Cable stripping device

A technology of cables and lenticels, applied in the field of cable stripping devices, can solve the problems of manual separation and automatic feeding, and achieve the effects of reduced load, good locking effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

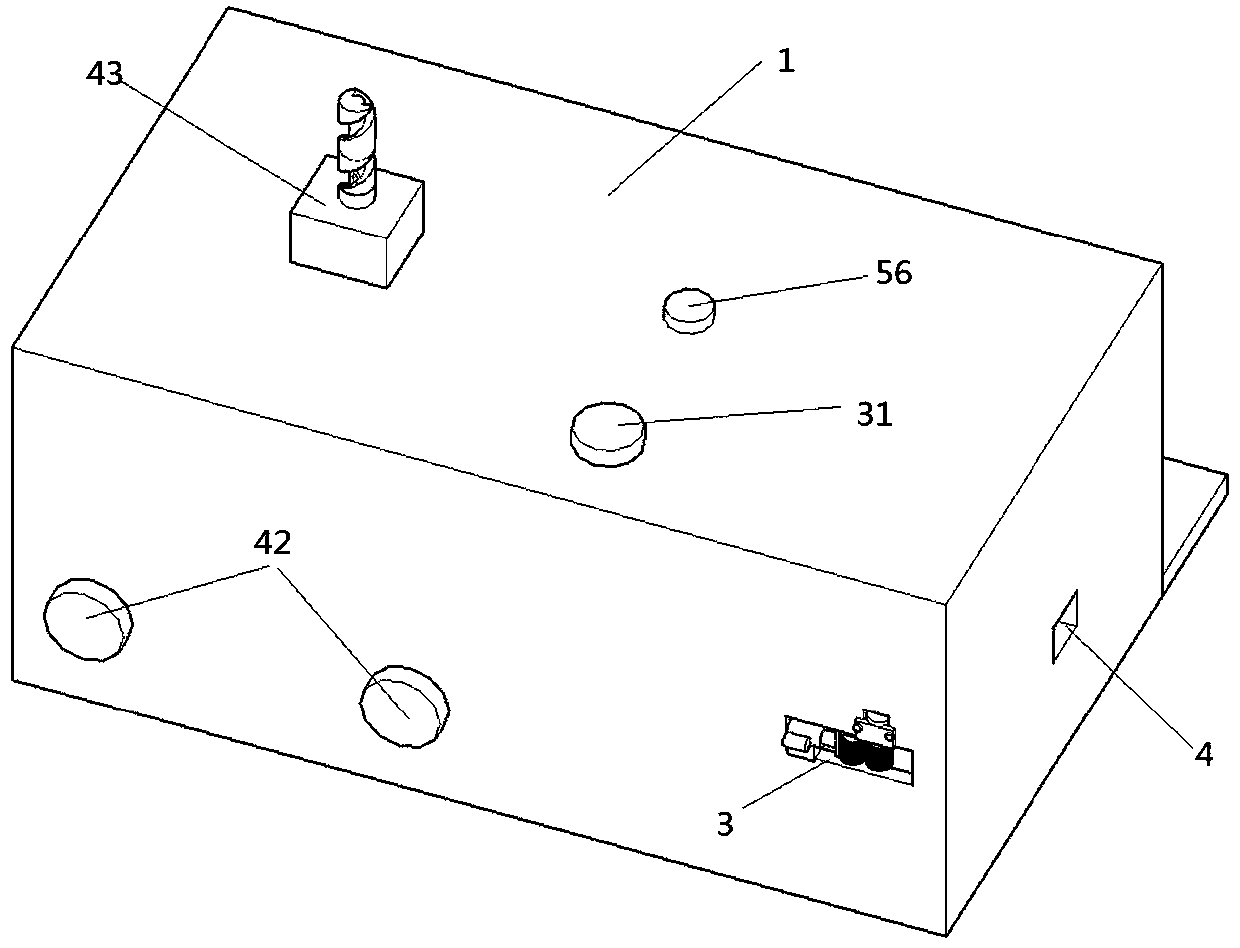

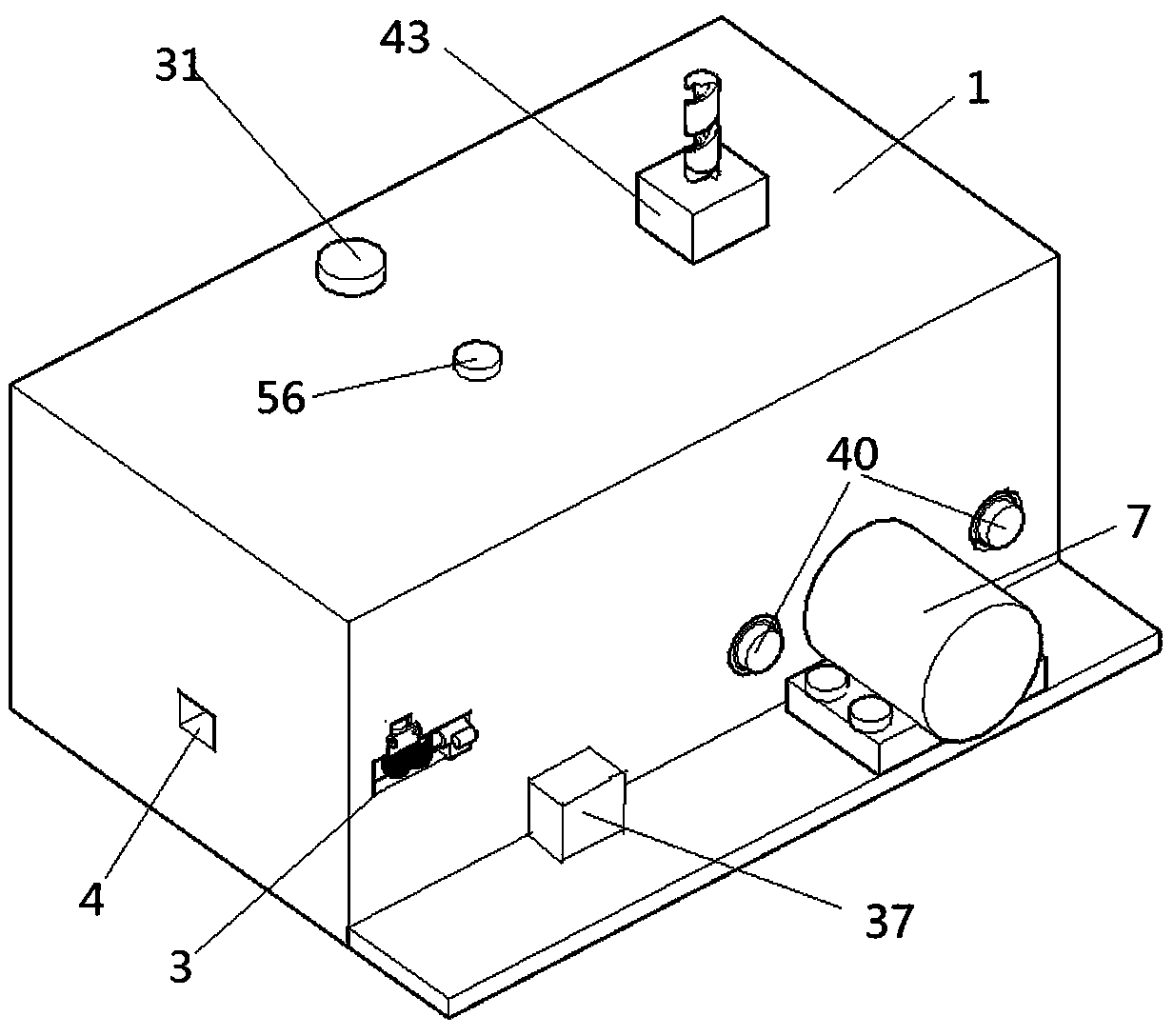

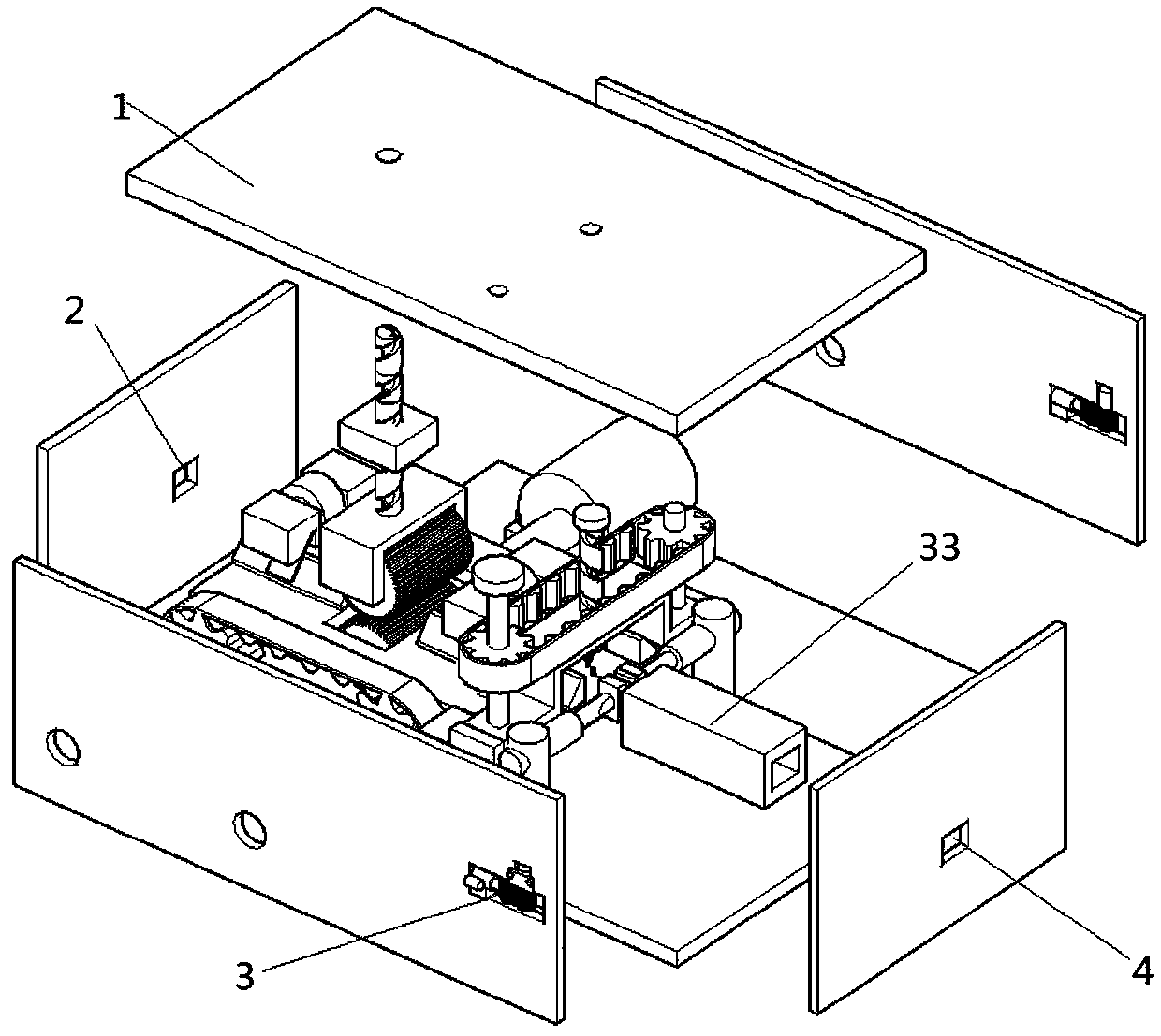

[0043] Such as Figure 1-13 Shown as the first embodiment of the present invention, a cable stripping device includes a fixed box 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the fixed box 1 is a rectangular parallelepiped shell structure welded by eight steel plates. The fixed box 1 is provided with a wire inlet 2, a skin hole 3, and a core hole 4 through a punching machine. There are two skin holes 3 , Are located on both sides of the fixed box 1, respectively, between the wire inlet 2 and the core hole 4, a correction mechanism, a wire feeding mechanism, a cutting