Patents

Literature

33results about How to "Change the temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

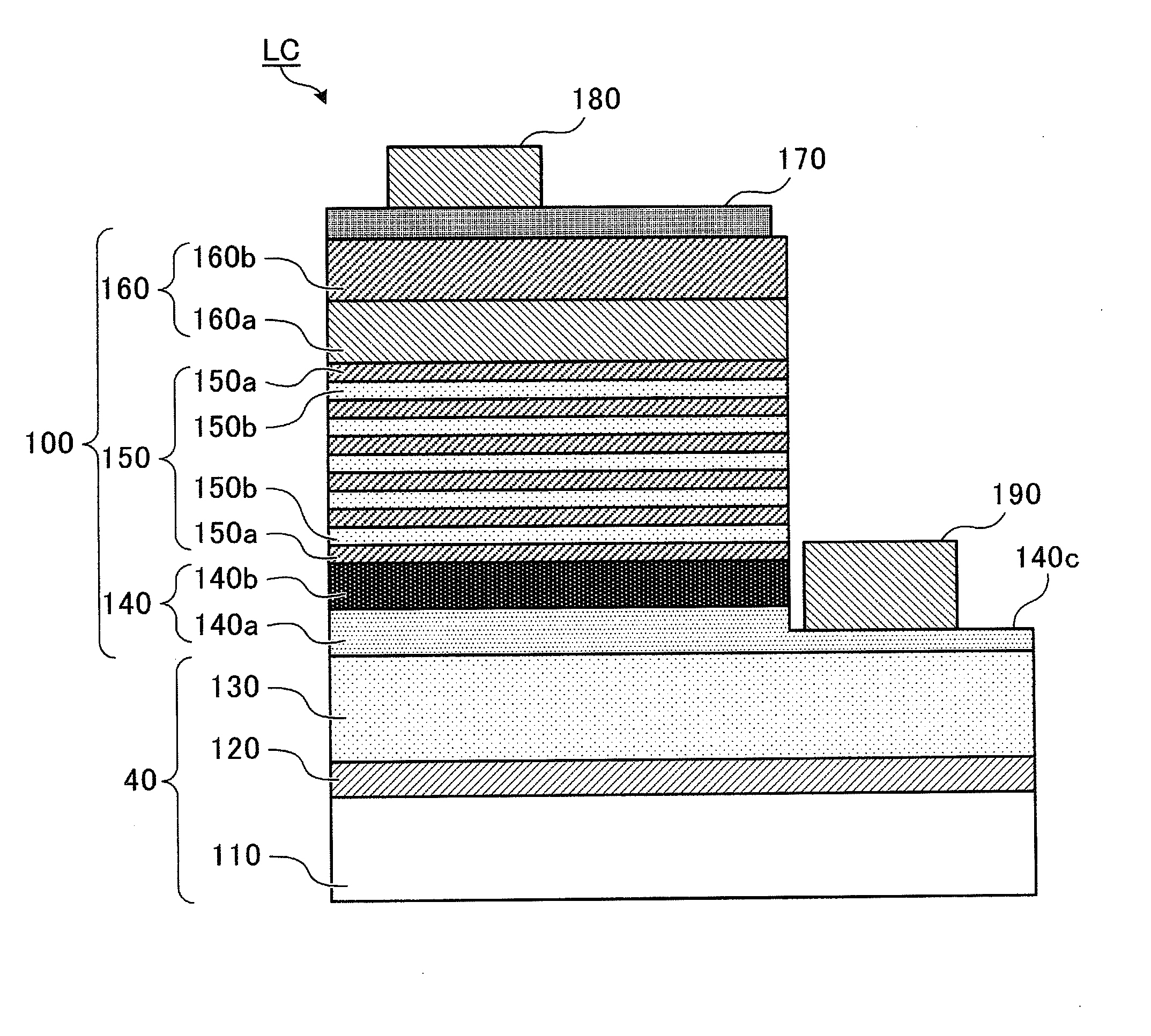

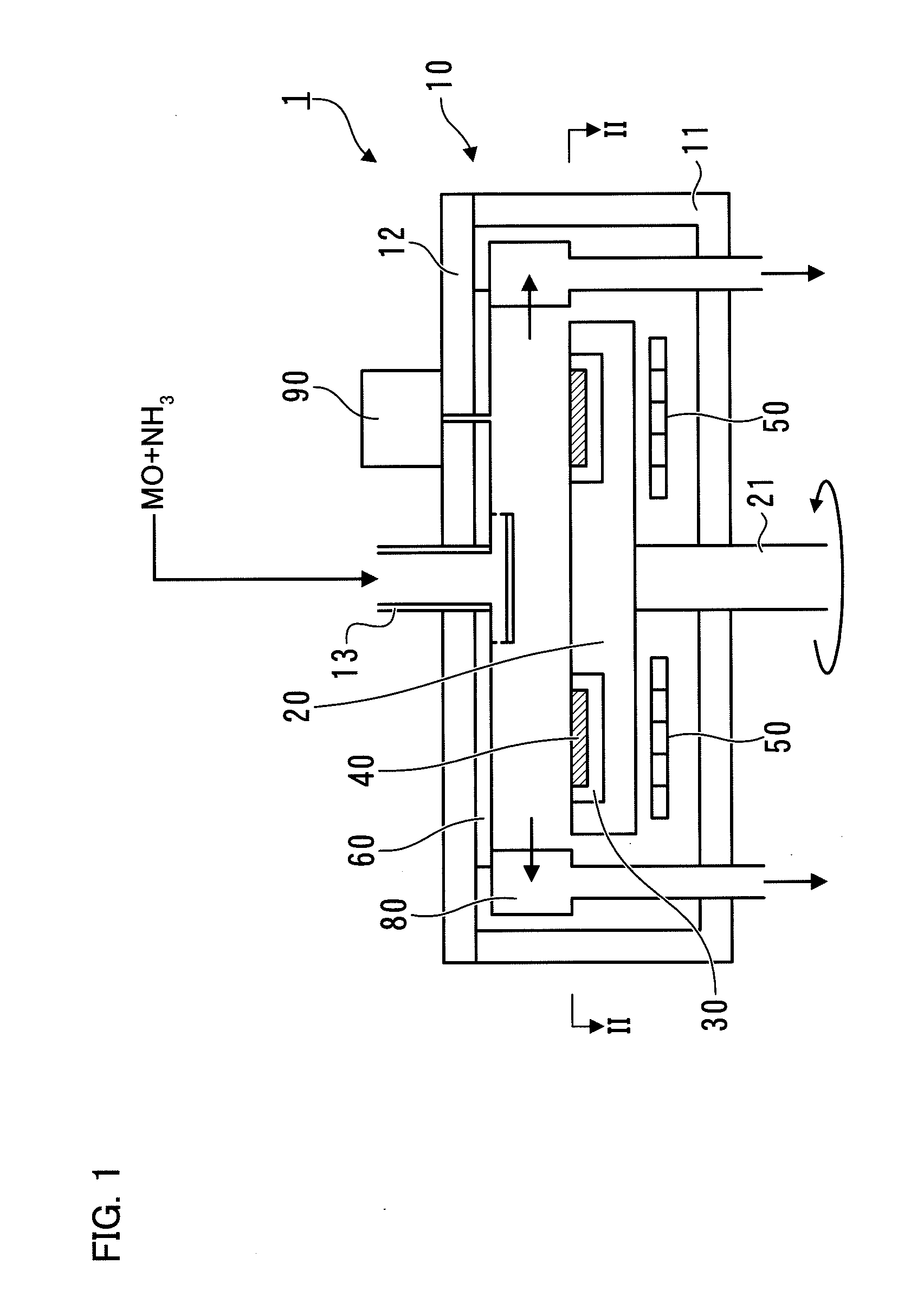

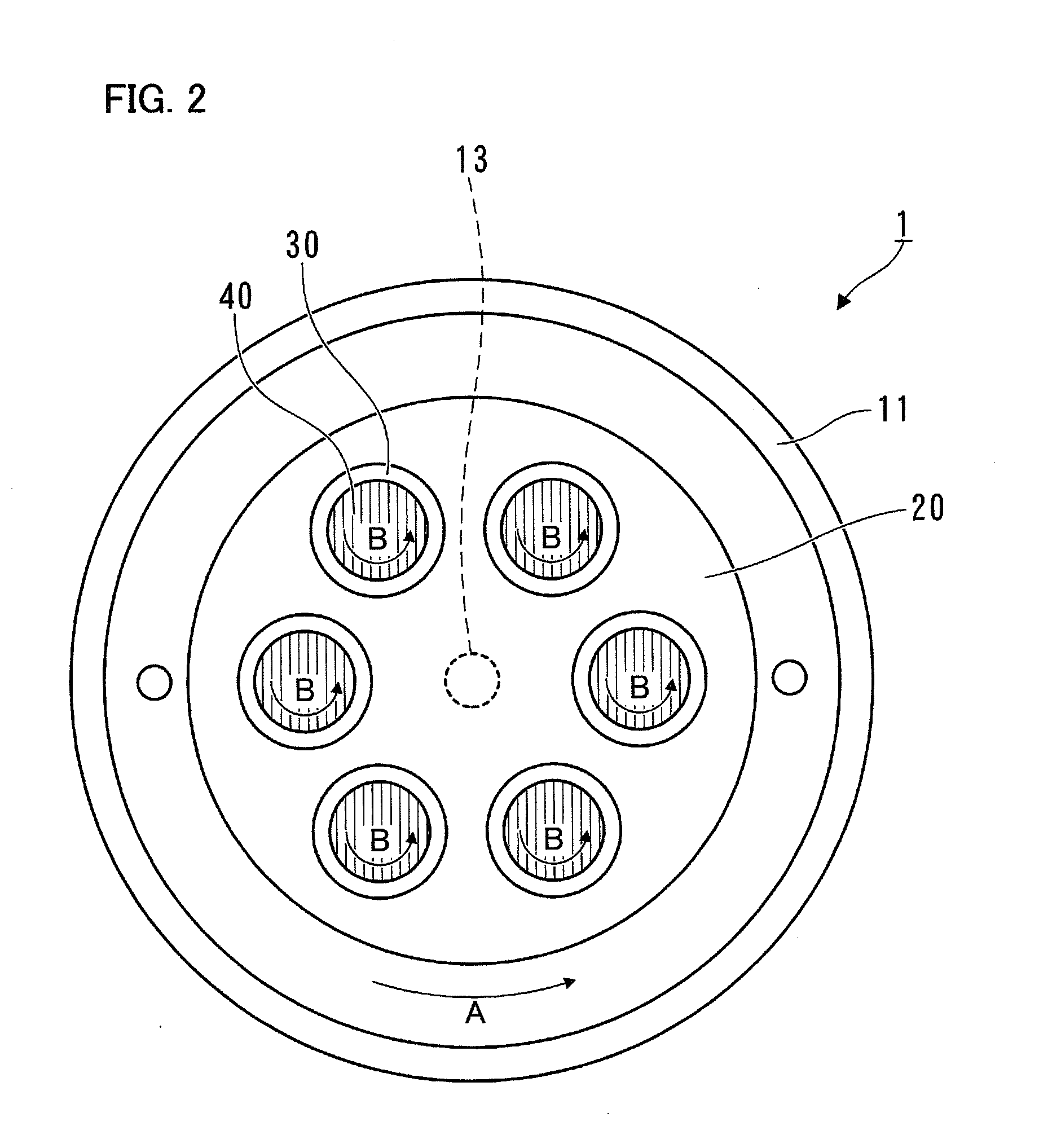

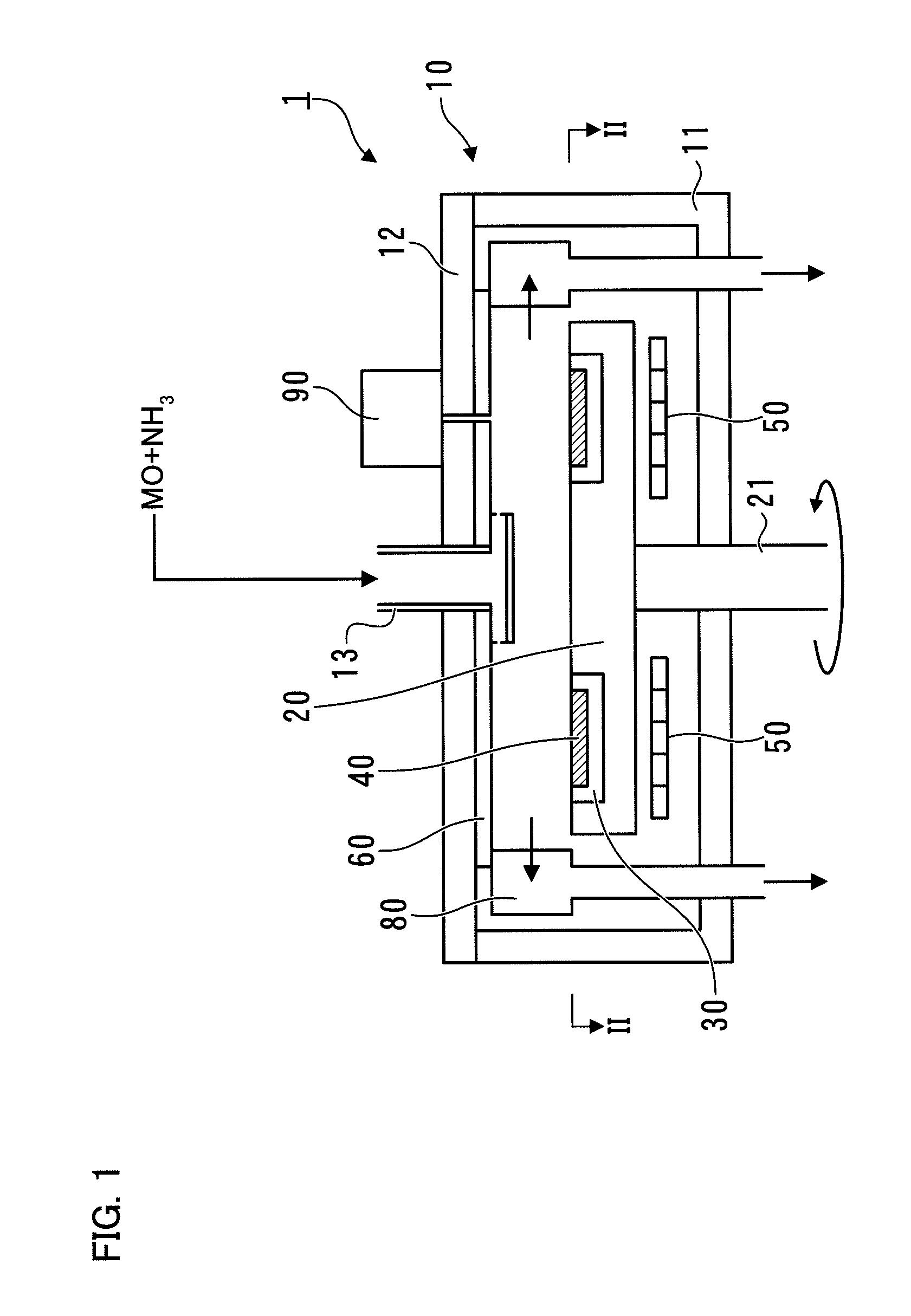

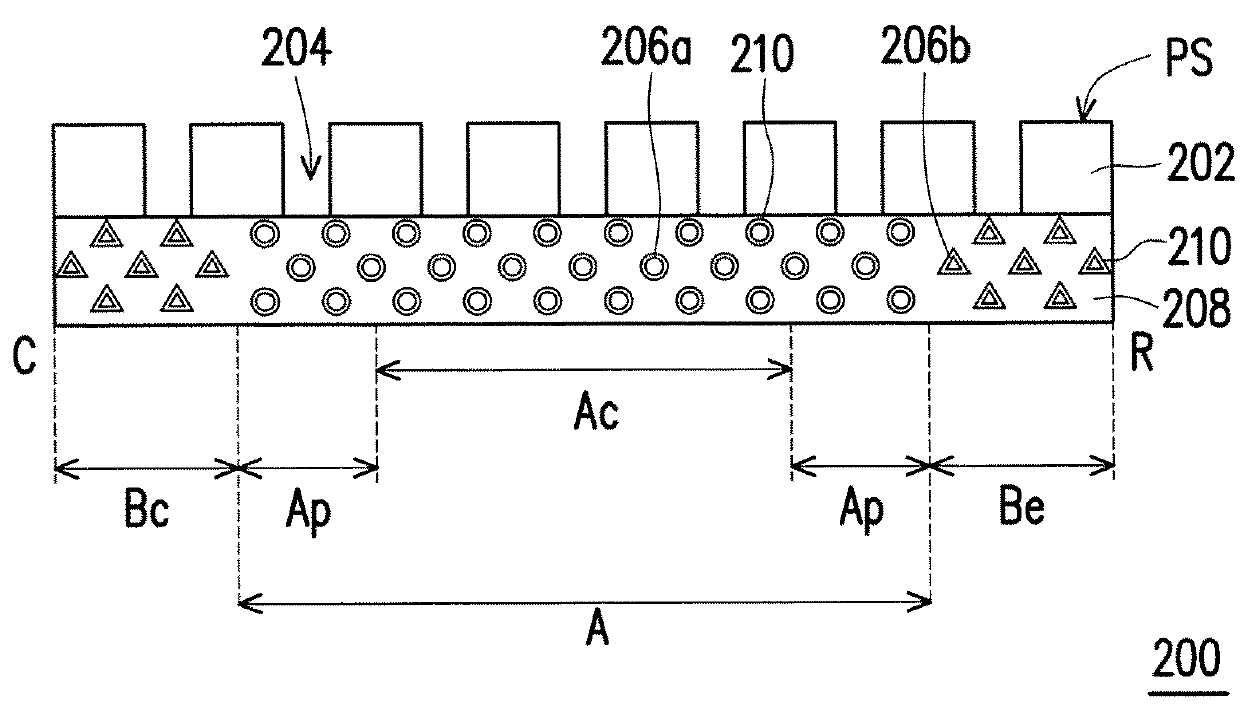

Apparatus and method for manufacturing compound semiconductor, and compound semiconductor manufactured thereby

ActiveUS20120146191A1Reduce uniformityChange the temperature distributionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineering

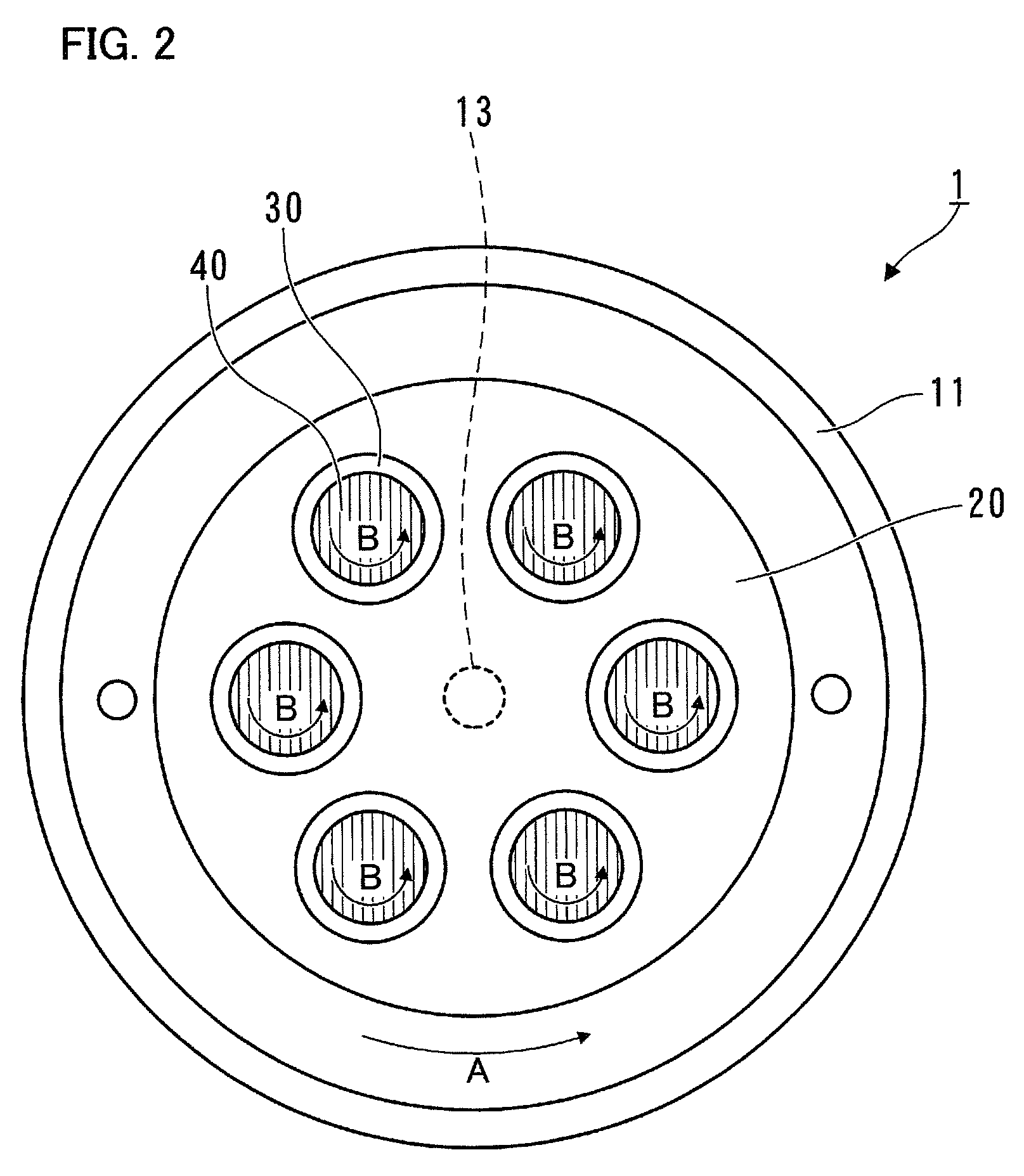

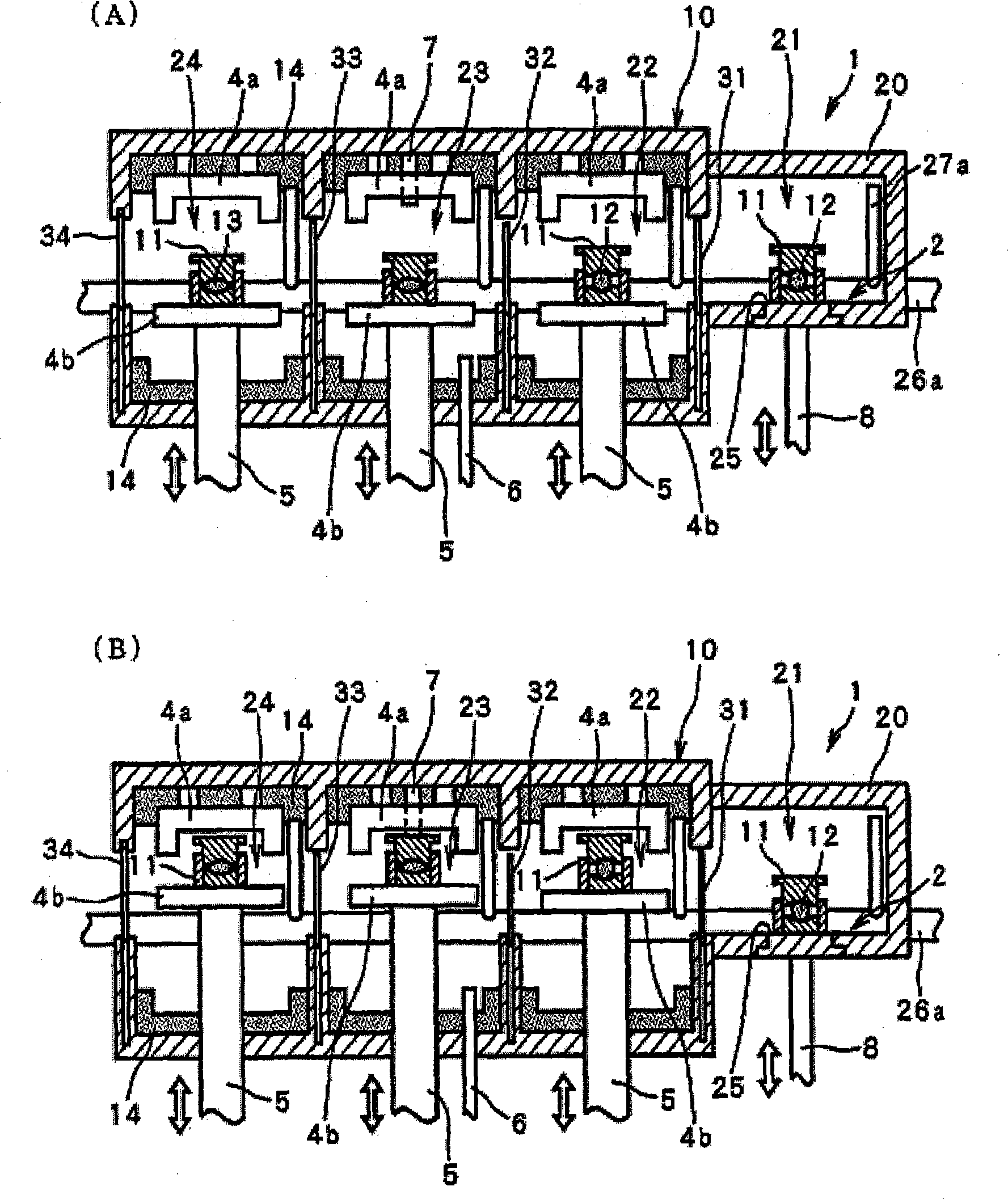

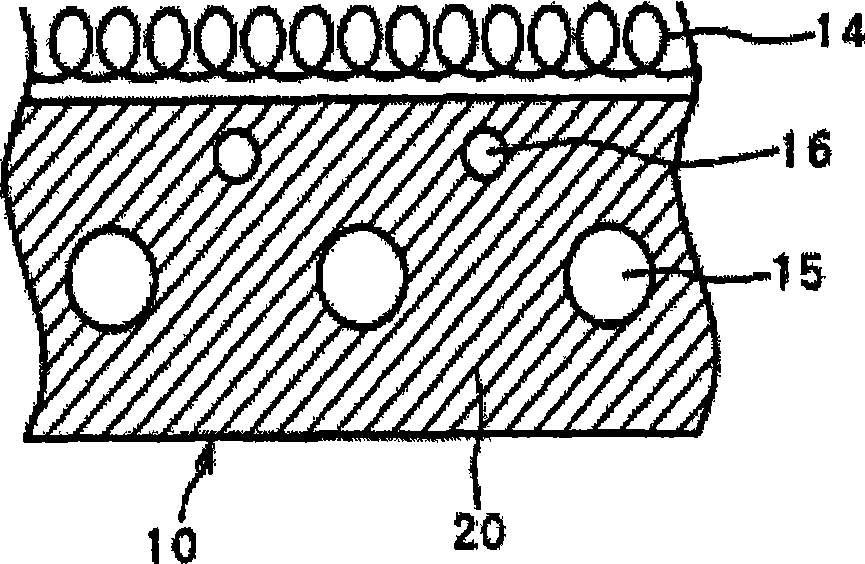

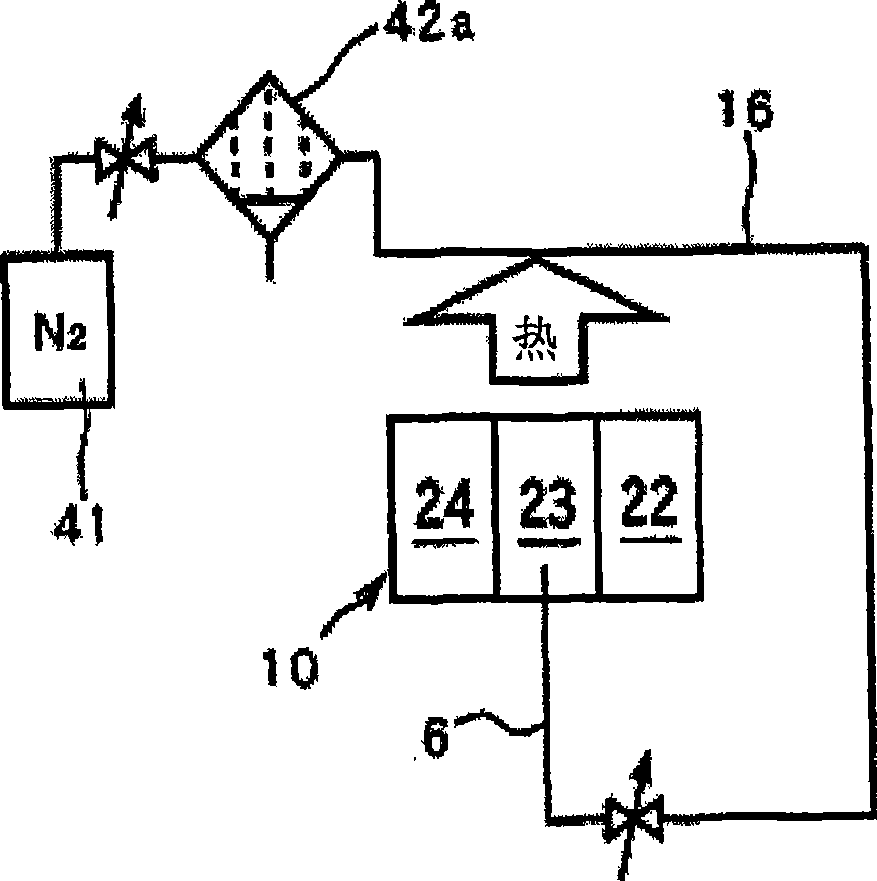

Provided is an apparatus for manufacturing a compound semiconductor by use of metal organic chemical vapor deposition including: a reaction container; a holder on which a formed body is to be placed so that a formed surface of the formed body on which layers of a compound semiconductor are to be formed faces upward, the holder being arranged in the reaction container; and a material supply port supplying a material gas of the compound semiconductor into the reaction container from outside, wherein the holder includes a support member supporting the formed body so that an undersurface of the formed body and a top surface of the holder on which the formed body is to be placed keep a predetermined distance.

