Coal underground gasification on-way sampling simulation experiment system and method

A technology of underground gasification and simulation experiments, applied in coal gasification, underground mining, earth drilling and mining, etc., can solve the problem of low calorific value of synthesis gas, achieve the effects of reducing pollution, optimizing gas production, and changing temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

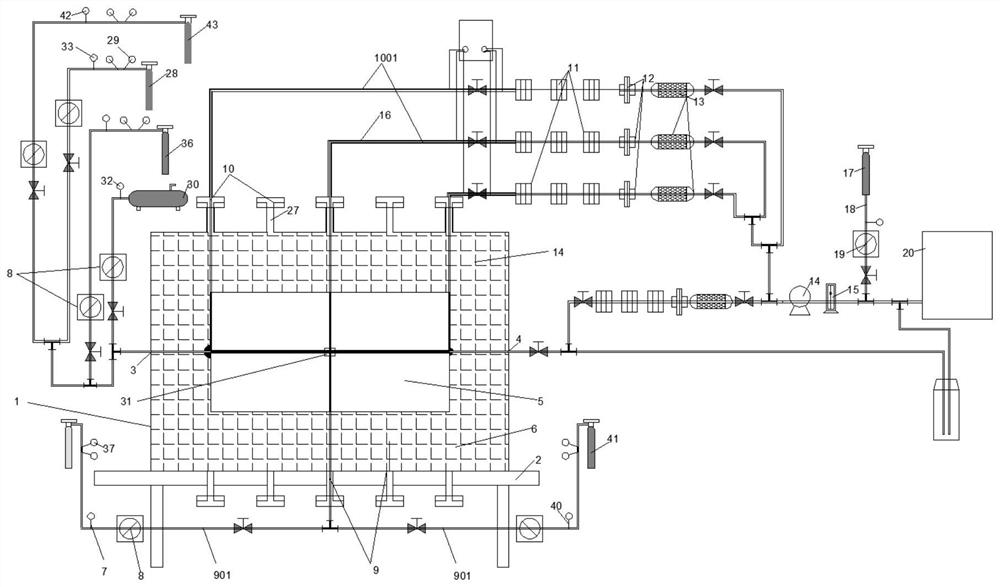

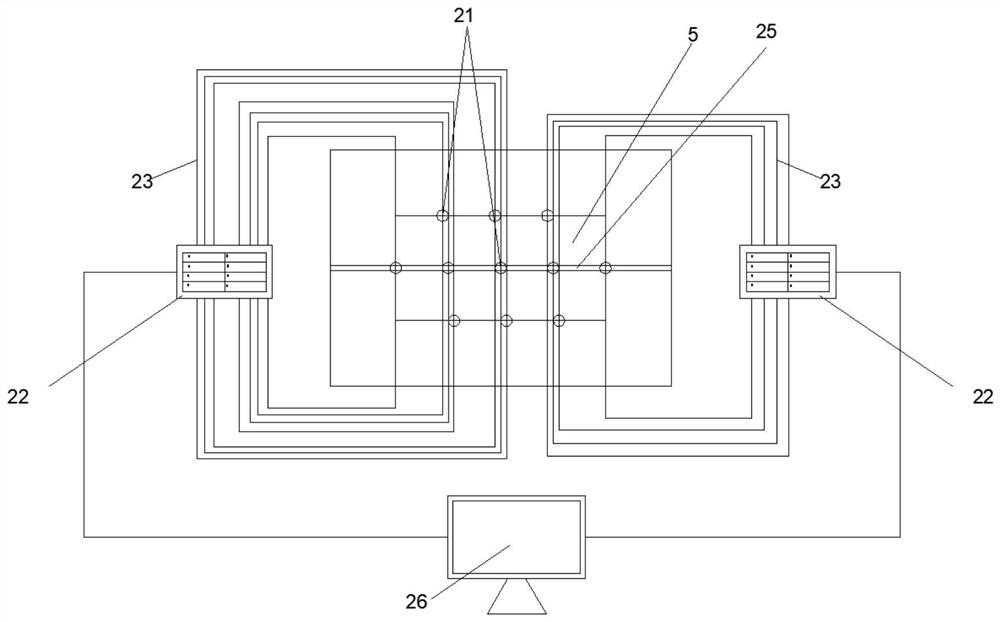

[0039] refer to Figure 1-5 , the present invention provides a technical solution, a simulated experimental system for sampling along the underground coal gasification process, including a gas supply device, a gasifier body, a sampling device along the process, and an analysis and testing device;

[0040]The main body of the gasifier includes a box body 1, the size of which is 746mm x 516mm x 519mm. The box body 1 can be placed on a support frame. The coal sample 5 is arranged in the box body 1, and the gasification channel 25 is arranged inside the coal sample 5. , the upper end of the box body 1 is evenly provided with five air outlet holes 10 along the process, the left and right ends of the box body 1 are respectively provided with an air inlet 3 and an air outlet 4, and the two ends of the gasification channel 25 are connected with the air inlet 3 and the air outlet respectively. The gas port 4 is connected, and the gas supply device is connected to the gas inlet 3 throug...

