Resistance heating body for adjusting temperature distribution inside high-temperature and high-pressure synthesis cavity body

A high-temperature and high-pressure synthesis and internal temperature technology, which is applied in the process of applying ultra-high pressure, and can solve the problems of high pressure, unreasonable pressure and temperature distribution, and low pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

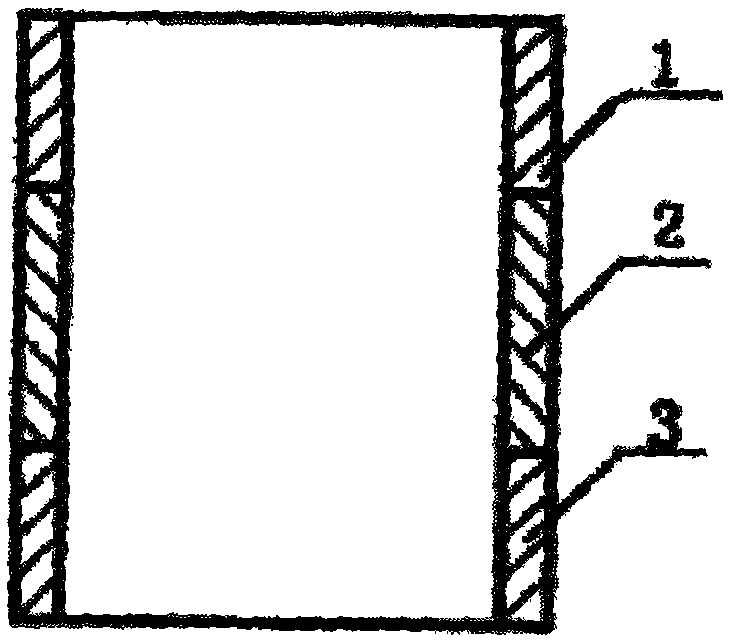

[0010] As shown in the figure: the present invention includes a heating body cylinder, which in simplified form is at least composed of upper and lower heating bodies 1, 2, and 3 with different resistivities, and the resistivity of the standby heating body gradually increases from the center to both ends. The resistance heating body used is shown in the figure. The commonly used heating body 1, 2, 3 and other parts are changed to the same structure of the same material, and the cylindrical heating body is divided into three or more heating parts along the axial direction. Part 1.3 of the heating body is a material with a relatively high resistivity. Depending on the specific application, parts 1 and 3 of the heating body can be symmetrically designed with the same material. Generally, graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com