Owner:TOYODA GOSEI CO LTD

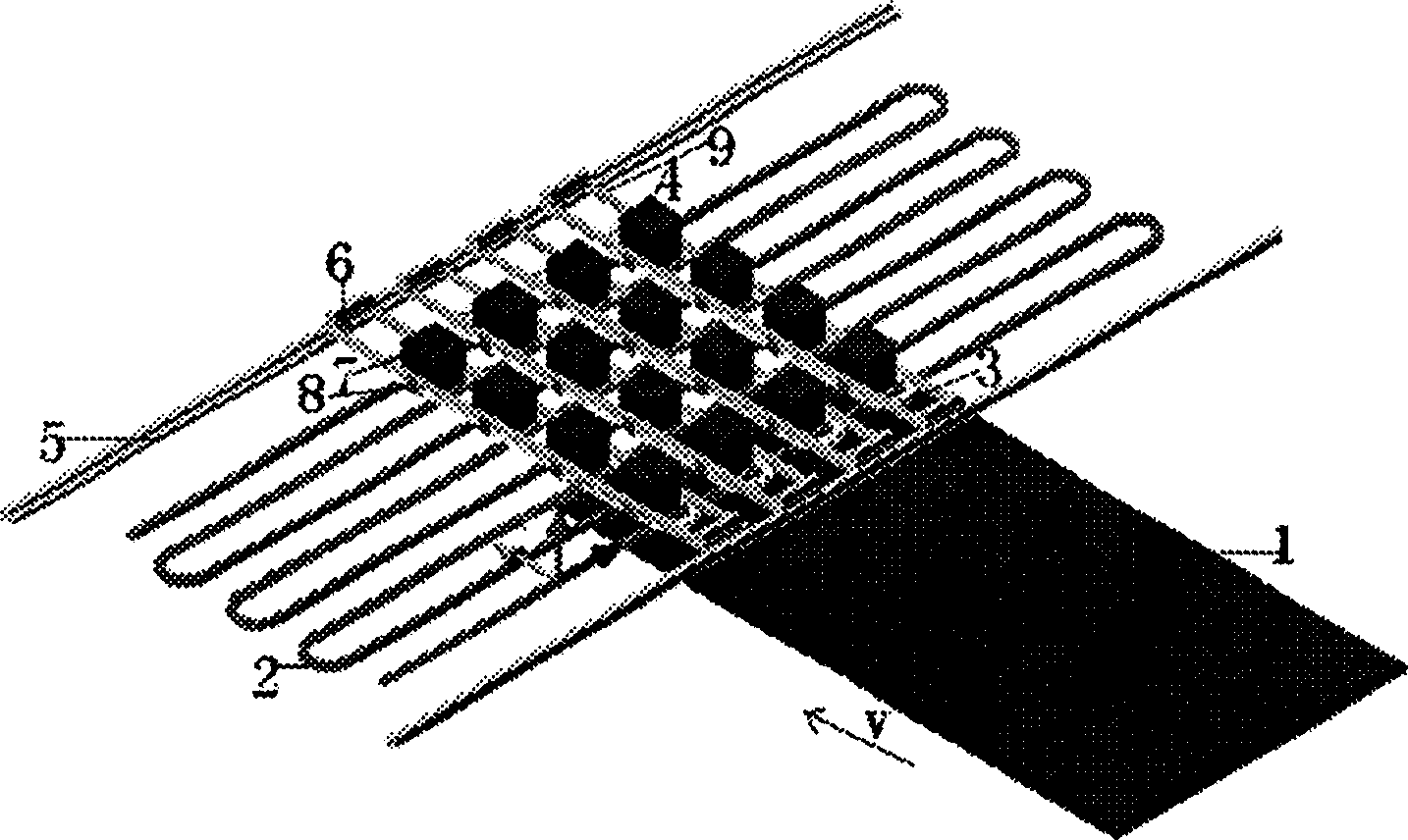

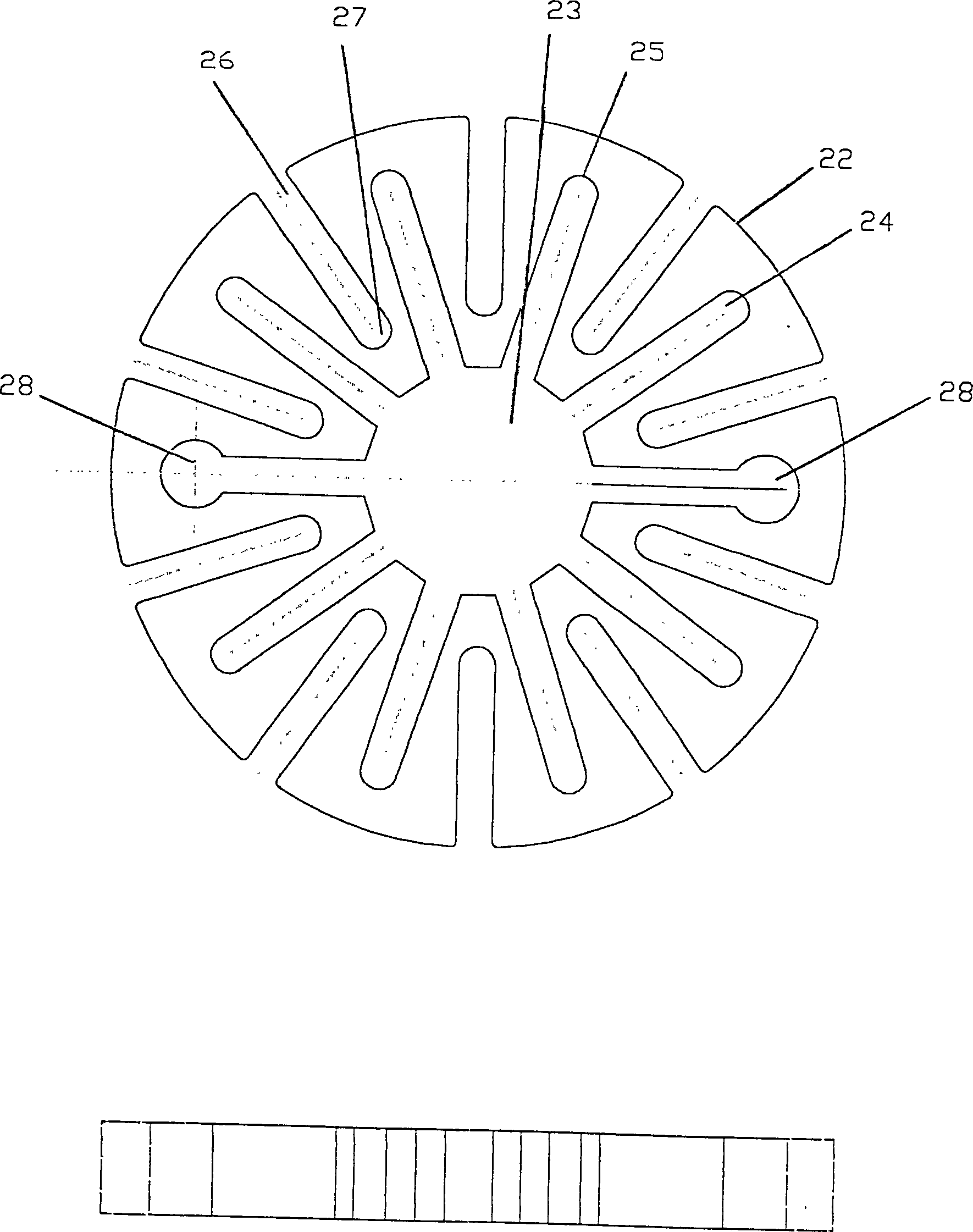

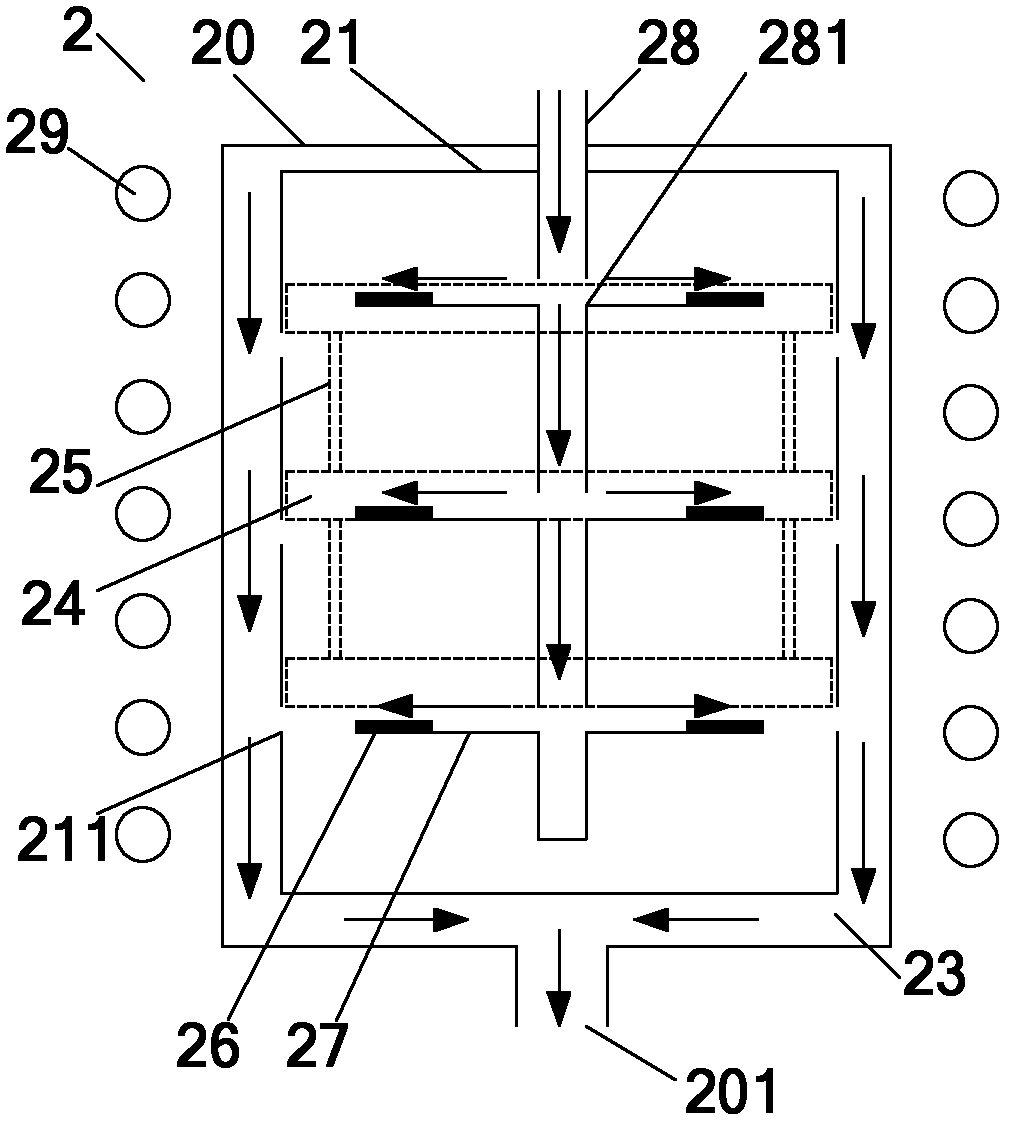

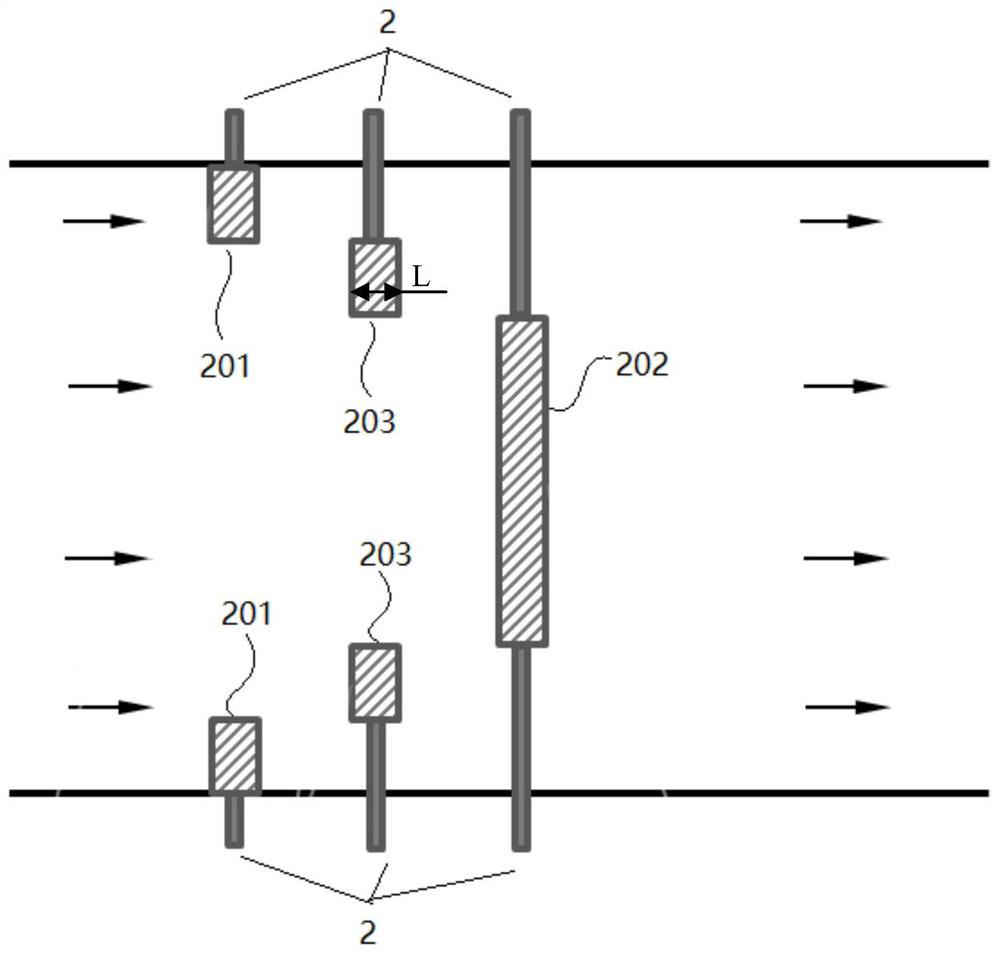

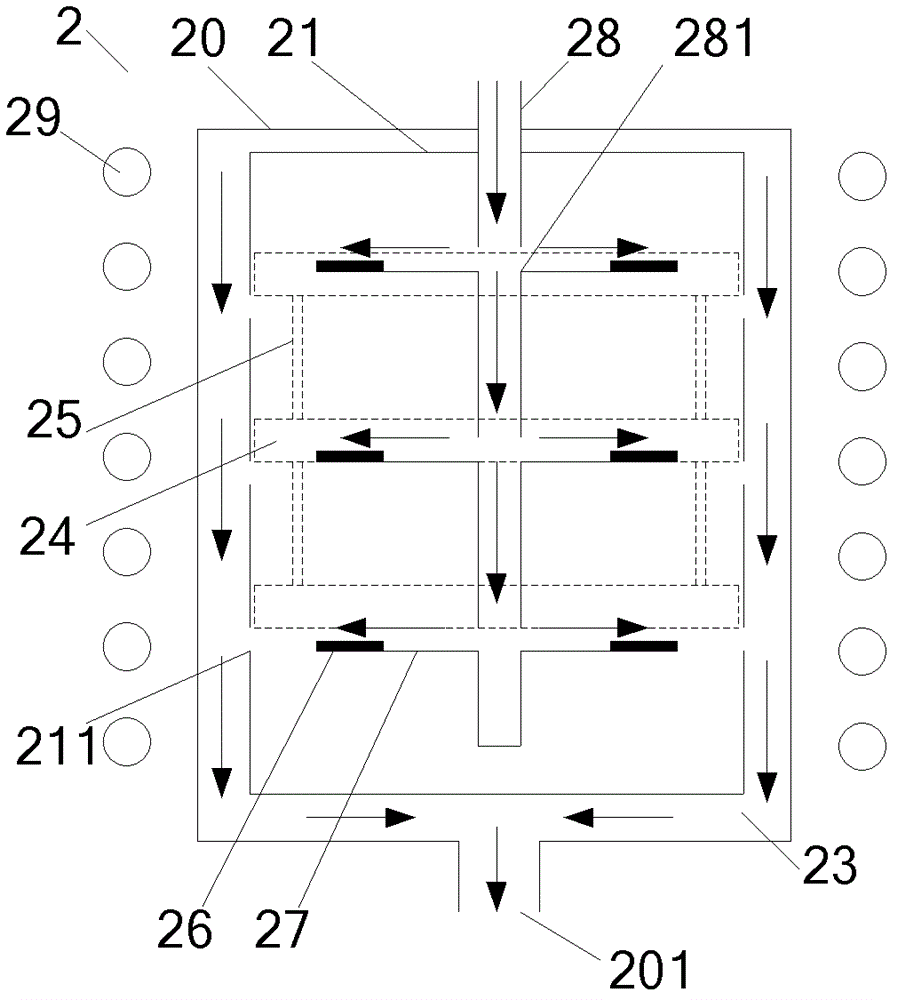

Width adjustable and temperature controllable transverse magnetic flux induction heating apparatus

InactiveCN1802044AUniform temperatureUniform and fine distributionCoil arrangementsIncreasing energy efficiencyMagnetic fluxTransverse magnetic

Present invention relates to a width adjustable and temperature controllable transverse direction magnetic flux induction heating apparatus. It contains belt material, fixed coil, mobile loop, yoke iron, guide way, travel mechanism, tank shape structure, fixed structure, and supporting rack, wherein fixed coil parallel to belt material surface, fixed coil long edge perpendicular to belt material direction of motion, removable loop parallel to belt material surface and located fixed coil outside it long edge parallel to belt material direction of motion mobile fixation to supporting rack, interior fixing several groove shape structure, yoke iron inserted in groove and fixed by fixing structure, each traveling loop can sliding in two ends guide way, supporting rack. Present invention is width and temperature controllable, can adapt belt material width variation in larger range and get more uniform temperature distribution, greatly raise production efficiency and save cost.

