Cover plate, forming method thereof, cover plate mother board and electronic equipment

A cover and motherboard technology, applied in the direction of circuits, electrical components, optics, etc., can solve problems such as difficult to meet product needs, poor performance of glass cover, etc., to achieve the effect of ensuring yield, reducing reliability risk and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It can be seen from the background art that the textured glass cover plate in the prior art often has the problem of poor performance. Now combine the structure of the textured glass cover to analyze the reasons for its poor performance:

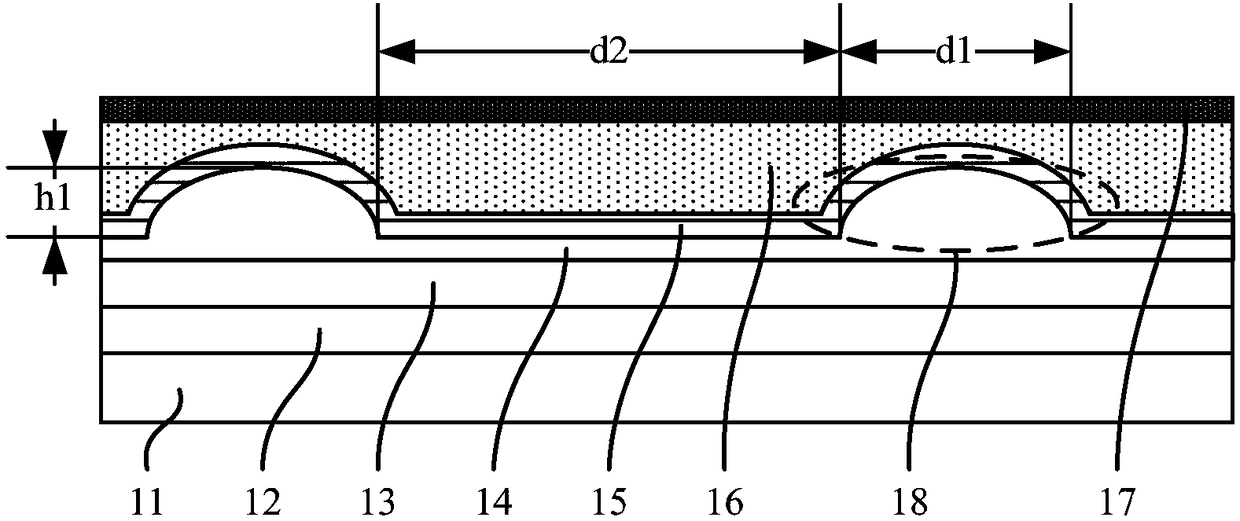

[0029] refer to figure 1 , shows a schematic cross-sectional structure of a glass cover plate.

[0030] There are two mainstream ways to make the glass cover appear textured, one is as figure 1 Rupture-proof membrane technology shown. Such as figure 1 As shown, the glass cover plate formed by the explosion-proof film technology includes: a glass base layer 11; an optical adhesive layer 12 covering the surface of the glass base layer 11; a resin layer 13 covering the surface of the optical adhesive layer 12; covering the resin layer 13 a graphic layer 14 on the surface; a black matrix layer 17 located on the graphic layer 14 .

[0031] Wherein, the material of the optical adhesive layer 12 is optically transparent adhesive (Optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com