crystal technology, applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of polysilicon melting taking a long time, increasing radial temperature difference, increasing the diameter of germanium single crystal, etc. , to achieve the effect of shortening the complete melting time of polycrystalline raw materials, speeding up complete melting and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

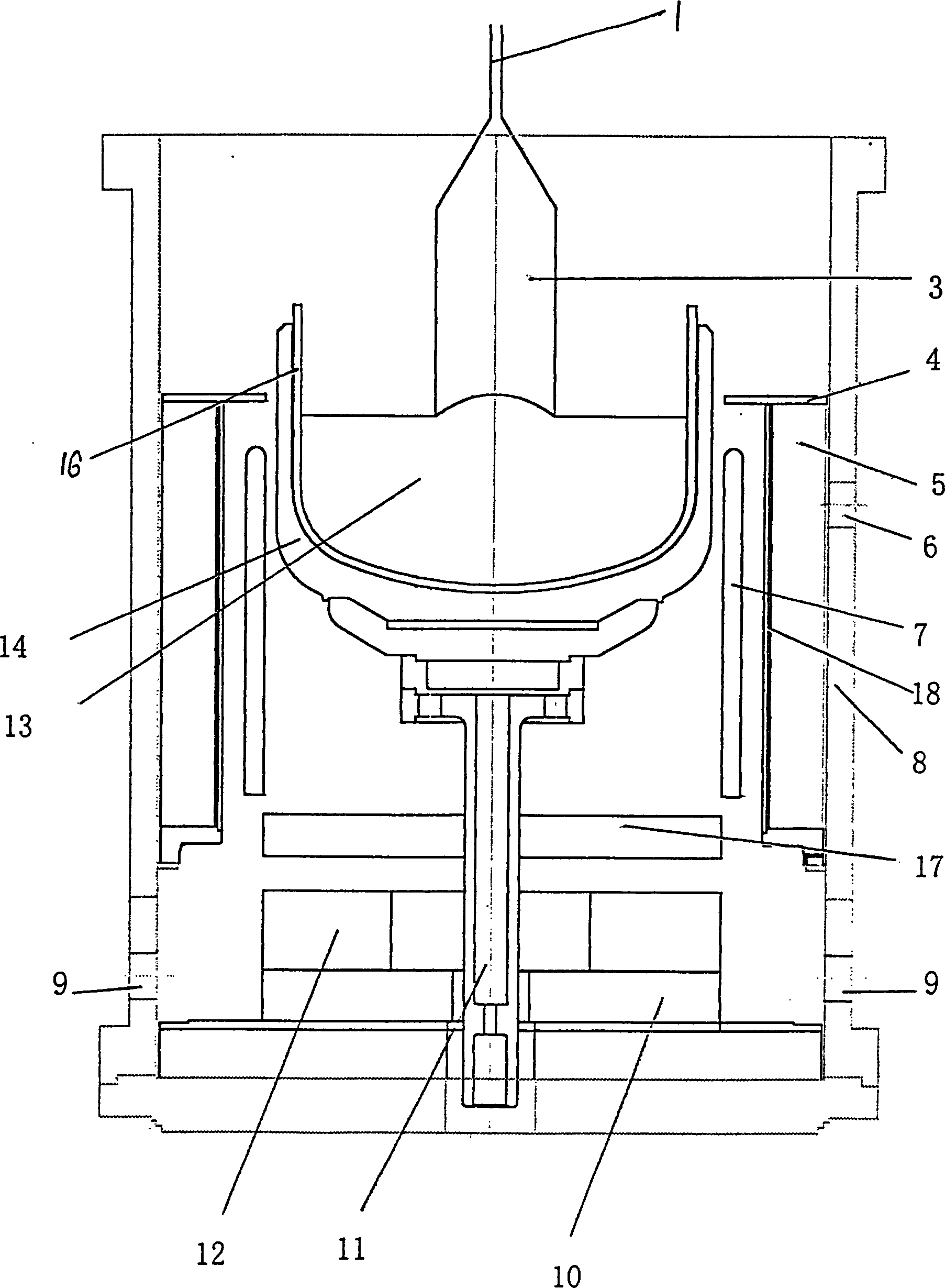

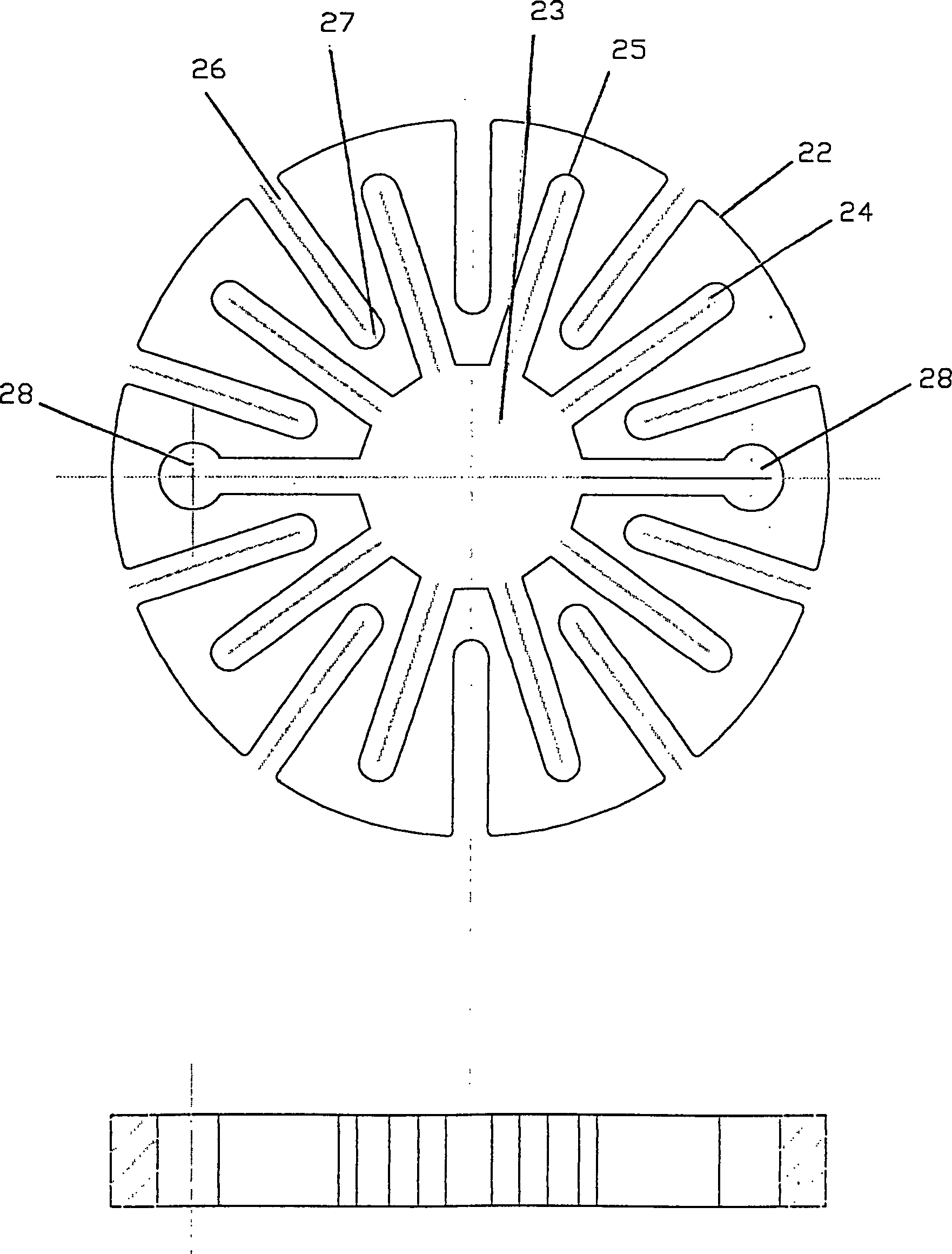

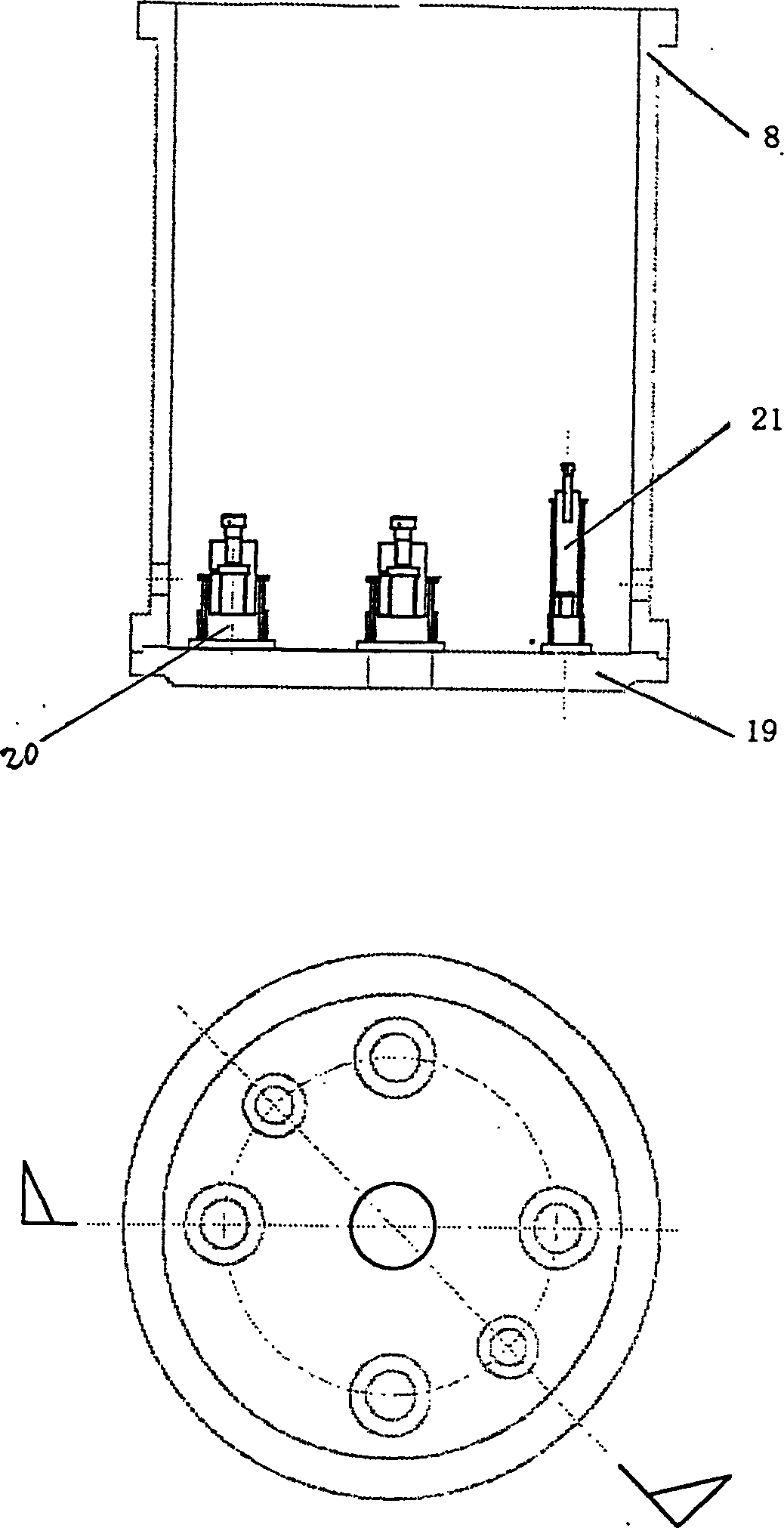

[0033] The melting method of single crystal silicon is quickened when drawing single crystal silicon of the present embodiment, adds polysilicon 120Kg in quartz crucible, closes furnace chamber, and vacuumizes to 2.66 * 103 Pa, to the main heating element 7 installed between the quartz crucible supporter made of graphite and the heat preservation cylinder in the silicon single crystal furnace, feed direct current, its voltage is 30 volts, current 2900 amperes, power is 87Kw, from the quartz crucible Side heated quartz crucible. Bottom heating element (disk-shaped heating element) is housed at the bottom of silicon single crystal furnace, feeds direct current in the bottom heating element (disc heating element 22), and its voltage is 20 volts, and electric current 650 amps, power 13Kw, from The bottom of the quartz crucible is heated to completely melt the polysilicon for 5.5 hours.

[0034] The heating element device at the bottom of the present embodiment, which is used to sp...

Embodiment 2

[0038] Its operation method and equipment are basically the same as embodiment 1, only difference is that the bottom heating element (disc-shaped heating element) feeds direct current, its voltage is 60 volts, and current 883 amperes, add main heating element power, total power is 100KW, 120kg polysilicon complete melting time is 4.5 hours.

Embodiment 3

[0040] Its operation method and equipment are completely the same as embodiment 1, only difference is heating and melting 120kg polycrystalline germanium, and the time of complete melting is 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com