Regulation and control method for realizing metamaterial soaking substrate

A technology in substrates and substrates, applied in thermodynamics-related fields, can solve problems such as complex manufacturing and use stages of the process, impossibility of long-term use, corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 - two-dimensional steady-state simulation

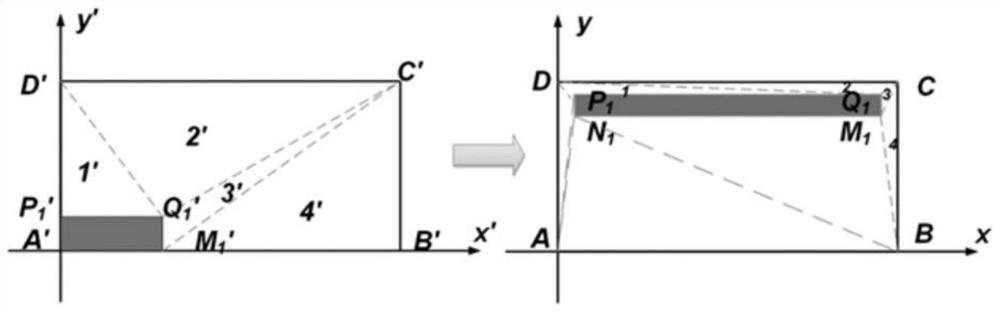

[0057] The two-dimensional schematic diagram of the soaking substrate to be solved is as follows: figure 1 shown, where the gray area P' 1 Q' 1 M' 1 N' 1 is the position of the heat source, and the heat source of the soaking substrate to be solved is in the lower left corner of the bottom. The function of regulating the heat conduction of the heat-spreading substrate to be solved is as follows:

