Reaction chamber and plasma processing equipment applying the same

A technology of reaction chamber and chamber, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of inability to adjust temperature and poor adjustability of process parameters, and achieve the effect of improving adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

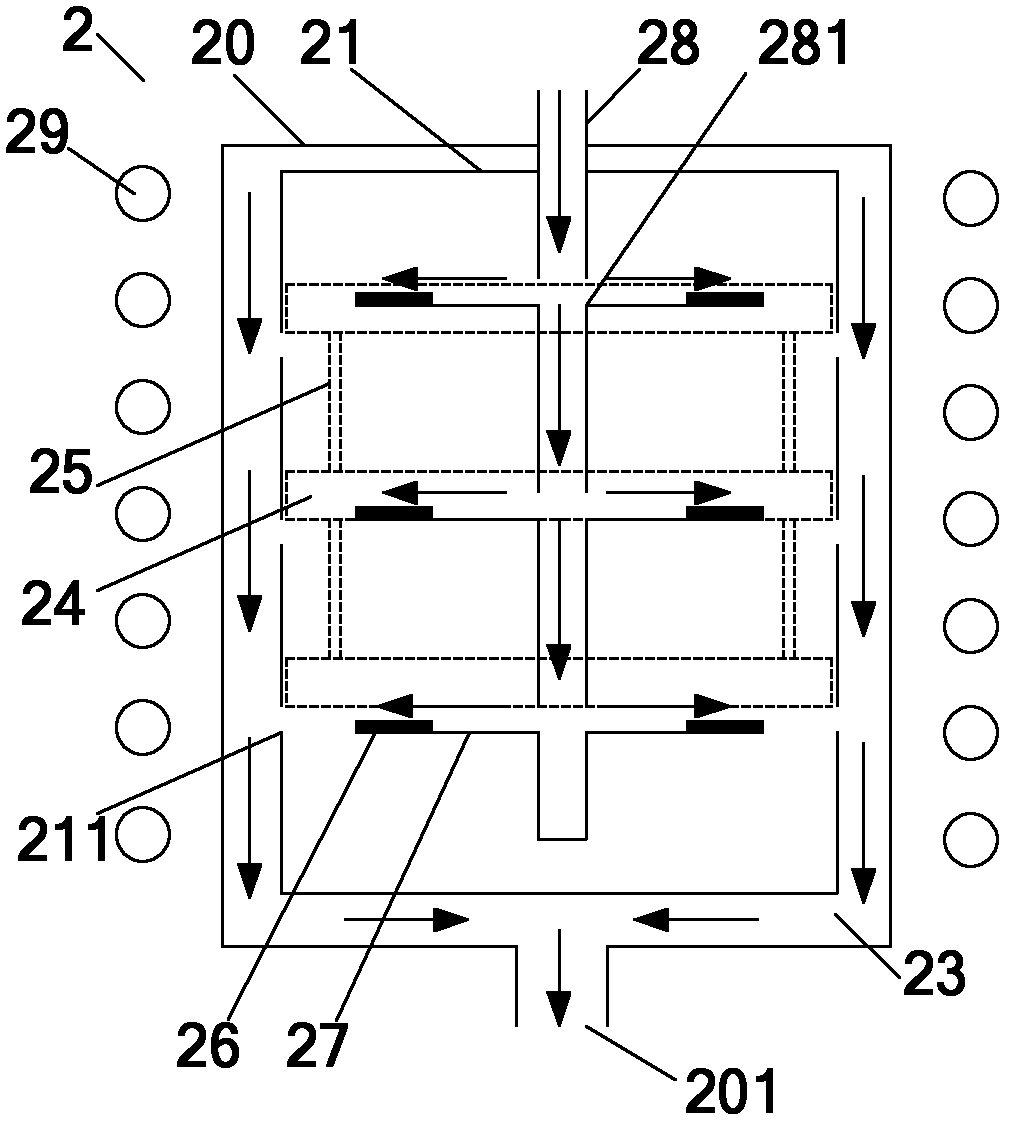

[0029] Figure 2a A schematic diagram of the structure of the reaction chamber provided by the present invention. see Figure 2a , the reaction chamber 2 includes an outer chamber 20 and an inner chamber 21 of a cylindrical structure and a gas delivery pipe 28, wherein an induction coil 29 is arranged on the outside of the outer chamber 20, and it is connected to an AC power supply (not shown in the figure) ) connection for heating the inside of the outer chamber 20; the inner chamber 21 is arranged in the outer chamber 20, thereby forming a gas channel 23 for gas flow between the inner chamber 21 and the outer chamber 20, and the gas The channel 23 communicates with the exhaust channel 201 arranged at the bottom of the outer chamber 20, so that the gas in the gas channel 23 can be gathered to the exhaust channel 201 to be discharged; Three rows of exhaust ports 211 are arranged in the axial direction, and each row of exhaust ports 211 is evenly distributed in the circumfere...

Embodiment 2

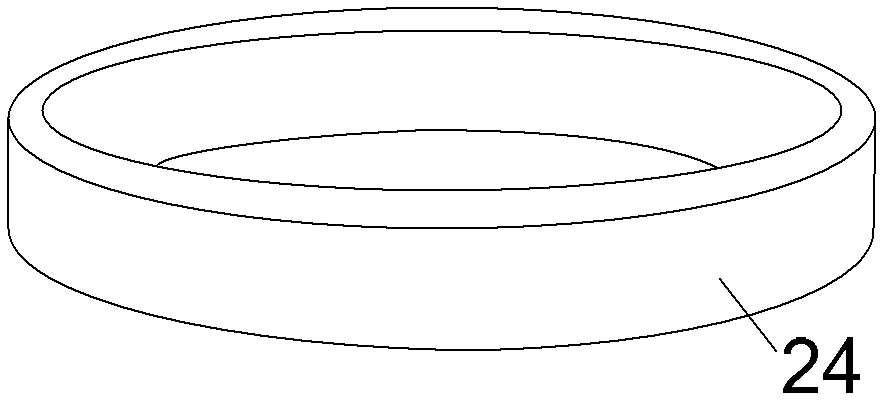

[0041] Figure 3a It is a schematic diagram of the shielding plate according to the second embodiment of the present invention. see Figure 3a , in this embodiment, the baffle plate 24 is a ring that is close to the wall of the cylindrical inner chamber 21 and is provided with a through hole 241 having the same size as the exhaust port 211 . The driving device is a rotary motor for driving the shielding plate 24 to rotate around the axis of the inner chamber 21 . When in use, the shielding plate 24 rotates clockwise or counterclockwise under the drive of the rotating motor. When the through hole 241 is completely overlapped with the exhaust port 211, the exhaust port 211 is the largest. At this time, the inner chamber 21 emits the most heat from the exhaust port 211, so that the heat loss rate of the reaction chamber 2 is the largest; In the process of interlacing the through holes 241 and the exhaust ports 211, the overlapping degree of the through holes 241 and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com