Embodiment 2

[0051] refer to Figure 1-5 , the present invention provides a kind of technical scheme, on the basis of embodiment 1, a kind of underground coal gasification sampling simulation experiment method along the process, adopts a kind of underground coal gasification sampling simulation experiment system along the process of embodiment 1, comprises the following step,

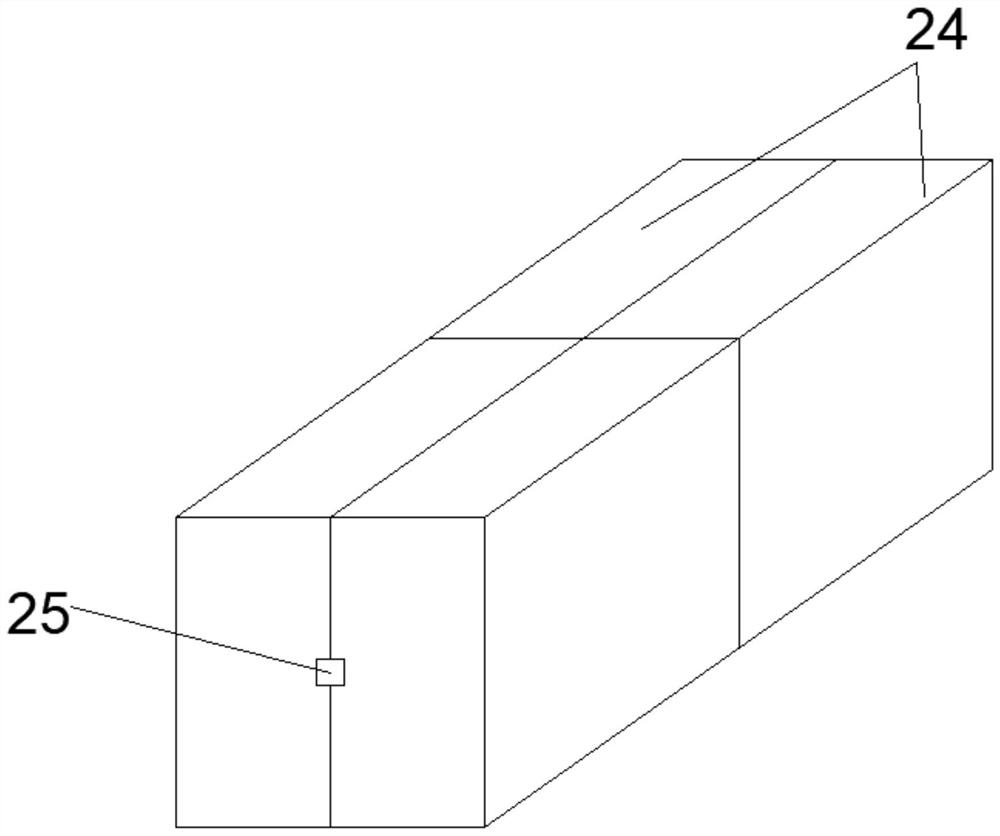

[0052] Step 1: Arrange the coal blocks 24 with grooves inside the box body 1, and the combined grooves of the coal blocks 24 after splicing form the gasification channel 25, and set the ignition device 31 inside the gasification channel 25, and the ignition device 31 is activated by electric Combination of firearms, alcohol cotton, and pulverized coal combustibles, four pieces of coal 24 with a size of 230mm x 115mm x 230mm are arranged inside the cavity of the gasifier, and the final size is 460mm x 230mm × 230mm, the coal block 24 is Shenmu bituminous coal, and the grooves processed in advance are spliced into ...

Embodiment 3

[0063] On the basis of Example 2, in step 5, during the gasification experiment, open the second pure oxygen cylinder 41 and the second carbon dioxide cylinder 37, and adjust the fourth secondary decompression valve 7 and the third decompression The valve 40 is used to control the flow ratio of carbon dioxide and oxygen injected into the gasifier body through the gas injection pipe 901 along the process, so as to prevent insufficient gasification at a position far from the air inlet 3 and increase the composition of effective gas production; The air holes 9 are arranged between the air inlet 3 and the air outlet 4, so as to improve the gasification reaction efficiency and degree at different positions in the gasification channel 25. By controlling the amount of additional gasification agents such as oxygen and carbon dioxide, To control the degree of reaction in the gasification channel 25, the overall temperature can be increased, especially in the middle and rear sections, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com