Electromagnetic assisted electric arc additive manufacturing and forming device and method

A technology of additive manufacturing and electric arc, which is applied in the direction of electrode support device, device for supporting electrode clamp, manufacturing tools, etc. It can solve the difficulty of controlling edge shape and forming accuracy, serious heat accumulation of stacked parts, and difficult shape of cladding layer, etc. Problems, to achieve the effect of heat dissipation in the molten pool, grain refinement of the weld structure, and reduction of weld bead flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

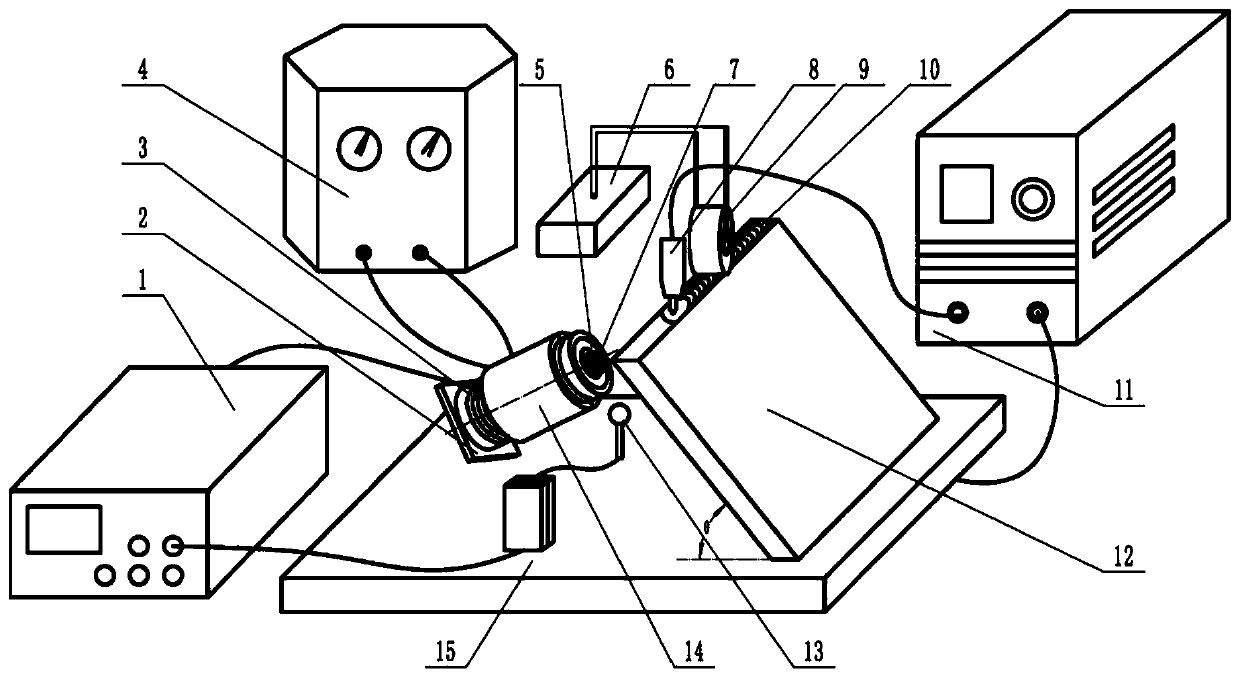

[0043] The manufacture of formed aluminum alloy inclined wall parts includes the following steps:

[0044] S1 Place the 5083 aluminum alloy plate substrate on the CNC machine tool work platform, use the clamping device to clamp the 5083 aluminum alloy substrate, adjust the welding process parameters, the discharge electrode of the arc welding torch 8 is perpendicular to the substrate 15, and keep a certain distance between them; adjust the electromagnetic The angle and distance between the coil and the part 12, the distance between the upper surface of the electromagnetic coil and the side of the part 12, set the electromagnetic frequency and magnetic field strength, and set the rolling pressure of the roll; the protective gas is 99.999% argon, and the protective gas flow rate is 25L / min;

[0045] S2 arc welding torch 8 melts the aluminum alloy wire to form a weld bead, and moves along the gap path to weld the gap to be welded on the 5083 aluminum alloy plate at a welding spe...

Embodiment 2

[0048] Manufacturing the inclined wall part of the formed stainless steel 316L inclined wall part comprises the following steps:

[0049] S1 Place the stainless steel 316L substrate on the CNC machine tool work platform, use the clamping device to clamp the stainless steel 316L substrate, adjust the welding process parameters, the discharge electrode of the arc welding torch 8 is perpendicular to the substrate 15, and keep a certain distance between them; adjust the electromagnetic coil and the parts The angle and distance of 12, the upper surface of the electromagnetic coil is a certain distance from the side of the part 12, the electromagnetic frequency and magnetic field strength are set, and the rolling pressure of the roll is set; the shielding gas is 5% CO2+95% argon, and the shielding gas flow rate is 20L / min.

[0050] S2 arc welding torch 8 melts the stainless steel wire to form a weld bead, moves along the gap path to weld the gap to be welded on the stainless steel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com