Owner:HEBEI UNIV OF TECH

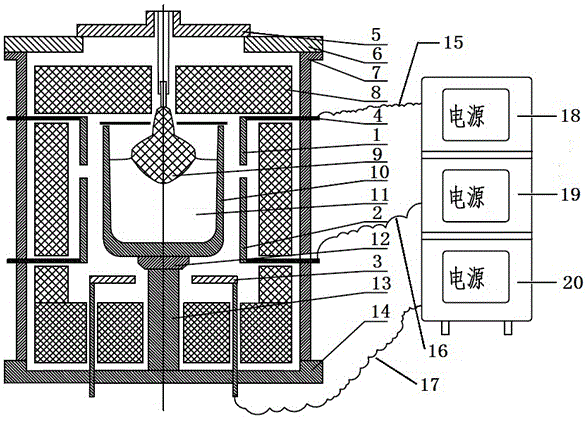

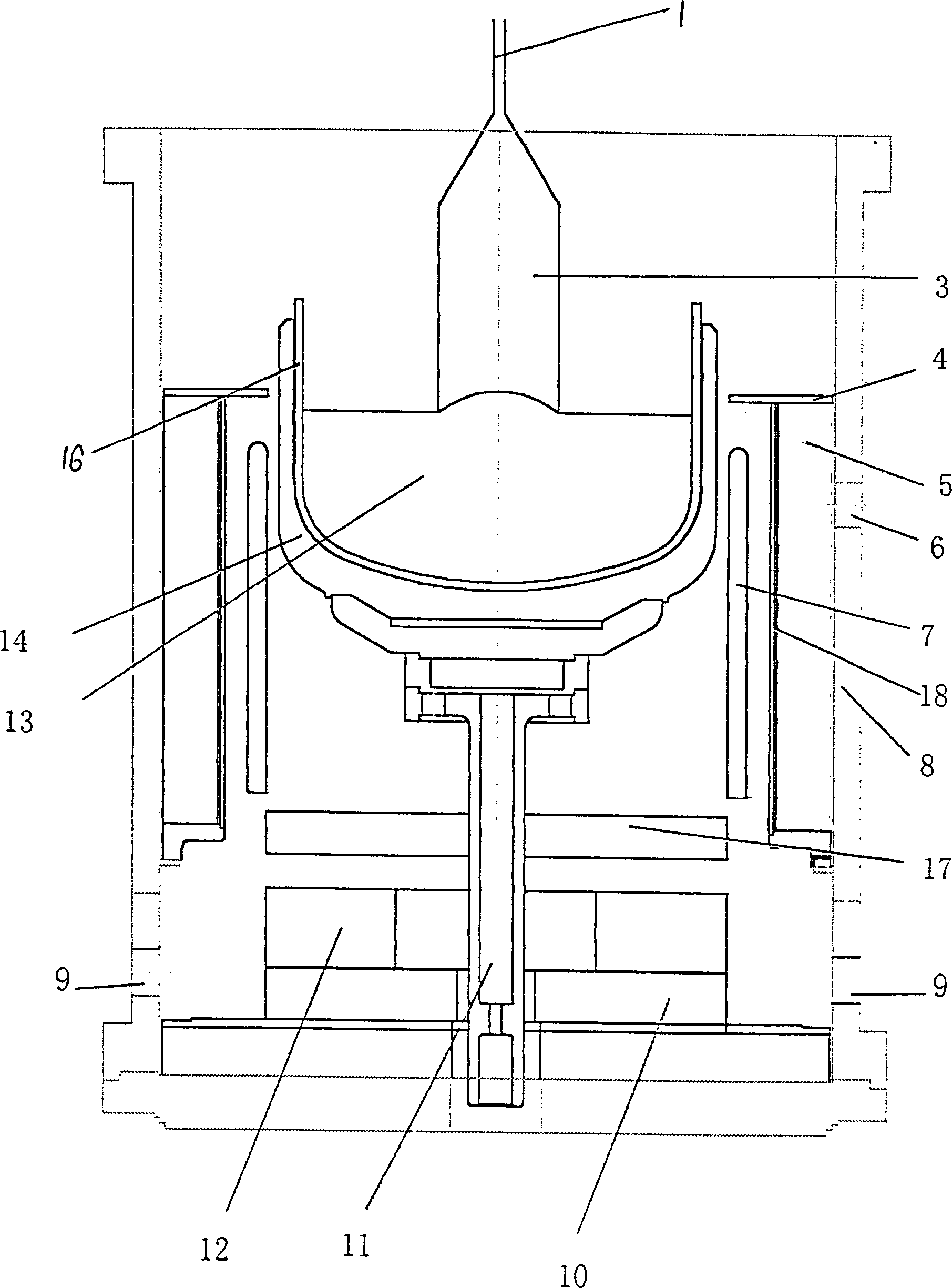

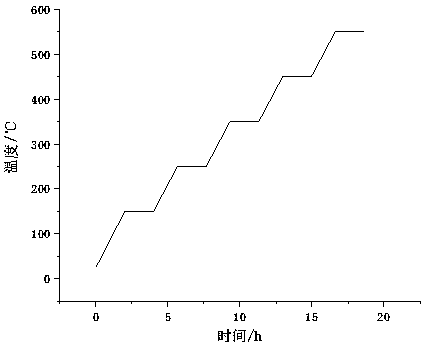

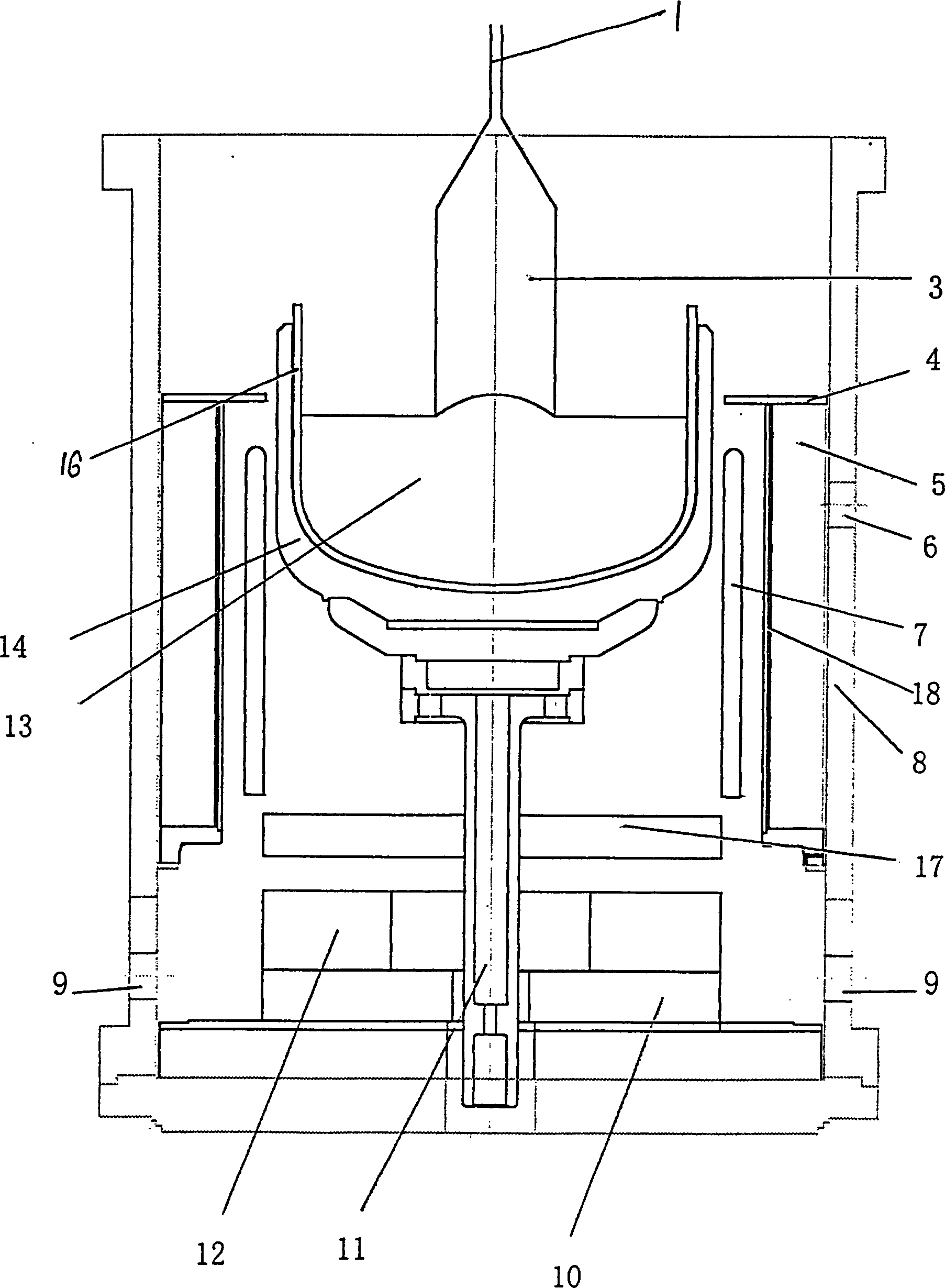

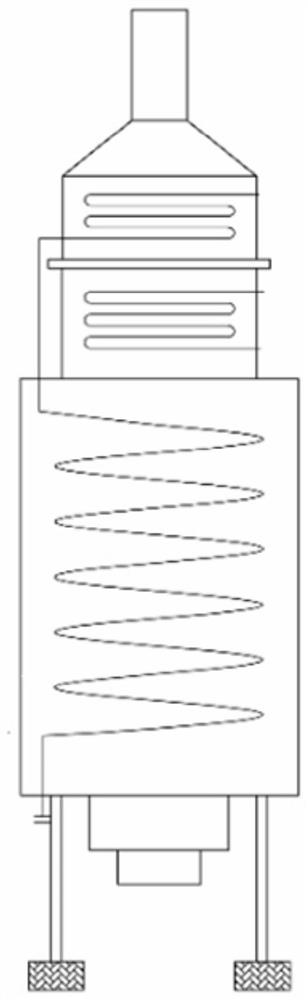

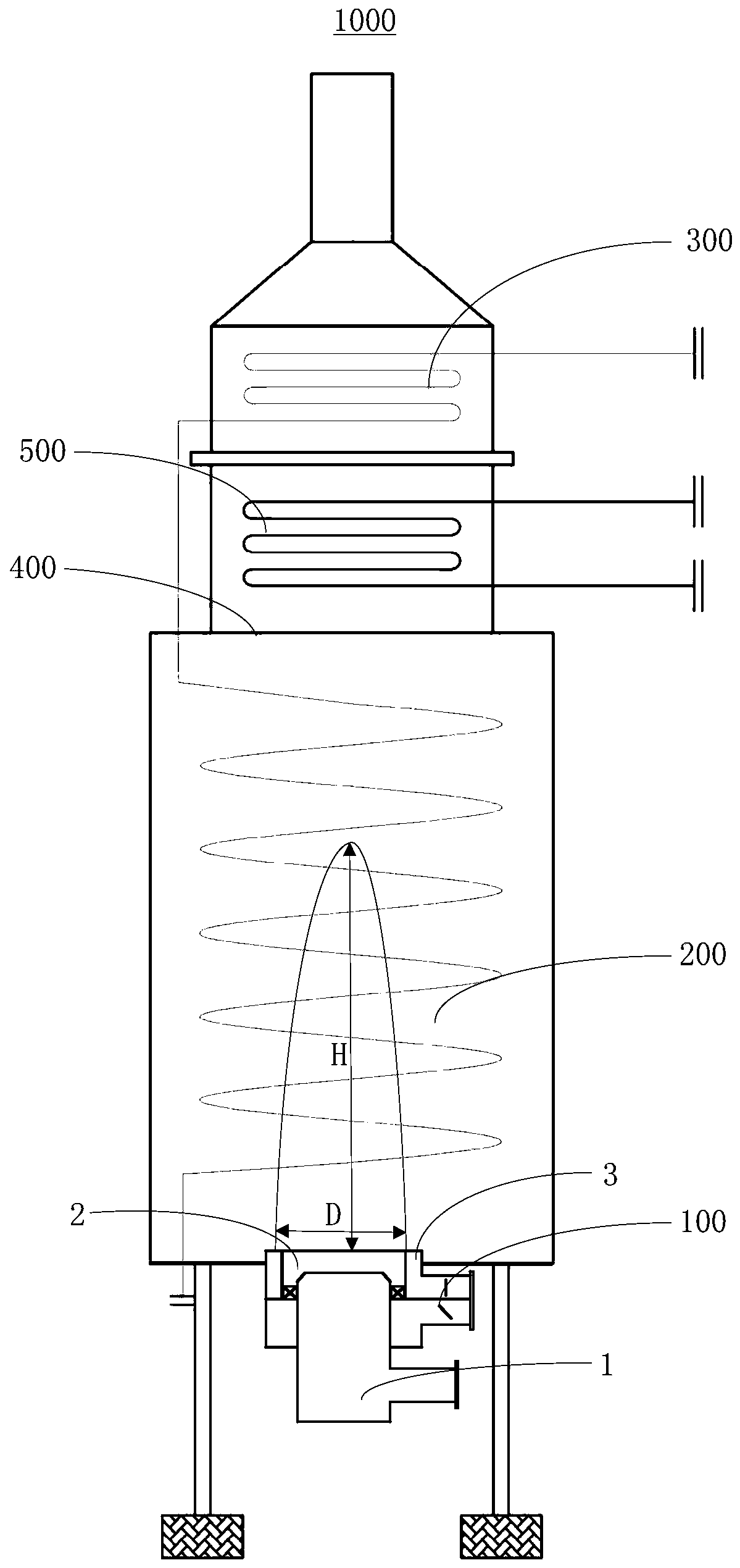

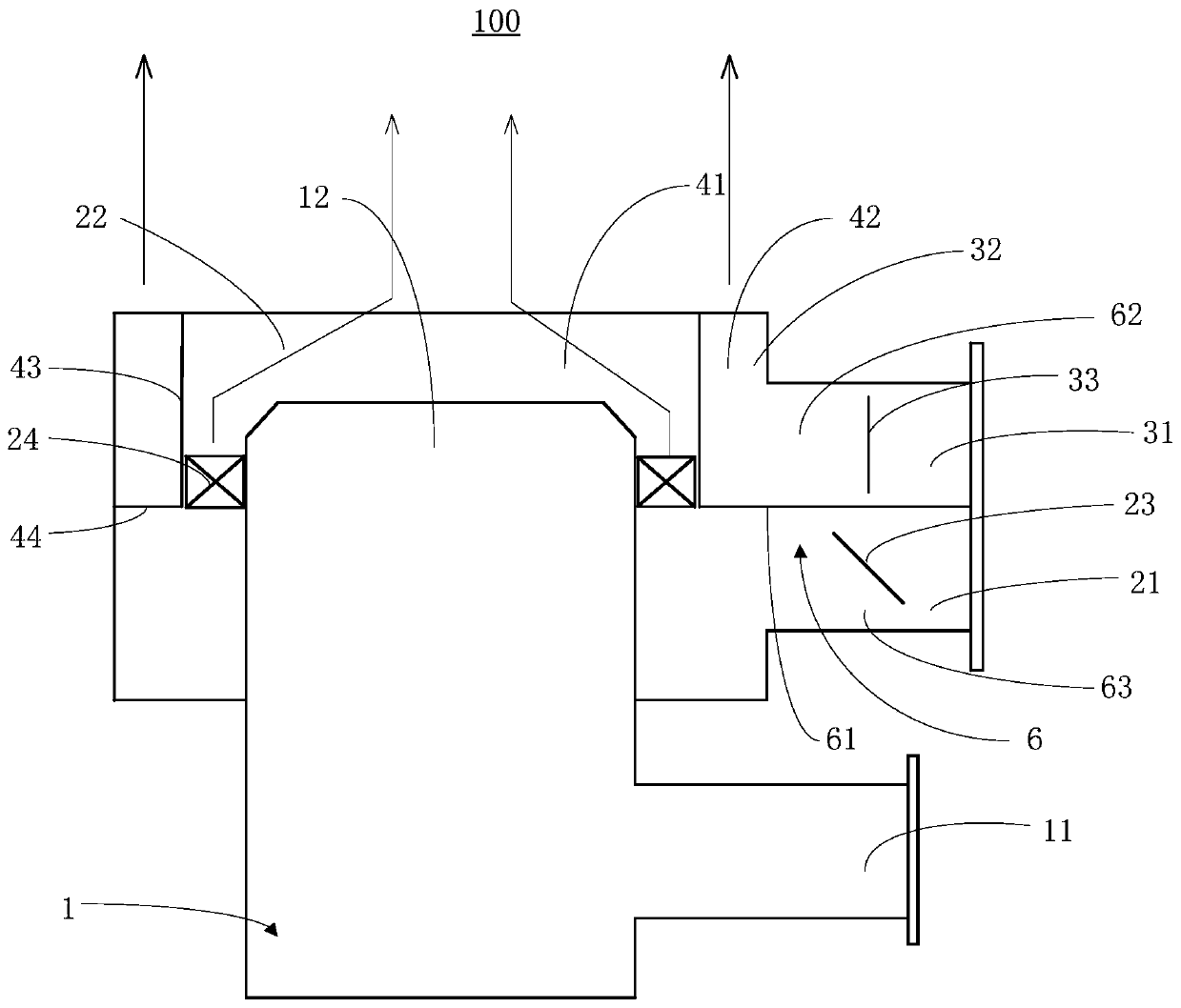

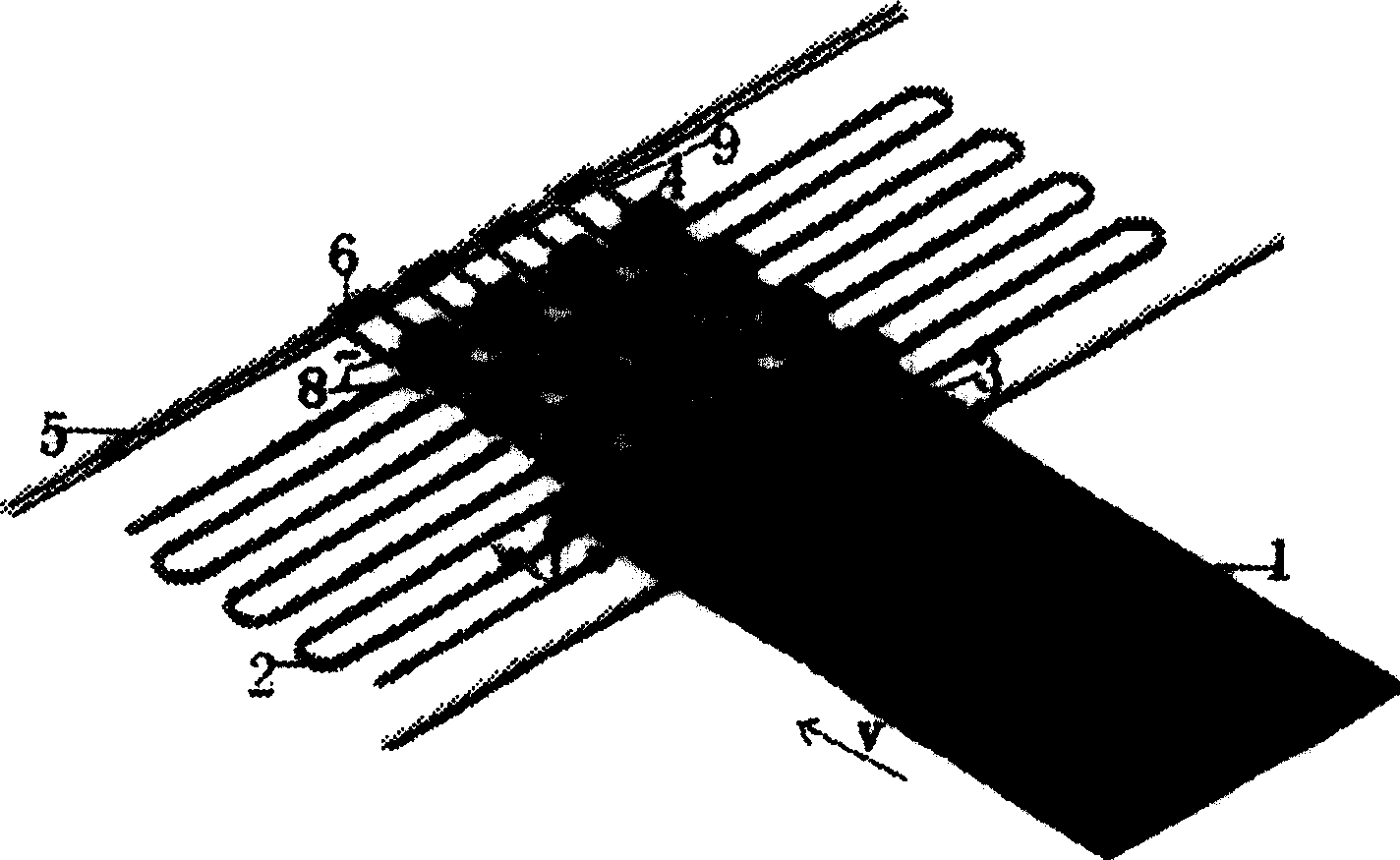

Multistage graphite heating system of sapphire crystal growth equipment and using method of multistage graphite heating system

InactiveCN104451892AImprove product qualityChange the temperature distributionAfter-treatment apparatusPolycrystalline material growthGraphite electrodeControl power

The invention belongs to the technical field of sapphire crystal growth furnace equipment, and provides a multistage graphite heating system of the sapphire crystal growth equipment and a using method of the multistage graphite heating system. The multistage graphite heating system comprises an upper heater, a middle heater, a bottom heater, three power supply devices, a growth furnace cavity, a crucible device and a heat preservation layer, wherein the growth furnace cavity comprises a small furnace cover, a large furnace cover, a furnace cylinder and a furnace base plate; the crucible device comprises a crucible, a crucible tray and a crucible supporting column; each of the upper heater and the middle heater comprise a continuous S-shaped fence-shaped graphite cylinder, four graphite round columns, two long water cooling copper electrodes and two short water cooling copper columns; the bottom heater comprises an S-shaped fence-shaped graphite disc, two graphite electrodes and a water cooling copper electrode; the three individually controlled power supplies are connected with water cooling cables of the upper heater, the middle heater and the bottom heater. The multistage graphite heating system of the sapphire crystal growth equipment and the using method of the multistage graphite heating system have the advantages that the temperature gradient requirement for the growth of large-sized sapphire crystals at each stage can be met, the cost can be reduced, and the quality can be improved.

