Down-hole oil production screw pump fixer

A technology of retainer and screw pump, which is applied in the direction of pumps, mining fluids, earthwork drilling, etc. It can solve problems such as oil pipe thread shackles, sucker rod wear, and unreliability, and achieve reliable anchoring and easy anchor release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

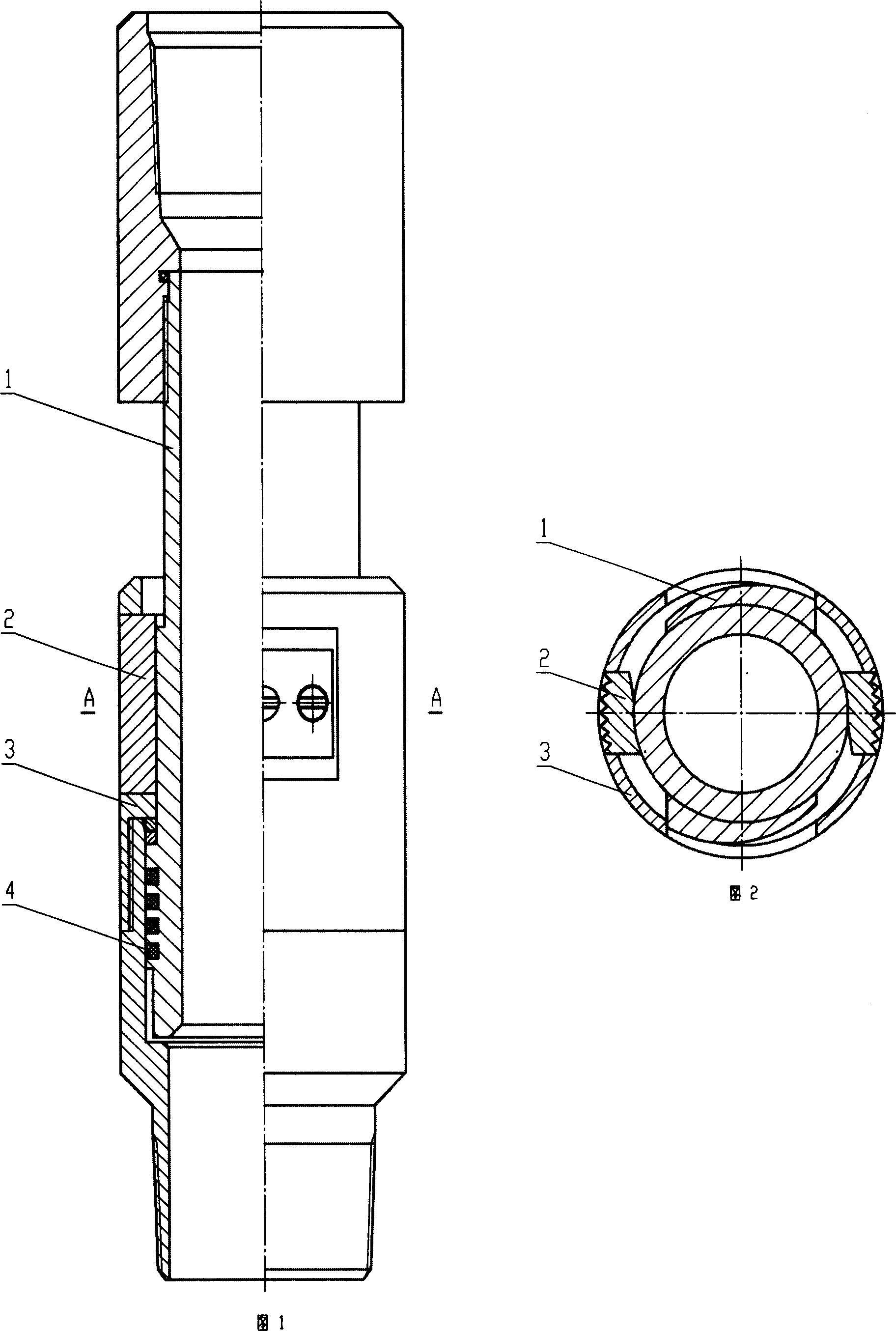

[0008] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0009] It is composed of inner tube 1, fluke 2, and fluke seat 3. The fluke seat 3 is suspended from the lower part of the inner tube 1. The fluke 2 is installed at the side window of the fluke seat 3. There is a cam device on the inner tube 1, and the fluke 2. The inner wall corresponds to the position of the cam device on the inner tube 1. There is a sealing ring 4 between the fluke seat 3 and the inner tube 1 . In order to facilitate assembly and positioning and prevent the fluke seat 3 from moving axially, the fluke seat 3 is composed of two pieces. The tail of the inner pipe 1 is not connected to other parts. The anchor fluke seat 3 bottoms can be male buckle, also can be female buckle. An anti-friction pad can be designed at the lower part of the inner tube 1 where the anchor lug seat 3 is suspended, so as to reduce the frictional resistance when rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com