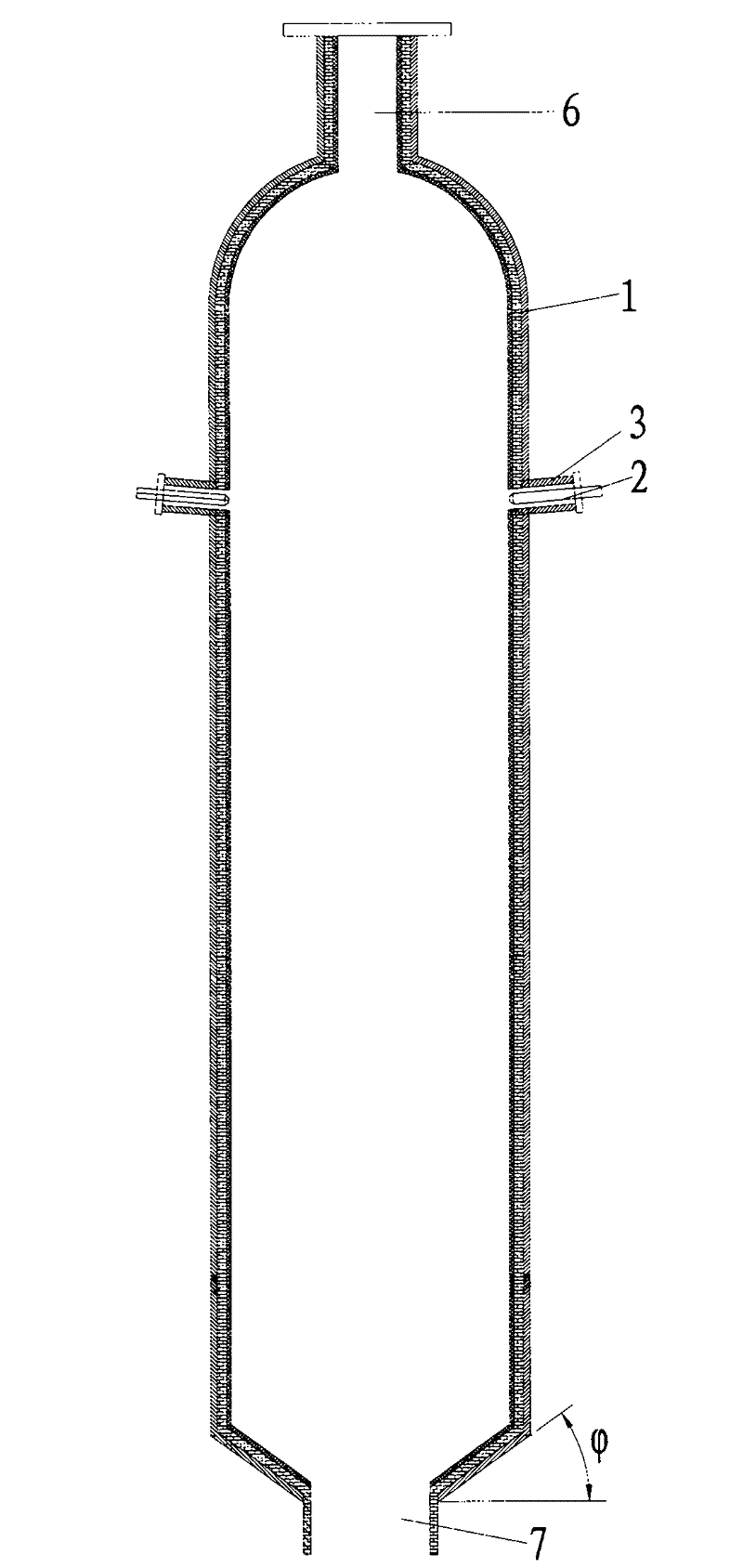

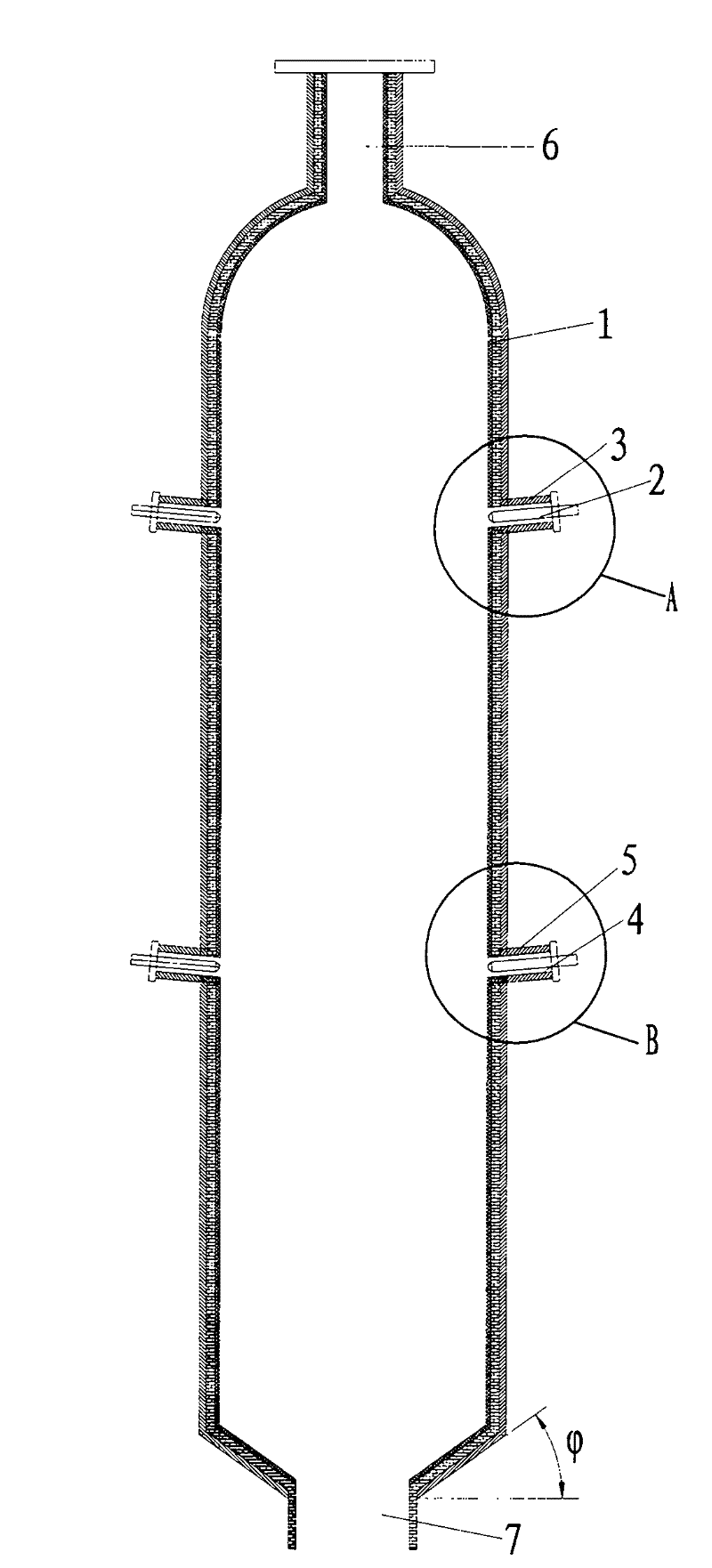

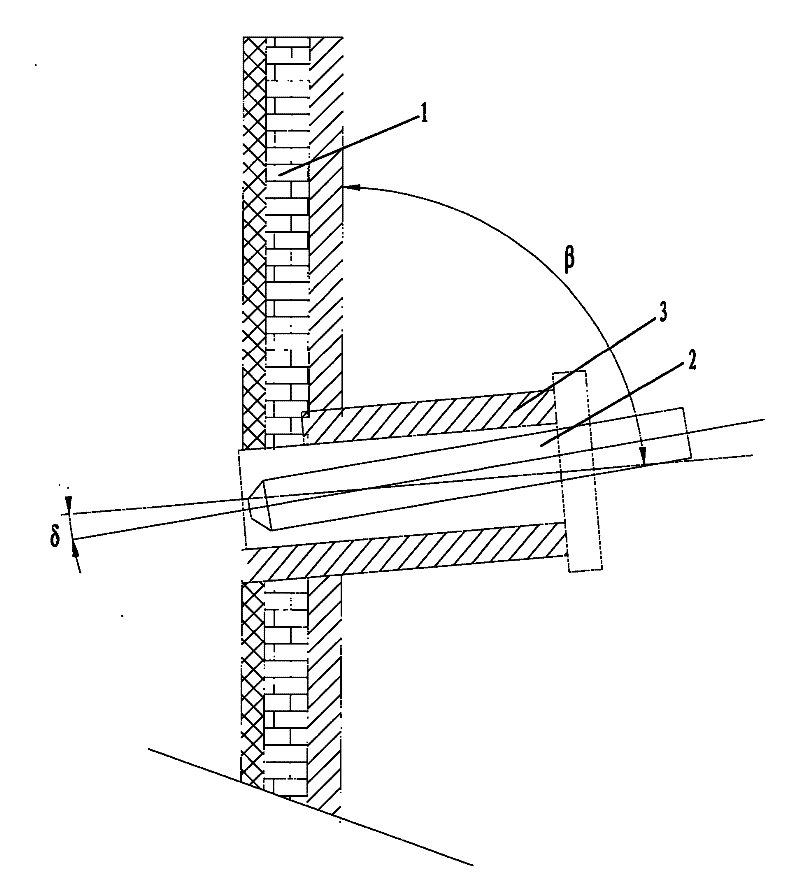

Multi-nozzle multi-stage oxygen supplying entrained-flow gasifier and gasification method thereof

A gasifier and oxygen flow technology, which is applied to the multi-nozzle graded oxygen flow bed gasifier and its gasification field, can solve the problems of unreasonable temperature distribution and short life of the refractory lining in local areas of the wall, and achieve good process and Engineering effect, life extension, effect of high gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This example illustrates the results obtained from the gasification test using the multi-nozzle staged oxygen fluidized bed gasifier of the present invention.