Owner:SHANGHAI HUICUI OPTICAL TECH

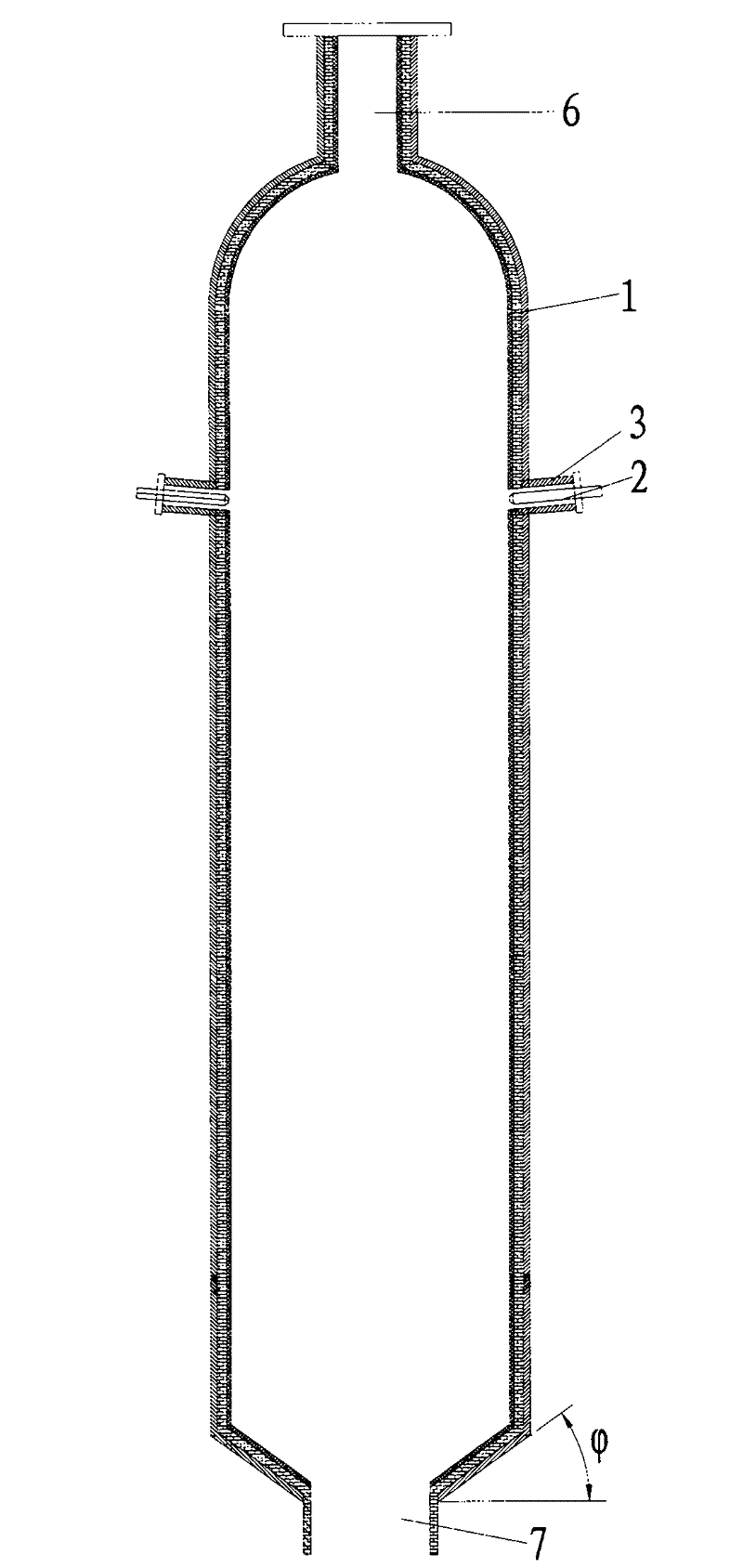

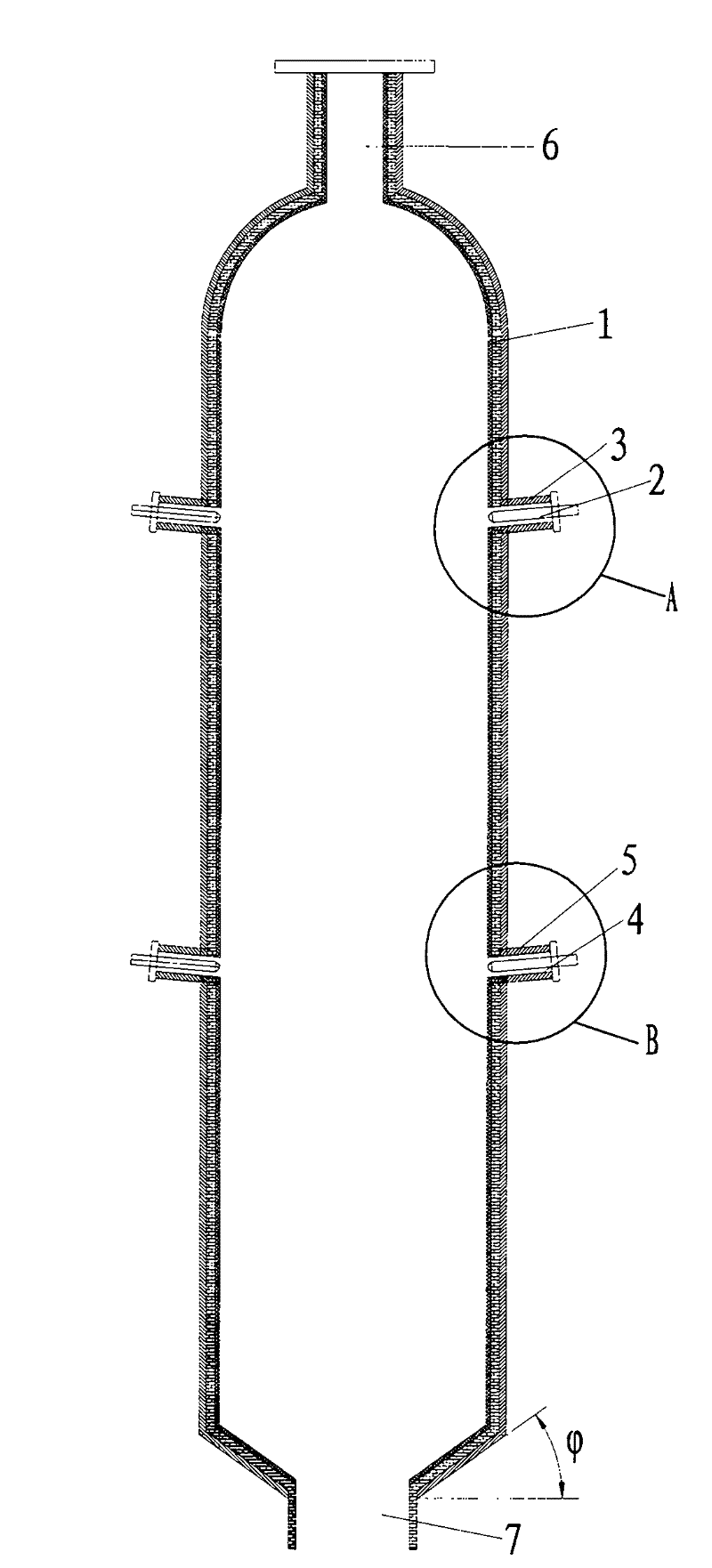

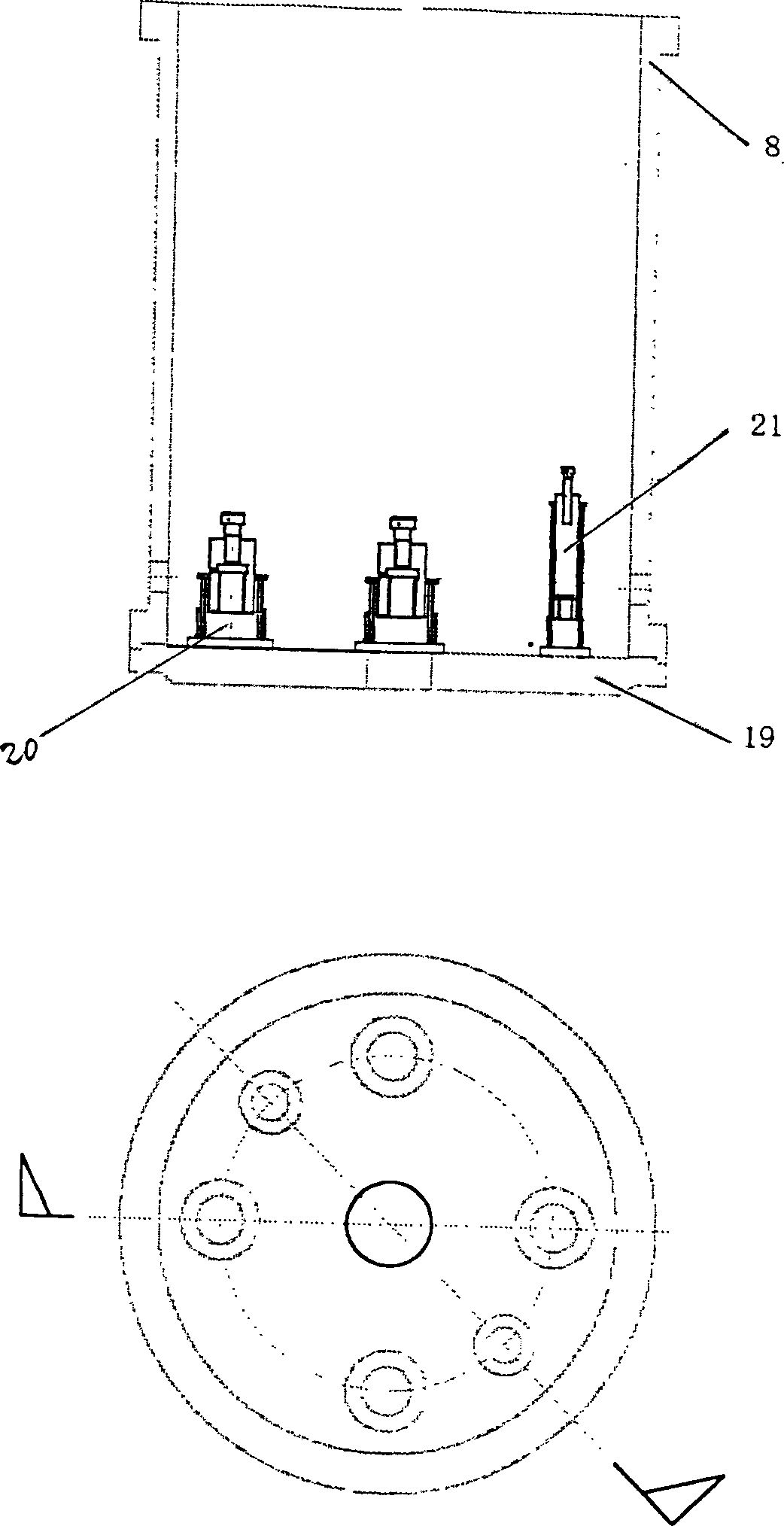

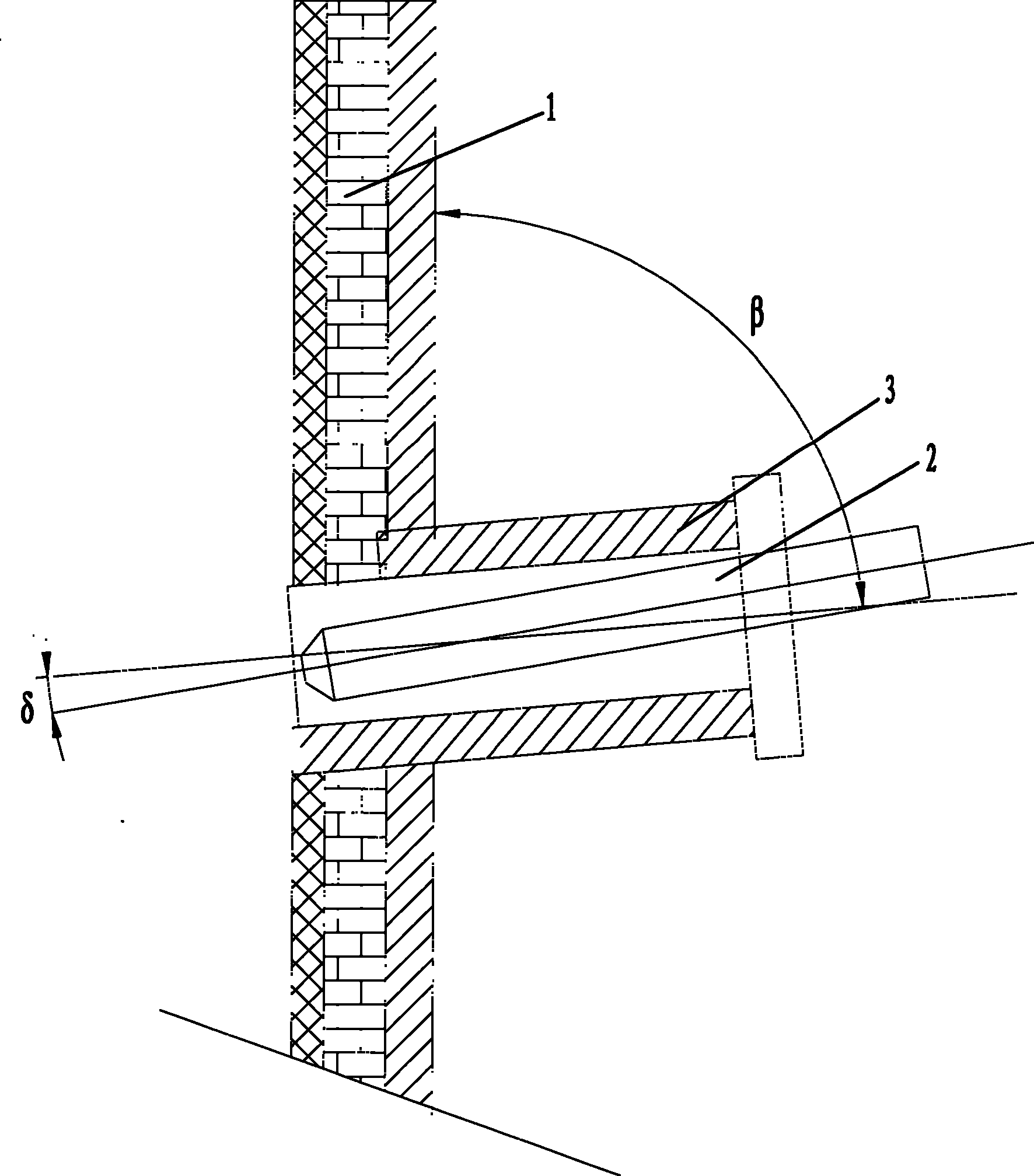

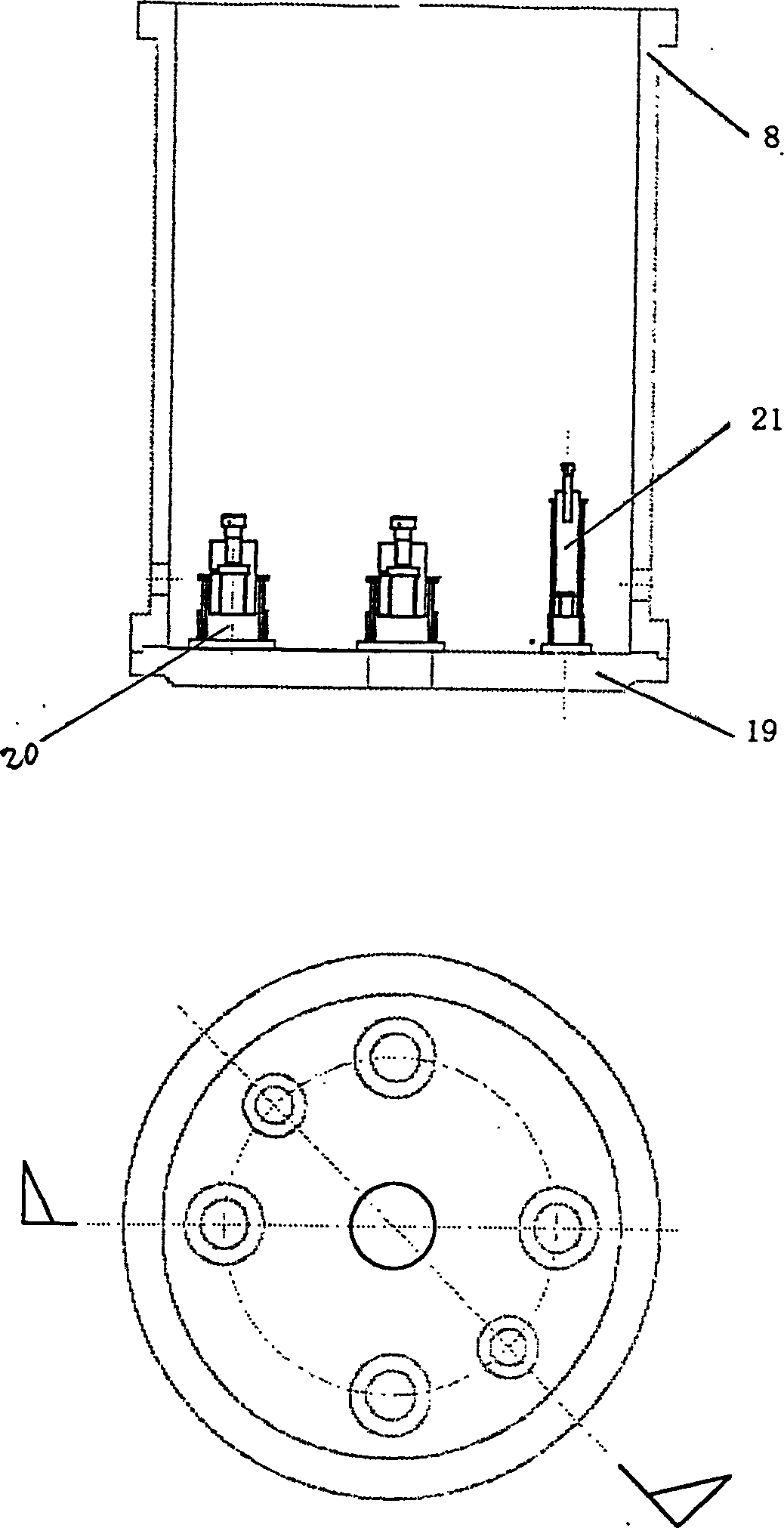

Multi-nozzle multi-stage oxygen supplying entrained-flow gasifier and gasification method thereof

ActiveCN102453550ASolution to short lifeSimple processHydrogenGranular/pulverulent flues gasificationSlagFire brick

The present invention discloses a multi-nozzle multi-stage oxygen supplying entrained-flow gasifier. The entrained-flow gasifier comprises a top closed type gasifier body, an ignition nozzle chamber, a gasifier outlet, and at least two process nozzle chambers, wherein process nozzles are arranged inside the process nozzle chambers. The entrained-flow gasifier further comprises at least two secondary oxygen supplying nozzle chambers, wherein secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers, the secondary oxygen supplying nozzle chambers are arranged between the process nozzle chambers and the gasifier outlet, and are symmetrically arranged on the circumference of the gasifier body, and the secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers. The present invention further discloses a gasification method of the gasifier. According to the gasification method, an oxidizing agent is introduced to the secondary oxygen supplying nozzle during the reaction process to promote the further gasification reaction. With the present invention, a plurality of the nozzles are adopted to carry out multi-stage oxygen supplying on the gasifier, such that the service life of the fire brick structure on the upper space of the gasifier is substantially prolonged so as to substantially improve the operating rate and the performance of the gasifier. In addition, with the present invention, the liquid slag tapping of the gasifier is ensured, and the phenomenon of slag blocking of the outlet is avoided.

Owner:EAST CHINA UNIV OF SCI & TECH

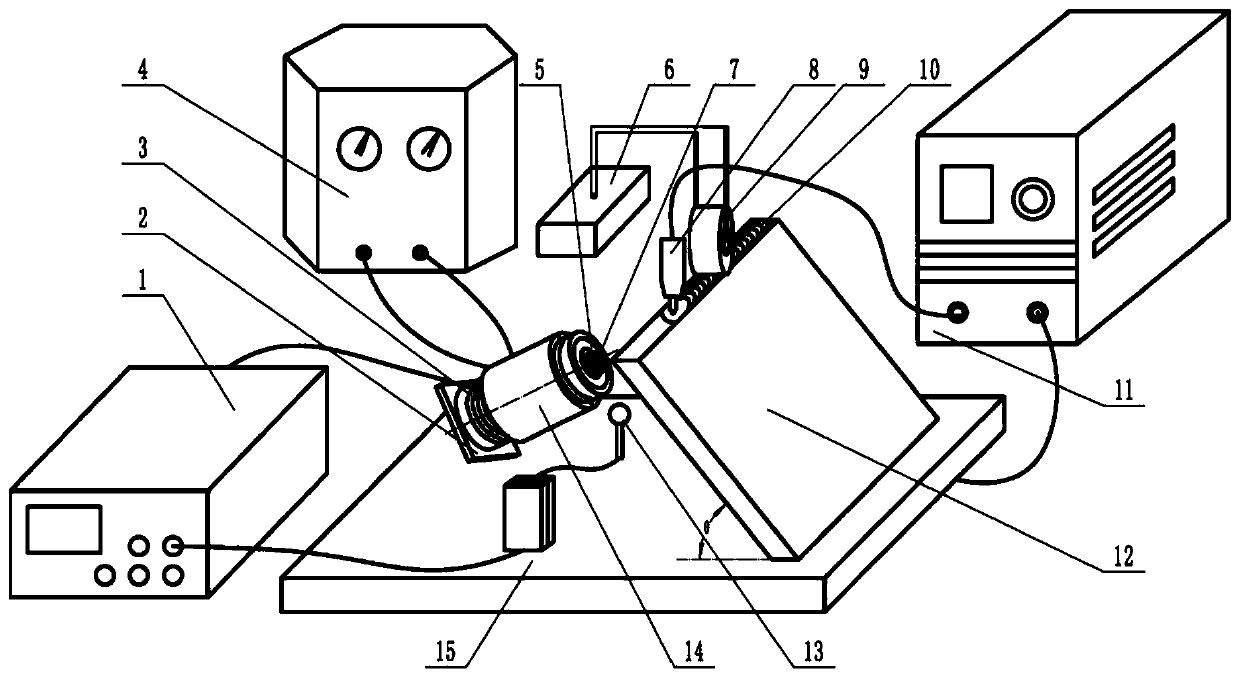

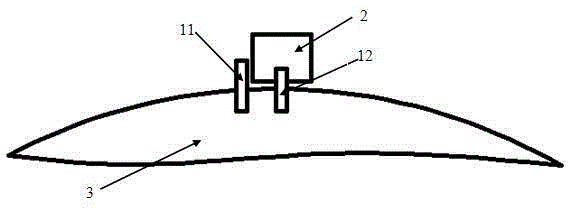

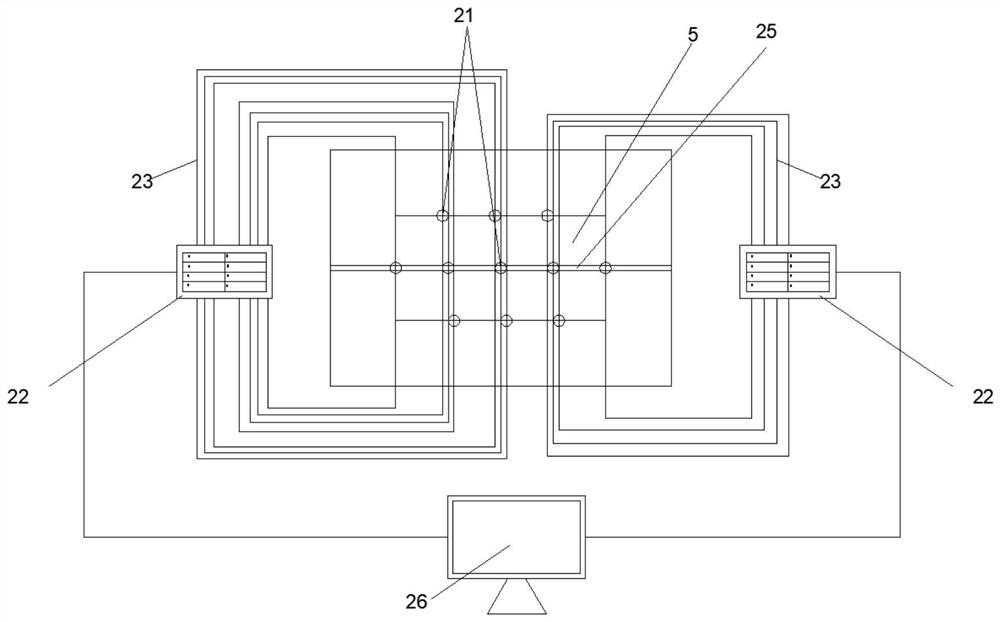

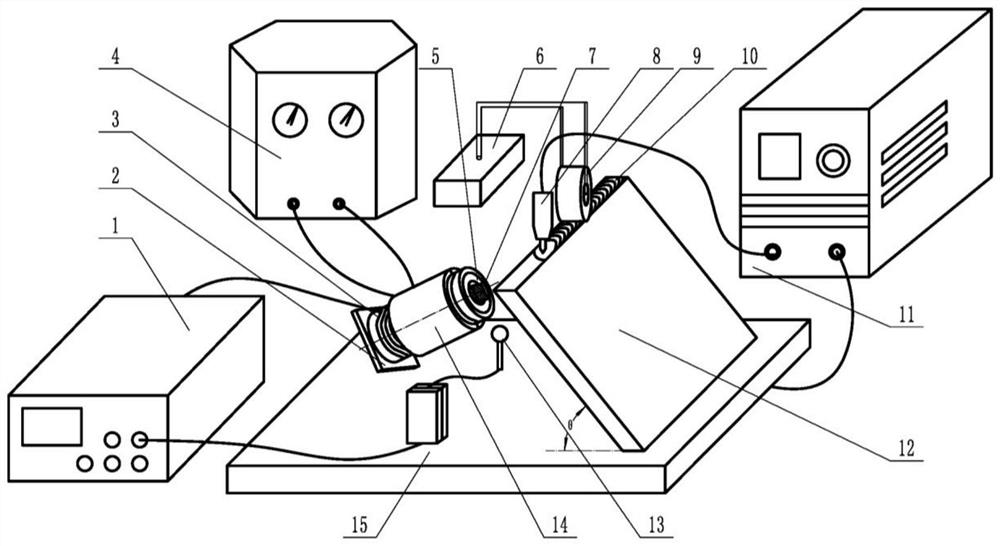

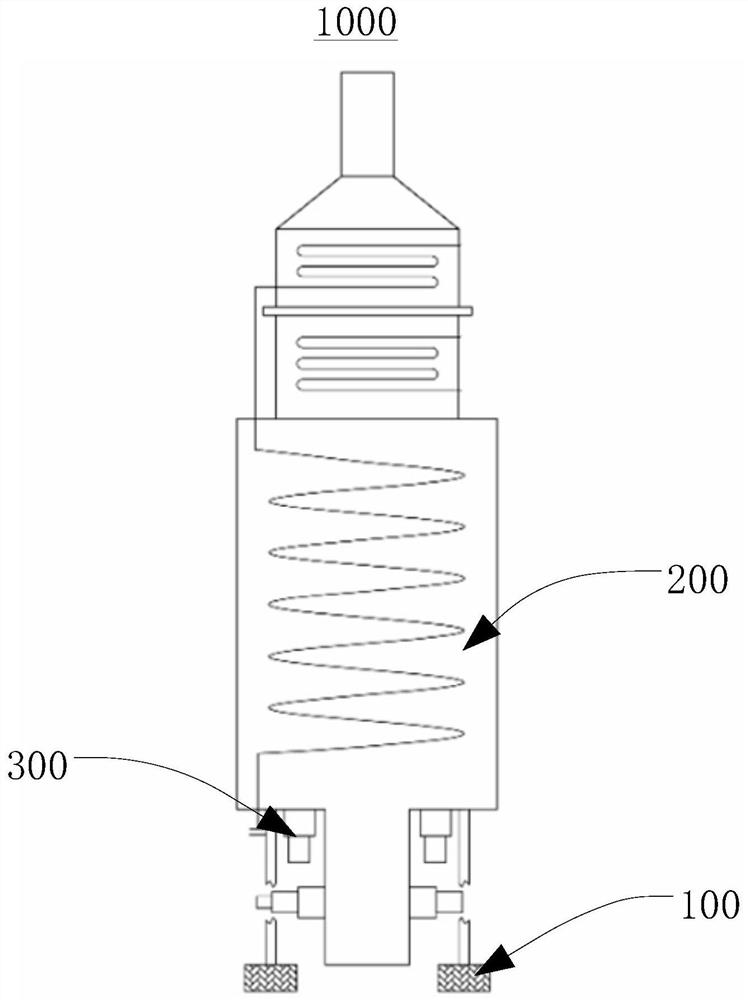

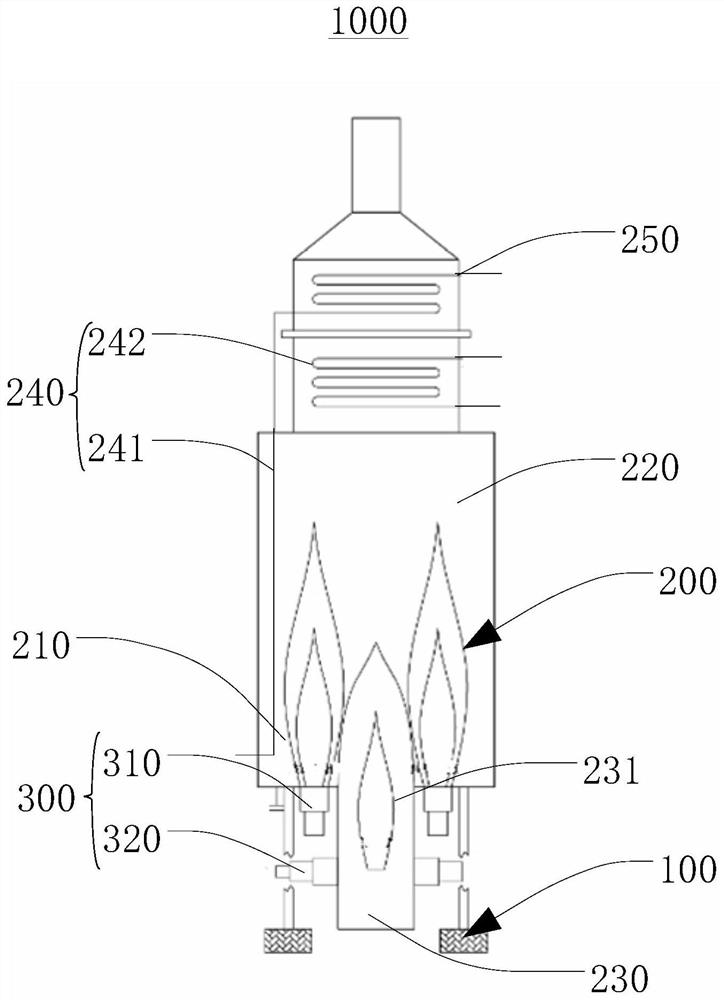

Electromagnetic assisted electric arc additive manufacturing and forming device and method

ActiveCN110802304AEfficient preparationImprove product qualityElectrode holder supportersUsing optical meansLaser scanningEngineering

The invention belongs to the field of metal additive manufacturing, and concretely discloses an electromagnetic assisted electric arc additive manufacturing and forming device and a method. The electromagnetic assisted electric arc additive manufacturing and forming device comprises a base plate, an electric arc welding gun, an electromagnetic coil, a line laser scanner and a magnetic-field measurement instrument, wherein the electric arc welding gun and the electromagnetic coil are located above the base plate; the electric arc welding gun is used for welding and forming a part to be formed on the base plate; the electromagnetic coil is used for applying a magnetic field on a weld pass molten pool of the part to be formed; the line laser scanner is located above the part to be formed andis used for inspecting a surface appearance of a weld pass; and the magnetic-field measurement instrument is located between the electromagnetic coil and the part to be formed, is connected with the electromagnetic coil, and is used for measuring and controlling the magnetic field intensity of the electromagnetic coil applied to the weld pass molten pool. According to the electromagnetic assistedelectric arc additive manufacturing and forming device and the method provided by the invention, during electric arc additive manufacturing, the weld pass molten pool is supported through an electromagnetic induction force, so that the weld pass is prevented from flowing, the residual stress of a welded joint is reduced, and a mechanical property of the formed part is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

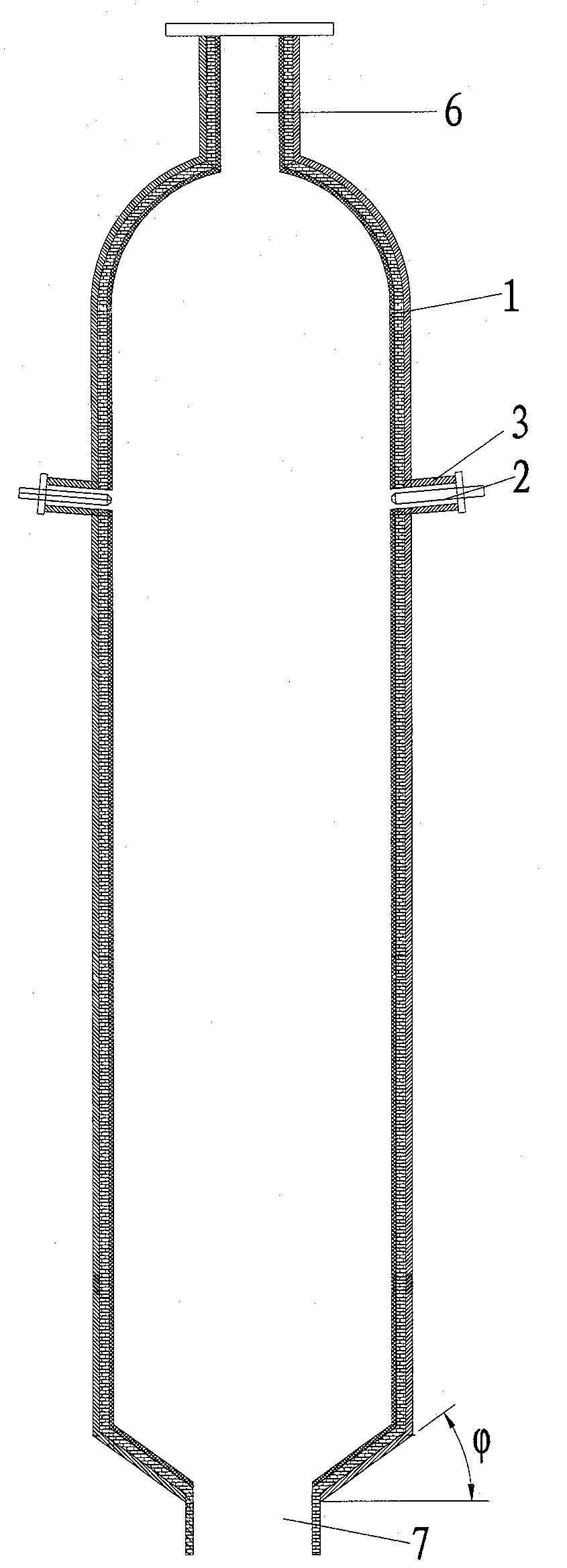

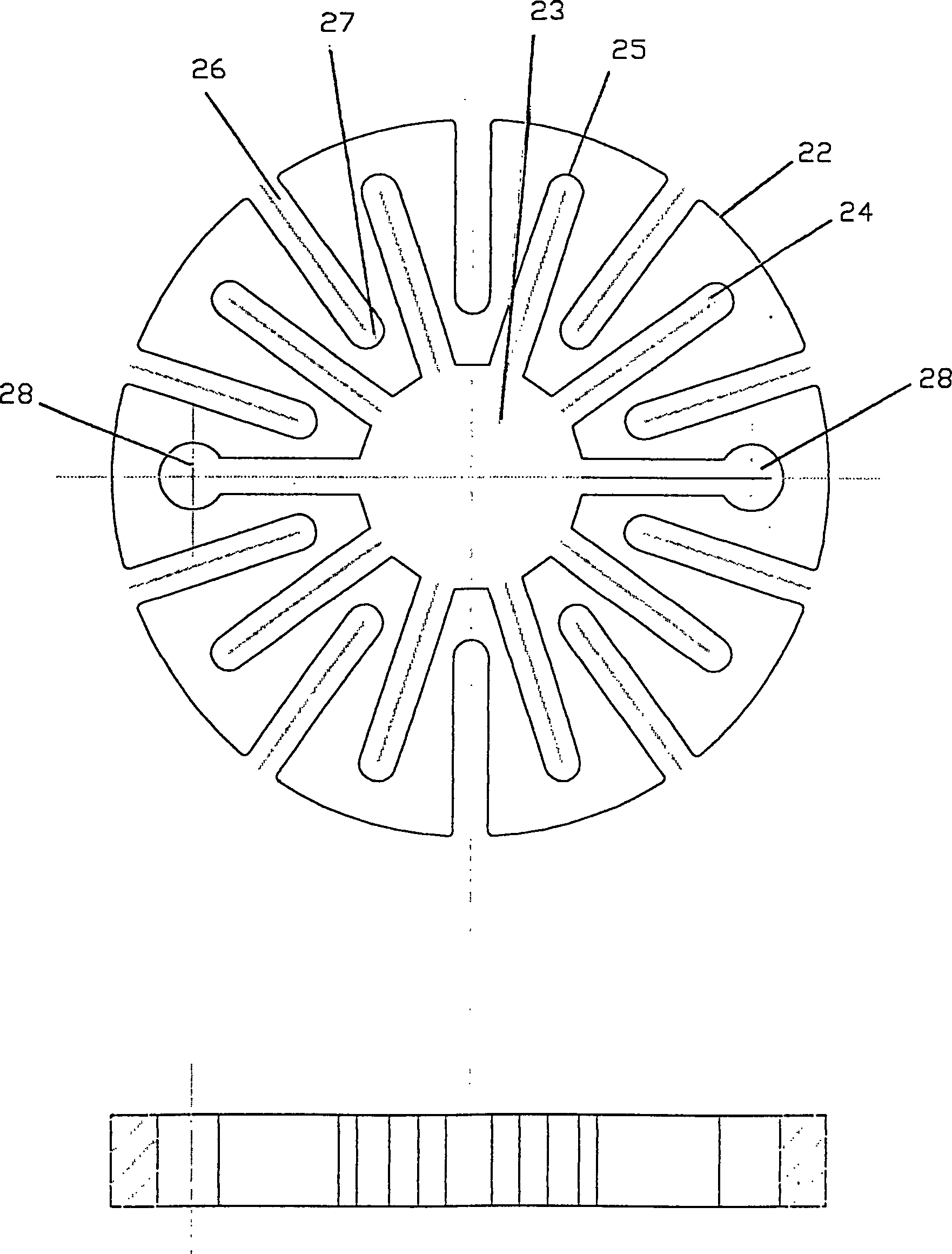

Method of speeding smelting of polycrystalline material and bottom heater for pulling monocrystal

InactiveCN1417388AIncrease temperatureChange the heating methodBy pulling from meltDc currentEngineering

