Graphite heater furnace

A technology of graphite heater and graphite heating, which is applied in the direction of electric furnace heating, lighting and heating equipment, furnace, etc., which can solve the problems of poor firing, temperature distribution difference, heat reduction, etc., and improve firing accuracy and firing quality , The effect of preventing characteristic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

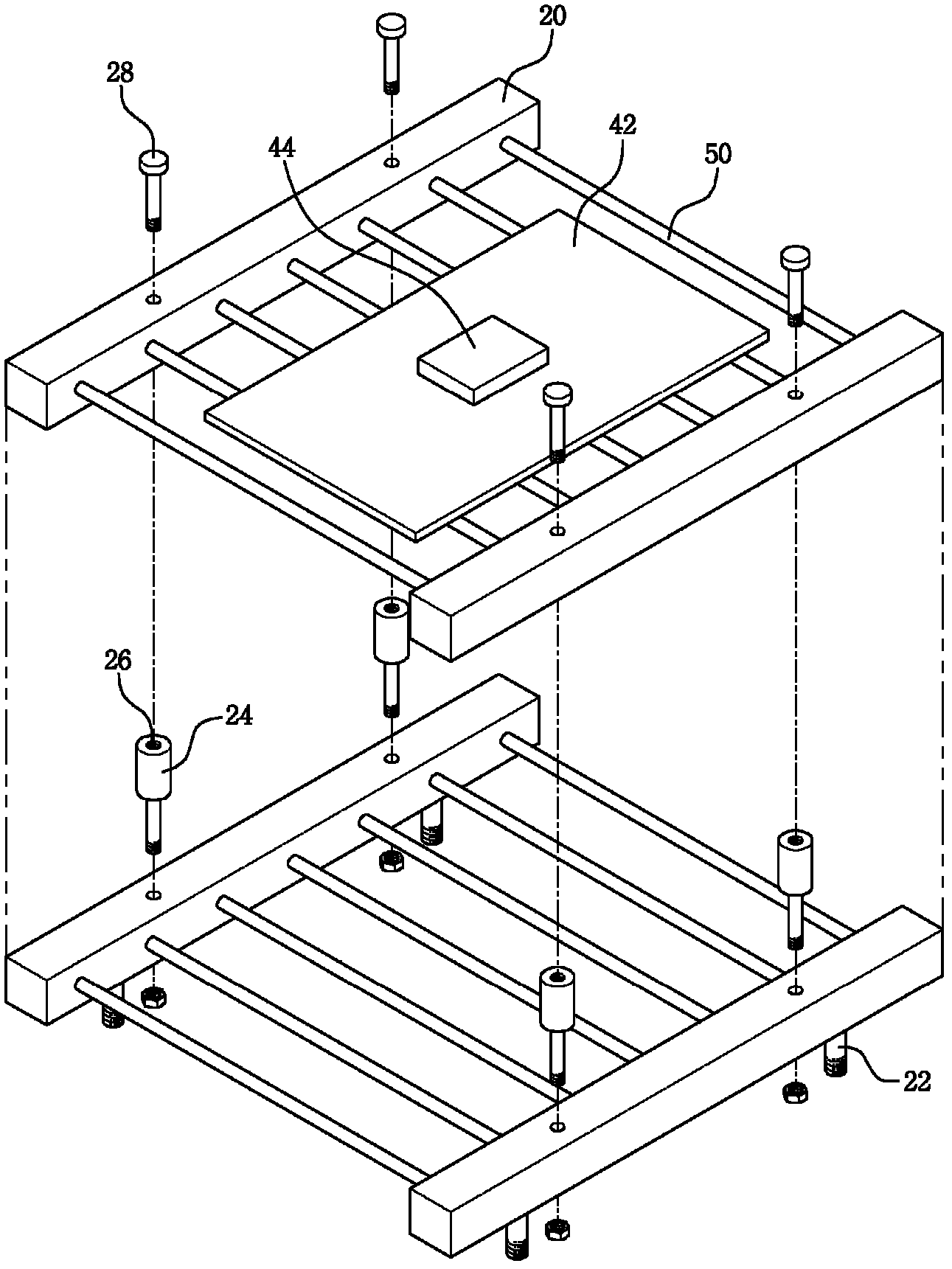

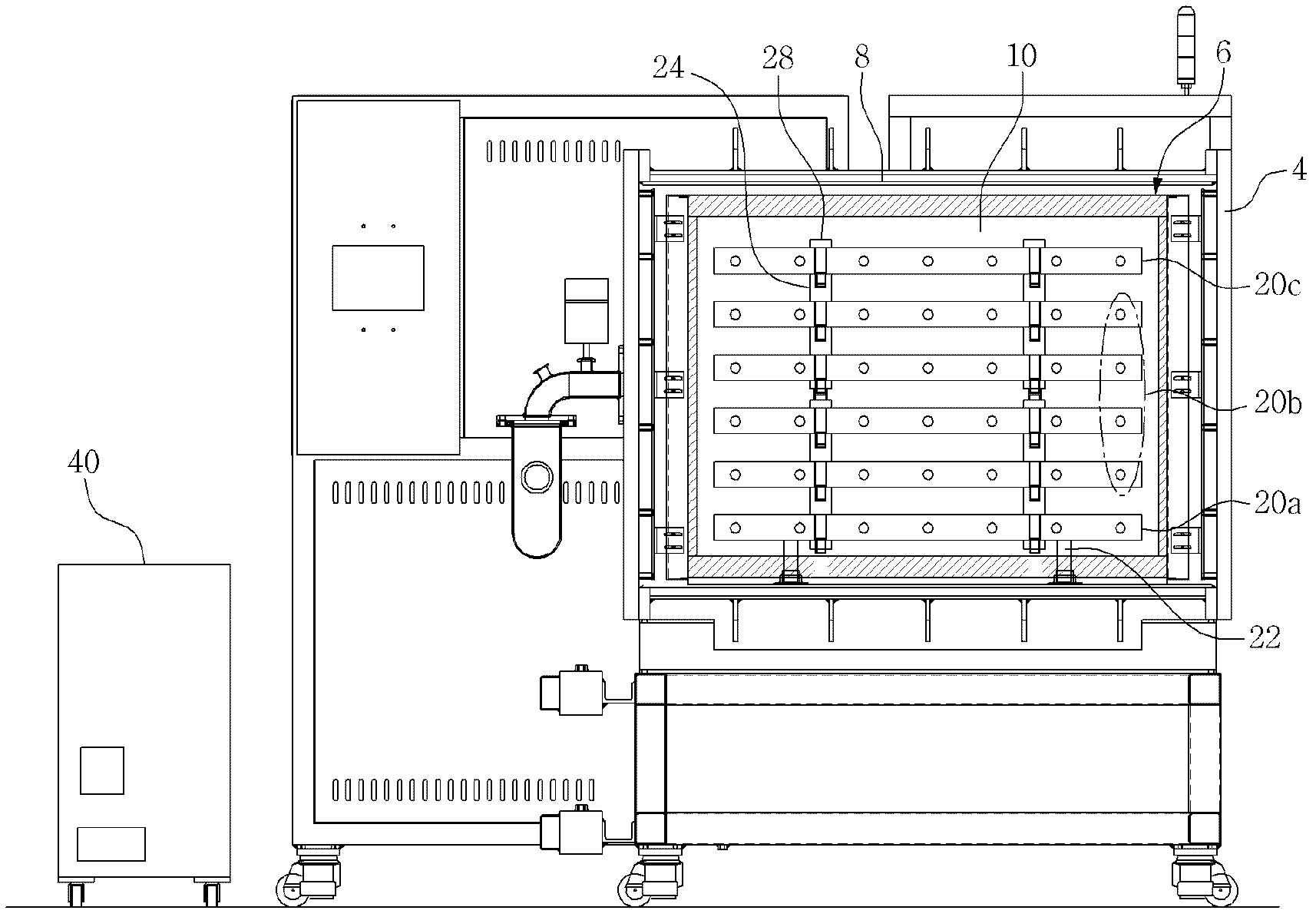

