Width adjustable and temperature controllable transverse magnetic flux induction heating apparatus

A technology of induction heating device and transverse magnetic flux, applied in the direction of induction heating device, induction heating, coil device, etc., can solve the problem of not significantly improving the uniformity of temperature distribution at the edge of the strip, overheating of the edge of the strip, and unsatisfactory effects, etc. problems, to achieve flexible temperature distribution, improve production efficiency, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

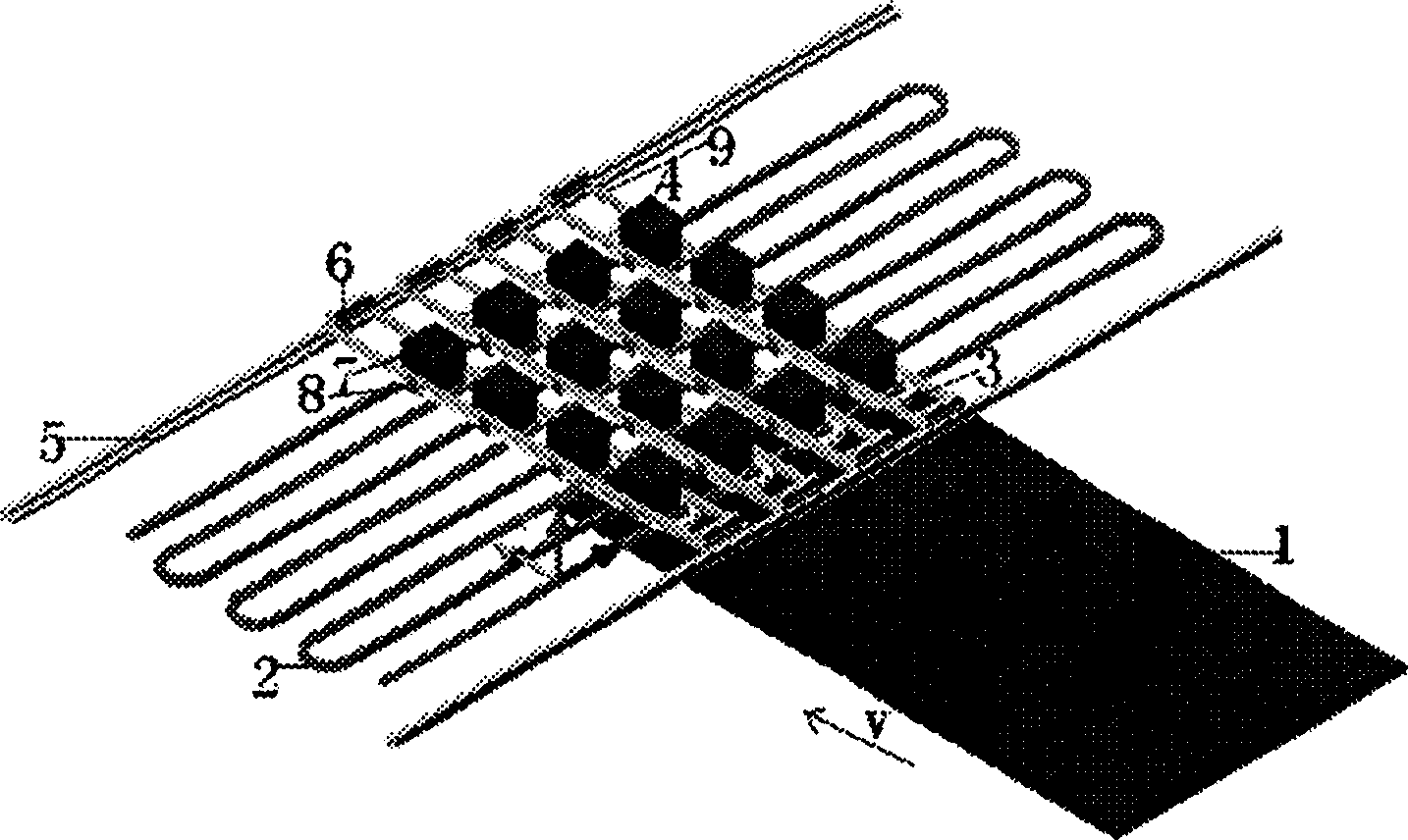

[0030] Such as figure 2 As shown, 1-strip, 2-fixed coil, 3-moving coil, 4-yoke block, 5-guide rail, 6-moving mechanism, 7-groove structure, 8-fixed structure, 9-support frame;

[0031] Yoke block: It is made of special silicon steel sheets with a thickness of 0.2 mm. In order to reduce eddy current loss, the surface of the silicon steel sheets is perpendicular to the workpiece. The basic shape of the yoke is a cuboid, which just fits through the slot when installed. The bottom surface of the yoke block is in the same plane as the bottom surface of the fixed coil. In order to determine its position in the slot, there is a structure similar to a clip on its upper surface, and the yoke block is clamped on the supporting frame. There are screw holes on the yoke block for easy fixing.

[0032] Groove: The groove is fixed on the supporting frame, and its basic shape is similar to that of the yoke iron block. There is a spring leaf structure inside it, and there are screw holes in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com