The present invention relates to a method of speeding melting of polycrystalline raw material and the bottom heater for pulling monocrystal. The method comprises leading DC current to bottom heater while leading DC current to the main heater, so that the quartz crucible is heated from both lateral side and bottom. The bottom heater comprises one disc heating body and two electrodes. The present invention can short the melting time of polycrystalline material and save electric power, and thus increase the yield of monocrystal silicon or germanium.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

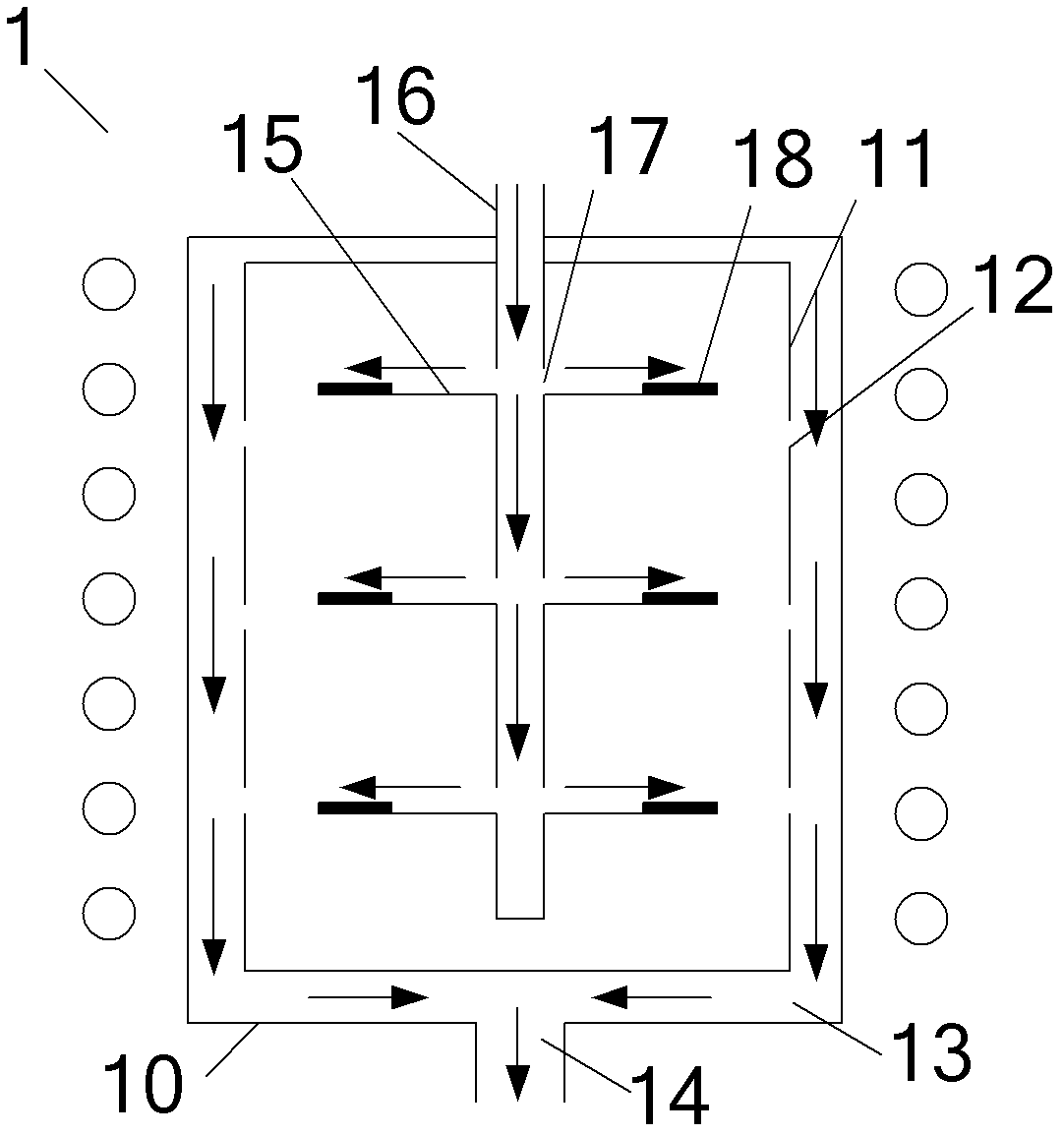

Reaction chamber and plasma processing equipment applying the same

ActiveCN103160813AImprove adjustabilityAdjust heat loss rateChemical vapor deposition coatingProduct gasAerospace engineering

Provided are a reaction chamber and plasma processing equipment applying the same. The reaction chamber comprises an outer chamber, an inner chamber and a gas delivery tube, wherein the inner chamber is arranged in the outer chamber, a gas passage is formed between the inner chamber and the outer chamber, the gas passage is communicated with an exhaust passage of the outer chamber, the gas delivery tube is arranged in the inner chamber, a plurality of gas inlets for delivering process gas to the inner chamber is arranged on the gas delivery tube and an exhaust port is arranged on the chamber wall of the inner chamber. An exhaust port adjustment unit is arranged at the position of the exhaust port to adjust the distribution of temperature in the inner chamber and to further improve the adjustability of the plasma processing equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Apparatus and method for manufacturing compound semiconductor, and compound semiconductor manufactured thereby

ActiveUS8753448B2Reduce uniformityChange the temperature distributionLiquid surface applicatorsSemiconductor/solid-state device manufacturingForming faceGas phase

Provided is an apparatus for manufacturing a compound semiconductor by use of metal organic chemical vapor deposition including: a reaction container; a holder on which a formed body is to be placed so that a formed surface of the formed body on which layers of a compound semiconductor are to be formed faces upward, the holder being arranged in the reaction container; and a material supply port supplying a material gas of the compound semiconductor into the reaction container from outside, wherein the holder includes a support member supporting the formed body so that an undersurface of the formed body and a top surface of the holder on which the formed body is to be placed keep a predetermined distance.

Owner:TOYODA GOSEI CO LTD

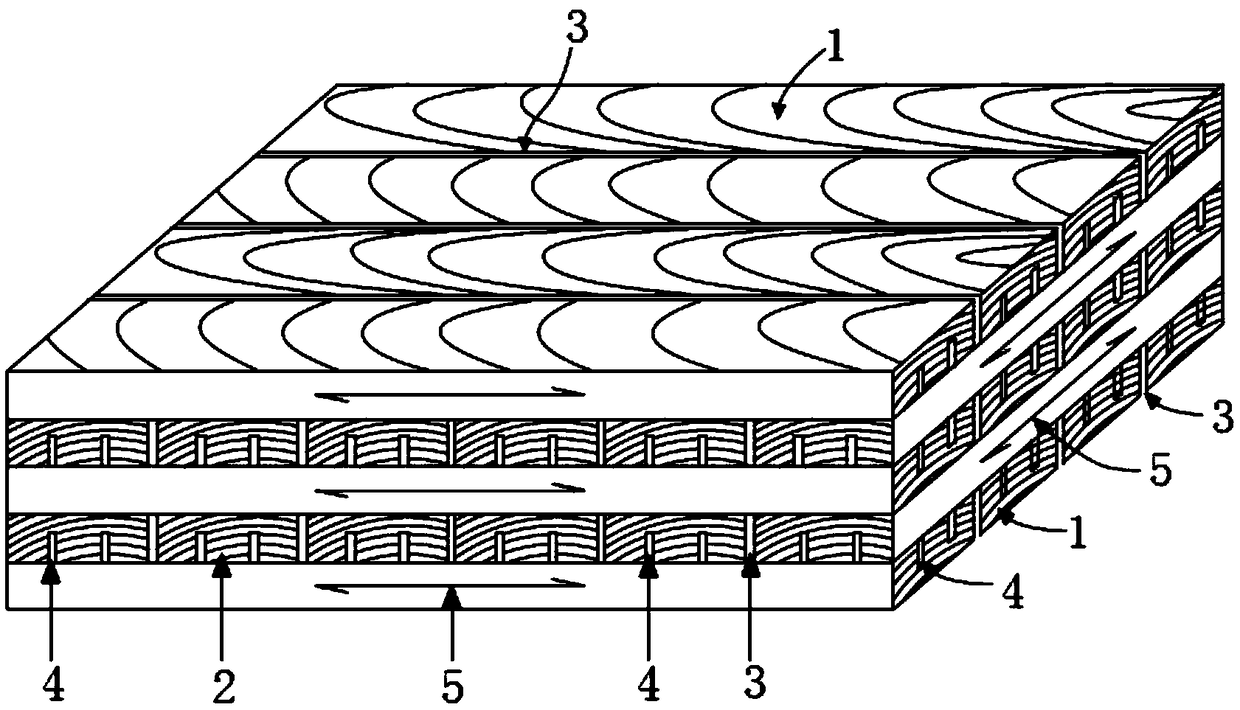

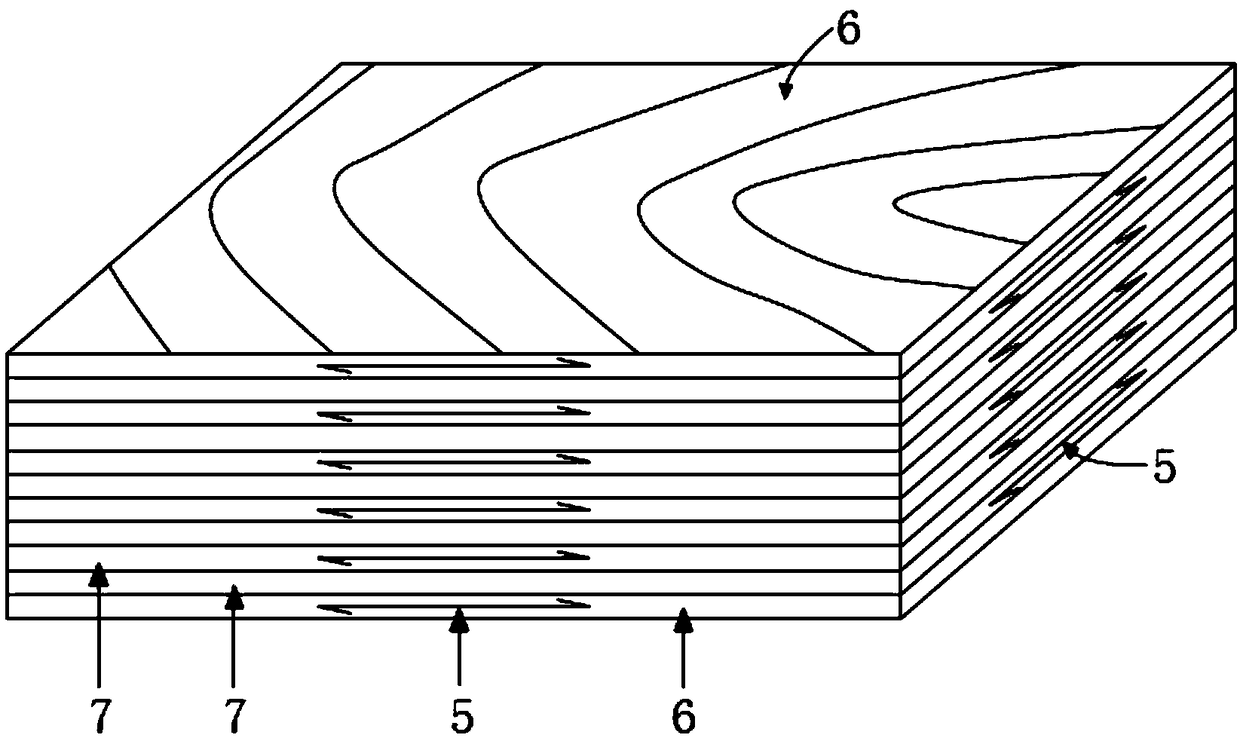

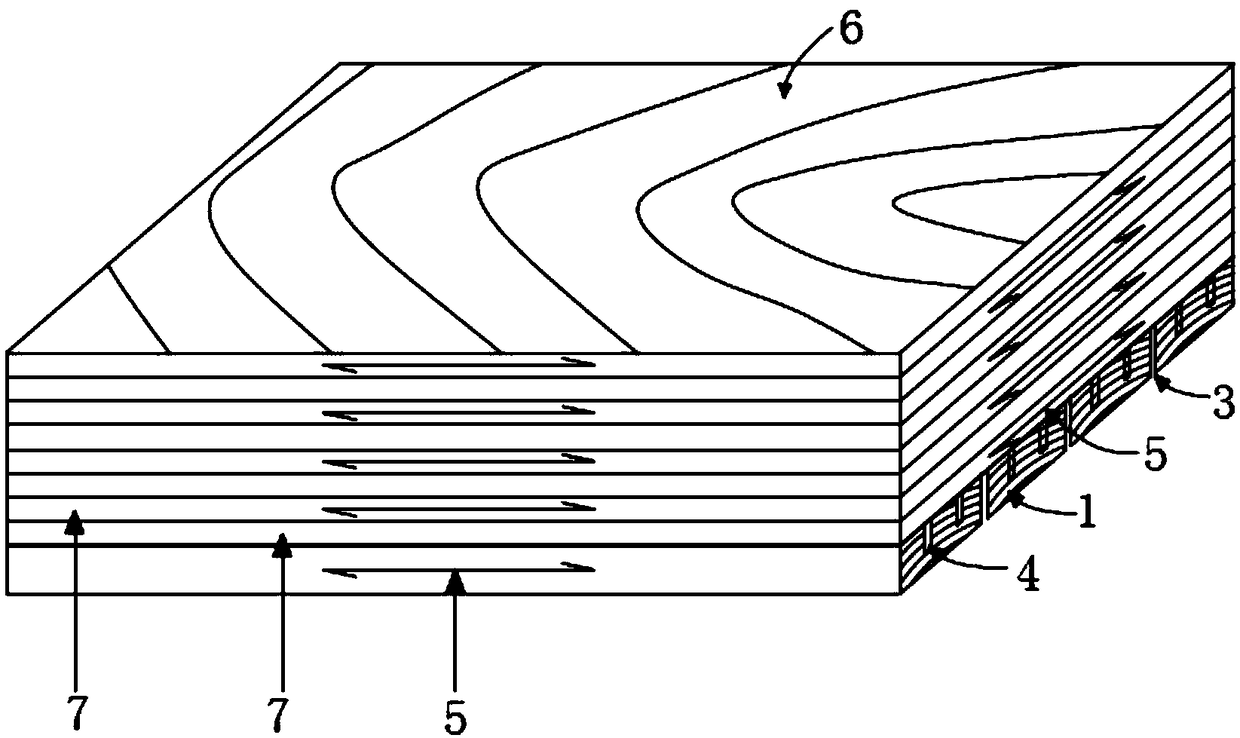

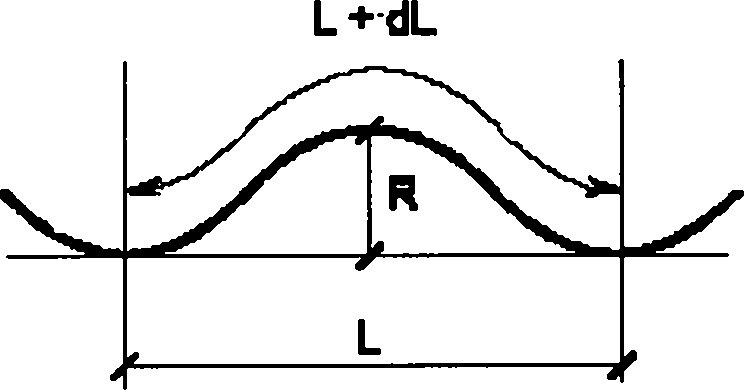

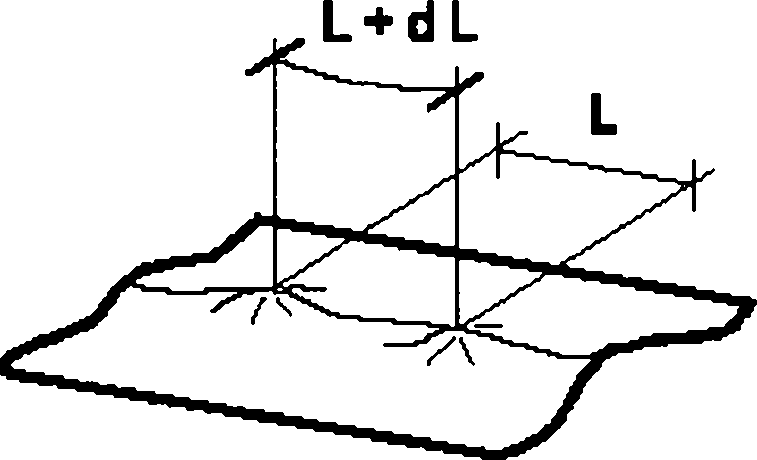

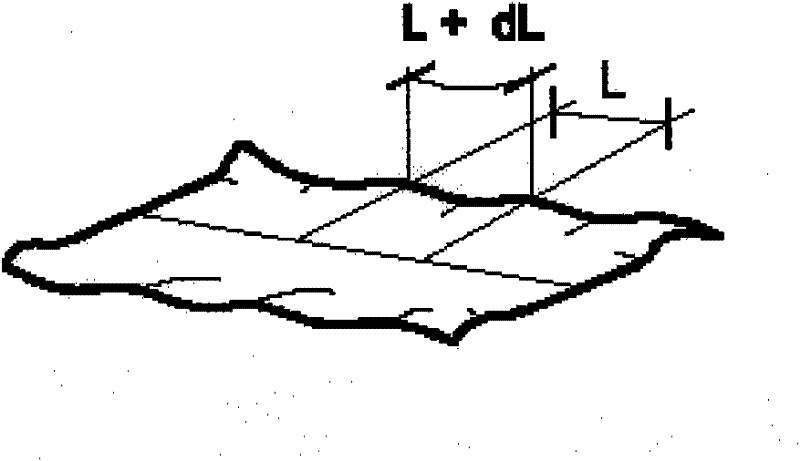

Cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and preparation method thereof

PendingCN109434975AImprove mechanical propertiesImprove fire resistanceLaminationLamination apparatusMechanical propertyAdverse effect

The invention discloses cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and a preparation method thereof, and belongs to the field of timber structures. A laminated board of the cross laminated timber comprises a fast growing timber laminated board with cracks, the fast growing timber laminated board is a whole cracked board, and lengths of all laminated boards of the cross laminated timber are consistent in the horizontal direction. In the preparation method, adjacent layers formed by the fast growing timber laminated board or fast growing timber laminated board combination are assembled and configured in a manner that wood textures are perpendicular to each other in the thickness direction of laminated wood. According to the cross laminated timber combining the fast growing timber material characteristics and meeting the building structure requirements and the preparation method thereof, the material characteristics that the fast growing timber is soft in material and prone to be made into the laminated board with the cracks in a rotary cutting mode are fully utilized, structural stock lumber is replaced for preparing the cross laminated timber, the utilization of the fast growing timber in the field of building structures is expanded, the material cost of a conventional component is greatly reduced, the component preparation process is simplified, the production period is shortened, and the problem that adverse effects on the mechanical property, durability and fireproof performance of the component are caused through gaps in laminated boards of a structural material cross laminated timber component is solved.

Owner:NANJING UNIV OF TECH

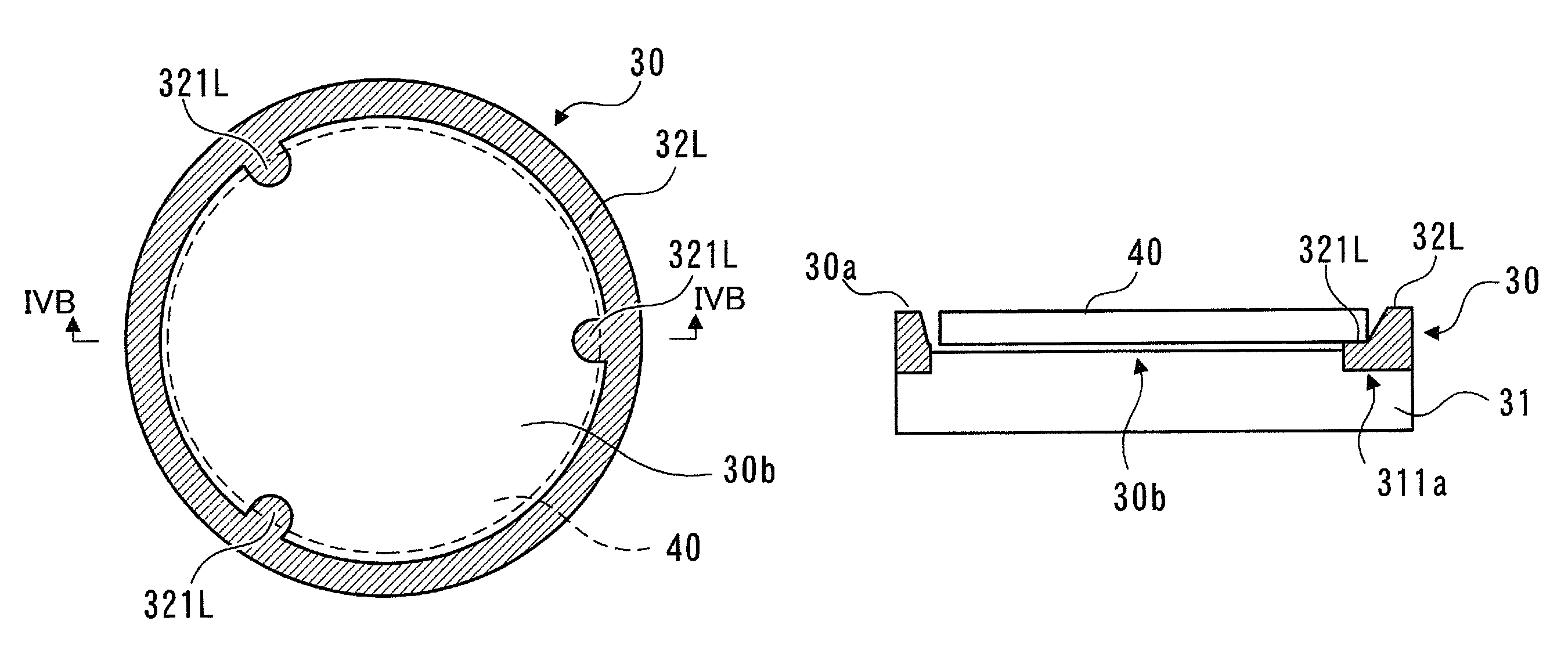

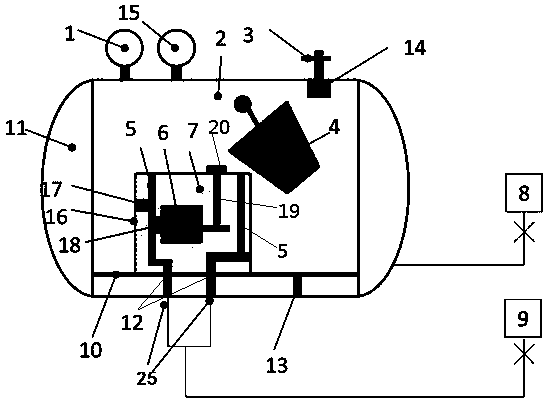

Press-molding apparatus

InactiveCN101370741AQuality assuranceStable productionGlass pressing apparatusGlass productionMetallurgyCooling chamber

A press-molding apparatus comprises a conveyance passageway and, disposed thereon, a heating chamber for heating a mold containing a raw material, a molding chamber for press-molding the raw material in a non-oxidizing gas atmosphere, and a cooling chamber for cooling the mold after molding and in which the mold is successively conveyed on the conveyance passageway. In the press-molding apparatus, each of the heating chamber, the molding chamber, and the cooling chamber is blocked from the atmosphere during the press molding. The apparatus has a means for blocking the molding chamber and the cooling chamber and has an opening for introducing the non-oxidizing gas into the press-molding apparatus, the opening being formed in at least either of the heating chamber and the molding chamber.

Owner:ASAHI GLASS CO LTD

Gypsum-mold vacuum pouring pressurized solidification casting method and device

The invention discloses a gypsum-mold vacuum pouring pressurized solidification casting method and device. A casting wax mold, a casting system wax mold and a ventilation passage wax mold are manufactured according to the shape size of a to-be-cast part, the ventilation passage wax mold is pre-placed in a gypsum mold, and after the wax mold is removed, a ventilation passage is formed, pressurizedgas is flowed through the ventilation passage, and then the effect of casting mold cooling is achieved; and depending on the arrangement of the ventilation passage, the temperature distribution of thecasting is changed, so that the solidification sequence of the casting is adjusted, the casting tends to solidify in sequence, and the yield of the casting is favorably improved.