[0045] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

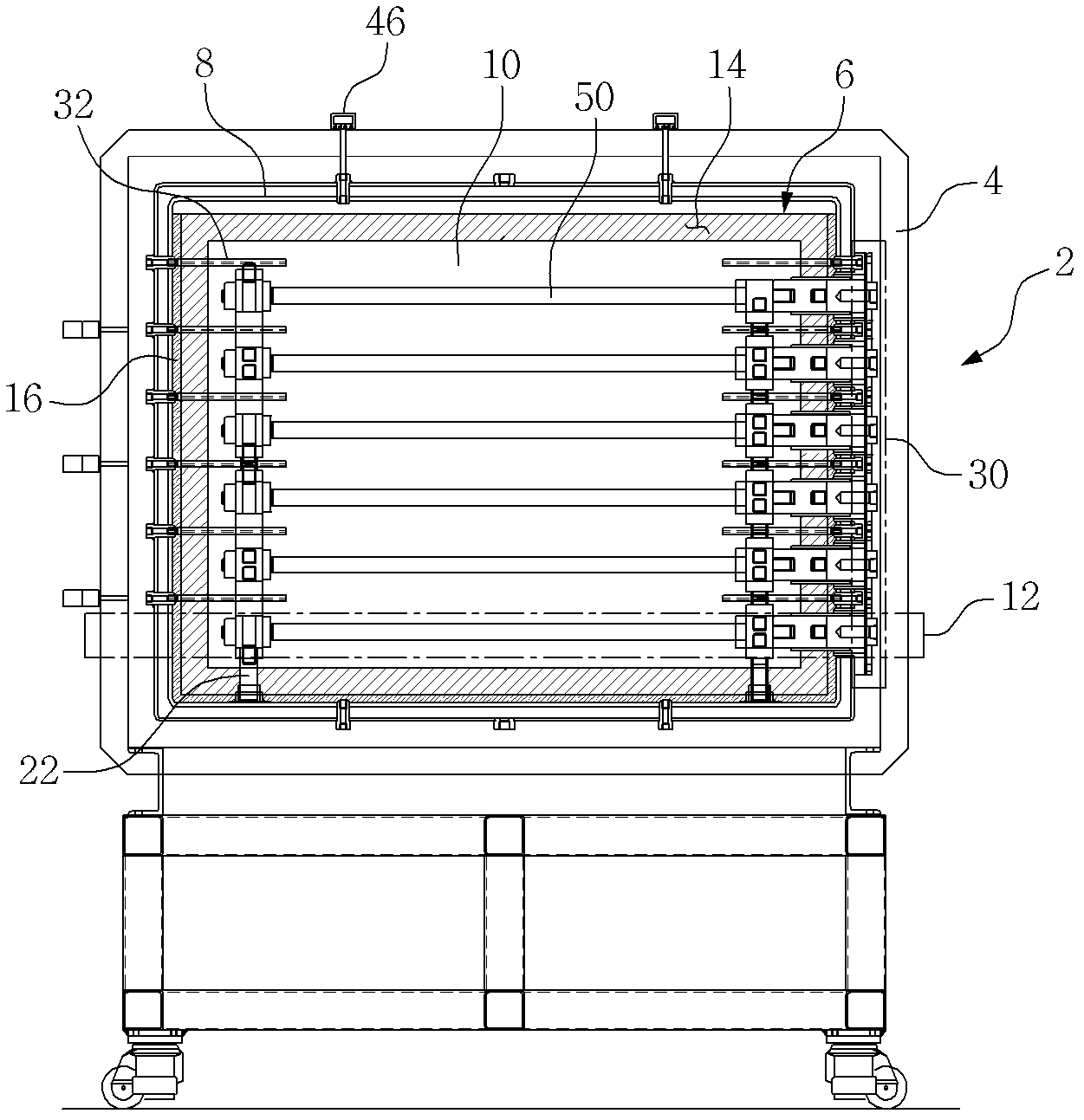

[0046] Such as figure 1 As shown, the graphite heater furnace 2 of the present invention includes a casing 4, a furnace body 6 including an insulator 14 located in the casing 4, a cooling water tank 8 arranged around the outside of the furnace body 6 to fill cooling water, and arranged horizontally on The heating space 10 inside the furnace main body 6 and the graphite heating elements 12 arranged in multiple stages.

[0047] Graphite heating elements 12 are provided in multiple stages in a heating space portion 10 located inside the furnace main body 6 including an insulator 14 .

[0048] In addition, a door (not shown) is provided on the furnace main body 6 so as to seal the heating space while the products to be fired are put in and taken out.

[0049] Between the furnace main body 6 and the cooling water tank 8, a heat insulating materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com