[0065] A coal-water slurry gasifier with a daily processing capacity of 3,000 tons of coal has a gasification pressure of 6.5MPa, a refractory brick wall, 4 process nozzles, and 4 secondary oxygen supply nozzles. Among them, the key dimensions in the gasifier are shown in Table 1 below:

[0066] Table 1. Key dimensions in the gasifier

[0067]

[0068] Wherein, the oxidizing agent is pure oxygen, and the amount of oxidizing agent for secondary oxygen supply accounts for 5%. The liquid slag discharge temperature is 1350°C, the coal slurry concentration is 65%, and the coal quality analysis data are shown in Table 2 to Table 5 below:

[0069] Table 2. Industrial Analysis Table

[0070] parameters

value

2.5% (wt)

57.88% (...

Embodiment 2

[0078] This example illustrates the results obtained from the gasification test using the multi-nozzle staged oxygen fluidized bed gasifier of the present invention.

[0079] A pulverized coal gasifier with a daily processing capacity of 3,000 tons of coal has a gasification pressure of 4.0 MPa, a water-cooled wall structure, 4 process nozzles, and 4 secondary oxygen supply nozzles. Among them, the key dimensions in the gasifier are shown in Table 6 below:

[0080] Table 6. Key dimensions in the gasifier

[0081]

[0082]

[0083] Among them, the gasification agent is pure oxygen, and the amount of oxidant for secondary oxygen supply accounts for 7%. The coal used is coal with high ash melting point (additional limestone fluxing agent), and the liquid slag discharge temperature is 1450°C. The coal quality analysis data are shown in Table 7 ~ as shown in Table 10:

[0084] Table 7. Industrial Analysis Table

[0085] parameters

value

Air-dry basis mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com