Owner:ZHONGBEI UNIV

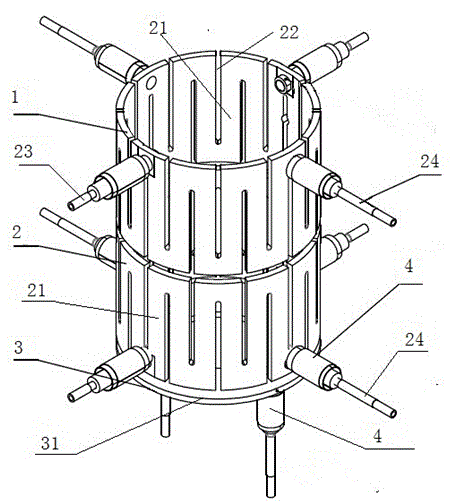

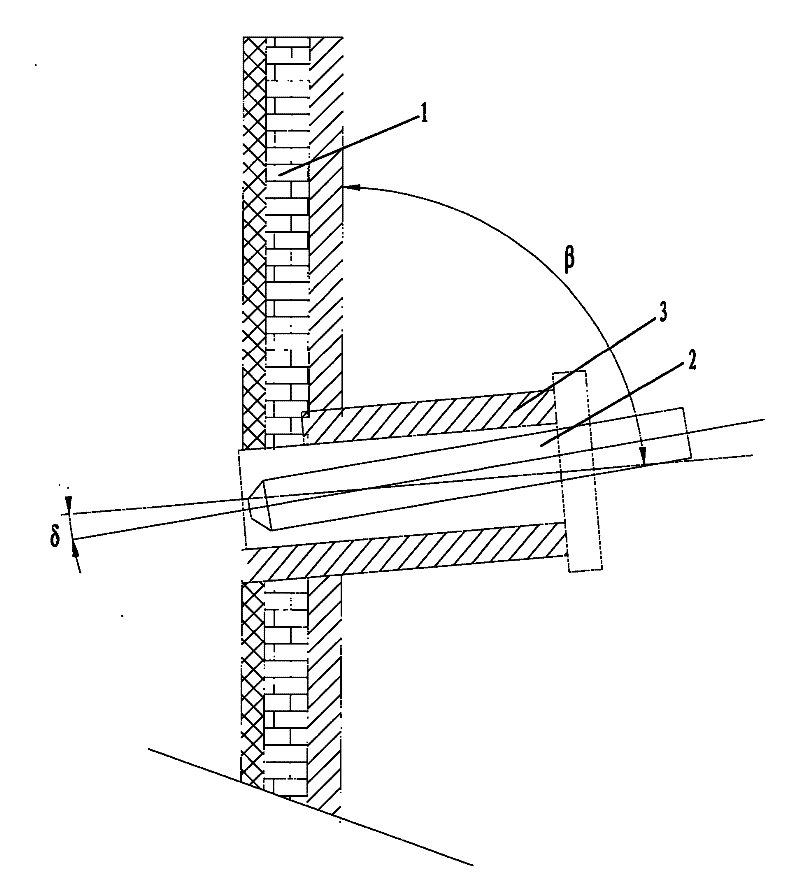

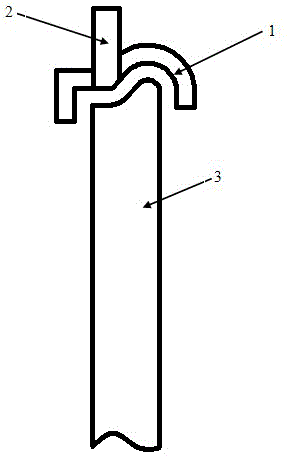

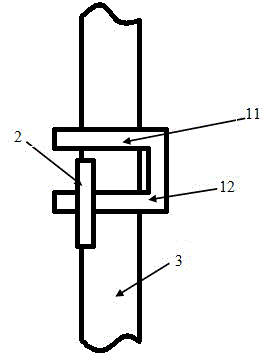

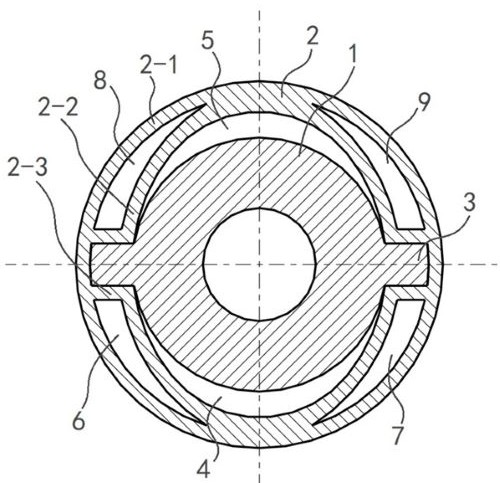

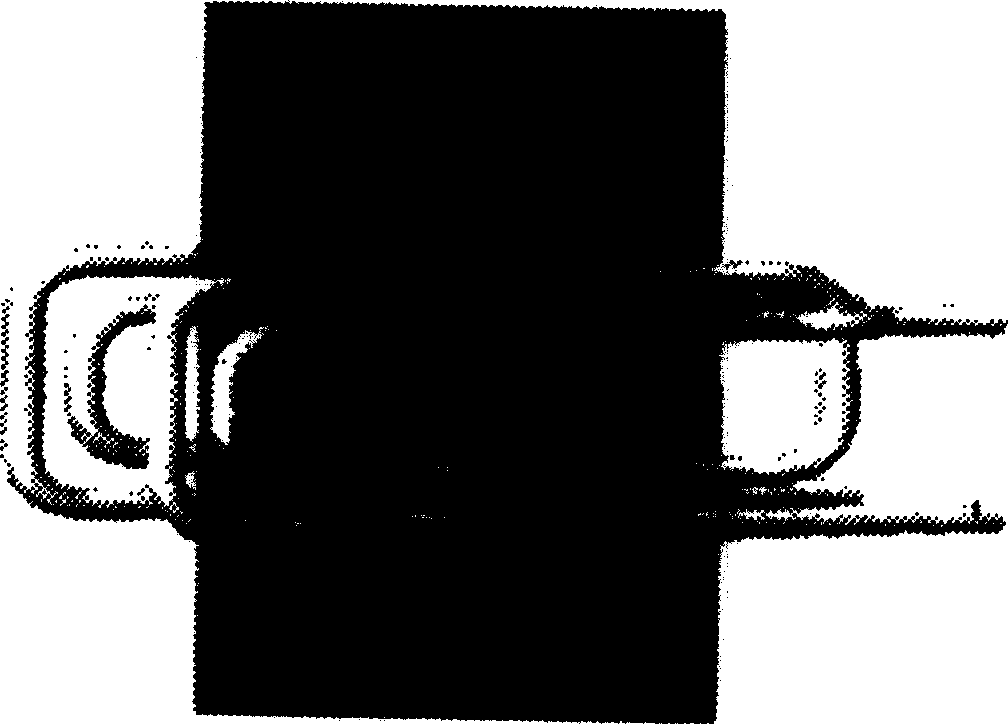

Inductor structure for special-shaped ultra-hard abrasive grinding wheel ultra-high frequency induction brazing and heating method

ActiveCN103949746ARealization of UHF Induction BrazingShort cycleGrinding devicesHeating appliancesInductorGrinding wheel

The invention discloses an inductor structure for special-shaped superhard abrasive grinding wheel ultra-high frequency induction brazing and a heating method. The inductor structure comprises a magnetizer and a heating induction coil, wherein the induction coil is a double-circuit line, the double-circuit induction coil comprises a first coil for preheating and a second coil for brazing, wherein the first coil and the second coil are placed above the outer circumference of a grinding wheel base body in the axis direction of a grinding wheel; the first coil and the second coil have shape following structures which are consistent with the surface of the grinding wheel base body, and the shape following structures comprise concave parts and convex parts; the magnetizer is arranged at each of the concave parts of the second coil. On one hand, the induction coil adopts the shape following structures, and the induction brazing is carried out on the grinding wheel base body to greatly shorten the production cycle of a formed grinding wheel and reduce deformation of the base body; on the other hand, the magnetizer is embedded in the hard-to-heat zone in a forming surface in an effort to reduce magnetic flux leakage in a magnetic circuit and to change the magnetic field distribution, so that the problem that the temperature of the forming surface is not distributed uniformly can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

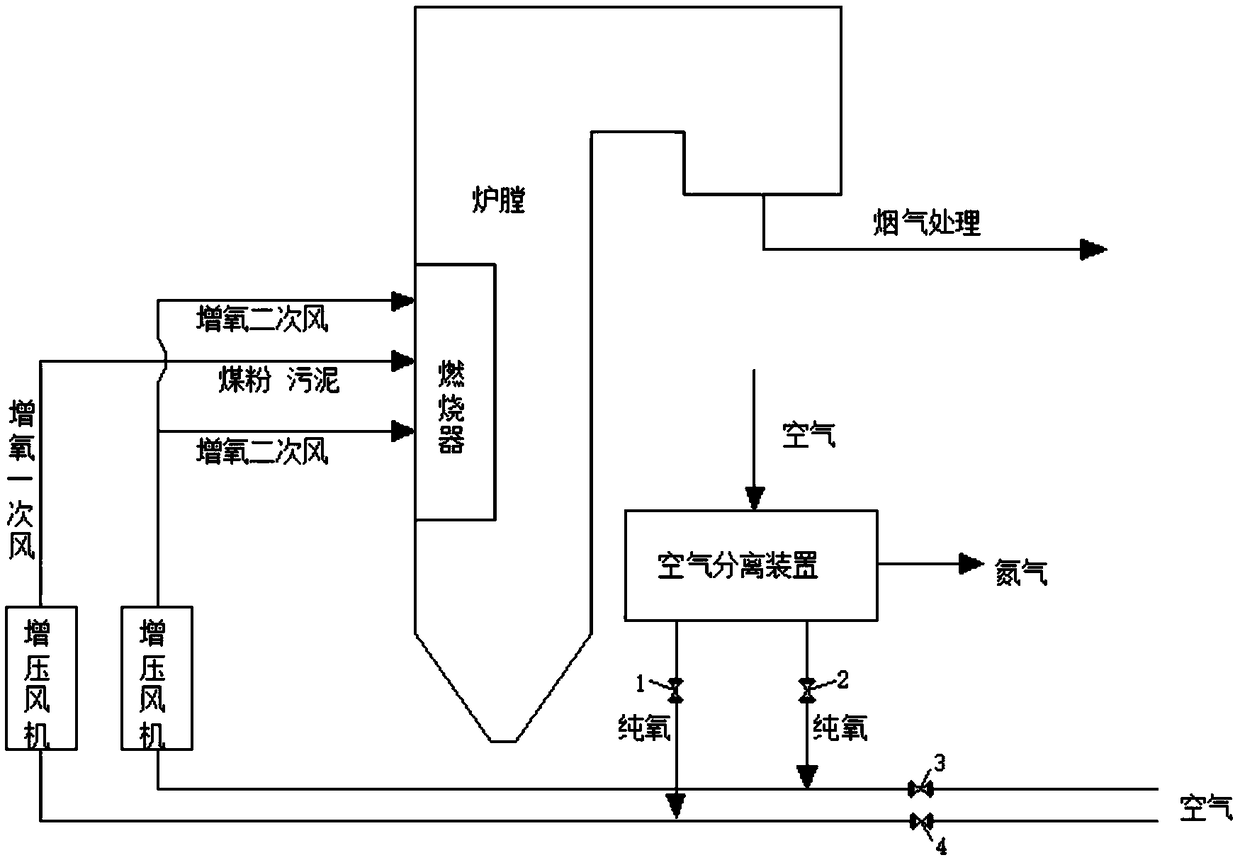

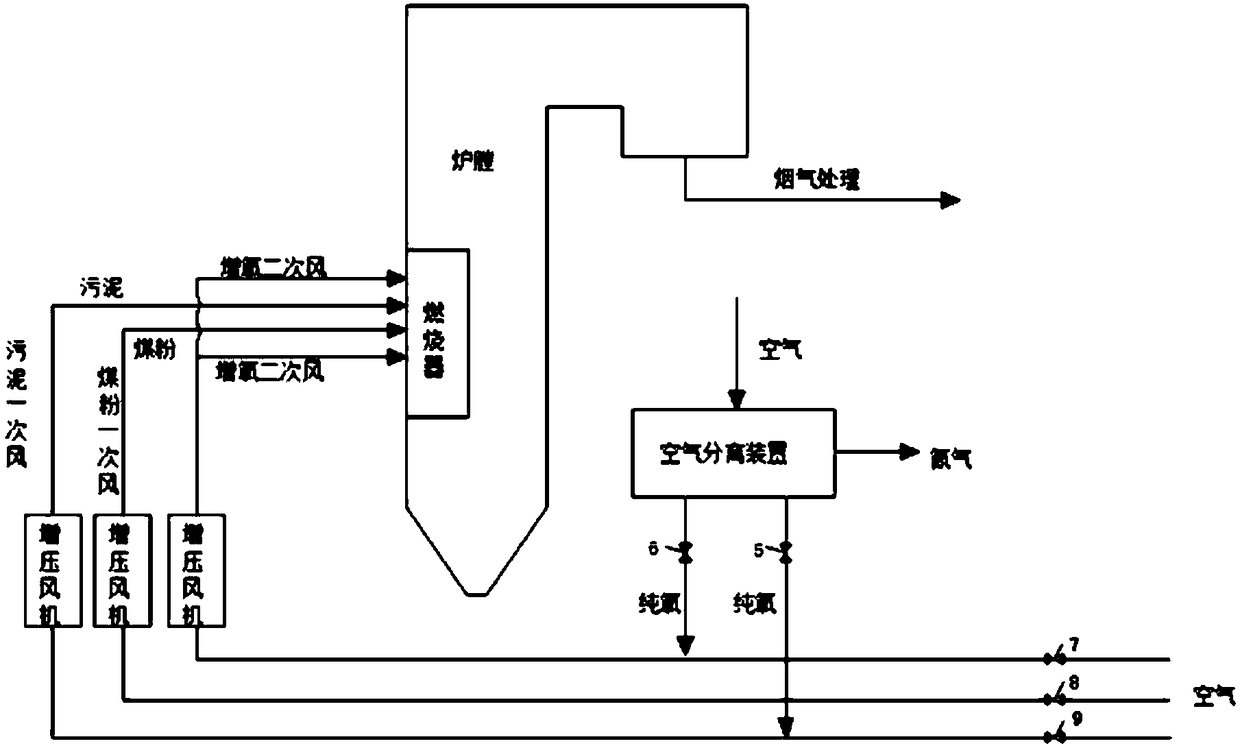

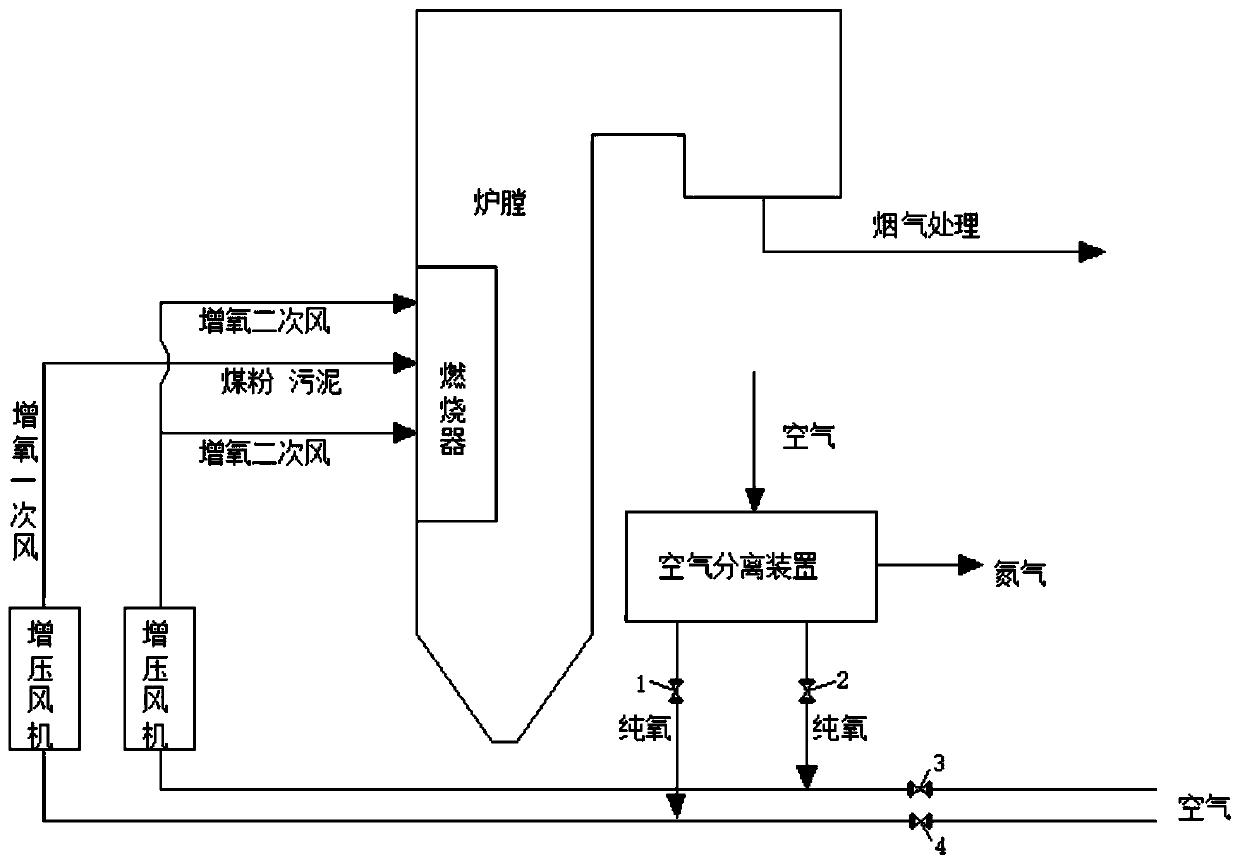

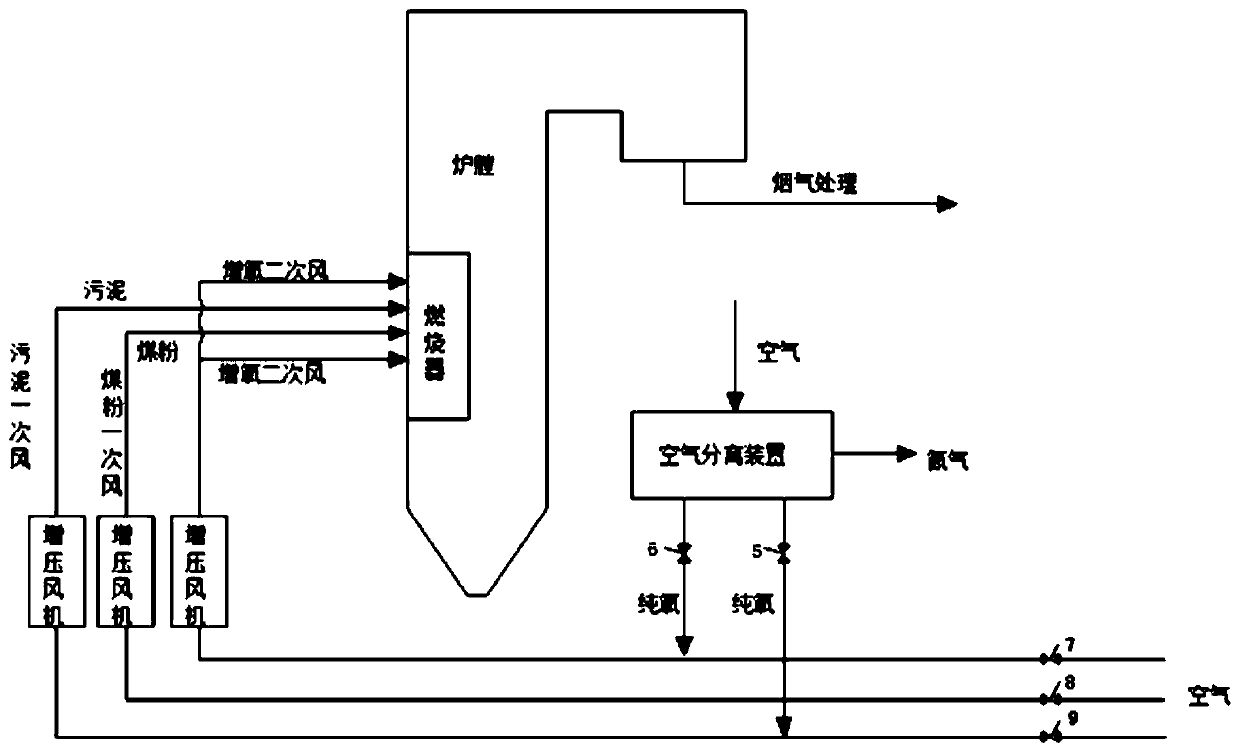

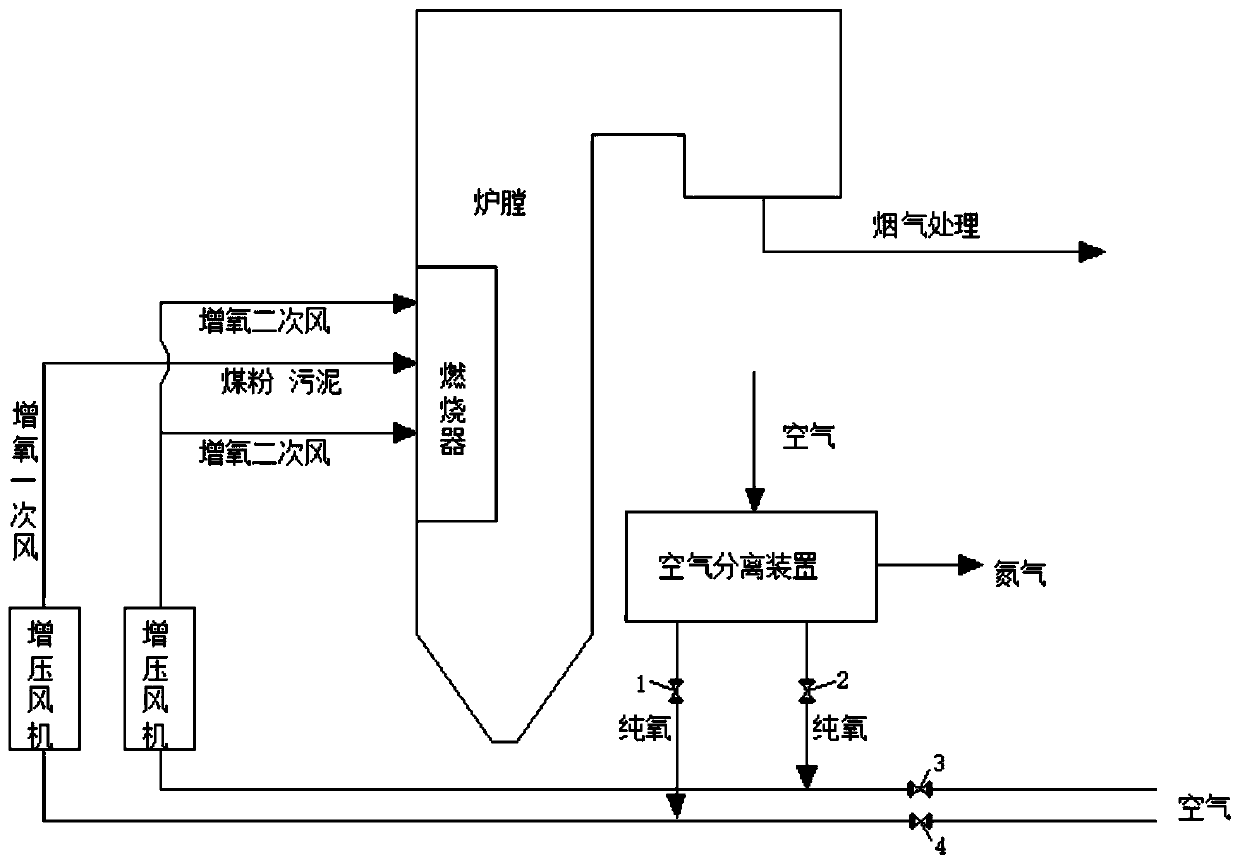

Pulverized coal and sludge mixed oxygenation combustion method

ActiveCN108644788ARatio of calorific value increasedImprove stabilityIndirect carbon-dioxide mitigationAir/fuel supply for combustionSludgeHearth

The invention belongs to the technical field of boiler combustion and discloses a pulverized coal and sludge mixed oxygenation combustion method. The pulverized coal and sludge mixed oxygenation combustion method is characterized in that a sludge and pulverized coal mixture is taken as a fuel, pure oxygen is injected into a primary air pipeline and a secondary air pipeline to increase the concentration of oxygen in a hearth and to promote stable and sufficient combustion of the fuel in the hearth, an air separation device provides two paths of pure oxygen, one path of pure oxygen and air are mixed in the primary air pipeline to serve as primary oxygenation air to enter the hearth, and the other path of pure oxygen and air are mixed in the secondary air pipeline to serve as secondary oxygenation air to enter the hearth. The ratio of oxygen in the primary air and the secondary air is adjusted to increase the concentration of oxygen in the hearth, so that the combustion stability is improved, the distribution of temperature during combustion is changed, finally, generation of NOX is reduced, the calorific value ratios of sludge and pulverized coal are increased, the sludge disposal capacity is increased, the heat efficiency and the burn-off rate are increased, and emission of such pollutants as NOX and dioxin is effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

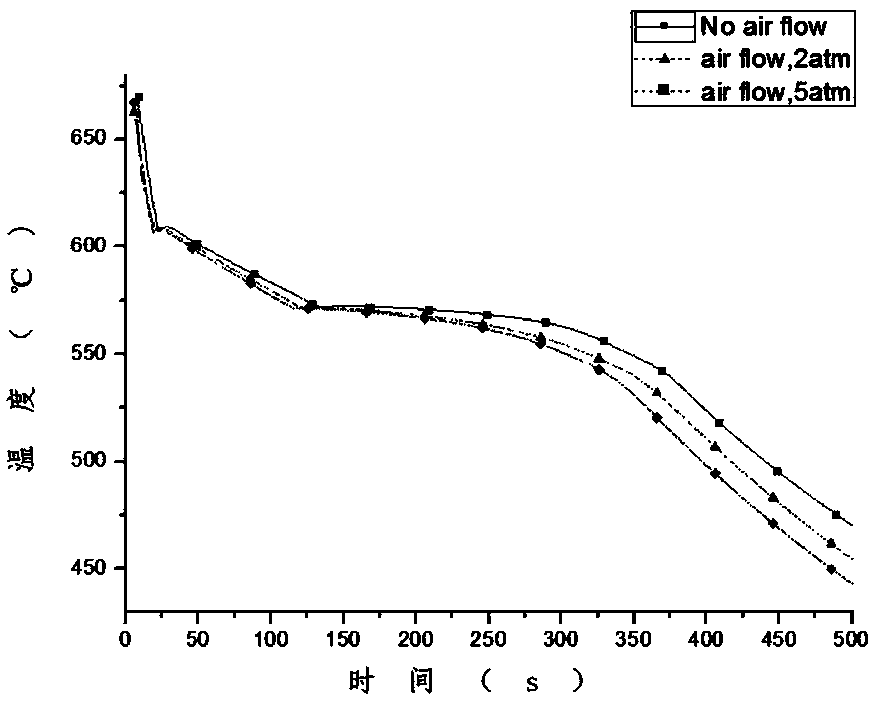

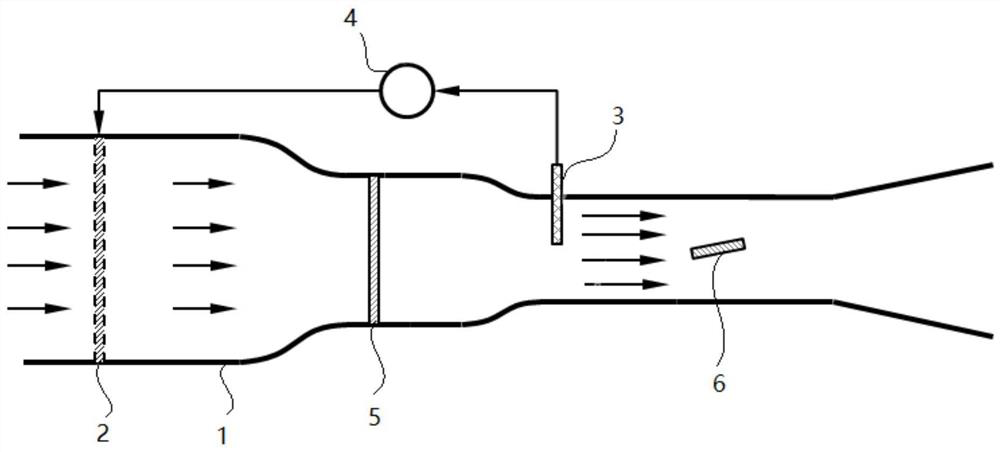

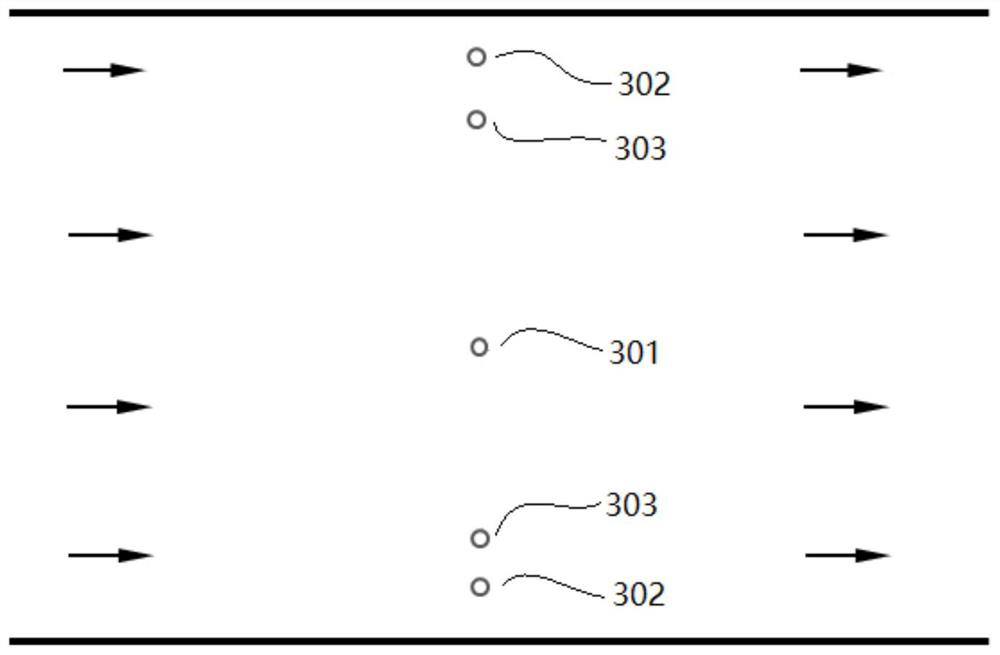

Stable-temperature airflow heating device for low-speed direct-current wind tunnel simulation experiment and wind tunnel