mechanism, a separating mechanism, a peeling mechanism and a core tube 33 are arranged in sequence. A fixed plate 18 with a rectangular parallelepiped structure is welded to the inner wall of the left side plate of the fixed box 1, and both sides of the fixed plate 18 are welded to the inner walls of the front and rear sides of the fixed box 1 through side plates.

[0044] Such as Figure 5 wit...

Embodiment 2

[0054] Such as Figure 14 with 15 Shown is the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that two rollers 34 are provided on the sliding plate 19 near the gap. The second roller 34 is a hollow cylinder. The two bearings are fixed with glue, the fixed shaft is welded in the bearing, the two ends of the fixed shaft are welded with connecting strips perpendicularly, and the ends of the connecting strips are welded on the sliding plate 19, the shortest distance between the two rollers 34 and the two sliding plates 19 The distance between the inner walls is the same.

Embodiment 3

[0056] Such as Figure 16 Shown is the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the receiving box 49 is fixed by glue under the heat insulation plate 44. When the heating plate 13 is tightly attached to the cable sheath, the receiving box and The cable sheath is not in contact. After the heating plate 13 is separated from the cable sheath, part of the cable sheath may be adhered to the concave surface of the heating plate 13. After the heating plate 13 is heated to the melting temperature of the cable sheath, the adhered part melts and drips to the accommodation Inside the box 49; a fan (not shown in the figure) is arranged above the contact part of the heating plate 13 and the cable sheath. The fan is installed on the top wall of the fixed box 1 by screws. The motor of the fan is electrically connected to the output terminal of the PLC37. Control the heating of the heating plate 13 while the PLC37 control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com