Multistage graphite heating system of sapphire crystal growth equipment and using method of multistage graphite heating system

A sapphire crystal and graphite heating technology, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of growing large-sized sapphire crystals, shortening the service life of heaters, and high production costs. Uniform heating effect, improved quality and utilization rate, excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the measures, creative features, goals and effects achieved by the technology of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

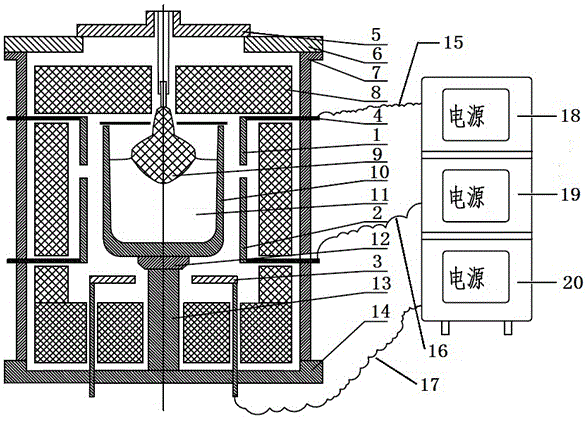

[0041] figure 1 It is a schematic diagram of the composition and structure of the multi-stage graphite heating system of the sapphire crystal growth equipment of the present invention.

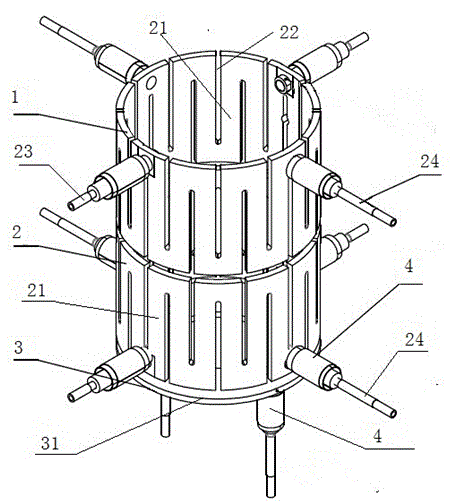

[0042] like figure 1 As shown, the multi-stage graphite heating system of sapphire crystal growth equipment, the multi-stage graphite heating system of sapphire crystal growth equipment, including: upper heater 1, middle heater 2, bottom heater 3, power supply unit, growth chamber body, crucible device and insulation layer 8; growth furnace cavity, including: small furnace cover 5, large furnace cover 6, furnace tube 7 and furnace chassis 14, and furnace tube 7 has upper and lower openings, and large furnace cover 6 is a circle The ring structure is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com