PendingCN112197930AImprove temperature uniformityChange the temperature distributionAerodynamic testingTemperature control using electric meansEngineeringAtmospheric sciences

The invention discloses a stable-temperature airflow heating device for a low-speed direct-current wind tunnel simulation experiment and a wind tunnel. The device comprises airflow heating units, a temperature monitoring unit and a control unit, at least two groups of airflow heating units are symmetrically arranged along the axis of the wind tunnel; each airflow heating unit group comprises at least two heaters, the heaters in each airflow heating unit group are sequentially distributed in the airflow direction in the wind tunnel, and the heaters are sequentially distributed from the positionnear the inner wall of the wind tunnel to the center of the wind tunnel in the radial direction of the wind tunnel. The input terminal of the control unit is connected with the temperature monitoringunit, and the output terminal is connected with the heaters. The device can heat the low-speed direct-current wind tunnel airflow and stabilize the temperature of the wind tunnel test section airflow; the temperature uniformity of the airflow on the cross section of the low-speed direct-current wind tunnel test section is improved, and the temperature distribution of the airflow on the cross section of the low-speed direct-current wind tunnel test section can be changed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

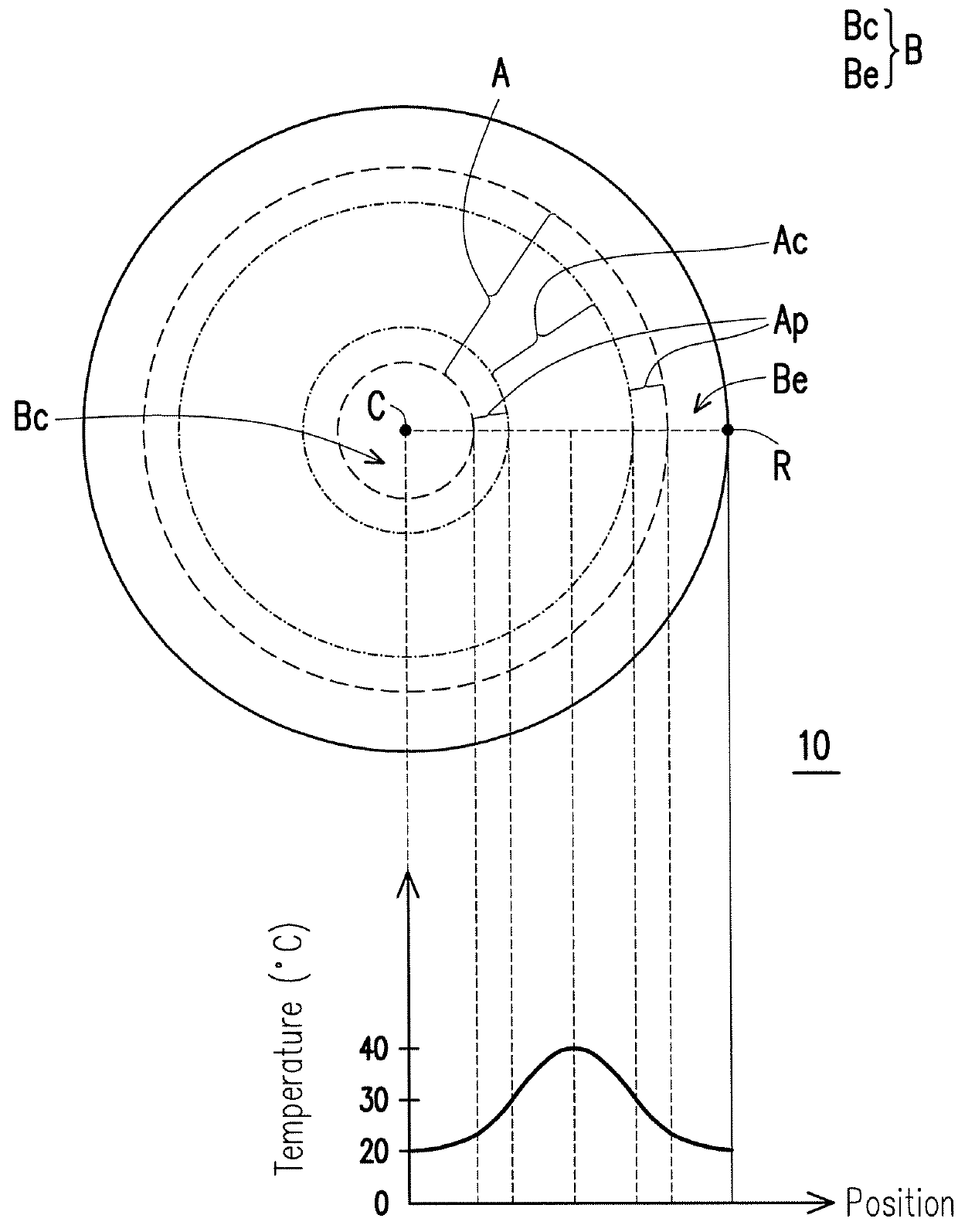

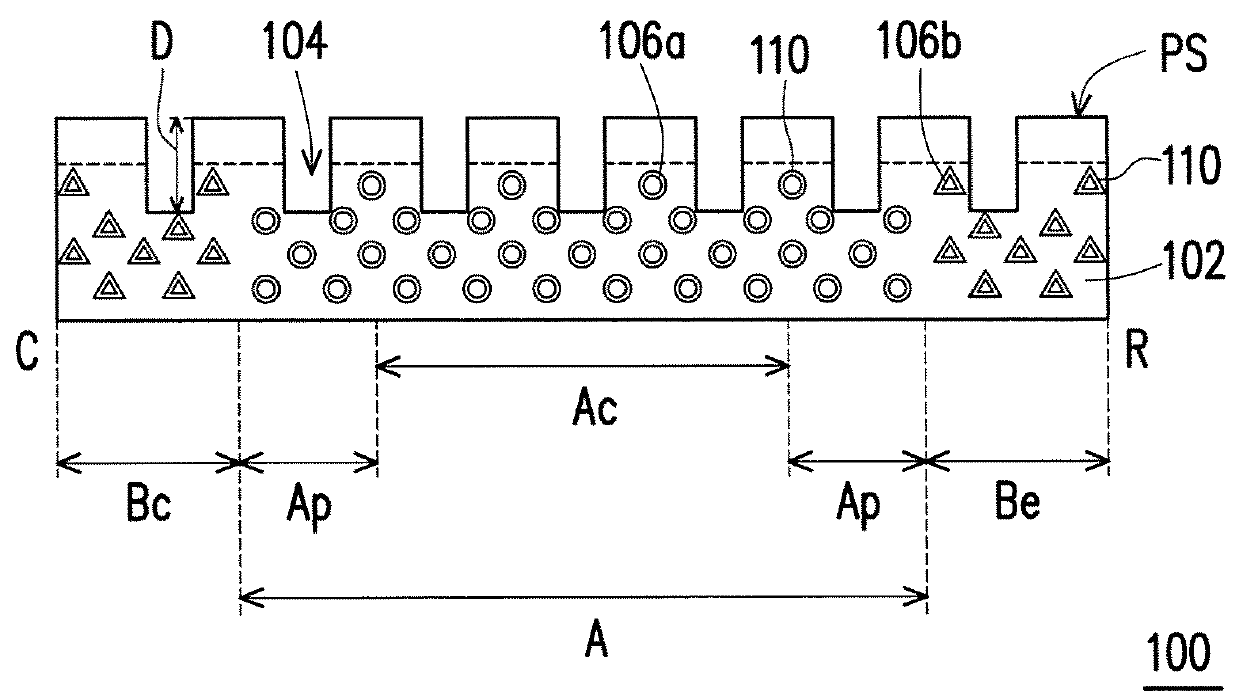

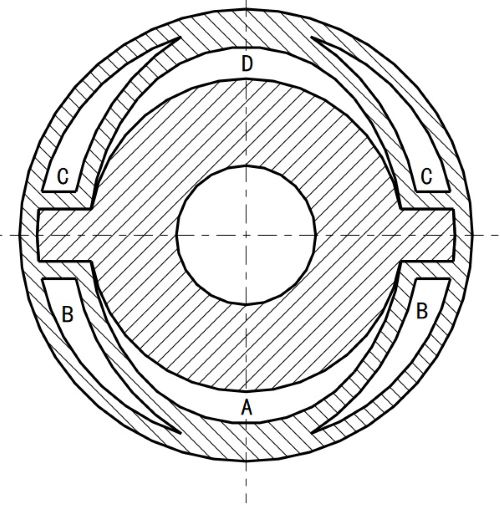

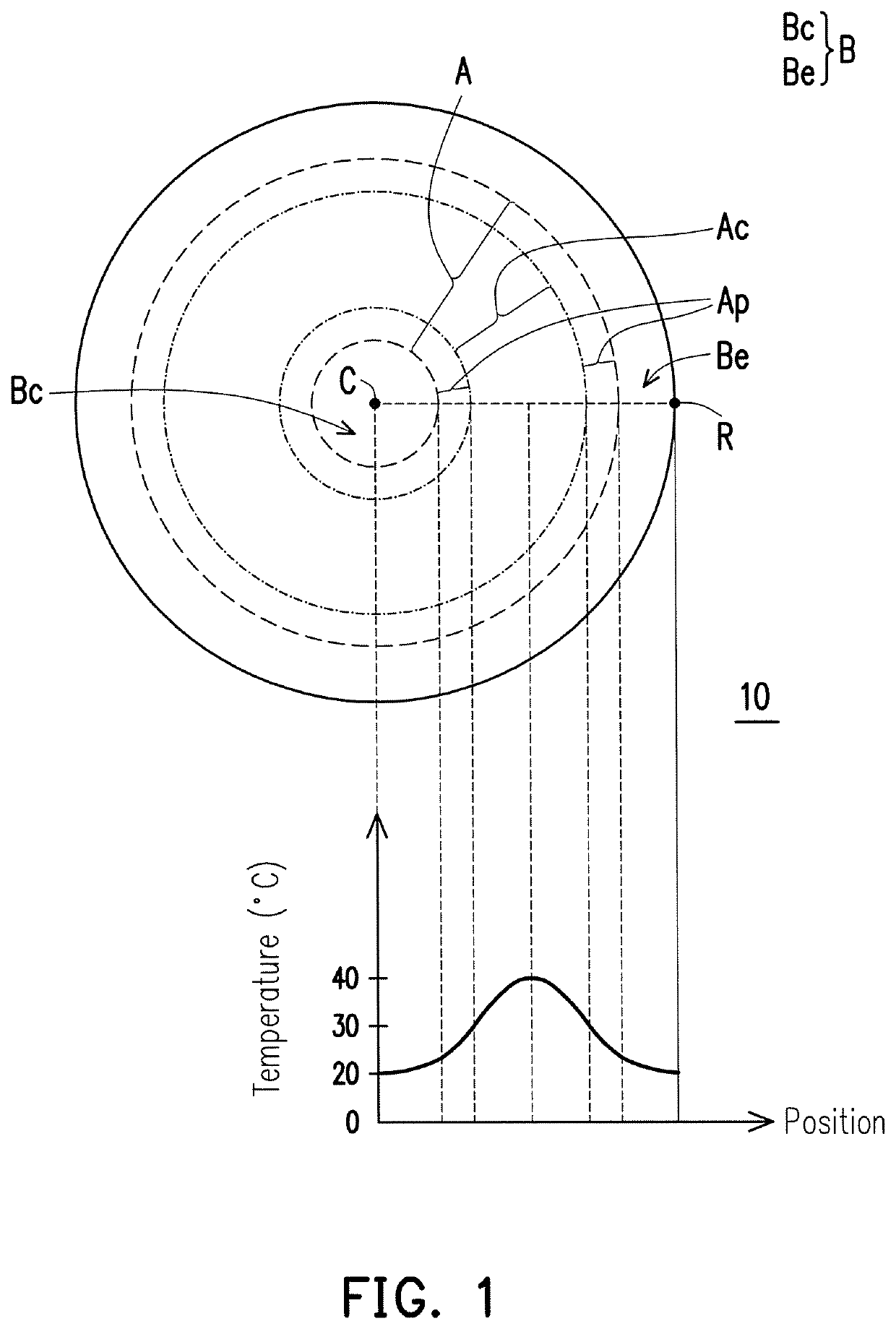

Polishing pad and polishing method

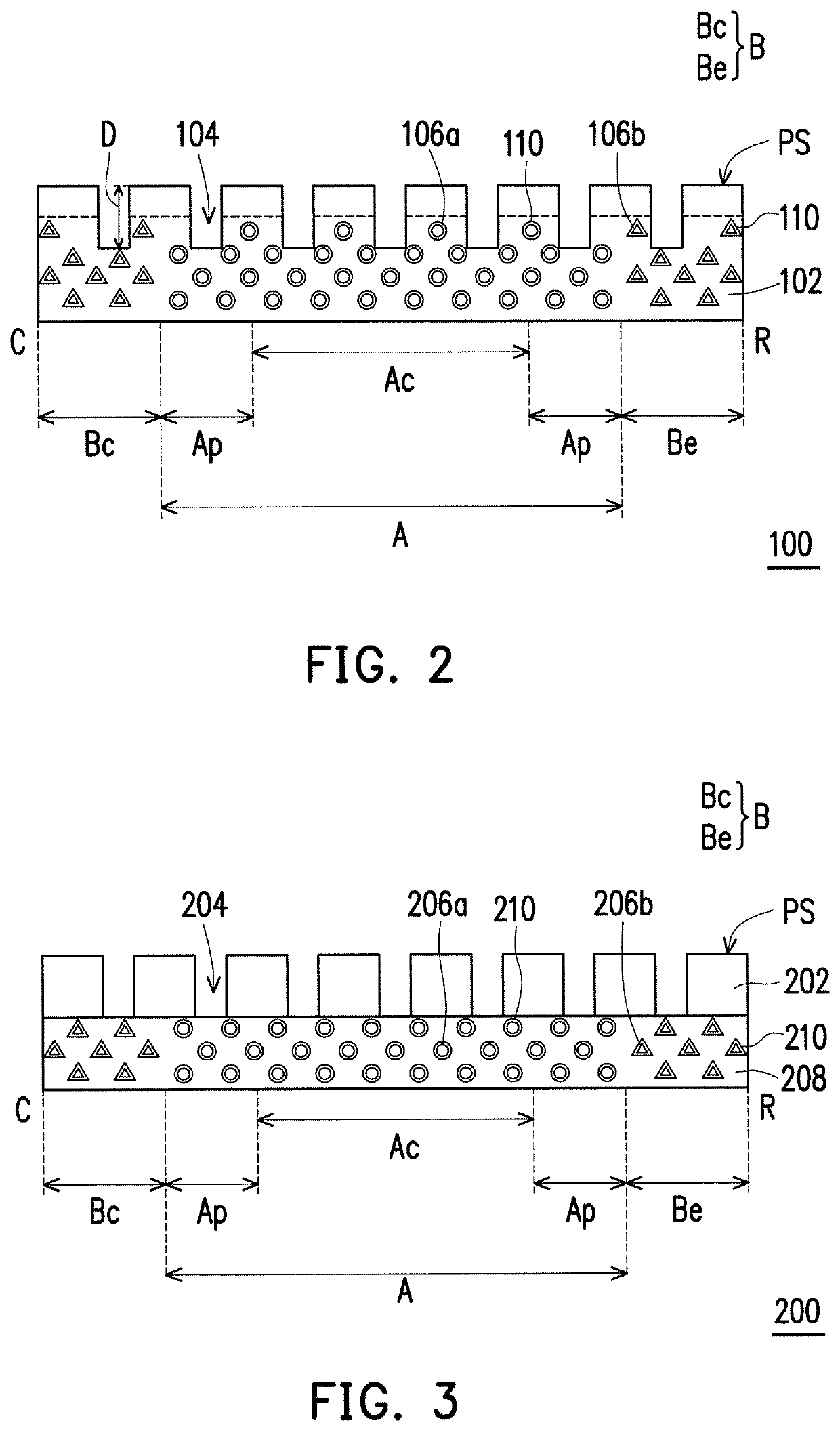

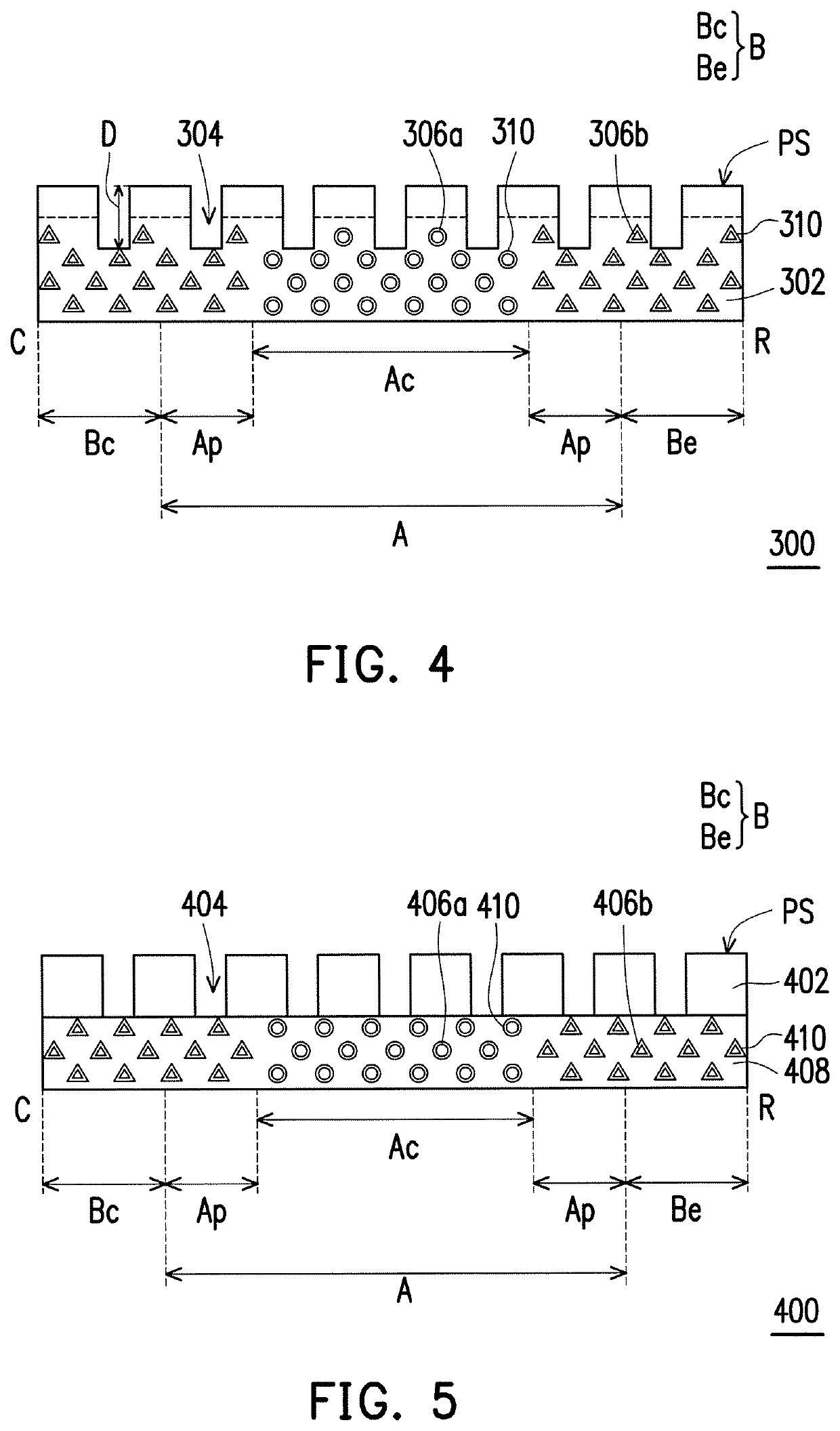

ActiveUS20180161959A1Reduce temperature gradientImprove applicabilityPolishing machinesAbrasion apparatusEngineeringSlurry

A polishing pad is provided. The polishing pad, suitable for a polishing procedure using a slurry containing water, includes a polishing track region and a first reactant. The polishing track region includes a central region and a peripheral region surrounding the central region. The first reactant is disposed in the central region of the polishing track region, wherein the first reactant is able to react endothermically with the water in the slurry.

Owner:IV TECH CO LTD

Water-cooling support rod and processing method thereof

ActiveCN112229598AGood effectMuch design freedomAdditive manufacturing apparatusAerodynamic testingMeasurement testMachining

The invention discloses a water-cooling support rod and a processing method thereof. The connected water-cooling sleeve and support rod are respectively provided with a first water path and a sixth water path which are arranged between the water-cooling sleeve and the surface of the support rod and are not communicated with each other, and a second water path, a third water path, a fourth water path and a fifth water path which are arranged in the water-cooling sleeve and are parallel to each other along the axial direction; all the water paths are of mutually independent structures and are sequentially connected to form a complete water path structure; the full-water-cooling supporting rod is designed and machined through a traditional machining method and a 3D printing technology combined machining method, the water cooling efficiency is improved, the temperature gradient of the supporting rod is reduced, deformation, caused by temperature changes, of the supporting rod in a wind tunnel test is restrained, and the hypersonic wind tunnel force measurement test precision is improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

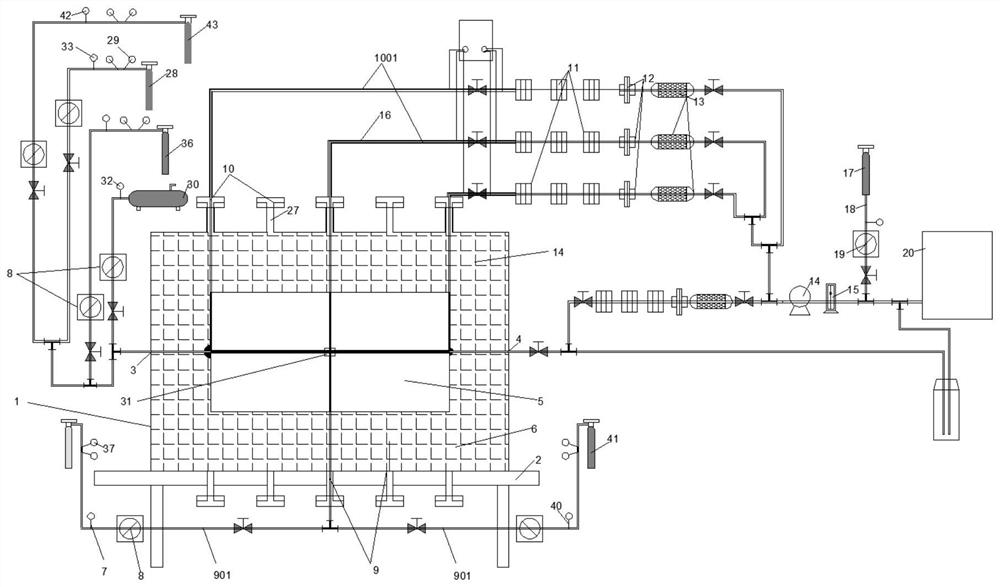

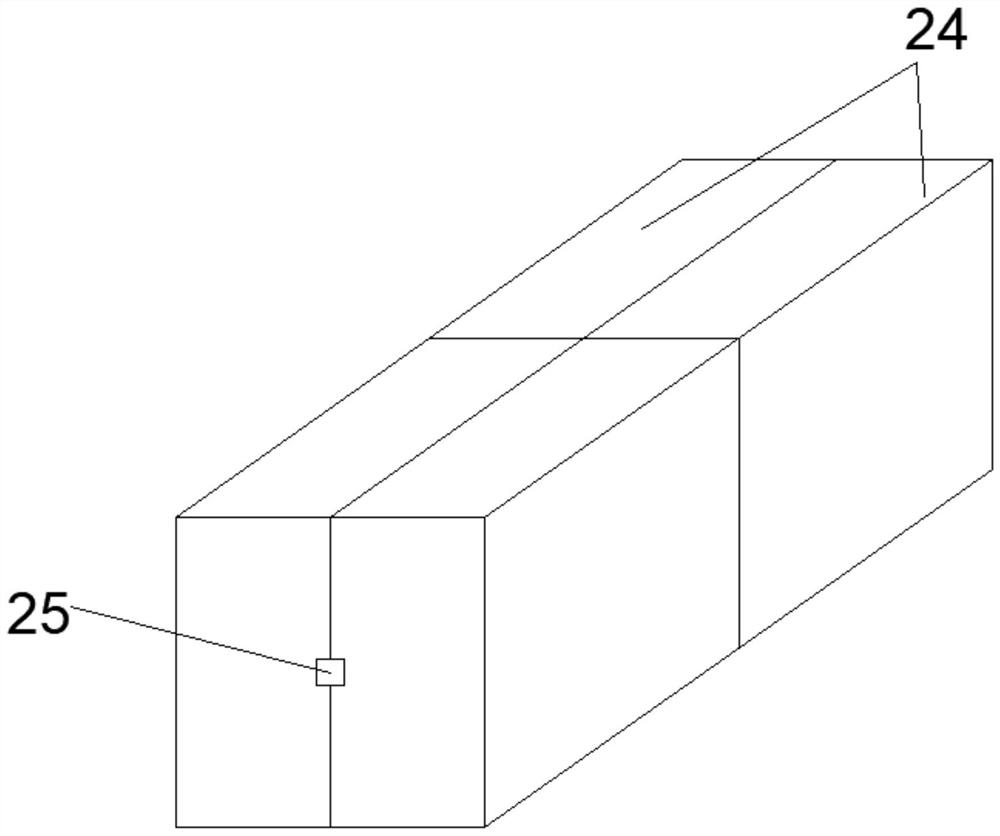

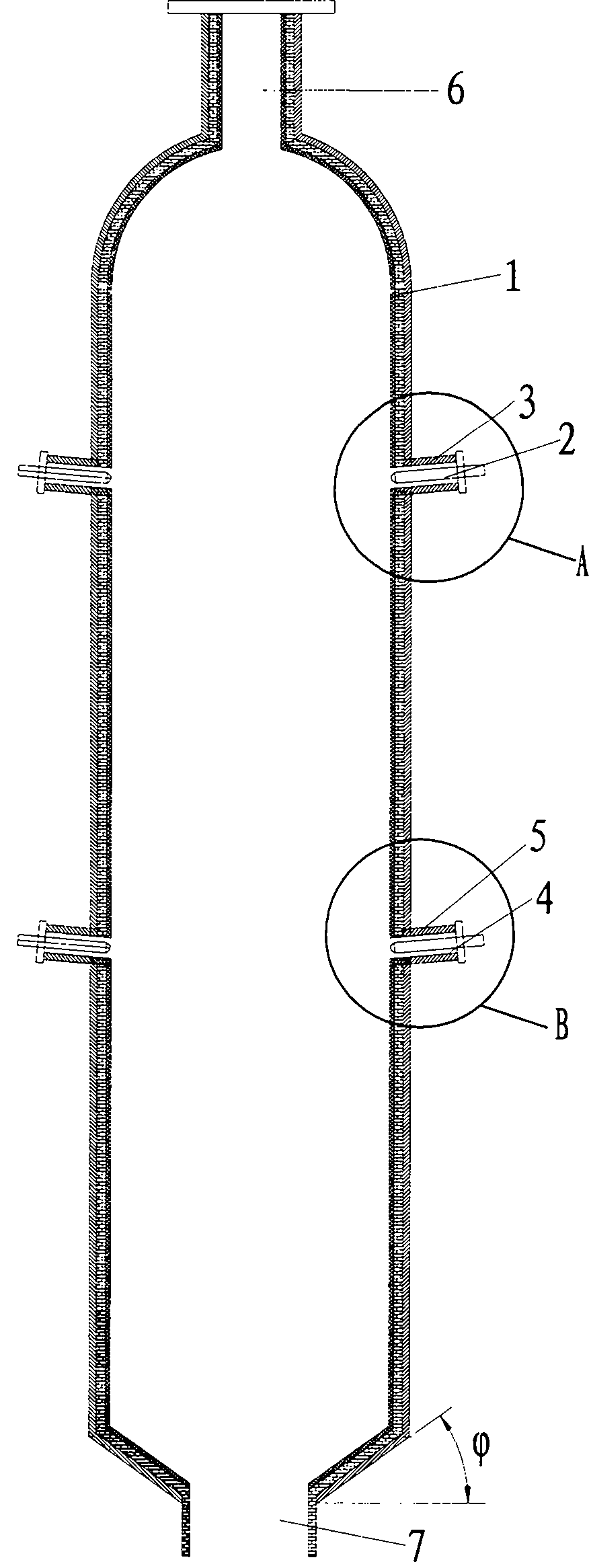

Coal underground gasification on-way sampling simulation experiment system and method

PendingCN114412432AChange the temperature distributionIncrease spawn rateSurveyConstructionsPhysicsParticle trapping

The invention discloses a coal underground gasification on-way sampling simulation experiment system and method, and belongs to the technical field of coal underground gasification simulation. The coal underground gasification on-way sampling simulation experiment system comprises a gas supply device, a gasification furnace body, an on-way sampling device and an analysis test device; the gas supply device is connected with the gas inlet through a pipeline and is used for injecting a gasifying agent into the box body; the on-way sampling device is connected with the on-way gas outlet hole through a pipeline and is used for extracting tar, particulate matters and produced gas in the direction of the gasification channel after the coal sample is combusted and gasified; the analysis testing device comprises a produced gas analysis device and a temperature monitoring device, and is used for analyzing products after combustion and gasification of the coal sample and on-way characteristics of an internal temperature field of the coal sample; the on-way sampling device is combined with the tar separation bottle, the particle trapping net and the gas dryer, so that on-way characteristics of tar, particles and produced gas are monitored, and the gasification reaction process is deeply mastered.