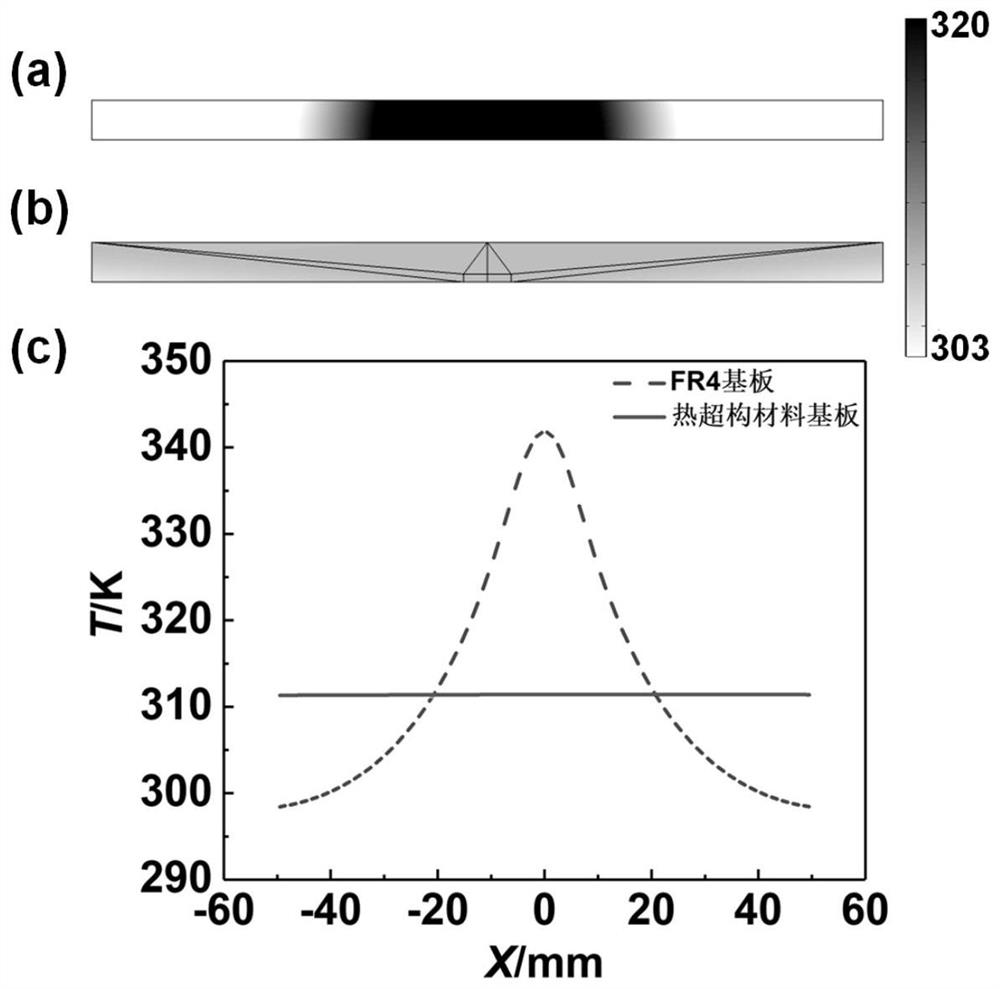

[0058] In order to demonstrate the correctness of the theory, the present invention utilizes the finite element simulation analysis method to verify. We assume that the substrate is a rectangular heat-conducting substrate with a length of 100mm and a width of 5mm. The parameter settings of the substrate to be solved for the uniform heat are designed according to formula (4). The results of the two-dimensional steady-state simulations are shown in figure 2 middle. During the simulation process, the upper boundary and...

Embodiment 2 — 3

[0061] Example 2 - Three-dimensional steady-state simulation

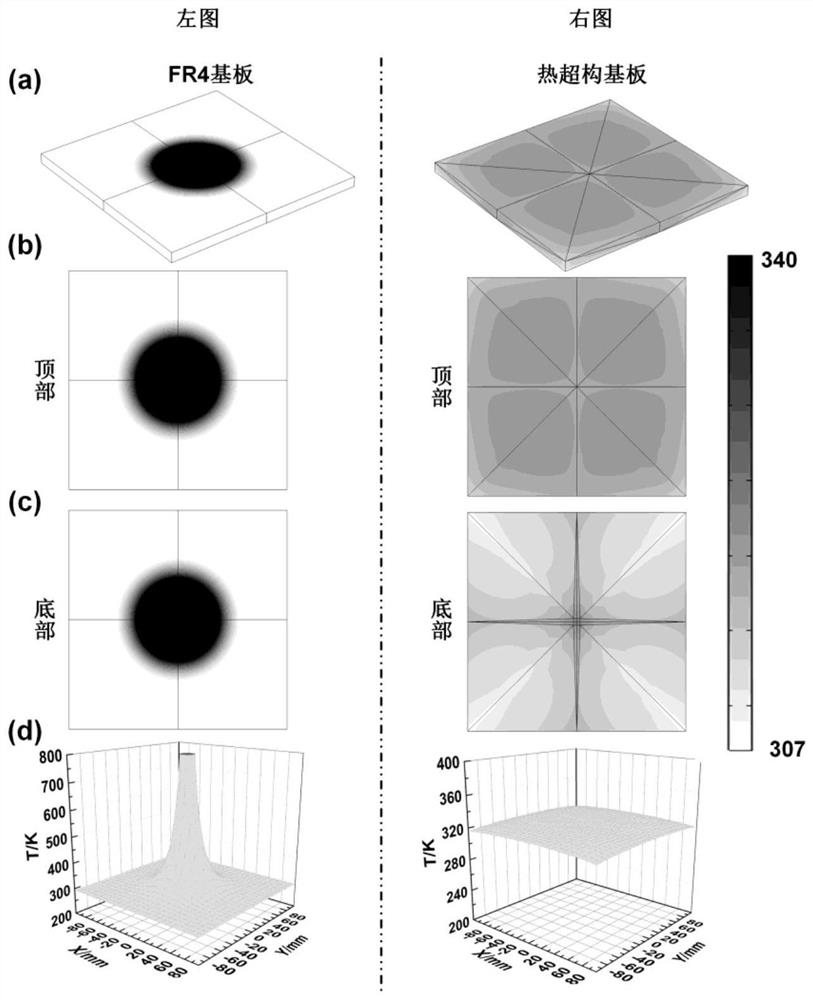

[0062] The present invention has also carried out three-dimensional steady-state simulation. At this time, the substrate to be solved is a three-dimensional cuboid. We set the substrate as a cuboid heat-conducting substrate. The substrate is 200 mm long, 200 mm wide, and 10 mm high. The results are shown in image 3 middle. During the simulation process, the six surfaces are convective heat transfer boundary conditions, and the convective heat transfer coefficient is 5W / (m 2 ·K), the parameter setting of the thermal superstructure soaking substrate is designed according to the formula (7).

[0063] Observe the simulation results image 3 It can be found that, similar to the two-dimensional results, image 3 In (b) right figure, the temperature on the top section of the soaking substrate to be solved is uniform, image 3 In (d), the temperature of all points on the top section of the soaking substrate to be solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com