Gypsum-mold vacuum pouring pressurized solidification casting method and device

A technology of vacuum casting and gypsum molding, which is applied to casting molding equipment, casting molds, cores, etc., which can solve the problems of shape and position restrictions, slow cooling of gypsum molding, and poor cooling effect, so as to improve the yield of finished products and facilitate replenishment Shrink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A gypsum type vacuum pouring pressurized solidification casting method, specifically comprising the following steps:

[0040] 1) Make casting wax molds, gating system wax molds, and airway wax molds according to the shape and size of the casting; control the final cooling rate by setting the distance between the airway and the casting wax mold and the size of the cross-sectional area.

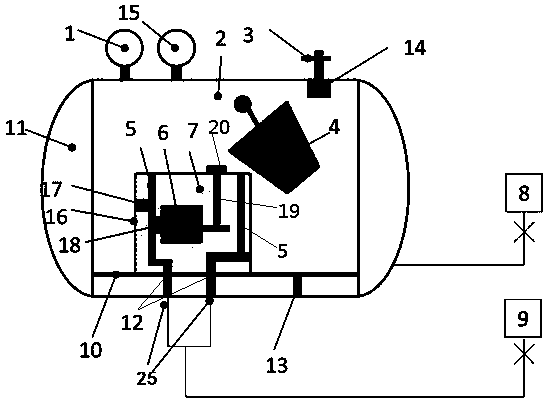

[0041]2) Set the sprue and air vent 12 on the casing 16, assemble the casting wax mold and the airway wax mold, and use the second connecting block 18 to fix the casting wax mold and the airway wax mold, and the casting wax mold One side is bonded to the sprue port of the sleeve box 16 through the wax mold of the gating system; the end of the airway wax mold is bonded to the vent 12 of the sleeve box 16, and the side wall of the airway wax mold and the sleeve box 16 adopts the first connection Block 17 bonding;

[0042] The pouring port is arranged on the top of the casing, and the vent...

example 2

[0055] (1) According to the shape and size of the casting to be cast, make casting wax molds, pouring system wax molds, and airway wax molds, and place them in the casing. The location is installed correctly;

[0056] (2) Put the casing 16, the airway wax mold and the casting wax mold into the vacuum tank, and pour the gypsum slurry;

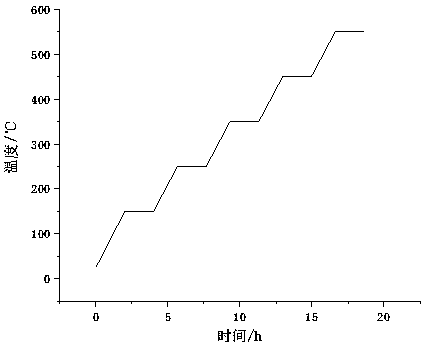

[0057] (3) After the poured gypsum mold is placed for 12 hours to be finalized, it is placed in a roasting furnace for dewaxing and roasting. The roasting process is as follows: figure 2 shown;

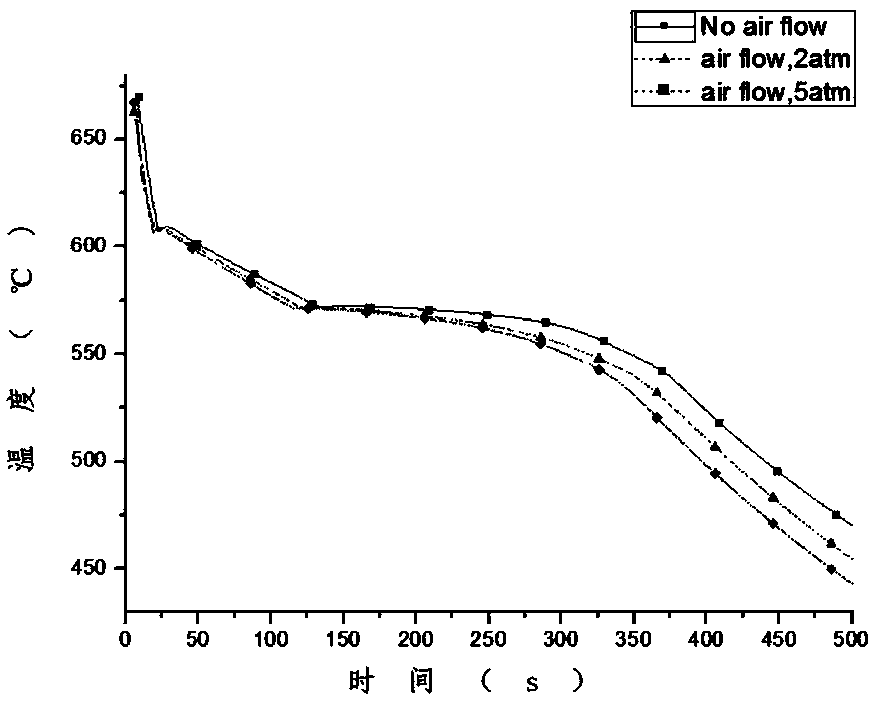

[0058] (4) After roasting, when the gypsum mold is cooled to 200-300°C, push the gypsum mold into the pressure tank, align the air passage in the gypsum mold with the pressurized air inlet, and fix the casing 16 to the bottom plate 10;

[0059] (5) Fill the ladle 4 with molten metal and hang it at the pouring position;

[0060] (6) Close the pressure tank door 11 and lock it;

[0061] (7) Open the valve 8 of the vacuum tank to reduce the pressure i...

example 3

[0065] (1) Bond the airway wax mold to the casting wax mold, and use cold iron and heat-resistant ceramic blocks at the joint to prevent the air from entering the mold cavity when the air is pressurized, and then the casting wax mold, the casting system wax mold, etc. Put the wax model in the casing, and ensure that the position of the vent is installed correctly;

[0066] (2) Put the casing 16, the airway wax mold and the casting wax mold into the vacuum tank, and pour the gypsum slurry;

[0067] (3) After the cast gypsum mold is placed for 24 hours, it is put into a roasting furnace for dewaxing and roasting, and the roasting process is selected according to the gypsum mold casting process manual;

[0068] (4) When the temperature of the gypsum mold after roasting is 200-300°C, push the gypsum mold into the vacuum tank, align the air channel in the gypsum mold with the pressurized air inlet, and fix the casing 16 and the bottom plate 10;

[0069] (5) Fill the ladle 4 with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com