Owner:CHINA UNIV OF MINING & TECH

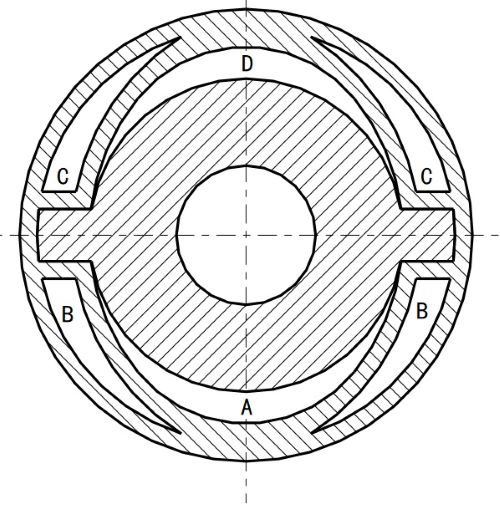

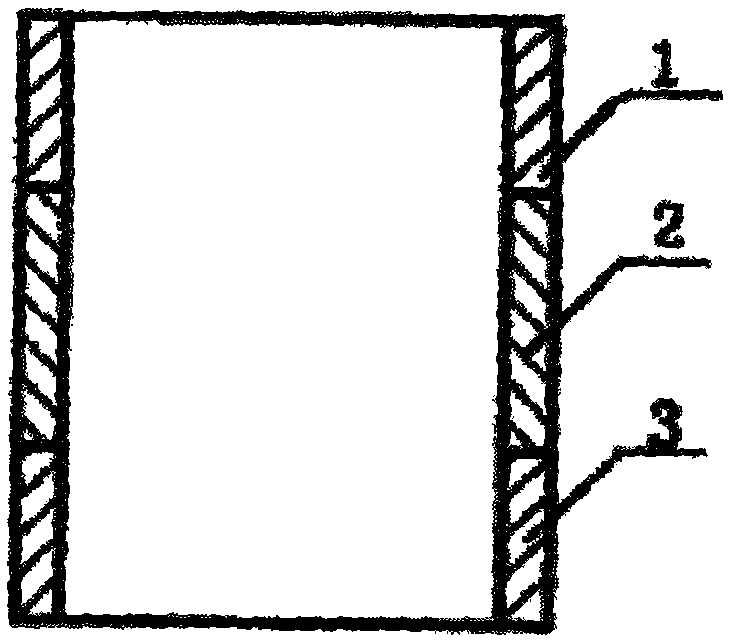

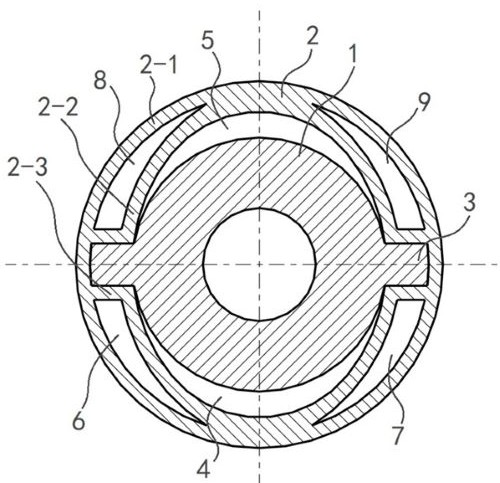

Resistance heating body for adjusting temperature distribution inside high-temperature and high-pressure synthesis cavity body

InactiveCN106669546AChange the temperature distributionAdapt to pressure gradientUltra-high pressure processesElectrical resistance and conductanceBarrel Shaped

The invention discloses a resistance heating body for adjusting a temperature distribution inside a high-temperature and high-pressure synthesis cavity body. The resistance heating body comprises a heating-body barrel body. The resistance heating body is characterized in that the barrel body consists of at least three heating bodies which are different in resistivity up and down; the resistivity of all the heating bodies from a center to two ends is gradually increased. According to the resistance heating body, as the heating-body barrel body is designed to be of a structure which consists of at least three heating bodies which are different in resistivity up and down, in comparison with the prior art, through dividing the barrel-shaped resistance heating body into multiple parts, which are different in resistance, at different positions along the axial direction, the temperature distribution inside a high-temperature and high-pressure synthesis reaction chamber is changed; the pressure gradient inside the reaction chamber is adapted; an area, which is suitable for the growth of cubic boron nitride and an artificial diamond, inside the reaction chamber is broadened; high-quality cubic boron nitride and artificial diamond products are synthesized more easily.

Owner:刘志林

Multi-nozzle multi-stage oxygen supplying entrained-flow gasifier and gasification method thereof

ActiveCN102453550BImprove combustion efficiencyEasy to adjust loadHydrogenGranular/pulverulent flues gasificationSlagFire brick

The present invention discloses a multi-nozzle multi-stage oxygen supplying entrained-flow gasifier. The entrained-flow gasifier comprises a top closed type gasifier body, an ignition nozzle chamber, a gasifier outlet, and at least two process nozzle chambers, wherein process nozzles are arranged inside the process nozzle chambers. The entrained-flow gasifier further comprises at least two secondary oxygen supplying nozzle chambers, wherein secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers, the secondary oxygen supplying nozzle chambers are arranged between the process nozzle chambers and the gasifier outlet, and are symmetrically arranged on the circumference of the gasifier body, and the secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers. The present invention further discloses a gasification method of the gasifier. According to the gasification method, an oxidizing agent is introduced to the secondary oxygen supplying nozzle during the reaction process to promote the further gasification reaction. With the present invention, a plurality of the nozzles are adopted to carry out multi-stage oxygen supplying on the gasifier, such that the service life of the fire brick structure on the upper space of the gasifier is substantially prolonged so as to substantially improve the operating rate and the performance of the gasifier. In addition, with the present invention, the liquid slag tapping of the gasifier is ensured, and the phenomenon of slag blocking of the outlet is avoided.

Owner:EAST CHINA UNIV OF SCI & TECH

Bottom heater for pulling monocrystal

InactiveCN1200147CIncrease temperatureChange the heating methodBy pulling from meltDc currentEngineering

The present invention relates to a method of speeding melting of polycrystalline raw material and the bottom heater for pulling monocrystal. The method comprises leading DC current to bottom heater while leading DC current to the main heater, so that the quartz crucible is heated from both lateral side and bottom. The bottom heater comprises one disc heating body and two electrodes. The present invention can short the melting time of polycrystalline material and save electric power, and thus increase the yield of monocrystal silicon or germanium.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

A kind of oxygen-enhanced combustion method of coal powder mixed with sludge

ActiveCN108644788BRatio of calorific value increasedImprove stabilityIndirect carbon-dioxide mitigationAir/fuel supply for combustionSludgeHearth

The invention belongs to the technical field of boiler combustion and discloses a pulverized coal and sludge mixed oxygenation combustion method. The pulverized coal and sludge mixed oxygenation combustion method is characterized in that a sludge and pulverized coal mixture is taken as a fuel, pure oxygen is injected into a primary air pipeline and a secondary air pipeline to increase the concentration of oxygen in a hearth and to promote stable and sufficient combustion of the fuel in the hearth, an air separation device provides two paths of pure oxygen, one path of pure oxygen and air are mixed in the primary air pipeline to serve as primary oxygenation air to enter the hearth, and the other path of pure oxygen and air are mixed in the secondary air pipeline to serve as secondary oxygenation air to enter the hearth. The ratio of oxygen in the primary air and the secondary air is adjusted to increase the concentration of oxygen in the hearth, so that the combustion stability is improved, the distribution of temperature during combustion is changed, finally, generation of NOX is reduced, the calorific value ratios of sludge and pulverized coal are increased, the sludge disposal capacity is increased, the heat efficiency and the burn-off rate are increased, and emission of such pollutants as NOX and dioxin is effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

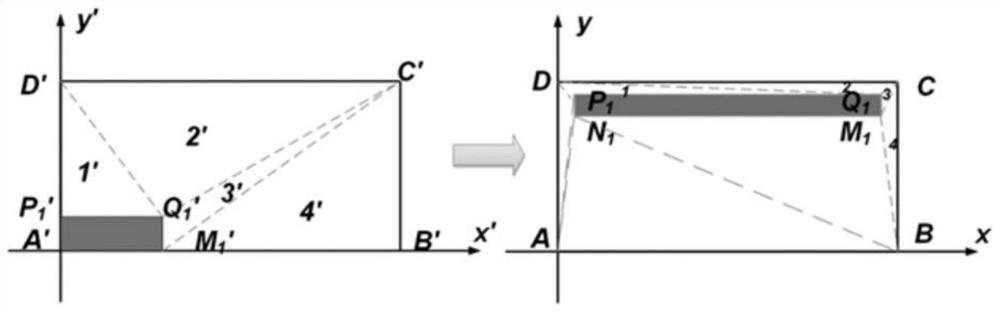

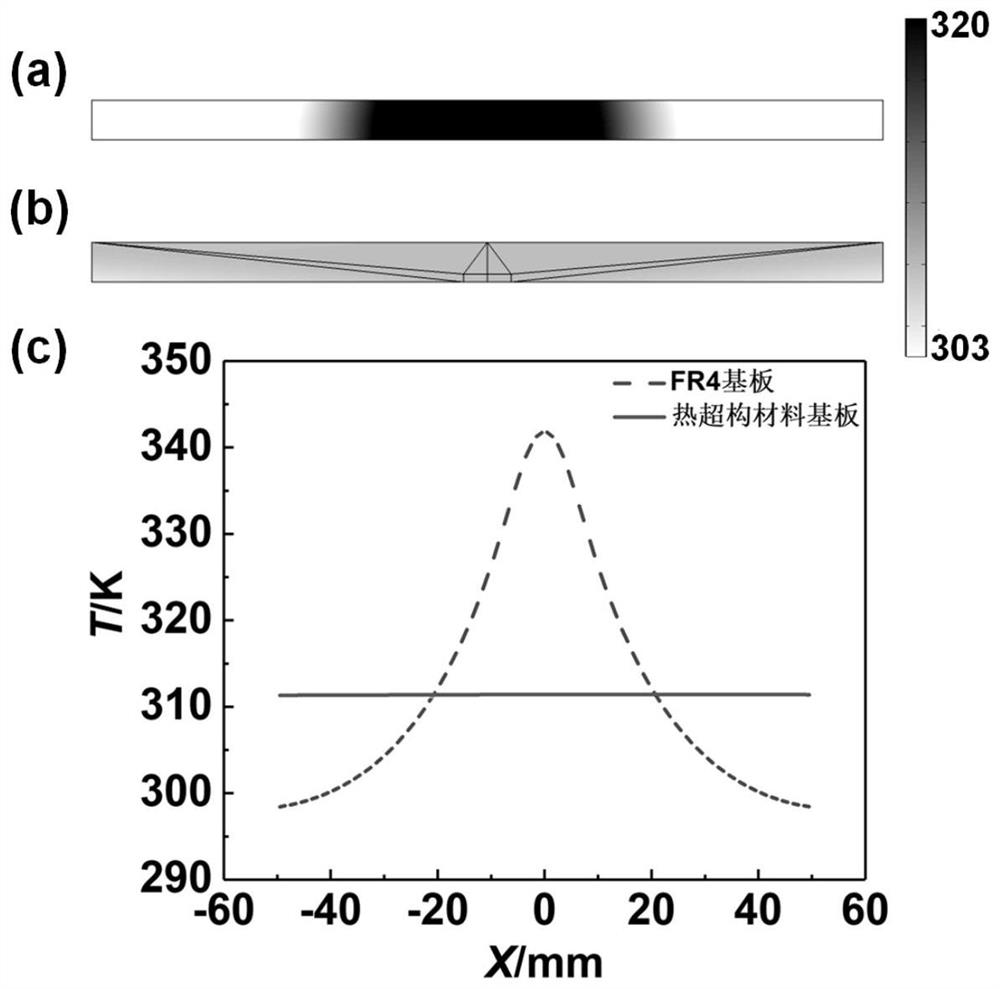

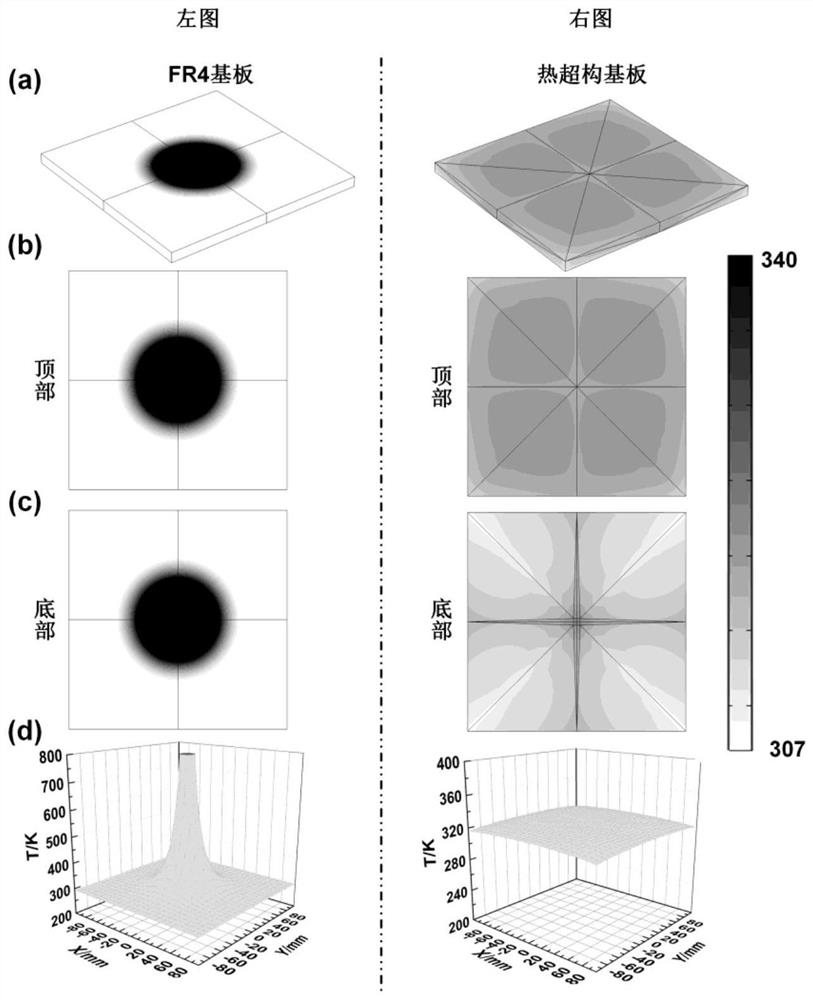

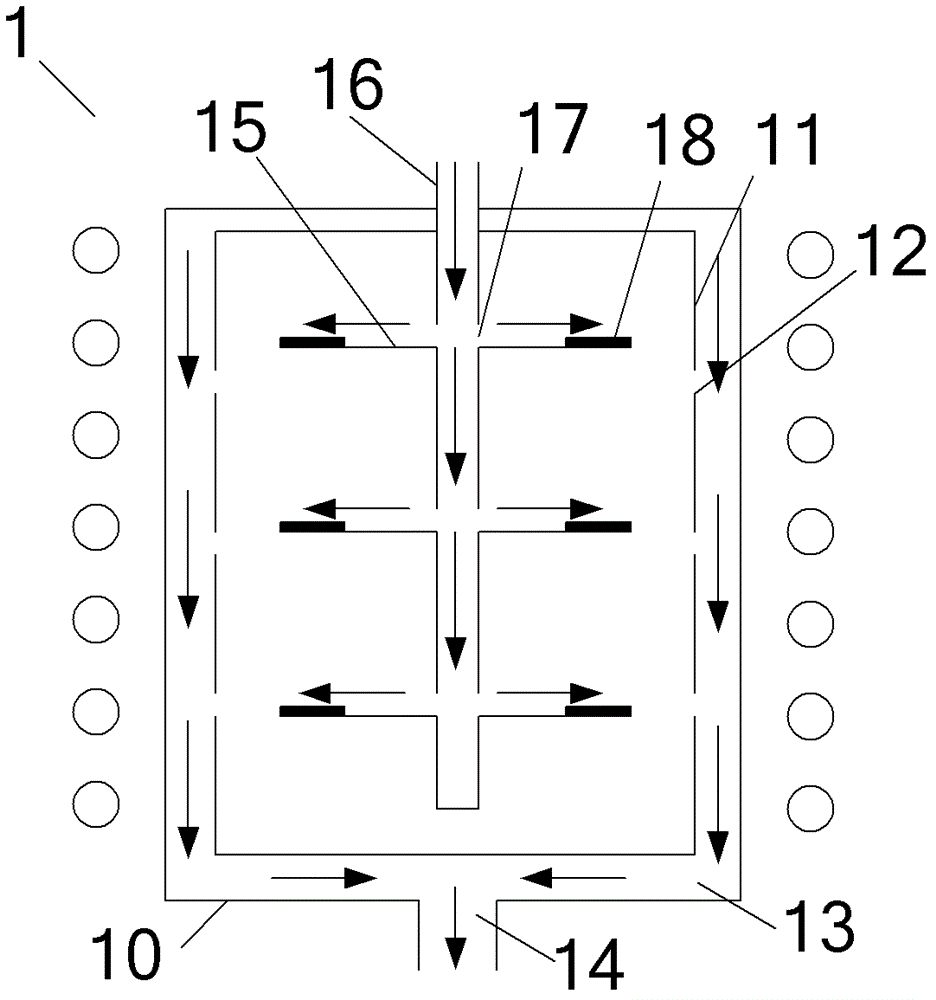

Regulation and control method for realizing metamaterial soaking substrate

PendingCN113191047AControlling thermal conduction propertiesChange the temperature distributionDesign optimisation/simulationSpecial data processing applicationsEngineeringMechanical engineering

The invention belongs to the technical field related to thermodynamics, and discloses a regulation and control method for realizing a metamaterial soaking substrate. The regulation and control method comprises the following steps: S1, setting a thermal conductivity coefficient of a homogeneous substrate and the position and size of a phantom heat source on the substrate; S2, dividing the positions of non-heat sources in the homogeneous substrate and the soaking substrate to be solved into a plurality of areas, wherein the areas are in one-to-one correspondence; constructing a coordinate transformation relation between the homogeneous substrate and the soaking substrate to be solved so as to obtain a transformation matrix between the homogeneous substrate and the soaking substrate to be solved; and S3, constructing a thermal conductivity coefficient relational expression of the conversion matrix and each region on the soaking substrate to be solved, calculating the thermal conductivity coefficient of each region on the soaking substrate to be solved, and selecting a material corresponding to each region on the soaking substrate to be solved according to the thermal conductivity coefficient, so as to realize regulation and control of thermal conduction of the soaking substrate to be solved. According to the invention, the temperature distribution of the substrate is changed, the effect of uniform temperature at the top of the substrate is realized, and the function of a vapor chamber is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

A reaction chamber and plasma processing equipment using the reaction chamber

ActiveCN103160813BAdjust heat loss rateChange the temperature distributionChemical vapor deposition coatingEngineeringPlasma processing

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A kind of electromagnetic-assisted arc additive manufacturing forming device and method

ActiveCN110802304BEfficient preparationImprove product qualityElectrode holder supportersUsing optical meansMeasuring instrumentLaser scanning

The invention belongs to the field of metal additive manufacturing, and specifically discloses an electromagnetic-assisted arc additive manufacturing forming device and method, which includes a substrate, an arc welding torch, an electromagnetic coil, a line laser scanner, and a magnetic field measuring instrument. The arc welding torch and The electromagnetic coil is located above the substrate, the arc torch is used to weld and form the part to be formed on the substrate, and the electromagnetic coil is used to apply a magnetic field at the weld pool of the part to be formed; the line laser scanner is located on the Above the part to be formed, it is used to detect the surface topography of the weld bead; the magnetic field measuring instrument is located between the electromagnetic coil and the part to be formed, and is connected with the electromagnetic coil, for measuring and controlling the electromagnetic The strength of the magnetic field applied by the coil to the weld pool of the weld bead. The invention supports the molten pool of the weld bead through the electromagnetic induction force during arc additive manufacturing, prevents the flow of the weld bead, reduces the residual stress of the welded joint, and improves the mechanical properties of the formed parts.

Owner:HUAZHONG UNIV OF SCI & TECH

Tube furnace with adjustable heat distribution ratio

ActiveCN111365992BChange distributionChange the temperature distributionCombustion using gaseous and pulverulent fuelFuel supply regulationThermodynamicsCombustion

Owner:武汉能望科技有限公司

Method and device for controlling strip shape and precision of hot rolling steel strips and plates

InactiveCN101780478BHigh thickness accuracyChange the temperature distributionWork cooling devicesWork heating devicesNonferrous metalEngineering

The invention belongs to hot rolling equipment and a hot rolling method, and particularly relates to a method and a device for controlling the strip shape and the precision of hot rolling steel strips and plates. The invention regulates the deformation capacity of the metal by changing the temperature distribution in the width direction of rolled pieces so as to reach ideal strip shape control, i.e. an aerial fog cooling medium is accurately sprayed on the rolled pieces to change the temperature distribution in the width direction of the rolled pieces; the cooling parameters for spraying along the width of the rolled pieces are regulated according to the set and feedback information to realize the open-loop or closed-loop strip shape control; aerial fog cooling devices are arranged in front of and at the back of a reversing mill; and the aerial fog cooling devices in front of rolling mills and among the standers of the rolling mills in series-type hot steel strip rolled pieces and simultaneously spray the aerial fog on the upper and lower surfaces of the rolled pieces. The invention has simple structure and strong applicability, can be used for the strip shape control of the newly-built hot rolling mill or be used for carrying out improvement of the strip shape control on the rolling mill, is also suitable to roll the hot rolling steel strips and plates of the nonferrous metals and has wide popularization value.

Owner:CISDI ENG CO LTD

Burner for furnace and heating furnace

InactiveCN111059534AImprove throughputSmall fluxFurnace componentsGaseous fuel burnerThermodynamicsCombustor

The invention discloses a burner for a furnace and a heating furnace. The burner for the furnace is in communication with a combustion chamber of the heating furnace, the burner for the furnace comprises a first channel, a first air duct and a second air duct, wherein the first outlet of the first channel is in communication with the combustion chamber and is used for providing first gas into thecombustion chamber, the first air duct outlet of the first air duct is arranged towards the first outlet and is used for providing second gas which is intersected with the spraying direction of the first gas into the combustion chamber; the second air duct outlet of the second air duct is arranged in parallel with the first outlet and is used for providing the second gas parallel to the spraying direction of the first gas into the combustion chamber, wherein one of the first gas and the second gas is fuel gas, and the other of the first gas and the second gas is combustion-supporting gas. According to the burner for the furnace, the flux of the second gas of the first air duct and the second air duct can be changed according to the condition that the actual heat load of a material deviatesfrom the designed heat load, and therefore, the flame height-to-diameter ratio of the flame sprayed by the burner for the furnace is changed so as to meet the optimal heating requirement of the material.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

Width adjustable and temperature controllable transverse magnetic flux induction heating apparatus

InactiveCN100488324CUniform temperatureUniform and fine distributionCoil arrangementsFurnace typesTransverse magneticMagnetic flux

Present invention relates to a width adjustable and temperature controllable transverse direction magnetic flux induction heating apparatus. It contains belt material, fixed coil, mobile loop, yoke iron, guide way, travel mechanism, tank shape structure, fixed structure, and supporting rack, wherein fixed coil parallel to belt material surface, fixed coil long edge perpendicular to belt material direction of motion, removable loop parallel to belt material surface and located fixed coil outside it long edge parallel to belt material direction of motion mobile fixation to supporting rack, interior fixing several groove shape structure, yoke iron inserted in groove and fixed by fixing structure, each traveling loop can sliding in two ends guide way, supporting rack. Present invention is width and temperature controllable, can adapt belt material width variation in larger range and get more uniform temperature distribution, greatly raise production efficiency and save cost.

Owner:HEBEI UNIV OF TECH

A water-cooled strut and its processing method

ActiveCN112229598BGood effectMuch design freedomAdditive manufacturing apparatusAerodynamic testingThermodynamicsMechanics

The invention discloses a water-cooled support rod and a processing method thereof. The connected water-cooled jacket and the support rod respectively have a first water channel and a sixth water channel which are not connected to each other and are arranged between the water-cooled jacket and the surface of the support rod along the axial direction. The water channels are arranged in the water cooling jacket parallel to the second water channel, the third water channel, the fourth water channel and the fifth water channel, and all the water channels are mutually independent structures, which are connected in turn to form a complete water channel structure; Method and 3D printing technology combined processing method to design and process fully water-cooled struts, improve water-cooling efficiency, reduce strut temperature gradient, suppress strut deformation caused by temperature changes in wind tunnel tests, and improve the accuracy of hypersonic wind tunnel force testing .

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Polishing pad and polishing method

ActiveUS10518386B2Reduce temperature gradientImprove applicabilityPolishing machinesAbrasion apparatusEngineeringSlurry

A polishing pad is provided. The polishing pad, suitable for a polishing procedure using a slurry containing water, includes a polishing track region and a first reactant. The polishing track region includes a central region and a peripheral region surrounding the central region. The first reactant is disposed in the central region of the polishing track region, wherein the first reactant is able to react endothermically with the water in the slurry.

Owner:IV TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com