Press-molding apparatus

A pressure molding and equipment technology, applied in glass molding, glass manufacturing equipment, glass pressing, etc., can solve problems such as increased cost, difficulty in precise temperature control, poor thermal efficiency, etc., to prolong life, reduce cost, and reduce frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

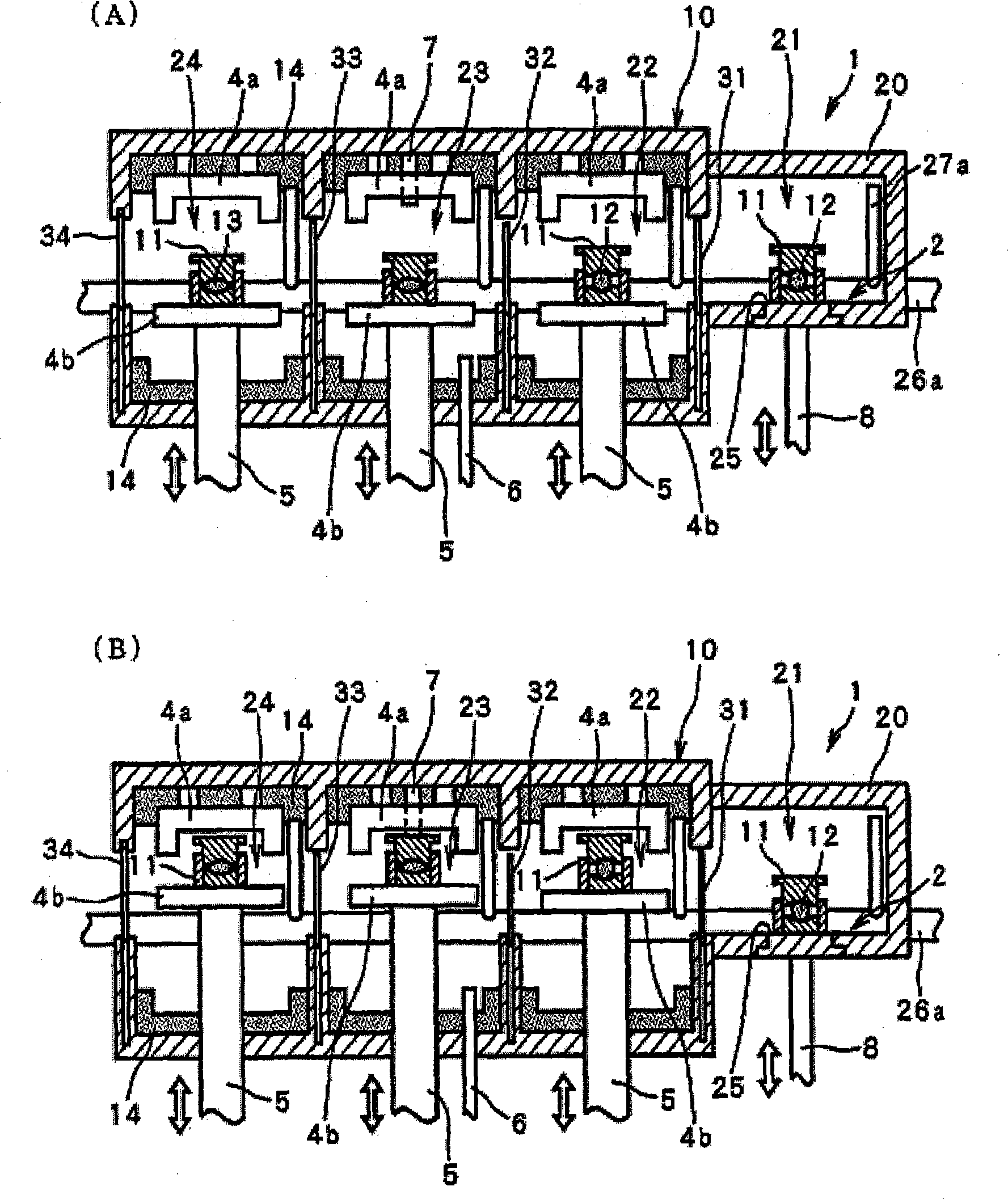

[0068] figure 1 A vertical sectional view showing an embodiment of the present invention. figure 1 (A) indicates the position of the mold during the mold delivery process, figure 1 (B) shows the position of the mold when the steps are carried out.

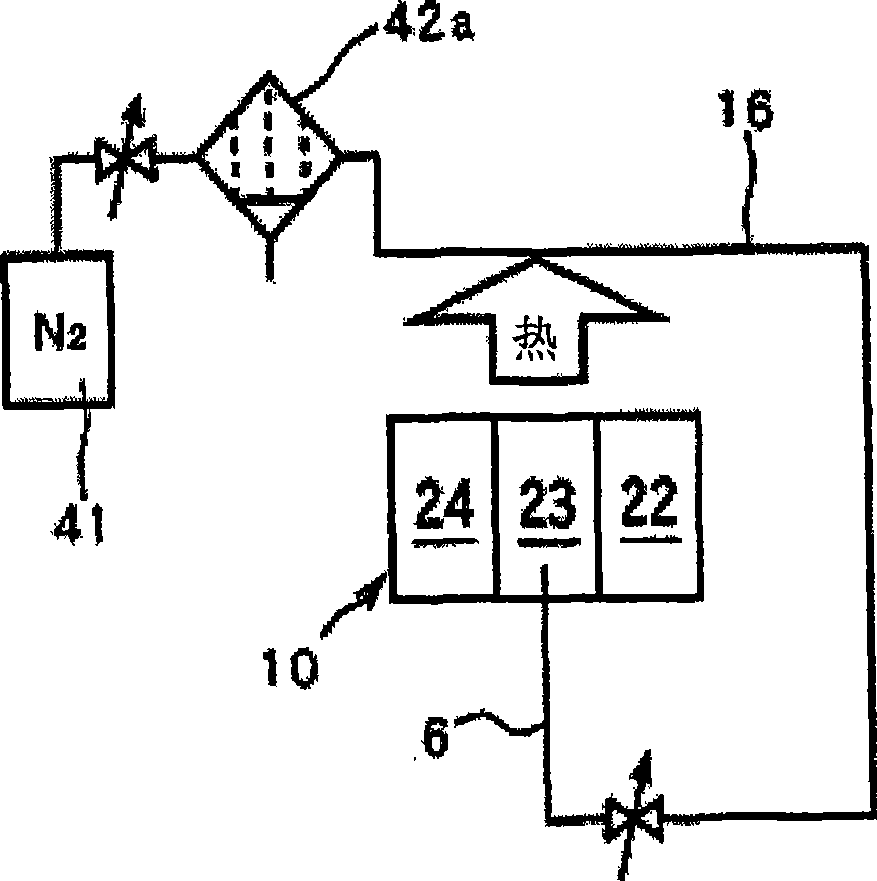

[0069] The molding apparatus 1 has a conveying channel 2 arranged in a chamber 10 for maintaining a non-oxidizing atmosphere, for example a nitrogen protective atmosphere, and in the figure a mold 11 is conveyed through the conveying channel from right to left 2. The preparation chamber 21 , the heating chamber 22 , the molding chamber 23 , and the cooling chamber 24 are arranged on a straight line along the conveying passage 2 in this order from the right in the drawing.

[0070] Each chamber has a shutter 31 , 32 or 33 at its border with an adjacent chamber, and a shutter 34 serving as an exit from the chamber 10 is provided behind (left side) the cooling chamber 24 . The shutters 31, 32, 33, and 34 are vertically moved an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com